People often use baghouses and dust collectors as synonyms. What is a baghouse? It is a system in which bags made of various materials filter the air. The system periodically cleans the bags to remove accumulated dust.

Today, cartridge dust collectors are increasingly popular in many industries, and for good reason. Cartridge filters can pack a lot of surface area into a small space. They can also filter very small (sub-micron) particulate very efficiently. For some industries, this is essential. This includes metalworking, which generates smoke and fumes that contain potentially toxic materials.

The baghouse, however, has been a workhorse for industrial dust control for many years and continues to serve its role today. While the basic concept remains the same, today they are more adaptable than ever. This is due to new filter materials and new ways to solve problems. Not every industry produces dust that’s fine enough to need the high efficiency of a cartridge collector. The baghouse efficiency is sufficient in plenty of cases.

Types of Baghouses

Types of Baghouses

So how does a baghouse dust collector work? Generally, all baghouses have a tube sheet to which the bags attach. They also have an inlet for dirty air and an outlet for clean air. Then there’s an opening at the bottom for collected dust to drop out. The location of these features depends on the type of baghouse. The main differences between types of baghouses are how they clean the bags.

Shaker Baghouses

A shaker baghouse cleans the bags by mechanically shaking them. The bags usually hang from the top of the unit and attach to the tube sheet at the bottom. In this type of system, air typically enters from the bottom. The system pulls the air through to collect dust on the inside of the bags. Clean air then exits at the top while collected dust remains inside the bags.

To clean the bags, the airflow must first be shut off. Then the hanging mechanism shakes the bags to get rid of the dust, which drops out the bottom. These are not the most efficient types of baghouses and can be high-maintenance. Yes, the design is simple and does not require compressed air or complicated supports for the bags. However, damage to the bags can occur from the mechanical shaking mechanism.

Reverse Air Baghouses

In a reverse air filter bag house like our BRF, dirty air enters the collector and dust collects on the outside of the bags, which are supported by a metal cage to keep the air pressure from collapsing them. Steady air circulation continuously pulls air through the filter bags. For cleaning, a fan rotates over the bags, blowing reverse air into them to remove dust.

This type of reverse air baghouse generates a lower pressure than the compressed air pulses of a pulse jet. This decreases wear and tear on the bags and saves on the cost of compressed air. They are usually very cost-efficient and when using within the design parameters, they are also very effective. Also, this type of reverse air baghouse can continue running while cleaning occurs.

An older type of baghouse, also sometimes referred to as reverse air, collects dust on the inside of the bags. Then it cuts off the inflow of dirty air and uses a reverse flow of clean air. This partially collapses the bags, which also removes the dust. These types of bags have rigid rings that allow them to flex but not collapse completely, or “pancake”.

These types of reverse air baghouses have to be taken offline for cleaning. But sometimes they are divided into compartments so one section at a time can be cleaned. So, you can see that the reverse air baghouse working principle can vary from brand to brand.

Pulse Jet Baghouses

A pulse jet baghouse design is somewhat similar. Metal cages support the bags and hang from a tube sheet at the top of the baghouse. Dust and air enter and dust collects on the outside surface of the bags, not the inside. Bursts or pulses of compressed air clean the bags. These travel down the length of the bag and dislodge the dust.

Because the pulse of air travels very quickly down the bags, the baghouse is cleaned without taking it offline. This allows them to operate more efficiently since the system removes dust from the bags at more regular intervals. The downside to the pulse jet bag filter design is the higher pressure and expense of compressed air. These both add to operating costs.

Operation and Maintenance Costs

The EPA provides information (link: https://www3.epa.gov/ttncatc1/dir1/cs6ch1.pdf) to help you make a general calculation of the capital costs of a baghouse dust control system. Their calculations include the cost of the collector, the bags (and cages if necessary), measurement instruments, installation costs, and the annual operating costs (electricity, compressed air, labor, and materials).

These costs will obviously vary widely. A pulse jet baghouse requires compressed air, which other types of baghouses do not need. But it may require fewer filters since they are more efficient.

