by Imperial Systems | Apr 7, 2016 | Dust Collection Filters

Discover the vast benefits of ServiceMAXX from Imperial Systems for all your dust collection needs

When quality is of the utmost importance, the continuing clients of Imperial Systems know that their dust collection equipment and servicing is reflective of a commitment to outstanding, high quality products and offerings to keep buyer’s employees and businesses safe from pollution, unsafe work environments, and the potential dangers faced by those who are employed in the metalworking industry.

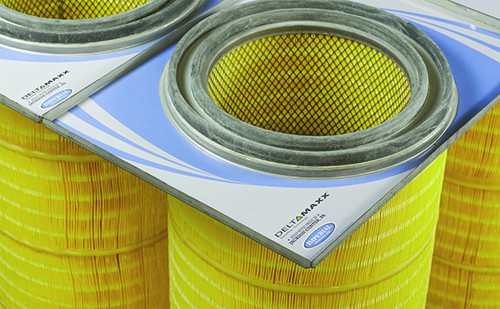

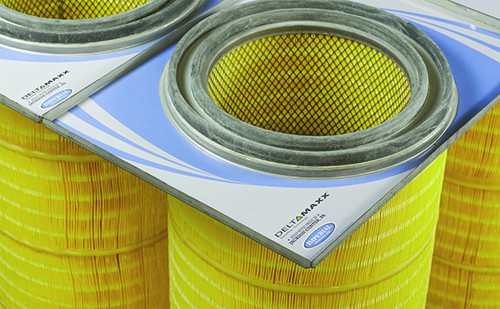

Dust collection equipment offered by Imperial Systems such as the CMAXX™ Dust Collection System and the DeltaMAXX™ Cartridge Filters are designed to provide many years of air filtration and air pollution control. Cleaner air means a healthier workplace environment––decreasing employee and production downtime. Using advanced and superior technology to provide our clients with the highest-quality pollution and particulate control is what Imperial Systems does best.

Dust collection equipment offered by Imperial Systems such as the CMAXX™ Dust Collection System and the DeltaMAXX™ Cartridge Filters are designed to provide many years of air filtration and air pollution control. Cleaner air means a healthier workplace environment––decreasing employee and production downtime. Using advanced and superior technology to provide our clients with the highest-quality pollution and particulate control is what Imperial Systems does best.

Paired with our solutions to manage dust collection in the metalworking industry, we provide dedicated and knowledgeable maintenance services through ServiceMAXX, a program which provides high quality, worry-free maintenance of your dust collection system and most importantly, your investment in a safe working environment free of particulates. Our experts will guide you in evaluating the equipment you have and design a customized and regularly scheduled maintenance program to give you best return on your dust collection system all year round.

At Imperial Systems, we are dedicated to helping metalworkers like you ensure the safety of your employees and efficiency of your workplace with ServiceMAXX. Keeping a maintenance schedule ensures that your dust collection equipment stays up-to-date and that no issues go unnoticed between checkups.

Below are the comprehensive points of our ServiceMAXX program:

- Priority over non-contracted service customers

- Enhances performance from a machine that is properly adjusted and calibrated

- Operating budgets are more accurate due to knowing the cost of maintenance

- Reduces the risk of downtime productivity loss

- No need to stop your production––Our trained ServiceMAXX Service Technicians handle it all

- Program available throughout the continental US

- Lower operating costs with scheduled maintenance vs. unplanned breakdowns

Proper preventative maintenance on your CMAXX™ Dust Collection System through the ServiceMAXX program will ensure both the cleanest air possible and maximizing the life of the equipment you’ve invested in.

What Does ServiceMAXX Include?

Now that we’ve discussed the high-level benefits of the ServiceMAXX program, here are the specific offerings Imperial Systems can provide for proper care of your dust collection system.

It’s important to remember that these services are designed primarily to save you time, money, and headaches while you’re making the most of your dust collection system:

- Visual inspection of internal components

- Airlock inspection if applicable

- Filter replacement and tube sheet cleaning (with purchase of filters)

- Observe and verify proper machine operation

- Identify needed parts

- Recommend maintenance

- Identify components nearing the end of life

- Calibration, tune-ups and updates

- Visual inspection of duct

- Free telephone support

As evidenced above, the level and quality of service provided in the ServiceMAXX program reflects our commitment to making lasting client relationships and utilizing our experience and knowledge to better serve our clients and their commitment to providing a pollution and particulate-free working environment for their metalworkers.

