by Greg | Mar 27, 2016 | Case Studies

Case Study – Weld Smoke Extraction Problems at This Metal Fabrication Facility Solved with the CMAXXTM Dust and Fume Collector

Product: CMAXXTM (CM020) Dust Collector (Total of 3 units)

Application: Capture weld smoke and fumes

Customer: Masaba, Metal Working Fabricator of Bulk Handling Equipment for Mining, Aggregate, Agriculture, etc.

The Challenge: Masaba’s manufacturing facility has a high ceiling that would become filled with smoke and fumes from their various welding bays. The old roof mounted system that was used to extract the weld smoke and fumes from the facility was not working properly. This system was a hybrid HVAC unit that incorporated industrial air filters. The weld smoke being produced during daily production proved to be too much for the current air extraction unit. The return air into the facility was not being filtered adequately, which defeated the purpose of the system altogether.

The Solution: The President of Masaba, Jerad Higman, was not satisfied with the current situation. As a business owner, he cared very much about his employee’s health and having a clean working environment. Though the air quality was good enough in the shop, Jerad wanted to make it even better and decided a new, more effective system design was needed. He called upon top industry dust collection manufacturers, Camfil Farr, Donaldson Torit, and Imperial Systems, Inc. to provide the best solution to his facilities’ air quality problems. He knew each company was capable of solving the problem, but after meeting with Imperial System’s President, Jeremiah Wann, and hearing his ideas about mitigating all the weld smoke issues, Jerad knew he had found the right company.

A relationship of trust quickly developed between Jerad and Jeremiah as they worked together on the design and layout for the new system. “I had a great experience in working with Jeremiah and Imperial Systems”, Jerad says. “I really liked the fact that they are an American owned company and were always available when we needed them.”

The installation of an ambient weld smoke system was the ultimate choice to clear Masaba’s facility of dirty air. Imperial Systems installed three exterior CMAXXTM (CM020) collector units and associated ductwork as part of the new system. Masaba manufactured the hoods that covered each welding bay. Once everything was connected, it didn’t take long after the system start-up to see the built up weld smoke dissipate. The new CMAXXTM system was moving and recycling the total air volume inside the shop six times per hour. The return air was being filtered properly by the DeltaMAXXTM filters, resulting in cleaner air and healthier environment.

Jerad Higman was amazed at the difference. “I was very impressed at how effective the CMAXX collectors were operating.” He goes on to say, “To this day, I have not experienced any problems with them and I would highly recommend Imperial Systems products to anyone that has issues with the air quality in their shop. Their level of expertise and service is just outstanding.”

For more information on how CMAXXTM Dust and Fume Collection systems can benefit your facility, call one of our experienced team members at 800-918-3013 or visit Imperial System’s website today.

