by Imperial Systems | Aug 26, 2015 | Uncategorized

Tired of being let down? Find out how our dust extraction cartridge filters surpass expectations.

In the metalworking industry, you probably hear promises from a lot of different products every day. However, before purchasing a new product, you need to be able to have confidence that it will live up to your high expectations. Not only is this an important matter for the safety and wellbeing of your employees and workspace, but improper safety equipment can also cost you! As Shannon Decamp of The Fabricator points out, OSHA continues to crack down on metal fabricators, costing the industry $7 million in citations alone last year. So, if your shop is looking for high performing dust extraction cartridge filters, you probably want some guarantee that this product will perform before you buy.

At Imperial Systems, we understand; you want to make the best possible choice in dust extraction cartridge filters that you can. So, we are proud to share a recent case study which demonstrates how our DeltaMAXX cartridge filters surpassed the expectations of a Texas Welding School.

At Imperial Systems, we understand; you want to make the best possible choice in dust extraction cartridge filters that you can. So, we are proud to share a recent case study which demonstrates how our DeltaMAXX cartridge filters surpassed the expectations of a Texas Welding School.

Exceeding Expectations

Perhaps no one knows better than an educational institution the challenge and the necessity of balancing the cost and performance when it comes to safety equipment. At Texas Community College, the welding technology program was looking for more cost effective cartridge filters for their Lincoln Statiflex 6000 Dust Collector. However, with the high stakes of students involved, this school also needed a product that they could rely on for the highest level of safety.

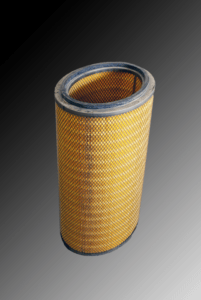

Enter the DeltaMAXX Cartridge Filter from Imperial Systems.

After reviewing our literature, the director of the welding program purchased four of these filters. We’ll let him tell you the rest of the story:

“The System is running very smooth, not much back blow. When turning on the dust collector in the past we have had problems with smoke blowing out of the back. That problem went away when we installed the DeltaMAXX filters”, said the Texas welding school instructor. “Imperial Systems’ dust collector filters are very durable and they are lasting much longer for us. My expectations were exceeded and you can count on us to be a returning customer.”

DeltaMAXX Dust Extraction Cartridge Filters: An Investment In Safety

We are confident that you will be just as impressed when you make the switch to our dust extraction cartridge filters as well. Just check out some of the great advantages the DeltaMAXX filters have to offer:

- Up to twice the filter life of the industry standard

- The most advanced Nanofiber technology

- MERV 15 Filtration Efficiency — the best in the industry

- Less pulse cleaning

- Lower operational mass emissions

- Reduced dust collector operational costs

- Highest quality pleated media

- The industry’s best surface loading technology

Ready to find out just how our DeltaMAXX filters will exceed your expectations as well? Contact us today at 800.918.3013.

Read more

by Imperial Systems | Aug 21, 2015 | Dust Collection Filters

DeltaMAXX is the #1 industrial filter we will stand by for optimal results.

In the metalworking industry, it’s important that you choose the best, most efficient filter for your facilities needs. According to 60 Minutes, CBSNews, there have been 350 explosions in the U.S. since 1980, in most cases due to the lack of efficiency in dust collection. Purchasing effective dust collection systems and researching types of industrial filters are crucial for maintaining safety standards.

Dust Collection Management Can Be a Matter of Life and Death

Dust Collection Management Can Be a Matter of Life and Death

On October 29, 2003, the Hayes Lemmerz factory exploded into a huge ball of fire due to aluminum dust that had piled up and detonated. A gentleman named Shawn Boone suffered from third and fourth degree burns across 92%-100% of his body. Due to the severity of the burns to his outside and internal organs, there was nothing that could be done for him. He was one of 15 people killed in dust explosions that year.

Along with the many others who have been seriously injured, or lost their lives due to dust explosions, there are those who have never experienced the depravity of such things. As a metalworking industry, it is important to keep your facility up to standard with only the best machinery and materials to keep your employees safe.

Here at Imperial Systems, we have compiled a list of the different types of industrial filters that many facilities use, but only one will stand out above the rest.Can you guess the most reliable, long-lasting filter?