Why You Can’t Afford the Time or the Effort of Not Having ServiceMAXX

In the metalworking industry especially, it’s important to place the safety of your employees above all else, and proper preventative maintenance can do a lot to relieve the stress of not knowing whether or not your system in functioning at full efficacy.

The cost of not taking extra care of your investment could be dangerous not only to your employees’ working environment but also your bottom line and return on investment. A scheduled ServiceMAXX™ program for your company is a common sense approach to managing your investment in the highest quality dust collection products.

Our team of experts will be able to diagnose and solve problems if they ever arise. There’s no one else with better knowledge than Imperial Systems on how to handle issues ranging from the ordinary to the severe.

No one likes an unplanned equipment breakdown. Most often, breakdowns like these don’t happen at random but are instead an cumulative result of everyday use over years. Businesses that forgo a comprehensive maintenance program often spend more money on expensive repairs, or, if the problem is not addressed promptly, a need for an entirely new system.

By having a regularly scheduled maintenance program like Imperial System’s ServiceMAXX, you can worry less about the safety of your work environment and more about the core functions of your business. Everything from elevators to automobiles have mandatory inspections in order to ensure safety so why shouldn’t your dust collection system?

Your metalworking business is not like those of other industries where the environment is not at increased risk of combustible dust or air pollution. It is vital that you act on your promise to the utmost safety and reliability of your dust collection equipment. Choosing ServiceMAXX is an extra investment but a necessary one over the long-lasting life of your dust collection system.

Choose Imperial Systems Today

https://www.isystemsweb.com/

If you haven’t yet decided whether or not to utilize the ServiceMAXX program, contact Imperial Systems today for a consultation at 800.918.3013 or learn more by emailing us at info@isystemsweb.com.

Read more

by Imperial Systems | Oct 14, 2015 | Dust Collection Filters

Just because it’s top-quality doesn’t mean it’s out of your price range.

On August 2, 2014 in Kunshan, China, a metal production company faced a day they won’t forget. A massive explosion occurred that morning, killing 146 people and injuring 114.

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing top dust collector filters and systems, along with strict guidelines into your company is vital in providing a safe environment.

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing top dust collector filters and systems, along with strict guidelines into your company is vital in providing a safe environment.

Why Use The Top Dust Collector Filters?

With an array of products available for your dust collection needs, it’s important to do your research. In helping you research, Imperial Systems has provided a list of qualities to look for in “so-called” top dust collector filters. Also, we have provided a summarized list of the NFPA 654, Standard for the Prevention of Fire and Dust Explosions.

These standards are:

- For process equipment and ventilation systems, minimize the escape of dust

- Use dust collector systems and the top dust collector filters

- Utilize surfaces that facilitate cleaning and minimize dust

- Clean dust on a regular basis

- Inspect for dust in hidden areas

- Only use vacuum cleaners approved for dust collecting

- Place relief valves away from dust hazard areas

- Develop a dust inspection, cleaning, testing and control guide specific to your facility

Notice that the standards include use dust collector systems and the top dust collector filters. Perhaps we added “the top” to the standards, and that’s ok! When it comes to your employees safety, you don’t want to cut corners.

Here are qualities of top dust collector filters:

- Nanofiber technology, stopping submicron particles from becoming embedded into the media, before they even enter the filter.

- The highest quality pleated media having a 99.9% efficiency

- Reduced dust collector operational costs

- The industry’s best surface loading technology

- Lower operational mass emissions

- The best in the industry, MERV15 filtration

- Less pulse cleaning

Where can you find these qualities? With Imperial Systems’ DeltaMAXX filters. DeltaMAXX filters are the top dust collector filters on the market. Not only do you receive a quality product, you receive service from a quality company. We are not here to treat you like customers, we are here to treat you like family.

If you would like more information on our DeltaMAXX filters or our CMAXX Dust Collection Systems and Fume Extraction Systems, you can visit our products page or give us a call at 1-800-918-3013.

Top Dust Collector Filters | Top Dust Collector Filter

Read more

by Imperial Systems | Oct 5, 2015 | Dust Collection Filters

Receive a fresh awareness of how dust can make or break your facility.

If you are in the food processing industry, you understand the importance of clearing the air through dust collection in your facility. Cross-contamination and sanitation standards are set at a high level for food processing facilities. So, how do you know you are keeping high standards? Imperial Systems has the answer with DeltaMAXX, our industrial replacement cartridge filters.