Filter Replacement

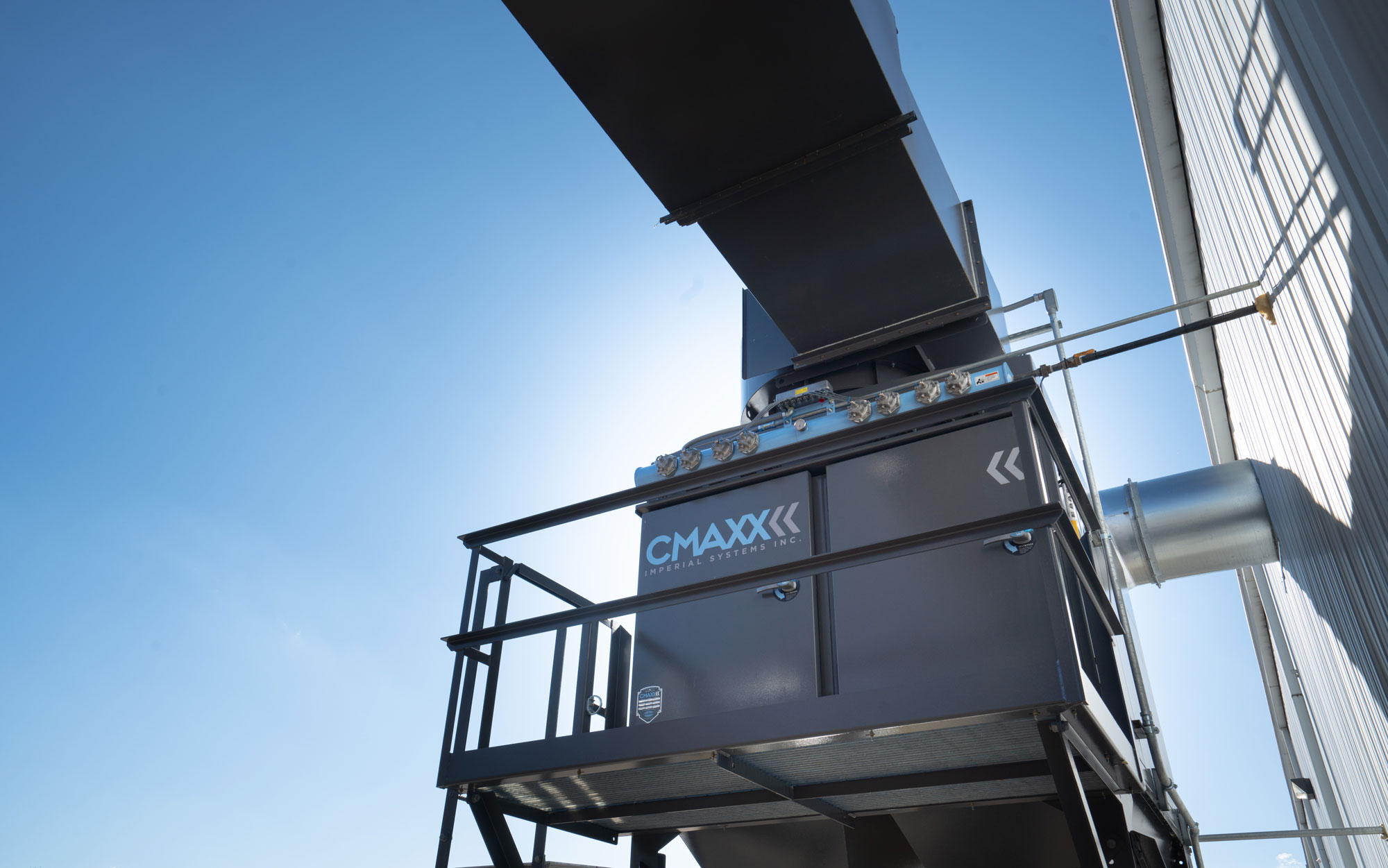

One thing that is a major headache for owners of any type of baghouse: replacing the bags. This is usually a dirty, messy, and time-consuming job. It also requires the collector to be offline for a considerable period of time. It often involves working in an enclosed space. Mechanisms for attaching the bags to the tube sheets vary widely. It can be a very involved process, especially when using cages. Some companies installing new dust control equipment choose a cartridge filter collector. This is because vertical collectors like our CMAXX™ are easy to change and do not involve issues with confined spaces.

For existing baghouses that need frequent bag changes, a pleated filter bag is an option that should be considered. These have a much larger surface area and last much longer than traditional bags, which means less frequent changes. Also, pleated filter bags do not require cages, which greatly simplifies the changing process.

Conclusion

Yes, there’s a lot to know about baghouses! Call us today at 800-918-3013. Our helpful, knowledgeable team members can answer any questions you may have about them. Our goal is to provide the right dust collection solution for your application. Learn more about Imperial Systems’ baghouses.