Types of Industrial Filters

- Cyclone Filters. Used as a simple way to remove dust from an air stream, it is more commonly used as a pre-filter for a dust collector. Cyclone’s require very little maintenance, with a discharge valve and fan to operate it.

- Electro Static Precipitator (ESP). This filter electrically charges particulates in the air with high voltage. the charged particulate is collected on charged plates as the air stream passes through. ESP’s are high maintenance and expensive.

- Cartridge Filters. These filters are best for metalwork (grinding, sandblasting, welding fumes, fine powders and more). Pleated media and DeltaMAXX’s Nanofiber technology allows for easy cleaning, double the average filter life and run at a 99% efficiency.

*Please note these are only a few examples of the types of industrial filters used for dust and particulates.

For more information on what types of industrial filters are best for your metalworking facility, give Imperial a call today at 800-918-3013.

Types Of Industrial Filters | Type Of Industrial Filters

Read more

by Imperial Systems | Aug 12, 2015 | Dust Collection Filters

Imperial Systems’ industrial filters offer major benefits in metalworking shops across the country.

If you have been in the metalworking field for any amount of time, you are probably well aware that industrial filters are a staple in any well equipped shop. These cartridge filters are instrumental in the proper functioning of your industrial dust and fume collection systems. However, you may not be aware of the true impact that the industrial dust filters you choose could be having on your business.

At Imperial Systems, we design and manufacture industrial filters every day. Because of that, we have an in depth awareness of the true impact of these products and want to help metalworkers like you discover the full extent of what industrial dust collection filters really do for your business.

At Imperial Systems, we design and manufacture industrial filters every day. Because of that, we have an in depth awareness of the true impact of these products and want to help metalworkers like you discover the full extent of what industrial dust collection filters really do for your business.

Your Industrial Filters Have A Major Impact in 3 Major Facets Of Your Business

As with almost any piece of equipment in your business, the choice you make in filters will either help or hinder three major areas of your work. With a high quality filter, you can expect to see great advantages in each of these categories. With moderate to poor quality filters, though, you may have to settle for one or two out of three.

- Safety. Perhaps the most obvious product of industrial filters, safety is rightly the number one priority when choosing a filter. You should have confidence that your filters are effectively collecting dust and fumes that are created as byproducts of your work, minimizing the risks of inhalation or even combustion. Adequately collecting the dust in your workspace can also help to prevent the malfunctioning of your equipment, which can lead to other dangerous accidents.

- Energy. Your choice in industrial dust collection filters will also make a significant impact on the energy used in dust collection. When Tomm Frungillo of The Fabricator analyzes the energy usage of various filters, he takes electrical costs, compressed air-usage, and CO2 emissions. Depending upon the filters design and materials, it may require more or less energy to continue running at its highest efficiency. Those able to operate with lower energy will save your shop money and time, as they often call for less cleaning and replacement.

- Operating Expenses. Finally, your industrial filters can have an impact on your overall operating expenses. As seen above, they can significantly change the amount of energy it takes to run your dust collection system efficiently on a daily basis. However, your overall costs will also include the lifespan of the filter, service time required, and even how they impact the operation of your overall system. Longer lasting filters are typically the best investment.

Read more

by Imperial Systems | Aug 11, 2015 | Dust Collection Filters

Imperial Systems offers the alternative to Torit dust collector filters that you need to know about.

Every day, more and more professionals in the metalworking industry are discovering the great alternative to Donaldson Torit Dust Collector Filters. Before you place your next order for cartridge filters, you should get the facts as well. Although these torit dust collector filters may have dominated the industry in the past, the reality is that they are no longer your best option for dust collection quality, safety, and value in a metalworking shop. Imperial Systems’ DeltaMAXX Cartridge Filters are quickly becoming the leaders in efficiency and performance for workplaces like yours, and we think you’ll like the savings as well.

Challenges of The Metalworking Industry

Metalworking is a challenging, often dangerous industry. Not only does structural metalwork often make the top ten most dangerous jobs in the nation, but a practice as common as welding carries a number of significant hazards as well. Lincoln Electric, a leader in the welding industry, enumerated the top dangers in this field:

Metalworking is a challenging, often dangerous industry. Not only does structural metalwork often make the top ten most dangerous jobs in the nation, but a practice as common as welding carries a number of significant hazards as well. Lincoln Electric, a leader in the welding industry, enumerated the top dangers in this field:

1. Electric Shock

2. Fumes and Gases

3. Fire and Explosions

4. Injuries from Insufficient Personal Protective Equipment

5. Environment Specific Considerations

With dangers like these, it is clear why metalworkers like you need to be informed of, and equipped with, the best safety equipment in the industry.

Industrial Dust and Fume Collection Systems play an important role in addressing the risks of both fumes and explosions. To ensure the highest performance of your system, you need to be able to have confidence in your cartridge filters. So, if you are still buying Torit dust collector filters, it is time to find out the difference DeltaMAXX cartridge filters can make.

DeltaMAXX Cartridge Filter Advantages Over Torit Dust Collector Filters

Our industrial dust collector cartridge filters are designed to provide the highest performance possible. Made with advanced Nanofiber Technology, they offer many advantages, including:

- High Efficiency: DeltaMAXX filters begin working right away because nanofiber does not require any time to warm up.

- Easy Cleaning: With a tight-knit surface, dust stays on the surface and does not penetrate the filter, saving time and energy during cleaning.

- Longer Lifespan: Our filters offer you up to twice the filter life of the industry standard, saving you time and money.

- Customization: We manufacture filters to fit all makes and models of dust collection systems

These filters are designed to offer metalworkers like you the highest performance with the maximum savings on price, time, and energy.

Imperial Systems

At Imperial Systems, we are dedicated to providing solutions for dust and fume collection in the manufacturing industry. To learn more about any of our products, or to place an order, please contact us today at 800.918.3013.

Read more

by Imperial Systems | Aug 6, 2015 | Dust Collection Filters

The competition may be close but DeltaMAXX comes in for the win!

Metalworking causes an abundance of dust and gasses to dwell in the air. Those that have professional dust collector systems in their metalworking facility understand the importance of the maintenance required for such systems. Fortunately for you, we have developed DeltaMAXX cartridge filters. As compared to Donaldson Torit cartridge filters, ours beat this competition by a landslide.

Donaldson Torit cartridge filters have certainly upheld their name for quite some time now, as one of the leading manufacturers for air purification and dust collection – until now.

Donaldson Torit cartridge filters have certainly upheld their name for quite some time now, as one of the leading manufacturers for air purification and dust collection – until now.

Why Choose Imperial Systems’ DeltaMAXX Over Donaldson Torit Cartridge Filters?

Thanks to the ever-increasing innovation in everything dust collection, Torit cartridge filters now make room for DeltaMAXX cartridge filters for these 3 main reasons.

- Quality. Thanks to the discover of Nanofiber technology, all of our cartridge filters are more efficient than ever with easier cleaning and longer filter life. Our cartridge filters are also customizable, with the ability to fit into any dust collector system. Our filters last twice the length of time as the average filter, using the highest quality pleated media. We also offer MERV15 filtration efficiency, industry-best surface loading technology and less pulse cleaning. These qualities then lead to lower operational mass emissions and reduced dust collector operational costs. Therefore, you get more bang for your buck!

- Price. Unfortunately for big-name companies like Donaldson Torit, their products have a higher price tag, rather than Imperial Systems. Imperial Systems is actually one of the top manufacturers not only in the nation, but in North America (serving Canada as well as the United States). With such a large clientele, we at Imperial Systems are able to keep our prices at a lower rate than those of Donaldson Torit.

- Service. This is where the rubber meets the road. Our service team here at Imperial Systems are the absolute best at what they do. From knowledge to respect to communication, our specialists have it all in their grasp. We are professional, friendly and best of all, an advocate for all of our clients, both current and potential.

Stop Waiting

The choice is yours. If you are a current user of Donaldson Torit cartridge filters, we hope that you have had success with their business, but have learned something new with Imperial Systems. Give us a call today at 724.662.2801 so we can show you how to get more efficiency from the dust collector systems you have.

Read more

At Imperial Systems, we understand; you want to make the best possible choice in dust extraction cartridge filters that you can. So, we are proud to share a recent case study which demonstrates how our DeltaMAXX cartridge filters surpassed the expectations of a Texas Welding School.

At Imperial Systems, we understand; you want to make the best possible choice in dust extraction cartridge filters that you can. So, we are proud to share a recent case study which demonstrates how our DeltaMAXX cartridge filters surpassed the expectations of a Texas Welding School.

Dust Collection Management Can Be a Matter of Life and Death

Dust Collection Management Can Be a Matter of Life and Death