by Imperial Systems | Jul 29, 2016 | Common Industrial Dust Collection System Problems, Uncategorized

Dust and Fume Collection: Some Industries That Might Not Know They Need It

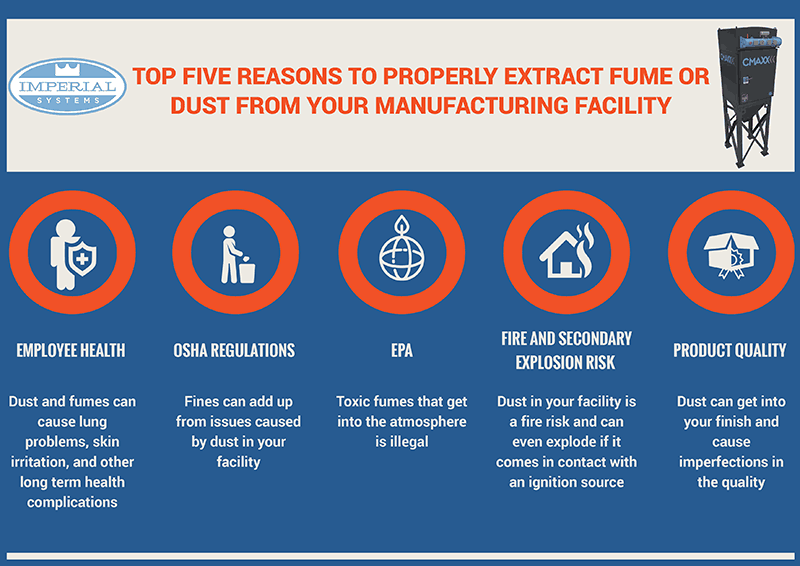

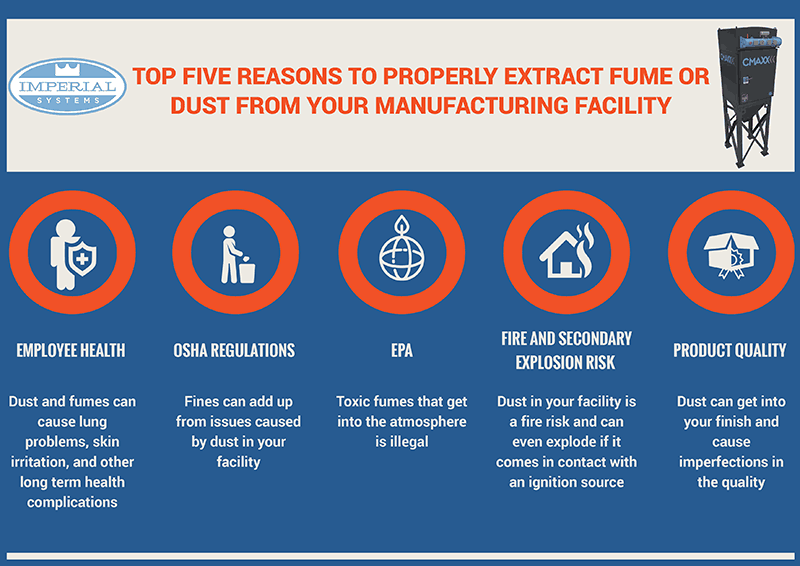

Dust and fume collection in a manufacturing facility is important for many reasons. Here are the top five reasons you should consider:

Not Convinced Yet?

Can you name the metal that causes cancer, damages skin, eyes, lungs, and kidneys, and is found in everything from stainless steel to dyes and pigments?

If you said this compound is Hexavalent Chromium (https://www.osha.gov/SLTC/hexavalentchromium/), you’re right.

Chromium is a component of stainless steel, added to make the steel more corrosion-resistant. Consequently, the fumes produced from welding, laser cutting, or plasma cutting stainless steel contain hexavalent chromium. While this form of chromium is known to cause cancer, it also directly attacks the lungs and kidneys and can cause severe eye and skin irritation.