Read more

by Imperial Systems | Mar 25, 2016 | Uncategorized

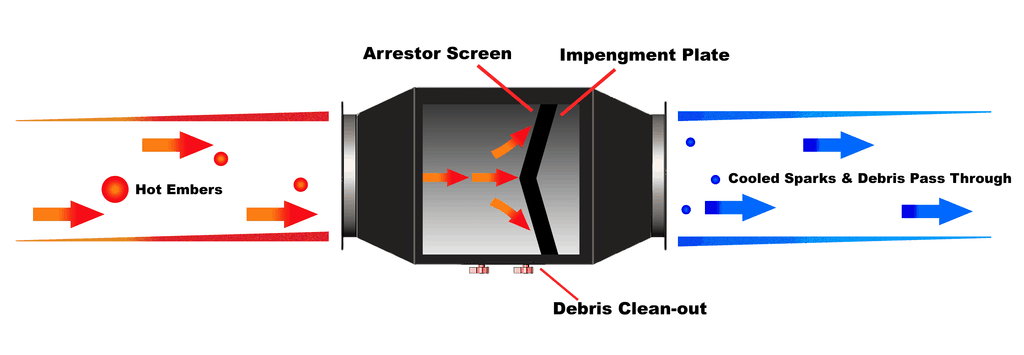

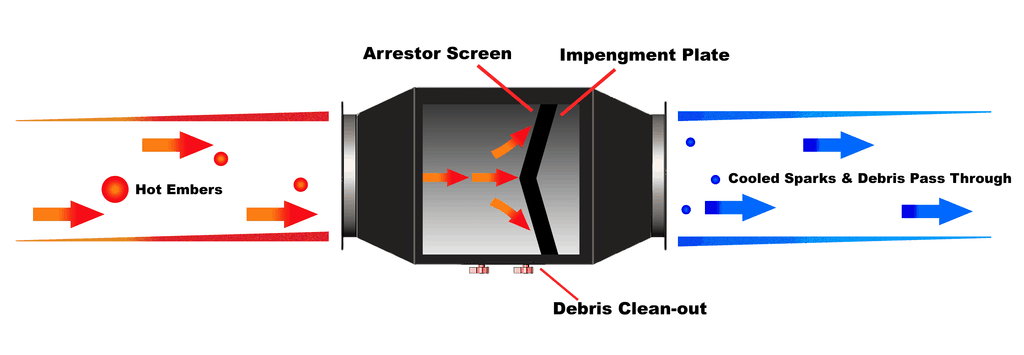

Don’t let the sparks fly in your metalworking facility. Employee safety is a top priority at Imperial Systems

All across the globe, metalworking plants have seen an overwhelming amount of damage and fatalities caused by explosions and fires that could’ve been prevented with quality spark traps, or spark arrestors, and dust collection systems.

The problem that is seen in the metalworking industry is when a spark finds its way into the main component of a dust collection system causing the ignition of combustible dust, which causes devastating damage to the lives of metal fabricators and metalworking plants.

The problem that is seen in the metalworking industry is when a spark finds its way into the main component of a dust collection system causing the ignition of combustible dust, which causes devastating damage to the lives of metal fabricators and metalworking plants.

The National Fire Protection Association has a comprehensive guide on the control of ignitions sources to prevent explosions (NFPA 654):

- The use of proper electrical equipment and wiring methods.

- The control of static electricity.

- The control of sparks, open flames, and smoking.

- The control of mechanical sparks and friction.

- The use of separator devices to remove foreign materials capable of igniting combustibles from process materials.

Consider that 7% of ignitions sources are caused by fabricated metal, while metal dust accounts for 20% of explosions. It seems surprising then that spark arrestors are often overlooked as a necessary device to help prevent explosions in the metalworking industry. The initial thought is that an efficient high quality dust collection system, efficient filters, and implementation of the safety standards set by OSHA and the NFPA will be enough to prevent fires and explosions from occurring. But consider the lives at stake, and the overwhelming cost of damage to your metalworking facility when the solution to preventing fires and explosions was purchasing efficient spark traps.

In-Line Spark Traps From Imperial Systems

- A simple installation: Our unique spark trap system does not require upkeep from their providers, meaning they are hassle-free in addition to being simple to install. They do not require any moving parts or additional welding.

- Optional sizes and features: You can choose between a carbon and stainless steel finish. In addition, you can choose to include raw inlets and outlet edges to your spark traps.

- Customized fit: With both horizontal and vertical configuration options, an Imperial Systems arrestor can be aligned to your collector without fail.

By now, you understand the importance of incorporating spark traps in your current dust collections system. At Imperial Systems, we don’t want safety to be a hassle. So we’ve made our spark arrestor easy to purchase and easy to install into any system.

Contact Imperial Systems today at 800.918.3013 or learn more by emailing us at info@isystemsweb.com to discuss the right spark arrestor for you.

Spark Traps | Spark Trap

Read more

by Imperial Systems | Mar 24, 2016 | Uncategorized

Minimize risk and increase safety with Imperial Systems!

At Imperial Systems, we understand choosing the right dust collection system for your metalworking plant isn’t a decision taken lightly. There are countless hours poured into the right dust collection system, why it’s the best dust collection system, and how each dust collection system and company compares to the rest.

The dangers involved in the metalworking industry come as no surprise to those who work in it day in and day out. Metalworkers step into a metalworking plant fully aware of what can go wrong, but what if you could give them reassurance with a dust collection system coupled with filters that are capable of deflagration isolation while stopping a flame front.

The dangers involved in the metalworking industry come as no surprise to those who work in it day in and day out. Metalworkers step into a metalworking plant fully aware of what can go wrong, but what if you could give them reassurance with a dust collection system coupled with filters that are capable of deflagration isolation while stopping a flame front.

