by Imperial Systems | Jan 25, 2016 | Uncategorized

Protect your employees from the hazards of thermal spraying!

Thermal spraying is a coating process that combines a heat source and a coating material in powder or wire form, melts it, and sprays onto surfaces at a high velocity. There are many variations of thermal spraying such as:

Detonation Spraying

Detonation Spraying- Plasma Spraying

- Twin Wire Arc Spraying

- High Velocity Oxy-fuel Coating Spraying (HVOF)

- Warm Spraying

- Cold Spraying

- Flame Spraying

Thermal spraying provides wear resistant coatings to protect from erosion and abrasion, and provides different degrees of electrical conductivity. Thermal Spraying has been utilized by many industries such as: Transportation, steel mills, medical, military, computers, aerospace, and many more.

The benefits of thermal spraying are abundant, but execution of the process presents many hazards. The Fabricators & Manufacturers Association, Intl. says that thermal spraying creates toxic dust and fumes due to the atomization of molten metals, posing a dangerous environment for operators carrying out the process. The Occupational Safety & Health Administration (OSHA) has acknowledged the dangers of explosive gas and carcinogenic fumes from detonation spraying, and recommend implementing their safety standards. Implementation of a high quality dust and fume collection system and proper ventilation can provide a solution to this hazardous situation.

Solutions For Detonation Spraying Hazards

What can Imperial Systems offer the thermal spraying industry to improve the safety and security of their thermal spraying operators?

Imperial Systems is among the top dust collection equipment manufacturing businesses in North America. The high quality and efficiency of our CMAXX™ Dust Collection System is how we provide those in the thermal spraying industry with the safety and security they desire.

Our CMAXX™ Dust Collection Systems are designed with revolutionary PD Technology for maximum cleaning performance and has 10% more filter media than other same-sized vertical cartridge collectors, neutralizing and keeping the air clean while you work. The CMAXX™ dust collector system also allows for 20% more area around the cartridge filters which causes the dust to fall into the hopper before attaching to the filters. Our CMAXX™ dust collector offers these other features:

- Vertical Cartridge Design for a longer filter life

- Internal Velocities are 20% Lower – Best in Class

- Increased Cleaning power with an energy efficient and High-Performance Manifold Mounted Pulse Valves

- Fewer Internal Ledges for Material to Build Up

- Slanted Inlet Design that prevents water build up on the top of the 90° inlet

- Up to 40% More Cleaning Power – Up to Twice the Filter Life

- 15 Year Manufacturer’s Warranty

Combine our quality CMAXX™ dust collector system with our DeltaMAXX™ Replacement Cartridge Filters and you have the solutions to those safety hazard problems. Our DeltaMAXX™ Replacement Cartridge filters have nanofiber technology that stops submicron particles from embedding into the media, has the highest quality pleated media at a 99.9% efficiency, and are able to reduce the operational cost of your dust collector system with less pulse cleaning.

For more information on our CMAXX™ Dust Collector System and our DeltaMAXX™ Replacement Cartridge Filters contact Imperial Systems today!

Read more

by Imperial Systems | Jan 7, 2016 | Common Industrial Dust Collection System Problems

Delaying your decision to install a dust collector spark arrestor may cost you. We can help you reduce the risk.

How much is your procrastination costing you? In some industries, putting decisions or actions off for a later date can have negative, if relatively mild, consequences. For instance, you’ll miss a deadline or lose an opportunity. You also may even disappoint a client or partner. While these consequences may be difficult for those having to deal with them, they pale in the face of the cost of procrastination within the metalworking industry. We’re talking about your dust collector spark arrestor here.

Unlike other businesses, your metalworking company is a high-stakes situation every single day. Specifically, you have the potentially explosive combination of combustible dust and sparks flying. So, it’s imperative that you act immediately to implement all of the required and recommended safety equipment. This certainly includes dust collection systems with sealed ductwork and an effective spark arrestor.

Of course, each of these pieces of equipment represents a major investment for your business. Therefore, it is important to do your homework and decide which one is the best fit for your business. However, letting that pending decision intimidate or hold you could be a serious hazard.

In this post, we will lead you through:

- Understanding the Risks of Combustible Dust and Sparks

- The Role of a Dust Collector Spark Arrestor in Risk Prevention

- Features and Benefits of Imperial’s Spark Arrestor

Understanding The Risk of Combustible Dust and Sparks

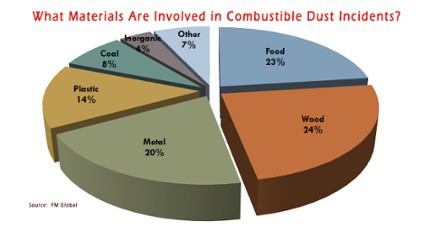

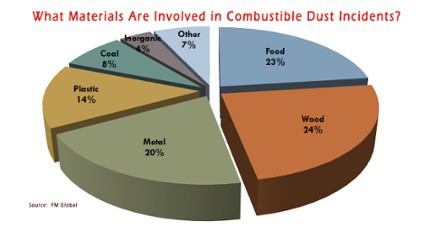

In metalworking, it’s no secret that materials you work with daily can create a serious risk for combustion. In fact, metals make up 20% of the materials involved in combustible dust incidents. Further, between 2008 and 2012 the United States Chemical Safety Board documented 50 combustible dust accidents. These led to a total of 29 fatalities and 161 injuries.

In metalworking, it’s no secret that materials you work with daily can create a serious risk for combustion. In fact, metals make up 20% of the materials involved in combustible dust incidents. Further, between 2008 and 2012 the United States Chemical Safety Board documented 50 combustible dust accidents. These led to a total of 29 fatalities and 161 injuries.

Unfortunately, as of 2014, metals and manufacturing were among the top industries being cited by OSHA for combustible dust, flammable dust, and other explosible dust hazards. This tells us that, although the risk is clear, it may not be clearly understood by those in the industry.

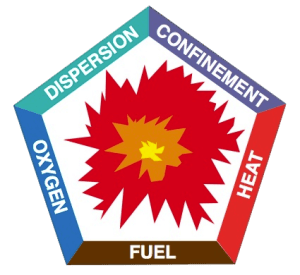

Five simple elements will cause combustion to occur:

- Heat

- Fuel

- Oxygen

- Dispersion

- Confinement

With each of these factors occurring effortlessly within most metalworking shops, tragedy lurks only a moment away. This is why, in 2006, the US Chemical Safety Board recommended a comprehensive combustible dust regulatory standard for all industries be added atop the initial regulations, which were developed in the grain industry in 1987.

With each of these factors occurring effortlessly within most metalworking shops, tragedy lurks only a moment away. This is why, in 2006, the US Chemical Safety Board recommended a comprehensive combustible dust regulatory standard for all industries be added atop the initial regulations, which were developed in the grain industry in 1987.

Clearly, the risks are both real and nearly ubiquitous. All within the affected industries must take them seriously. One of the best ways to do this is to evaluate your workspace and ensure that it has all of the equipment necessary to meet OSHA, NFPA, and other regulations. Additionally, you should regularly evaluate your equipment to ensure that it is in good working order.

The Role of A Dust Collector Spark Arrestor in Risk Prevention

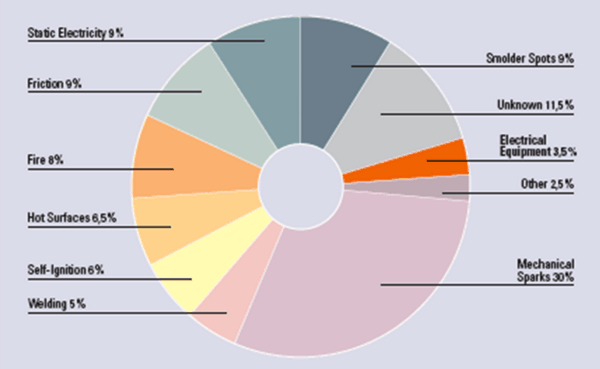

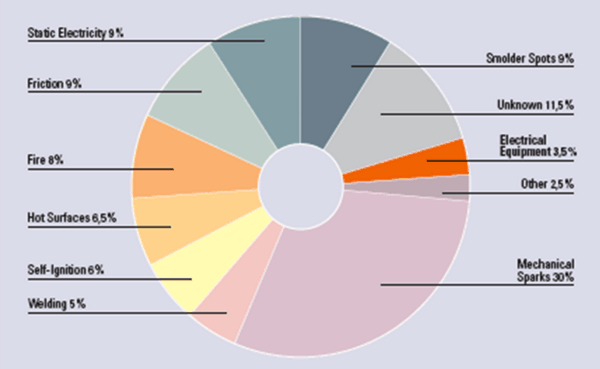

At its most basic, the role of a spark arrestor is to prevent the emission of flammable materials from combustion. Sparks, in various forms, are the major cause of combustion in combustible dust accidents:

Because a spark is often carried along through the exhaust gas stream, it has not cooled from its temperature of 600 degrees Fahrenheit by the time it arrives at the solids separator. At this point, it can be deposited onto the filter element surface, positioned as a glowing risk of combustion. The filter element surface is at high risk for combustion, no matter what material it is made of. This is because of its role in collecting tiny metal particles and dust that are produced by nearly every manufacturing and metalworking process. Even a simple spark is enough to insight disaster.

This is why OSHA’s ignition control recommendations regarding combustible dust include the following:

- Control smoking, open flames, and sparks

- Control mechanical sparks and friction

Use separator devices to remove foreign materials capable of igniting combustibles from process materials

Use separator devices to remove foreign materials capable of igniting combustibles from process materials- Separate heated surfaces from dusts

- Use an equipment preventive maintenance program.

OSHA’s injury and damage control methods also include:

- Separation of the hazard (isolate with distance)

- Segregation of the hazard (isolate with a barrier)

- Deflagration isolation/venting

- Specialized fire suppression systems

- Explosion protection systems

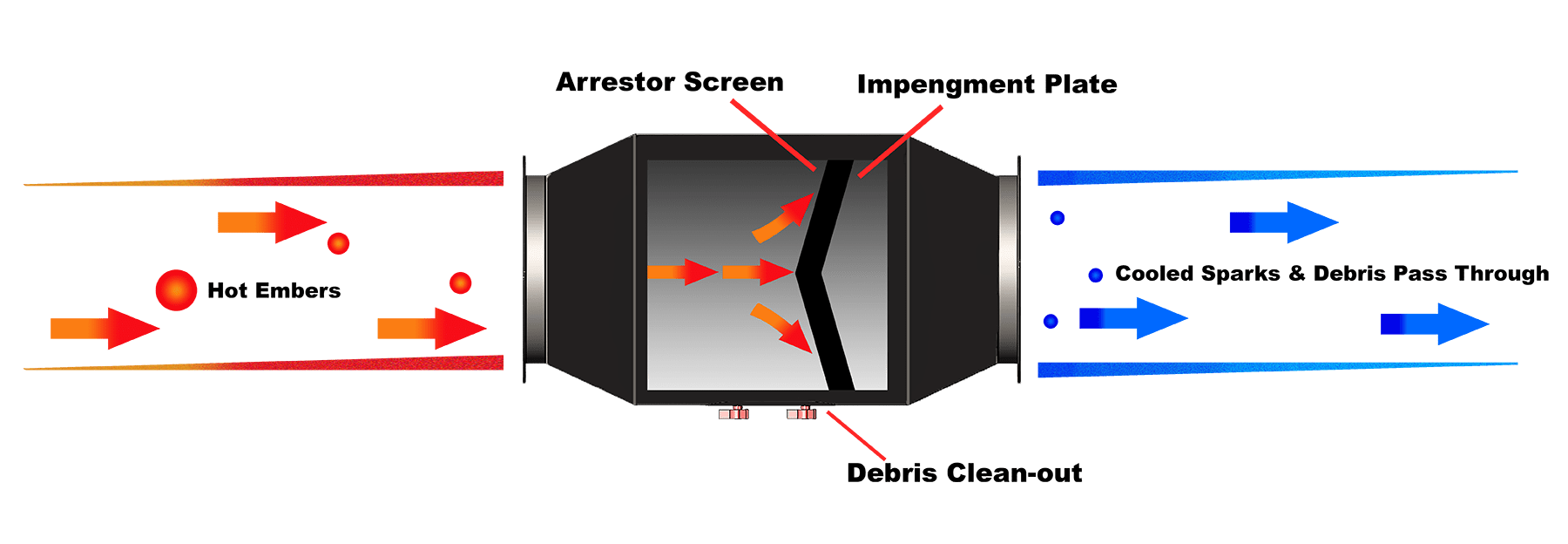

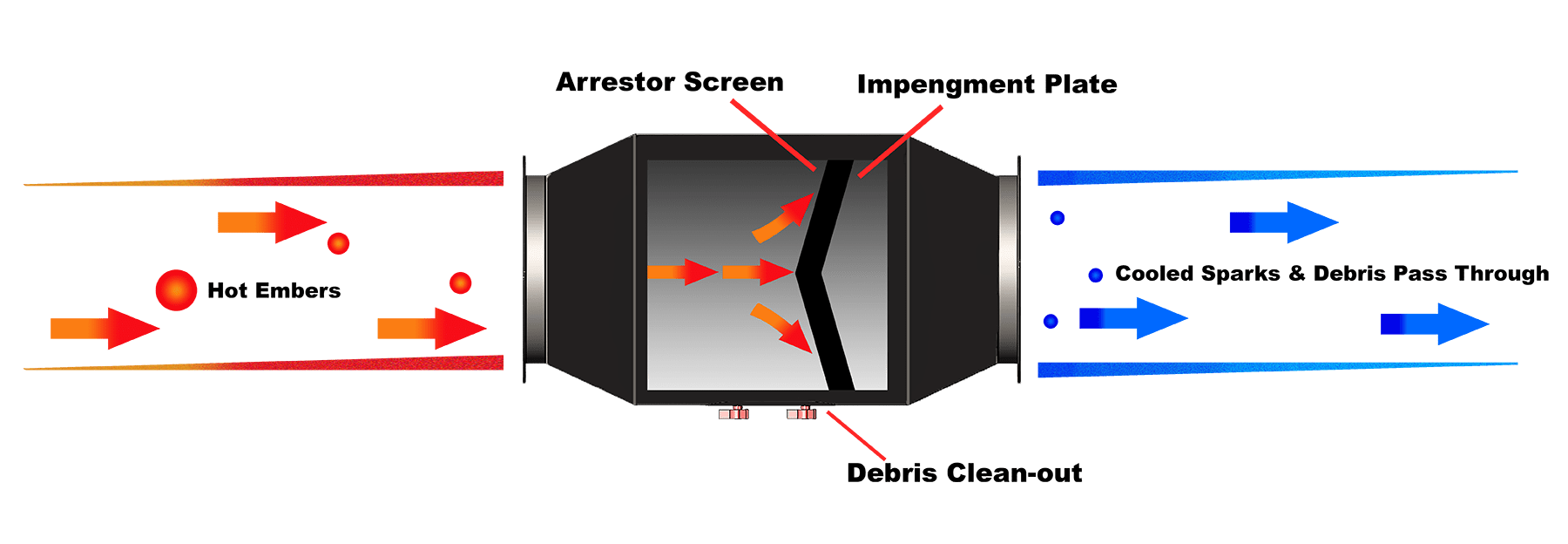

A Spark Arrestor is an instrumental part of these methods, working to minimize risk by cooling and thus extinguishing sparks before they reach the filter surface. In the diagram below, note how the hot spark enters the arrestor which both cools and collects debris, before allowing the cooled ember to pass through.

The spark arrestor fits within the full dust collection system as the first line of defense. They take up little or no extra space, but provide powerful results.

Features and Benefits of Imperial’s Spark Arrestor

At Imperial Systems, our highest priority is to provide the best solutions in dust collection and air pollution. We are determined to provide the best protection for your workers, your plant, and the environment. For over a decade, we have been serving metalworking businesses like yours all over the United States and Canada.

In an effort to provide fully comprehensive dust collection equipment, we have debuted our own spark arrestor named Spark Trap. It’s standard features include:

- Heavy duty construction

- No maintenance

- Clean-out door

- Fully welded construction

- Easy install into any system

- Can be installed in horizontal or vertical configurations

- No moving parts

- Carbon steel or stainless steel available

- No water required

- Available in sizes: 6 in. to 40 in.

Additionally, you can opt for raw inlet/outlet edges, rolled angle flange for bolt-together ducts, or clamp together for clamping duct.

As with all Imperial Systems’ products, you can count on the highest quality materials, top safety features, and unbeatable value.

The Cost of Procrastination

So back to our original question. If you haven’t yet decided on a spark extinguisher for your metalworking business, what is that procrastination costing you? Let’s take a look at the numbers:

From 1996-2005, 106 explosions resulted in 16 fatalities, 126 injuries, and an estimated cost of $162.8 million in damages to the facilities.

We know from previously cited studies that sparks are a major cause of such explosions. Will you absolutely face a combustible dust explosion if you put off your decision about a spark extinguisher? Perhaps not. But is it really worth the risk?

If you are ready to take the next step towards improving the safety of your workplace with a spark arrestor for your industrial dust collector, contact us today.

Read more

Detonation Spraying

Detonation Spraying

In metalworking, it’s no secret that materials you work with daily can create a serious risk for combustion. In fact, metals make up 20% of the materials involved in combustible dust incidents. Further, between 2008 and 2012 the United States

In metalworking, it’s no secret that materials you work with daily can create a serious risk for combustion. In fact, metals make up 20% of the materials involved in combustible dust incidents. Further, between 2008 and 2012 the United States  With each of these factors occurring effortlessly within most metalworking shops, tragedy lurks only a moment away. This is why, in 2006, the US Chemical Safety Board recommended a comprehensive combustible dust regulatory standard for all industries be added atop the initial regulations, which were developed in the grain industry in 1987.

With each of these factors occurring effortlessly within most metalworking shops, tragedy lurks only a moment away. This is why, in 2006, the US Chemical Safety Board recommended a comprehensive combustible dust regulatory standard for all industries be added atop the initial regulations, which were developed in the grain industry in 1987.

Use separator devices to remove foreign materials capable of igniting combustibles from process materials

Use separator devices to remove foreign materials capable of igniting combustibles from process materials