Further, hexavalent chromium doesn’t just appear in welded or heated stainless steel. Electroplating with chrome also presents a hazard, and hexavalent chromium compounds are used as pigments in inks, paints, and many types of plastic. In fact, working on any material plated with chrome or coated with a chromium-containing material may release hexavalent chromium into the air.

Think hexavalent chromium isn’t something to worry about in your type of business? You certainly may need to reconsider. That’s because OSHA testing showed which types of facilities had detectable levels of this dangerous metal in their air. The following are some of the top offenders:

- Nonresidential building

- Highway, street, and bridge

- Foundation and structural materials

- Foundries

- Forging and stamping

- Architectural and structural metals

- Boiler, tank, and container

- Coating

- Engraving

- Heat-treating

- Agricultural machinery

- Mining machinery

- Ventilation and air-conditioning

- Aerospace products and parts

- Ship and boat building

- Automotive repair and maintenance

Any surprises on this list? If your facility is part of any of these industries, contact us at 800-918-3013 for an assessment of your dust and fume collection needs.

Related blog posts:

Read more

by Imperial Systems | Jul 26, 2016 | Uncategorized

Dust explosions are bad to begin with, but what do you know about secondary explosions? There are many factors that determine how likely a particular type of dust causes deflagration. When you think of combustible dust, do you think of the explosions you’ve heard about at grain handling facilities? Maybe you think of the explosive potential of aluminum dust.

Secondary Dust Explosion Incidents

Three dust explosions occurred in 2003. They demonstrate how many different types of production and manufacturing can produce a deflagration risk, including a secondary dust explosion. In a North Carolina plant, the application of a polyethylene coating to rubber caused accumulation of the dust. As the material dried, dust formed and accumulated above the work area. The work area was clean. But a layer of dust 1/4″ thick was enough to cause an explosion that killed six people. In this situation, a dust collection system in the production area could have captured the dust particles before they circulated through the facility.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

Aluminum dust from scrap processing fueled the explosion in Indiana. The dust collector in this case was the source of the explosion. It did not have explosion vent panels, and instead of being directed safely, the explosion traveled back into the building and ignited dust in the ductwork. A secondary explosion occurred when dust accumulated on surfaces inside the facility ignited. A dust collector designed to isolate and redirect a deflagration could have prevented this accident.

NFPA Recommendations

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

It’s often this accumulated dust, hidden on high surfaces, in corners, or inside ductwork, that ignites to cause a secondary explosion that’s far more dangerous than the original one. Witness reports of dust explosions often include descriptions of a smaller explosion followed by one or more larger ones; this is secondary ignition. Dust control throughout the facility, along with fire prevention equipment such as abort gates, spark arrestors, and explosion venting, can control a potential explosion and prevent a small fire from becoming a fatal disaster.

Read more

by Imperial Systems | Jul 22, 2016 | Uncategorized

Asking Questions About the Air You Breathe at Work

OSHA rules mandate that you have a right to know about any safety hazards that are present in your workplace, including the air you breathe. Most managers, supervisors, and owners certainly want their employees to be safe and want to avoid putting their employees in danger. But there may be workplace hazards they don’t know about. In addition, sometimes an employee’s questions can help them become aware of a situation.

For managers, supervisors, and other bosses, an employee’s concern about a safety issue is an opportunity. That is to say, it’s a chance for you to work on resolving the problem as a team. Consequently, the biggest OSHA fines go to employers who ignore safety issues. But employers who are working in good faith to resolve safety issues may receive recommendations from OSHA. But employers who have shown that they don’t care about fixing safety issues often receive gigantic fines.

Team Communication

The best way to avoid safety issues at work is for employees and bosses to communicate in a cooperative way. This benefits everyone. An employer who listens to and works to resolve the concerns of their workers will find that a reputation for being proactive and concerned about employee safety is good for business.