Our CMAXX™ Dust Collection System together with our DeltaMAXX™ IDA (In-Line Deflagration) Cartridge Filters can provide you with the advanced features you need and the safety you deserve!

Deflagration Isolation and More Advanced Features of the DeltaMAXX™ IDA Filters

The hazards of a machine malfunctioning, dust, fumes, or sparks can present serious safety risks to your business and your employees. The purpose of our DeltaMAXX™ In-Line Deflagration filters is to prevent disastrous fires or explosions from taking lives, and decimating your metalworking business. Without the IDA’s advanced and innovative technology the effects of an untamed flame front and the inability to isolate a deflagration could be disastrous!

Here’s how the certified technology of our CMAXX Dust Collection System and DeltaMAXX™ IDA (In-Line Deflagration Arrester) Cartridge Filters work.

In order to ensure our DeltaMAXX™ IDA Cartridge filters were capable of stopping a flame front we had a third party test the CMAXX™ Dust Collection System multiple times. Our numerous tests proved that the DeltaMAXX™ IDA Cartridge Filters were capable of a deflagration isolation and stopped a flame front test after test after test. We knew the DeltaMAXX™ In-Line Deflagration filters could stop a flame front, but we had to look further than that. Yes, it stopped the flame front, but was there any damage to any other portion of the dust collection system? The answer is NO! Not only was the DeltaMAXX™ IDA Filter able to stop the deflagration but there were no traces of sparks or flames down from the filters or the clean air plenum!

The testing continued to see how effective the CMAXX™ Dust Collection System was without explosion venting. We wanted to see if the body could withstand a deflagration isolation of cornstarch at 185 KST with pressures exceeding 4 PSI. The explosions diverted through the filters, the internal cages of the filters remained in perfect shape, and the seals were not deformed or melted.

CMAXX™ and DeltaMAXX™ IDA Filters – the security you need for your metalworking business!

Read more

by Imperial Systems | Mar 19, 2016 | Uncategorized

Reduce emissions with our DeltaMAXX™ replacement cartridge filters!

What are you looking for in a quality cartridge filter replacement? With any search for the perfect filter, you’re looking for a replacement cartridge filter that improves the efficiency of your dust collection system, reduces the change-out frequency which saves you time and money, and the capability to customize the cartridge filter to your dust collection system.

Nearly three years ago Forbes named metalworking as #5 on their list of deadliest jobs in America. At Imperial Systems, we know the hazards that metalworkers face due to the fumes, dust, smoke, and sparks they work with daily. That’s why it’s important to find a cartridge filter replacement manufacturer that can provide you with the features you need to keep your metalworkers safe!

Why Make DeltaMAXX™ Your Cartridge Filter Replacement?

Longer Filter Life – Our filters have an advanced NanoFiber technology that stops submicron particles from entering and becoming embedded into the media beneath the NanoFiber. Because of our nanofiber technology this prolongs the life of our filters. Giving you what you need – twice the filter life. Longer filter life minimizes workers exposure to dust, saves on maintenance and disposal costs, and has less impact on the environment.

Longer Filter Life – Our filters have an advanced NanoFiber technology that stops submicron particles from entering and becoming embedded into the media beneath the NanoFiber. Because of our nanofiber technology this prolongs the life of our filters. Giving you what you need – twice the filter life. Longer filter life minimizes workers exposure to dust, saves on maintenance and disposal costs, and has less impact on the environment.

- Best Surface Loading Performance – Adding to the longer filter life you need is the best surface loading performance in the industry.The DeltaMAXX™ Cartridge Filter Replacement uses less compressed air due to the reduced buildup in and on the filters. Because of less buildup there are fewer pulses, and fewer pulses leads to a longer filter life.

- Highest Efficiency – Due to our highest quality pleated media our filters have a high efficiency of 99% .3 -.5 Miron. In order to perform at their peak level, average filters need time to warm up. DeltaMAXX™ Cartridge Filter Replacements have nanofiber technology that gives our filters the ability to work at their peak performance immediately!

These are the top three reasons why you should choose DeltaMAXX™ as your cartridge filter replacement, but here are a few more reasons to consider Imperial Systems cartridge filters:

- Our filters are manufactured for all makes and models of cartridge dust collectors.

- Our impressive MERV 15 Filtration Efficiency Rating!

- Lower Operational Mass Emissions

- Reduced Dust Collector Operational Costs

- Replacing the cartridge filters can be one with just one person, and can take less than an hour to replace.

