Thermal Spray Fumes Polluting Your Workplace? Don’t Miss The Optimal Solution.

Find out how metalworkers like you can address the issue of thermal spray fumes.

Enhancing the wear resistance of agricultural tools.

Enhancing the wear resistance of agricultural tools.

Protecting the elements of jet engines from high temperatures and oxidation.

Even providing electrical insulation for electronic devices.

These are just a few of the many uses of thermal spray coating technologies. Your own metalworking business probably has many other uses for the processes, ranging from large scale jobs to highly detailed ones. Although many different processes and uses fit within the category, they all share similar properties… and risks. Along with the versatility and usefulness of of thermal spray techniques come the dangers of ultraviolet light, fumes, dust, compressed air, gases. Are you protecting your operators sufficiently?

At Imperial Systems, we are dedicated to to helping metalworkers like you ensure the safety and efficiency of your workplace. In this blog, you will find:

- A clear outline of the risks associated with thermal spray

- A breakdown of OSHA safety recommendations

- A valuable solution to reduce the risks of fumes, dust, and gases

- An opportunity to collaborate with others in the industry about problems and solutions

Risks Associated With Thermal Spray Equipment And Use

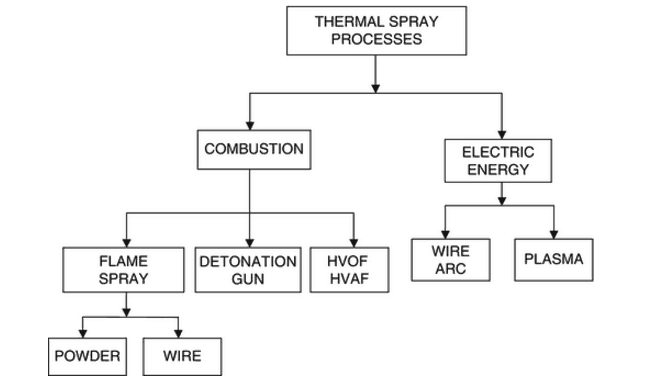

As mentioned, there are countless uses for thermal spraying processes. To keep things simple, we’ll start by breaking them down into the different sorts of processes that fall within the category addressed in the blog. In the chart below, you can locate the process or processes used in your own workspace.

There are a number of distinct risks that are associated with each of these types of thermal spraying, including:

- Ultraviolet Light: Thermal spray systems product UV light, defined as non-ionizing radiation. The spectrum varies depending upon the type of process used. For example, flame spray processes produce such radiation in the UV-B or erythemal region of the electromagnetic spectrum. Plasma systems, on the other hand, operate with much greater intensity in the UV-C region. With prolonged exposure, such radiation can damage the eyes (flash burn), burn the skin, and cause changes in skin cell growth.

-

- Fumes and Dust: Another byproduct of the thermal spray process, dust and fumes created by atomized molten metals, can pose significant health and safety hazards. Not only do they form a potential combustion risk, but they are also hazardous if inhaled, causing a variety of negative reactions.

- Compressed Air: Aside from the well known danger when directed at unprotected skin or eyes, compressed air that is not properly regulated poses a number of other risks. Its noise levels can often cause hearing loss. Additionally, it is imperative to maintain the good condition of equipment, as damaged hoses can lead to explosion.

- Fumes and Dust: Another byproduct of the thermal spray process, dust and fumes created by atomized molten metals, can pose significant health and safety hazards. Not only do they form a potential combustion risk, but they are also hazardous if inhaled, causing a variety of negative reactions.

- Industrial Gases: The list of gases used in thermal spray processes is extensive, including: argon, helium, hydrogen, kerosene, and oxygen, among others. Each of these gases carries with it its own dangers. Many are flammable, corrosive, or pose the risk of combustion. Additionally, many are toxic when inhaled.

OSHA Safety Recommendations

Recognizing the numerous risks associated with thermal spray processes, the Occupational Safety & Health Administration has outlined a number of regulations and recommendations to keep you, your workers, and your workplaces safe.

