by Imperial Systems | Mar 27, 2017 | Uncategorized

It’s no secret here that we love vertical dust collectors. They’re better than horizontal collectors in just about every way, which we discussed in our last post. Not all vertical dust collectors are created equal, however. Today, we’re sharing a customer’s experience with a competitor’s vertical dust collectors and why he’s choosing a CMAXX this time.

Competitive Design Prone to Corrosion

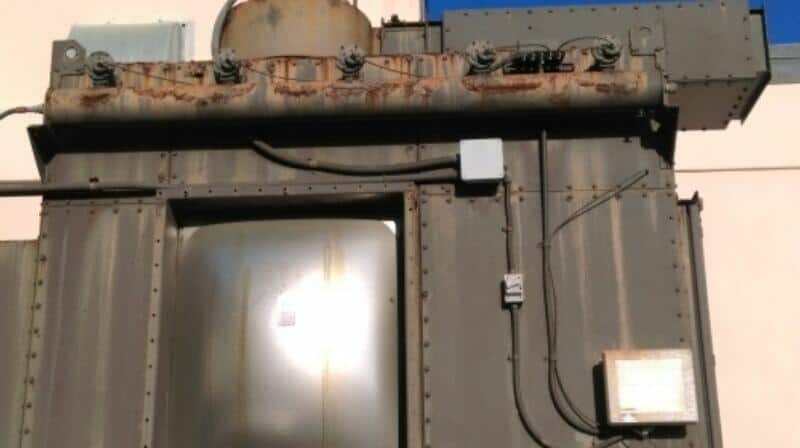

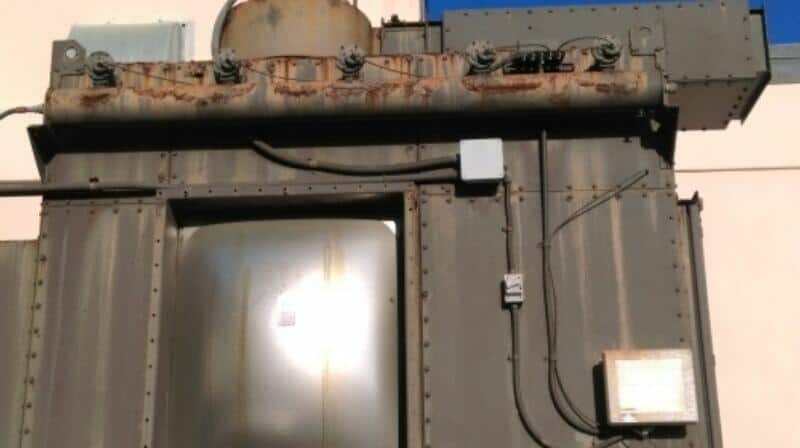

A manufacturing company approached us recently, looking to replace their current vertical cartridge collector. Since they purchased it, they’ve experienced many of the problems we often see with other dust collector brands. They even sent us these pictures to show us what they were dealing with.

Rust is a major factor for any piece of metal equipment that’s going to be outside. Exposure to the elements will occur for many years. Most vertical dust collectors that competitors such as Camfil Farr manufacture bolt together from the outside. Every external bolt hole is an opportunity for rust. In the photos, it’s easy to see where the bolt holes have rusted. Consequently, rust continues to form all over the collector.

The customer told us that they prefer the CMAXX design specifically because of experiencing this problem with their current collector. There are no external bolt holes on the CMAXX, so this is one problem they won’t have to worry about.

Another problem the customer has experienced with their current vertical dust collector is the roof. They have had to repaint it three times just to keep it from rusting through completely. This is a major issue because a hole in the roof allows water to get inside, wetting the cartridges. This will ruin them. The customer has had serious concerns about the roof of this collector for years. They have been struggling to keep the rust problem under control.

CMAXX Vertical Dust Collector Dons Crown

The customer liked the domed CrownTech roof of the CMAXX, which allows snow, water, and debris to slide off the roof instead of sitting on top. Unlike any of our competitors in the vertical dust collector market, the CMAXX is specifically designed to solve the problem of rusting on the collector roof. On a Camfil Farr or any other vertical dust collector brand, everything that falls onto the roof sits on it. Over time, this causes the roof to rust and fail.

The customer liked the domed CrownTech roof of the CMAXX, which allows snow, water, and debris to slide off the roof instead of sitting on top. Unlike any of our competitors in the vertical dust collector market, the CMAXX is specifically designed to solve the problem of rusting on the collector roof. On a Camfil Farr or any other vertical dust collector brand, everything that falls onto the roof sits on it. Over time, this causes the roof to rust and fail.

When you choose a dust collector, you’re making a major investment. Like our customer, you’re expecting this purchase to last for many years. You know you’ll have to replace filters. You’re expecting that certain parts, like valves, may need maintenance occasionally. This is typical maintenance you’ll perform on any vertical dust collector, whether it’s a CMAXX, Camfil Farr, or any other brand. However, repairing holes in a rusting roof is something you probably didn’t plan to do. With the CMAXX design, you won’t have to.

Our customer sent us these photographs of their current collector to show us the concerns they had with it, especially the issue of rust on the roof and around external bolts. They are switching to CMAXX because its design doesn’t have these problems. With no external bolt holes and a domed roof to protect it from the weather, their new collector will give them many years of rust-free service.

Read more

by Imperial Systems | Mar 20, 2017 | Uncategorized

Horizontal dust collectors are popular. They can fit a lot of filters into a fairly small footprint. Manufacturers will tell you that they work better. In reality, horizontal filters and dust collectors have some serious design issues. Donaldson Torit may be one of the biggest names in dust collection. But there are some serious flaws in their collectors. As many owners have found out, it’s a design prone to failure.

Filters in Horizontal Dust Collectors

Donaldson knows well that there’s a major problem with having horizontal filters on top of each other in a collector. They’ve tried everything, from suggesting you rotate the horizontal filters to designing new and weird filter shapes. But they can’t get around one basic problem. It’s the fact that dust that pulses off a filter will land on the filter underneath it. With each compressed air pulse, a shower of dust falls directly down on the next layer of filters.

This problem blinds off a large part of the horizontal filter. To try to decrease the area that blinds, Donaldson has produced oval and now triangle-shaped cartridges with less surface area facing upwards. This still doesn’t solve the basic design problem. It doesn’t make sense to filter dust just to drop piles of dust on top of your filters.

Filters in a horizontal collector cannot work at full efficiency because dust from the layer above them is always partially covering them. Some horizontal collector manufacturers recommend you rotate their filters to keep the side that’s facing up from blinding… but do you want to get into your collector and rotate dust-covered filters on a regular basis?

Yokes and Gaskets

In a horizontal dust collector, metal yokes support the filters. These yokes bolt to the tube sheet on one end. As you put the filters on the yoke, the first one presses back against the tube sheet. The last filter to go in presses against the door when it closes.

There are several places for this arrangement to go wrong.

- The yokes can easily bend while putting filters on or taking them off

- Yokes can pull away from the tube sheet, causing the gasket to leak

- Weight on the yokes can pull on and warp the tube sheet itself, causing more leaks

- The gasket sealing the filter to the door can fail if the yoke is bent

- The gaskets on the door and tube sheet ends, as well as the ones between the filters, provide multiple points of failure and leaks

Doors and Access

If you look at a horizontal dust collector, the first thing you’ll see is an array of doors. They’re usually round, only a little wider than the horizontal filter that goes in them. There are usually many of them as well.

Changing filters, or accessing anything inside the collector, means trying to work through these small round doors. Filters must be pulled off the yoke, and the ones in the back are difficult to reach. There isn’t that much room to reach in or access anything through these small doors.

Comparing a horizontal and a vertical collector, it’s easy to see how all of those small, round doors are a serious design problem. A vertical collector will usually have either one or two doors. When these doors are open, they give access to the entire space inside the collector.

With the doors of a vertical collector open, you can clearly see down into the hopper, and it’s easy to inspect for problems such as bridging. With the small round doors, it’s nearly impossible to see down into the hopper.

Clean Air Plenum Access

Because of the design of a Donaldson collector, there is no direct access to the clean air plenum. There are several reasons this can be a serious problem:

- You can’t reach a leak occurring on the clean air side for repairs

- No way to do routine maintenance or checks in this space

- If a leak lets dust into the clean air plenum, there is no way to access it for cleaning

If one of the yokes gets bent, or for some other reason a gasket seal on the tube sheet fails, dust will get into the clean air plenum.

On a vertical collector like the CMAXX, it’s easy to open the doors, access the clean air plenum, and get rid of the dust.

In a Donaldson or other horizontal dust collector, accessing the clean air plenum often requires a crane to remove ductwork so you can get in and cut an access panel.

If you can’t do that, the dust in the clean air plenum will continue to get blown back into your facility over time. If it’s a health or fire hazard, this is a major issue.

What are the Advantages of Horizontal Dust Collectors?

The major advantage of a horizontal dust collector is the ability to stack filters on top of each other. This can save floor space by making the collector taller instead of wider. This is one of the major selling points of Donaldson Torit and other horizontal collectors.

Besides size, the other advantages usually listed are higher efficiency and less maintenance. These vague statements don’t really tell you much: the horizontal filters in a horizontal collector lose efficiency more quickly than in a vertical one because the tops of the filters blind off.

Also, anyone who has ever dealt with the many gaskets, easily damaged yokes, and tiny access doors might argue about the “less maintenance”. There is less to maintain on a horizontal dust collector because you cannot access most of the collector to do maintenance on it. If you do need to do maintenance or troubleshooting on the hopper or clean air plenum, you won’t have an easy time doing it.

Choosing the CMAXX

A vertical collector like the CMAXX has none of the design flaws of Donaldson Torit and similar collectors. The single gasket where the filter meets the tube sheet greatly decreases the number of places you can get a leak. The clean air plenum and hopper are easy to access.

Everything in a vertical collector is easy to access: with a large door that opens to let you reach all the filters at once, you can easily get to every part of the collector. Filters are supported by sturdy lift rails that hold the filters securely against the tube sheet.

Because the filters in a CMAXX are not stacked on top of each other, dust that is pulsed off drops straight down into the hopper, instead of landing on other filters. The filters maintain a higher efficiency over time.

With all the advantages of a CMAXX, it seems clear that it’s a better choice. The people who may appreciate it the most are the people who have to maintain the system. After all, if you’re trying to fix a problem, you’d probably rather do it through one wide-open access door than through a whole bunch of little round doors not much wider than a filter.

Read more

The customer liked the domed CrownTech roof of the CMAXX, which allows snow, water, and debris to slide off the roof instead of sitting on top. Unlike any of our competitors in the vertical dust collector market, the CMAXX is specifically designed to solve the problem of rusting on the collector roof. On a Camfil Farr or any other vertical dust collector brand, everything that falls onto the roof sits on it. Over time, this causes the roof to rust and fail.

The customer liked the domed CrownTech roof of the CMAXX, which allows snow, water, and debris to slide off the roof instead of sitting on top. Unlike any of our competitors in the vertical dust collector market, the CMAXX is specifically designed to solve the problem of rusting on the collector roof. On a Camfil Farr or any other vertical dust collector brand, everything that falls onto the roof sits on it. Over time, this causes the roof to rust and fail.