If you’re in the market for a reliable, efficient, longer-lasting filter think Imperial Systems! Contact us today, and let’s get your dust collection system fitted with our DeltaMAXX™ replacement cartridge filters!

Read more

by Imperial Systems | Mar 16, 2016 | Common Industrial Dust Collection System Problems

Don’t choose sub-standard sheet metal duct fittings for your metalworking business. Save time and money by choosing Imperial Systems.

When the company first began back in 2001, Imperial Systems was strictly a fabricator of custom sheet metal duct fittings. Although Imperial Systems is now considered a manufacturer of industrial dust collectors, we are also still experts in custom duct and fitting jobs. Our pride in developing custom sheet metal duct fittings has always remained intact as we feel we are the best and most experienced in the industry with these custom jobs.

Why Choose Imperial For Custom Sheet Metal Duct Fittings?

Paired with our outstanding customer service, we manufacture only the highest quality products that are reliable, durable, and guaranteed to last. Below are a few reasons why you should consider replacing your current duct and fittings with Imperial Systems:

Paired with our outstanding customer service, we manufacture only the highest quality products that are reliable, durable, and guaranteed to last. Below are a few reasons why you should consider replacing your current duct and fittings with Imperial Systems:

- Your current sheet metal duct fittings are in disrepair. Don’t let dust and fumes escape, causing your employees to be sick. Even more serious is the risk of combustion in the workplace.

- You’ve noticed your employees getting sick more often. The cause may be leaky ducts and fittings. Look into replacing your current system with Imperial Systems’ trusted products.

- Poor customer service. If you find that your current provider for sheet metal duct fittings is lacking in quality customer service, find out why Imperial Systems maintains trustworthy business relationships with our clients.

- Your system is outdated. With an updated system regulated by OSHA and NFPA standards, you can save time and money. You may also reduce a risk of an accident or hazard.

We are often called upon to take jobs focused on ducting and sheet metal in addition to the dust collection systems we are best known for. Our standard of quality applies not only to dust collection but to the sheet metal duct fittings that enhance your current system so you know you’re in good hands.

When making a purchase decision in the metalworking industry, you must take into consideration both the quality of the product being purchased as well as the effectiveness and safety for the end-user–your employees. Today’s advances in dust collection systems have lessened replacement costs and injury or death due to faulty equipment.

Ready for Sheet Metal Duct Fitting Solutions From Imperial?

Don’t let your employees risk their health due to the fine dust particles that is a common byproduct in the metalworking industry. Keep your employees healthy and your environment safe with our quality sheet metal duct design work. Our ducts and fittings can be added to any current system you have, or we can replace your system with one of our highly demanded CMAXX™ Dust Collector Systems.

If you’d like to request a quote or schedule an assessment based on your needs for a hardworking, high-quality sheet metal duct fitting which is both OSHA and NFPA regulated, get in touch with us today at 724.662.2801 or by finding out more about us.

At Imperial Systems, we specialize in advanced safety solutions you can count on.

Read more

The problem that is seen in the metalworking industry is when a spark finds its way into the main component of a dust collection system causing the ignition of combustible dust, which causes devastating damage to the lives of metal fabricators and metalworking plants.

The problem that is seen in the metalworking industry is when a spark finds its way into the main component of a dust collection system causing the ignition of combustible dust, which causes devastating damage to the lives of metal fabricators and metalworking plants. The dangers involved in the metalworking industry come as no surprise to those who work in it day in and day out. Metalworkers step into a metalworking plant fully aware of what can go wrong, but what if you could give them reassurance with a dust collection system coupled with filters that are capable of

The dangers involved in the metalworking industry come as no surprise to those who work in it day in and day out. Metalworkers step into a metalworking plant fully aware of what can go wrong, but what if you could give them reassurance with a dust collection system coupled with filters that are capable of

Longer Filter Life

Longer Filter Life

Paired with our outstanding customer service, we manufacture only the highest quality products that are reliable, durable, and guaranteed to last. Below are a few reasons why you should consider replacing your current duct and fittings with Imperial Systems:

Paired with our outstanding customer service, we manufacture only the highest quality products that are reliable, durable, and guaranteed to last. Below are a few reasons why you should consider replacing your current duct and fittings with Imperial Systems: