by Imperial Systems | Oct 30, 2015 | Uncategorized

Find out what our IDA has to offer your metalworking business.

If you are in the metalworking or manufacturing industries, safety is, by necessity, one of your highest priorities. From the good keeping and proper use of equipment to consistent use of personal safety gear, there are countless things you monitor each day to keep your employees and your workspace safe. But are you doing enough? Or are you at risk for potential combustion due to your dust and fume collection system?

Without IDA (In-line Deflagration Arrester) filters, you and your employees may be at risk. Discover how this proprietary technology from Imperial Systems could prevent disaster in your workshop while reducing your costs and improving your efficiency.

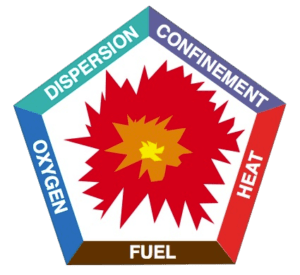

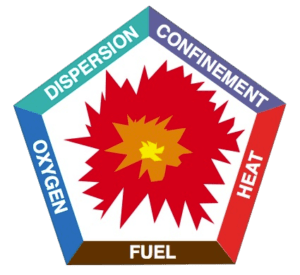

The Danger of Combustion

It’s no secret that dust explosions are a common risk in metalworking and manufacturing industries. Processes including welding, grinding, polishing, and more can create the perfect combination of dust and sparks in the air that can lead to serious consequences. For example, three workers were killed in 2010 in a titanium dust explosion in West Virginia. This incident is in addition to the 281 combustible dust incidents identified by the U.S. Chemical Safety and Hazard Investigation Board between 1980 and 2005. In those incidents, 119 workers were killed, 718 injured, and many industrial facilities sustained extensive damage.

It’s no secret that dust explosions are a common risk in metalworking and manufacturing industries. Processes including welding, grinding, polishing, and more can create the perfect combination of dust and sparks in the air that can lead to serious consequences. For example, three workers were killed in 2010 in a titanium dust explosion in West Virginia. This incident is in addition to the 281 combustible dust incidents identified by the U.S. Chemical Safety and Hazard Investigation Board between 1980 and 2005. In those incidents, 119 workers were killed, 718 injured, and many industrial facilities sustained extensive damage.

Recognizing these dangers, OSHA and the NFPA have created standards aimed at minimizing the risks to life and property that are posed by combustible dust. Important steps to reduce the danger of combustion include:

- Analyzing the hazards present in your facilities

- Utilizing an effective dust collection system

- Monitoring this system and others to ensure proper operation

- Limiting smoking, open flames, and sparks in work areas

- Installing spark arresters in dust collection ductwork

More important combustion prevention guidelines and recommendations can be found with the NFPA or OSHA.

The mistake made by many metalworking and manufacturing businesses is to some, but not all, of the recommended safety steps. A dust collection system without an IDA present can still combust, creating a deadly flame front.

Imperial Systems’ IDA Filter Technology

At Imperial Systems, we are proud to announce our proprietary IDA DeltaMAXX filters, which bring advanced safety features to our CMAXX Dust Collection System. Together, they offer excellent protection against combustion.

At Imperial Systems, we are proud to announce our proprietary IDA DeltaMAXX filters, which bring advanced safety features to our CMAXX Dust Collection System. Together, they offer excellent protection against combustion.

In a recent study of the CMAXX Dust Collector with IDA DeltaMAXX filters, backed by third party testing, we found that in all tests the filters were able to isolate a deflagration and stop a flame front. The results showed no trace of flame or spark transmission downstream from the filters or in the clean air plenum.

In fact, the body of the CMAXX Dust Collection System, without explosion venting, was also tested to withstand a deflagration of corn starch at 185 KST with pressures exceeding 4 PSI. In this case, the full explosion diverted through the IDA DeltaMAXX filters. Afterwards, the filters showed no sign of deformation; their internal cages maintained their shape perfectly, and the seals were not deformed or melted either.

Note: Although the test described above was performed without explosion vents, as a demonstration of the worst-case scenario, dust collectors should always be properly vented.“discharged into a safe, unrestricted, outdoor location, and the discharge shall not be obstructed” (See NFPA 69 Chapter 12). Where the CMAXX is vented through a pipe or duct, the duct must be designed to withstand the pressure of an explosion. These pressures can be provided at the time of engineering. Imperial Systems can have your dust tested prior to final engineering to determine the proper venting calculations.

Comprehensive Combustion Safety

In addition to their high performance in the above testing, the CMAXX Dust Collector with IDA DeltaMAXX cartridge filters also offers several advantages over similar systems that have been tested. These include:

- Elimination of the need for expensive after-filters that can prematurely blind, causing issues like high-pressure drops, increased filter expenses, additional labor, decreased headroom for indoor applications, and enlarged filter housing.

- Online filter cleaning using the same primary system that the CMAXX uses, ensuring consistent cleaning of the filters during operation

- Compatibility with inline HEPA filters or a remote HEPA filter system as required, unlike other systems which require such filters to be mounted on top of the collector, limiting its flexibility.

The combined features of the CMAXX and IDA DeltaMAXX filters offer metalworkers and manufacturers the quality, safety, and value that we are dedicated to providing here at Imperial Systems.

Of course, it’s no surprise that together our products demonstrate some of the highest performance on the market, especially when you consider the impressive advantages each has to offer on its own. For over a decade, Imperial Systems has offered manufacturers and metalworkers like you advanced, reliable dust and fume collection equipment. Just check out the numbers– they speak for themselves!

CMAXX Dust Collector Advantages

- 10% more filter media than other same-sized vertical cartridge collectors

- 20% more internal area around the cartridge filters, collecting more dust in the hopper before attaching to the filters

- 20% lower internal velocities– BEST in Class

- 100% total pulse distribution across filter media

- Up to 40% more cleaning power

- 15 year manufacturer’s warranty

- Heavy duty 7 & 10 gauge construction

- 0 bolt holes– no rusting or leaks!

|

DeltaMAXX Cartridge Filter Advantages

- Up to twice the Filter Life as the industry standard

- MERV 15 Filtration Efficiency– best in the industry

-

- 99.9% Efficiency for .3 to .5 Micron with the highest quality pleated media

- Reduced dust collector operational costs

- Lower operational mass emissions

- Less pulse cleaning with Advanced NanoFiber Technology

- Best surface loading technology in the industry

DeltaMAXX cartridge filters are made to fit all makes and models of cartridge dust collection systems |

All of our products also come with the Imperial Systems’ guarantee of outstanding customer service. We are dedicated to engineering and providing the solutions that manufacturers can rely on for the highest levels of quality, safety, and value. Whether you talk with our sales engineers or our field crews, we are confident that you will be impressed by our dedication to your service and safety.

If you would like to learn more about any of our products and how they may be able to improve safety and reduce costs in your workplace, please contact us today! You can reach us at 800.918.3913.

We Want To Hear From You

The particular needs and safety strategies for dust and fume combustion will vary from one workshop to the next. So, we want to hear from you! What challenges does your business face when it comes to handling combustible dust and fumes? What are you currently doing to control the risks? What solutions are you still looking for?

Let us know in the comments section below; we can’t wait to hear from you!

Read more

by Imperial Systems | Oct 14, 2015 | Dust Collection Filters

Just because it’s top-quality doesn’t mean it’s out of your price range.

On August 2, 2014 in Kunshan, China, a metal production company faced a day they won’t forget. A massive explosion occurred that morning, killing 146 people and injuring 114.

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing top dust collector filters and systems, along with strict guidelines into your company is vital in providing a safe environment.

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing top dust collector filters and systems, along with strict guidelines into your company is vital in providing a safe environment.

Why Use The Top Dust Collector Filters?

With an array of products available for your dust collection needs, it’s important to do your research. In helping you research, Imperial Systems has provided a list of qualities to look for in “so-called” top dust collector filters. Also, we have provided a summarized list of the NFPA 654, Standard for the Prevention of Fire and Dust Explosions.