Since industrial dust and fume control is our business, making sure that workers are breathing clean, safe air is the aspect of safety we’re most concerned with. Many workplaces don’t know they need a dust or fume collector or don’t know when their collector isn’t working efficiently. Employees are sometimes concerned about what they might be breathing or exposed to in the air. A good employer should listen to those concerns and find answers to them.

Workers can be proactive in protecting their health. That’s by learning some important information about the materials they work with and what risks they might involve. For example, workers who are involved in cutting, welding, or otherwise producing fumes from stainless steel should have some awareness of hexavalent chromium. Further, workers who manufacture plastic products need to know about toxic elements like cadmium. Intended as stabilizers, they can also be hazards from the plastic itself. You may be uncertain about what hazards might be in your workplace. If so, you have a right to ask for more information about the air you breathe.

If employees have questions, OSHA has many options for safety training and awareness. An employer may be able to make concerned workers feel empowered and more knowledgeable by answering their questions and making sure they get the training they need. Employers must provide their employees with information about any hazards in their workplace. But sometimes those hazards may not be recognized until an employee asks a question.

Effective Discussions About the Air You Breathe

You have a right to ask your employer if you’re not sure what’s in the air you breathe at work. As an employer, it’s your job to check out your employee’s concerns. Then you can determine whether there is a health hazard to address. Proactively dealing with an employee’s concern shows respect for their needs and also a meaningful interest in employee safety and health.

If you feel that there’s a health risk in your workplace that you need to talk to your supervisor or employer about, you should know that OSHA regulations protect you from punishment or from any kind of retaliation, and your employer probably knows this.

The discussion will be more productive if a few points are kept in mind:

- The discussion is not an accusation. It is a question or issue that you would like more information about or are concerned about.

- The focus should be on making sure you and your coworkers are healthy and safe, because this is good for everyone and for the company.

- You have a right to ask for more information, more training, better protective equipment, or whatever you feel like you need to be safer. Being specific about how the problem could be solved helps people move forward with solutions.

- Be specific about your concerns and ask questions. If you feel like you don’t have enough information, talk to someone who can help you find what you need or look up some general information on the topic.

- Approach the discussion with the attitude that you and your employer have a mutual problem that you can work together to solve.

An example of how you might start a positive conversation:

1) I have a question about the welding fumes in the shop. It seems like some of the stations have a lot of fumes around them sometimes. Is there something we could do about that?

Or:

2) Some of us noticed that even though we do a lot of sweeping and cleaning up, there’s dust getting stuck up in places where we can’t reach it. What’s the safest way for us to deal with that?

Or:

3) I noticed there’s a sign up about (safety hazard), but I’m not sure we all know as much about it as we should. Is that something we could get some more information about?

Good ways for a supervisor or employer to respond to these might be:

1) We can definitely look at those stations and see if something needs to be done about the welding fumes. Are there places in the shop that are the biggest problem?

Or:

2) That’s a good question. We’ll have to figure it out. Does anybody out in the plant have any ideas for how to handle it?

Or:

3) Let me check out the OSHA website and see what they’ve got. I want to make sure you have all the information you need.

Of course, these things only matter if you follow up. Ignoring an employee’s safety concerns isn’t just disrespectful. It’s also a violation of OSHA regulations. And employees who aren’t comfortable talking to their supervisors about safety issues always have the right to contact OSHA for assistance. An employer who retaliates against, punishes, or fires an employee for reporting a safety concern to OSHA can face lawsuits and very large fines. Keeping the lines of communication open benefits everyone if a company can work as a team to identify and solve safety issues.

Read more

by Imperial Systems | Jul 19, 2016 | Uncategorized

We manufacture dust control systems that use filters (bags or cartridges). So, we obviously have a preference for dry systems. But what about a wet dust collector?

Wet Dust Collector Pros and Cons

Both wet and dry systems have their advantages and disadvantages. Many of them depend on your process, the type of dust you produce, and your individual needs. Baghouse and cartridge filter dust collectors work safely and efficiently for many years and in many different applications. However, as the concern of combustible dust issues grows, some companies are considering a wet dust collector. This system “scrubs” the air stream with water for dust control. Read on for some points to think about.

Type of Dust

Industrial wet dust collector design systems are often used where there is a concern about combustible dust. This is especially true for metal dust, which has a high likelihood of sparks coming into contact with the dust. You can also use dry systems in this application. But if there is a risk of deflagration, the system should include safety devices. This includes spark traps and fire-retardant filters that will not fuel a fire. Our DeltaMAXX™ nanofiber fire-retardant filters are rated to safely control a deflagration inside the collector.

Wet systems (often called wet scrubbers) can decrease the risk of fire or explosion as well. Water “scrubs” the air traveling through the collector, mixing with dust and forming sludge. This ensures that even if there is an ignition source, there’s no dust cloud or dry dust to ignite. At the same time, you can use dry collectors with proper maintenance and housekeeping safely for many years. They also can collect almost every type of dust imaginable.

Particulate Size

The filters in dry systems are more efficient at collecting and removing very fine particulate. Nanofiber filters are 99.9% efficient in capturing particulate down to .3 microns. Some cutting and grinding produce larger particulate. But applications like welding, plasma and laser cutting, and other processes produce very fine particulate metal fumes. A dry collector system can more efficiently capture these particles. In a wet system, it may be difficult to get very small particulate to settle out of the water to collect them. However, some wet system designs will handle this. Overall, a dry collector is more efficient for smaller particulate, smoke, and welding fumes.

Wed Dust Collector Operation Costs

To make a wet dust collector efficient at removing smaller particles, the system requires higher water pressure and a lot of energy. This increases cost. For larger particles, the energy costs are lower because it’s easier to get these particles to drop out. A dry collector requires compressed air to periodically clean the filters. Adjust the frequency of pulsing to suit individual needs. Filter media like DeltaMAXX nanofiber that pulse-clean more efficiently can further decrease the frequency. Both types of systems require appropriate equipment to maintain the correct airflow.

System Setup

Individual workstations such as downdraft tables often use a wet dust collector. With a central dust collection system, the requirements for ductwork and proper system CFM may be similar for wet and dry types. Because a dry system is more efficient at capturing smaller particles, you can use these where there are multiple locations in a facility producing welding or cutting fumes. Since dry systems are more effective in collecting smoke and fumes, they may be able to operate at a lower CFM. As a result, this saves energy and decreases the noise produced by the system.

On equipment like a downdraft table where sparks and metal dust are in close proximity, one can use a wet collector. However, many downdraft tables use a dry collector because they produce small particulates, smoke, or fumes. A full assessment of your company’s needs will help determine which type of system would be most beneficial for you. The assessment will consider both safety and long-term operating/maintenance costs.

Maintenance and Disposal

Maintaining a dry dust control system usually means changing the filters regularly and monitoring differential pressure. You must dispose of the filters which contain dust according to the standards for that material. You must dispose of the collected dust as well. Maintaining a wet dust collector system includes making sure the water remains clean, without too much material dissolved in it. Dispose of the contaminated wastewater. A wet collector requires the removal and disposal of sludge. The sludge may also need to be mixed with other materials or dried to make it safer or more easily disposable. Both system types will require proper housekeeping and maintenance of the ductwork and work areas to make sure dust doesn’t accumulate.

Depending on your type of dust, there may be regulations for how your material needs to be disposed of. With a dry system, bags or cartridge filters usually filter the dust into a container for disposal. With a wet system, the accumulated dust settles out of the water and the sludge must be collected and disposed of. Since the sludge will eventually dry, it is often mixed with an inert substance like sand to make it safer to handle. Many waste management facilities have different regulations for dry and wet materials.

Conclusion: Consult a Pro Before Buying a Wet Dust Collector

Contact the professional staff at Imperial Systems today to learn more about solutions to your dust control concerns. Fill out our contact form or give us a call at 800-918-3013.

Read more

by Imperial Systems | Jul 15, 2016 | Uncategorized

Stalemate Between Federal Agencies May Be Moving Toward Resolution

A combustible dust standard may mean more stringent control measures and a lot more new tests and reports. Additionally, major growth in the air quality control industry may result, especially for dust collection systems.

Since 2008, the National Fire Protection Association (NFPA) and the U.S. Chemical Safety Board (CSB) have been making recommendations to OSHA. They assert a need for a formal standard for combustible dust. This is to prevent worker injuries and deaths due to dust explosions. OSHA established a “National Emphasis Program” to provide more information and awareness about dust control and combustible dust hazards. They have yet to establish any formal, enforceable standards. The CSB continues to make recommendations for such a standard in their investigations of explosions and resulting fatalities (http://www.csb.gov/us-chemical-safety-board-determines-osha-response-to-seven-open-csb-recommendations-on-dust-fuel-gas-and-process-safety-management-to-be-unacceptable/) and has deemed OSHA’s response to their recommendations to be “unacceptable”. They consider an OSHA combustible dust standard to be the most important safety measure they have recommended.

Combustible Dust Standard 652 in Revision

According to John S. Forester, the managing editor at Powder & Bulk Solids, (http://www.powderbulksolids.com/) the NFPA is currently working on revisions of its standard 652, its proposed standard for combustible dust, intended to be comprehensive and to cover all industries to which it would apply.

This combustible dust standard (https://www.nfpa.org/Assets/files/AboutTheCodes/652/652_PreliminaryDraft.pdf) would require all facilities, new or existing, complete Dust Hazard Analysis testing and report their results. Also, some of the standards will apply retroactively to existing businesses. In response, OSHA seems to be responding to the call for increased regulation for the first time since 2010. However, there’s no sign of new enforceable regulations in the immediate future. Facilities that need to meet NFPA standards may find themselves dealing with the mandated Dust Hazard Analysis. This will mean increased investment in dust control systems.

The article notes market changes due to increasing regulation and the adoption of NFPA standards globally. Specifically, the market for industrial dust collectors will likely increase significantly in the following years. Demands for explosion isolation equipment will predictably be even higher. This due to reports of industrial accidents and stricter regulations circulating in the industry. An example is Imperial Systems’ independently tested, NFPA-standard CMAXX with In-Line Deflagration Arrester filters.

Testing and Analysis

The NFPA 652 will require industry-wide testing of all dusts that might be combustible. This includes a full analysis of all facilities for areas and equipment that might create a risk of dust accumulation. Examples are conveyor belts, elevators, ductwork, and ovens. Dust testing may include standards on the amount of dust allowed to accumulate on any surface and testing to determine whether the dust is in contact with hot surfaces or static buildup that could trigger ignition of that particular dust. These assessments will be an ongoing headache for many companies. Installing a system of correctly functioning dust collection equipment (and maintaining it or having our ServiceMAXX professionals maintain it) can minimize that headache by keeping the dust problem minimal and keeping the facility up to standards.

While the expected boom in sales of industrial dust extraction and explosion suppression equipment is good news for our industry, it’s especially good news for Imperial Systems, since our CMAXX with IDA filters already meets NFPA standards and should continue to meet the new standards in the future. If you already have one of our systems and it is well-maintained and operating properly, you should be prepared to weather any new regulations for explosion-containing dust collection systems. Perhaps you’re using another type of dust collector. In that case, measures such as high-speed abort gates and our fire-retardant DeltaMAXX nanofiber filters can help you be in compliance with current and future standards.

Have questions about what you need to be prepared? Then give one of our knowledgeable team members a call today at 800-918-3013!

Read more

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An