First and foremost, owners and operators of such spraying equipment should understand and implement the operational procedures outlined by the product’s manufacturer. Additionally, all of OSHA’s standards on Welding, Cutting and Brazing should be heeded. Although they are numerous, the outline below will give you a basic idea of what steps can be taken to reduce this risks described above.

- Ultraviolet Light: Ensure that operators, assistants, and others in the vicinity of thermal spraying use the appropriate protection for their eyes and skin. This clothing should be tightly woven, including both gloves and coveralls. Additionally, tinted welding curtains and screens can reduce exposure to nearby workers.

- Fumes and Dust: To reduce the risk of various dangers associated with fumes and dust, make sure that you have a dust and fume collection system that is fitted to the necessary specifications. If you are working with toxic materials, HEPA filters may be necessary. In addition to an industrial dust collection system, it is also important to establish a respiratory protection program for workers, including proper fitting of respirators and regular medical screenings.

-

- Compressed Air: In addition to following manufacturer provided safety instructions for any compressed air, be sure to regularly inspect all of your equipment and follow the best practices for use. Not only will this promote safety for those using it, but it will also ensure the efficiency of the work being done.

- Compressed Air: In addition to following manufacturer provided safety instructions for any compressed air, be sure to regularly inspect all of your equipment and follow the best practices for use. Not only will this promote safety for those using it, but it will also ensure the efficiency of the work being done.

- Industrial Gases: Along with the safety precautions described for fumes and dust, it is also important to conduct regular air sampling to determine workers’ exposure to airborne contaminants. This is especially important when the gases being used in your manufacturing processes are potentially toxic; thermal metal spraying and practices like it can create fumes and gases at concentrations exceeding their Permissible Exposure Limits.

A Valuable Solution For Thermal Spraying Dusts, Fumes, and Gases

Although some safety precautions–such as eye protection and respirators– may be easy to address, an industrial dust collector is a very different kind of solution. A larger investment, such collectors require you to take a full assessment of your workplace to determine the specifications you will need. Not only do you have to consider the safety provided by this system, but you also need to think about its efficiency and ease of use.

At Imperial Systems, we had your needs in mind as we designed our CMAXX™ Cartridge Dust Collector, as well as the DeltaMAXX™ Cartridge Filters. This equipment ranks high in efficiency, while providing the outstanding protection you need. Just check out what the CMAXX™ has to offer:

- Best in Class Internal Velocities

- Vertical Cartridge Design for Longer Filter Life

- Tool-Free, Heavy Duty Filter Door to Reduce Service TIme

- Modular Design with No External Bolt Holes

- 100% Total Pulse Distribution

- Up to 40% More Cleaning Power Than The Industry Standard

This high performing dust collection system is designed to be used with our DeltaMAXX™ Replacement Cartridge Filters, which deliver the cleanest air and the longest filter life… meaning the greatest cost benefit to you. With the most Advanced NanoFiber Technology, it offers an impressive MERV 15 filtration efficiency.

Best of all, at Imperial Systems, we are dedicated to providing the best possible solution for metalworkers like you. So, if you aren’t sure what specifications are best for your shop, give us a call. One of our service engineers will help you make the best decision to keep your business running safely and efficiently.

Collaborating on Thermal Spray Solutions

Thermal spray equipment and processes have created major opportunities… and challenges. What problems have you encountered in your own work? Have you found a solution that works, or are you still searching?

Share your stories and questions in the comments section below to join the conversation on making thermal spraying processes as safe and efficient as possible.

Space Saving – Low Profile Design, Small Footprint

Space Saving – Low Profile Design, Small Footprint

You may already know that Imperial Systems prides itself on engineering outstanding, high quality products to keep buyer’s employees and businesses safe from dust collection and air pollution. With the current competitive economic environment, it’s imperative for businesses in the thermal spray industry to focus more on a dust collection system that lasts a long time.

You may already know that Imperial Systems prides itself on engineering outstanding, high quality products to keep buyer’s employees and businesses safe from dust collection and air pollution. With the current competitive economic environment, it’s imperative for businesses in the thermal spray industry to focus more on a dust collection system that lasts a long time.