These standards are:

- For process equipment and ventilation systems, minimize the escape of dust

- Use dust collector systems and the top dust collector filters

- Utilize surfaces that facilitate cleaning and minimize dust

- Clean dust on a regular basis

- Inspect for dust in hidden areas

- Only use vacuum cleaners approved for dust collecting

- Place relief valves away from dust hazard areas

- Develop a dust inspection, cleaning, testing and control guide specific to your facility

Notice that the standards include use dust collector systems and the top dust collector filters. Perhaps we added “the top” to the standards, and that’s ok! When it comes to your employees safety, you don’t want to cut corners.

Here are qualities of top dust collector filters:

- Nanofiber technology, stopping submicron particles from becoming embedded into the media, before they even enter the filter.

- The highest quality pleated media having a 99.9% efficiency

- Reduced dust collector operational costs

- The industry’s best surface loading technology

- Lower operational mass emissions

- The best in the industry, MERV15 filtration

- Less pulse cleaning

Where can you find these qualities? With Imperial Systems’ DeltaMAXX filters. DeltaMAXX filters are the top dust collector filters on the market. Not only do you receive a quality product, you receive service from a quality company. We are not here to treat you like customers, we are here to treat you like family.

If you would like more information on our DeltaMAXX filters or our CMAXX Dust Collection Systems and Fume Extraction Systems, you can visit our products page or give us a call at 1-800-918-3013.

Top Dust Collector Filters | Top Dust Collector Filter

Read more

by Imperial Systems | Oct 8, 2015 | Common Industrial Dust Collection System Problems

Did you know that 30,000 US manufacturing facilities are considered at-risk for explosion by OSHA?

The Structure of a Dome: What’s to Like?

A domed roof design has been called “the king of all roofs”, and they support that name by covering many of the world’s most important and famous buildings. What is a dome? Domes have a curved structure, without corners, angles, or supporting columns. The design options for domes are many. You may see a dome on private homes, commercial buildings, or governmental and religious edifices.

A domed roof design has been called “the king of all roofs”, and they support that name by covering many of the world’s most important and famous buildings. What is a dome? Domes have a curved structure, without corners, angles, or supporting columns. The design options for domes are many. You may see a dome on private homes, commercial buildings, or governmental and religious edifices.

Lightweight yet self-supporting, the dome provides a focal point and a natural attraction. In buildings, the airy dome structure creates an atmosphere evocative of pre-historic civilizations. Indeed, the dome’s deeply rooted origins in many cultures of the ancient world brings an air of richness and sophistication.

Design, quality and function combine to make this architectural structure a winner no matter where or what you’re building. And these observations hold true not just for buildings, but also for technology. What we refer to is industrial manufacturing. In many industries, the domed roof design has been shown to provide many benefits in the building. At Imperial Systems, we wanted to take the ingenuity of the domed system just one step further. For a quintessential dust collection system, we offer dust cartridge collectors with a superior domed roof design, providing industrial manufacturers with the many benefits of a long-lasting and safe instrument.

CMAXX Offer a Superior Domed Roof Design

CMAXX offers a superior domed roof design for cartridge dust collectors, providing a solid roof to increase efficiency. The roof on the CMAXX has a domed structure to make water run off and to improve the strength of the unit. These changes mean that the CMAXX is the only dust collector equipment that does not require external bolt holes. What does it include?

CMAXX domed roof design = NO bolt holds; NO individual panels; and NO roof seams!

How CMAXX Stays Ahead of the Competition

Industrial manufacturing requires instruments that can endure tough conditions, lasting for years and producing a high-quality material, all the while maintaining safety for those who use these instruments. That’s a tall order. At Imperial Systems we are interested in producing the best technologies, using scientific innovations as well as lessons from the past to create an equipment that will hold up to the pressures of your work. Safety equipment, such as cartridge dust collectors, must especially be designed to endure harsh environments.

Industrial manufacturing requires instruments that can endure tough conditions, lasting for years and producing a high-quality material, all the while maintaining safety for those who use these instruments. That’s a tall order. At Imperial Systems we are interested in producing the best technologies, using scientific innovations as well as lessons from the past to create an equipment that will hold up to the pressures of your work. Safety equipment, such as cartridge dust collectors, must especially be designed to endure harsh environments.

Compared to the competition, the CMAXX domed structure excels in every way. If you research a similar unit without the domed roof design, you’ll discover a 16-cartridge dust collector with about 160 bolt holes and 1000 holes spaced throughout the collector. This design represents the old style of industrial fabrication, and the bolted panels hold water, leading to leaks and rusting and freezing. All these conditions signify damaged equipment for you.

But check out our the alternative!

Domed Roof Dust Collector Technology: A Challenge to the Status Quo

We know already that weather can be the most unpredictable and difficult element to control when it comes to producing safely and efficiently. At Imperial Systems, we’re not content to until we can provide you with the best for your manufacturing needs. The harsh external elements have resulted in warping, rust, leaks, and other problems for many metalworking and other industrial manufacturers. But your livelihood and the success of your business depends upon decreasing the instances of these types of problems. And the best way to eliminate the flaws in your production is to go back to its source: equipment.

The defects produced by your equipment can compromise the integrity of your unit. This undermines the safe environment you are seeking to create! Thus, we suggest that you confront these problems using a new and reformed dust collection system technology. We use four features to guarantee your protection against leaking and water damage.

- Positive Bow. The shape allows debris to run off more easily with water so that the unit becomes easier to clean. This inhibits pooled-up water from freezing on top of the unit, causing damage.

- One-piece Roof. Eliminating the individual-panel design, the one-piece roof offers a design that will be strong against leaking and warping.

- Zero Bolt Holes. The system is sealed because we have eliminated the external bolt holes altogether. Now, you can rest assured that you will not have to deal with rusty bolts, leaks, and breaking parts.

- A Strong Frame. The 3/16” roof is thick, fully welded, and the welds have been ground smooth. And, 1/4’” plate internal stiffeners offer the additional benefit of a reinforced structure.

What are the Biggest Threats to Dust Efficiency?

We believe that our domed dust collector structure presents a solution to the biggest challenges in the manufacturing business. The above-described features account for the major problems that will confront every industrial manufacturer: combustion, exposure, and pollution.

- Combustion. Fire explosion is a primary hazard that can only be avoided by preventing the build-up of dust particles. Employees should also be aware of the locations of the nearest fire extinguishers and the exit protocol in case of an emergency. While new OSHA guidelines have decreased the number of fires occurring in industrial plants in the U.S. it is estimated that there are still 30,000 facilities at risk for dust combustion.

- Exposure. According to the Vision Council, 61% of reported eye injuries occur in trade, manufacturing, and construction jobs. The eyes are exposed to chemical fumes, metal, dust, concrete, and other particles that can be injurious to the worker. Besides affecting the eyes, chemical exposure is also dangerous to the nervous, reproductive, and urinary systems. For these reasons, employees should always wear their personal protective equipment such as eye goggles and dust masks. A well-built dust collector decreases these risks by decreasing the amount of material that can exit the system.

- Pollution. When there is a high concentration of dust, smokes, and particles in the air, this affects the ability to breath. Inhalation of such particles can cause damage to the major organs and cause other health problems. Dust in particular can cause breathing problems, injuring the lungs and aggravating any health conditions the worker may already have. The presence of dust in the air is also a predictor of accidents, as the worker is less able to see in these environments.

Invest in Quality.

The domed roof design dust collector provides a one-piece structure that protects your workers against leakage and damage. With many risks at stake, it’s important to consider the best options for your company so that you can avoid being another explosion statistic! For more information or questions, please talk to us at Imperial Systems. We are available to help you decide the best dust collector for your current needs.

Read more

by Imperial Systems | Oct 5, 2015 | Dust Collection Filters

Receive a fresh awareness of how dust can make or break your facility.

If you are in the food processing industry, you understand the importance of clearing the air through dust collection in your facility. Cross-contamination and sanitation standards are set at a high level for food processing facilities. So, how do you know you are keeping high standards? Imperial Systems has the answer with DeltaMAXX, our industrial replacement cartridge filters.

So how do our DeltaMAXX industrial replacement cartridge filters keep your facility safe and running smoothly? Let’s take a look at some problem areas that most facilities experience.

So how do our DeltaMAXX industrial replacement cartridge filters keep your facility safe and running smoothly? Let’s take a look at some problem areas that most facilities experience.

Safety In The Workplace

Keeping your facility clean is an important rule of safety in the workplace. In many food processing facilities, grain and dust accumulate on floors, causing them to become especially slippery. Keeping dust at bay can prevent many slip and fall injuries, allowing your employees to work at the speed they need without getting injured. This also prevents you from having to pay an exorbitant amount of workers compensation claims.

By using our industrial replacement cartridge filters you are also keeping your employees healthy by preventing airborne illnesses through ingesting allergen particles. These particles can cause not only serious illness, but even death.

By utilizing a proper dust collection system such as our CMAXX Dust Collection System, you can also prevent dust explosions caused by specific powders. With powders such as cornstarch (kst value of 202) and sugar (kst value of 138). The kst defines the value of a pressure wave.

Keep your facility up to OSHA standards with our DeltaMAXX industrial replacement cartridge filters.

How Do DeltaMAXX Industrial Replacement Cartridge Filters work?

Our DeltaMAXX industrial replace cartridge filters are the best in the business. With our Nanofiber Technology, you won’t get a better industrial cartridge filter anywhere else. Our DeltaMAXX filters will help keep your facility clean by providing:

- Nanofiber technology, stopping submicron particles from becoming embedded into the media, before they even enter the filter.

- The highest quality pleated media having a 99.9% efficiency

- Reduced dust collector operational costs

- The industry’s best surface loading technology

- Lower operational mass emissions

- The best in the industry, MERV15 filtration

- Less pulse cleaning

- and more..

Get Your Quality DeltaMAXX Filters Today

A fresh awareness of the importance of quality industrial replacement cartridge filters allows you to stay one step ahead and provide a safe, healthy, and productive workplace for you and your employees.

For more information on our DeltaMAXX filters, contact us online or give us a call at 1-800-918-3013.

Industrial Replacement Cartridge Filters | Industrial Replacement Cartridge Filter

Read more

It’s no secret that dust explosions are a common risk in metalworking and manufacturing industries. Processes including welding, grinding, polishing, and more can create the perfect combination of dust and sparks in the air that can lead to serious consequences. For example, three workers were killed in 2010 in a titanium dust explosion in West Virginia. This incident is in addition to the 281 combustible dust incidents identified by the U.S. Chemical Safety and Hazard Investigation Board between 1980 and 2005. In those incidents, 119 workers were killed, 718 injured, and many industrial facilities sustained extensive damage.

It’s no secret that dust explosions are a common risk in metalworking and manufacturing industries. Processes including welding, grinding, polishing, and more can create the perfect combination of dust and sparks in the air that can lead to serious consequences. For example, three workers were killed in 2010 in a titanium dust explosion in West Virginia. This incident is in addition to the 281 combustible dust incidents identified by the U.S. Chemical Safety and Hazard Investigation Board between 1980 and 2005. In those incidents, 119 workers were killed, 718 injured, and many industrial facilities sustained extensive damage.  At Imperial Systems, we are proud to announce our proprietary IDA DeltaMAXX filters, which bring advanced safety features to our CMAXX Dust Collection System. Together, they offer excellent protection against combustion.

At Imperial Systems, we are proud to announce our proprietary IDA DeltaMAXX filters, which bring advanced safety features to our CMAXX Dust Collection System. Together, they offer excellent protection against combustion.

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing

Industrial manufacturing requires instruments that can endure tough conditions, lasting for years and producing a high-quality material, all the while maintaining safety for those who use these instruments. That’s a tall order. At Imperial Systems we are interested in producing the best technologies, using scientific innovations as well as lessons from the past to create an equipment that will hold up to the pressures of your work. Safety equipment, such as cartridge dust collectors, must especially be designed to endure harsh environments.

Industrial manufacturing requires instruments that can endure tough conditions, lasting for years and producing a high-quality material, all the while maintaining safety for those who use these instruments. That’s a tall order. At Imperial Systems we are interested in producing the best technologies, using scientific innovations as well as lessons from the past to create an equipment that will hold up to the pressures of your work. Safety equipment, such as cartridge dust collectors, must especially be designed to endure harsh environments.

So how do our DeltaMAXX

So how do our DeltaMAXX