So how do our DeltaMAXX industrial replacement cartridge filters keep your facility safe and running smoothly? Let’s take a look at some problem areas that most facilities experience.

So how do our DeltaMAXX industrial replacement cartridge filters keep your facility safe and running smoothly? Let’s take a look at some problem areas that most facilities experience.

Safety In The Workplace

Keeping your facility clean is an important rule of safety in the workplace. In many food processing facilities, grain and dust accumulate on floors, causing them to become especially slippery. Keeping dust at bay can prevent many slip and fall injuries, allowing your employees to work at the speed they need without getting injured. This also prevents you from having to pay an exorbitant amount of workers compensation claims.

By using our industrial replacement cartridge filters you are also keeping your employees healthy by preventing airborne illnesses through ingesting allergen particles. These particles can cause not only serious illness, but even death.

By utilizing a proper dust collection system such as our CMAXX Dust Collection System, you can also prevent dust explosions caused by specific powders. With powders such as cornstarch (kst value of 202) and sugar (kst value of 138). The kst defines the value of a pressure wave.

Keep your facility up to OSHA standards with our DeltaMAXX industrial replacement cartridge filters.

How Do DeltaMAXX Industrial Replacement Cartridge Filters work?

Our DeltaMAXX industrial replace cartridge filters are the best in the business. With our Nanofiber Technology, you won’t get a better industrial cartridge filter anywhere else. Our DeltaMAXX filters will help keep your facility clean by providing:

- Nanofiber technology, stopping submicron particles from becoming embedded into the media, before they even enter the filter.

- The highest quality pleated media having a 99.9% efficiency

- Reduced dust collector operational costs

- The industry’s best surface loading technology

- Lower operational mass emissions

- The best in the industry, MERV15 filtration

- Less pulse cleaning

- and more..

Get Your Quality DeltaMAXX Filters Today

A fresh awareness of the importance of quality industrial replacement cartridge filters allows you to stay one step ahead and provide a safe, healthy, and productive workplace for you and your employees.

For more information on our DeltaMAXX filters, contact us online or give us a call at 1-800-918-3013.

Industrial Replacement Cartridge Filters | Industrial Replacement Cartridge Filter

Read more

by Imperial Systems | Sep 29, 2015 | Dust Collection Filters

Imperial Systems replacement filters bring longer life to employees and machines.

For years, Imperial Systems has been offering metalworking facilities advanced and reliable dust and fume collectors. We also offer high-performance metalworking dust collector filters for systems by other brands. These upgrade filters are designed to provide outstanding energy savings, filtration efficiency, and cleaner working environments. When efficiency and employees are at their peak, so is productivity. All of these come together to protect the overall health of the business and its bottom line.

Common dust collector filter for metalworking

Any metalworking business involves grinding, sanding, buffing, cutting, and/or polishing indoors. As a result, potentially hazardous dust contaminates the air in your facility. But the dust or fume from these processes is usually invisible. It can degrade your air quality, which is detrimental to employee health as well as the integrity of your machines. The health of your business significantly depends on your properly functioning collection system and high-quality filters inside it.

Besides just cleaning the air, Imperial’s replacement filters can significantly improve the performance of your existing collection system. We uniquely engineer them for longer life and higher filtration efficiency. They are the most cost-effective choice for any collector and any environment. So, your collectors will keep running efficiently and energy-smart. Imperial Systems replacement filters rank among the highest in performance, efficiency, and value.

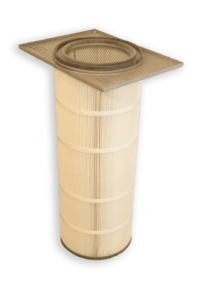

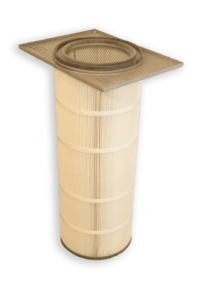

Types of Metalworking Dust Collector Filters

The kind or style of replacement filters you need depends on the dust collection system on your site. Some common types include cartridge collectors, cyclones, wet scrubbers, and electrostatic precipitators (ESPs). Nearly all industrial filtration systems require periodic replacement of filters to eliminate contaminants consistently. We will help you determine which filter variation is the best fit for your system.

All types of industrial air filtration systems are available from Imperial Systems. Plus, we offer replacement filters that are compatible with all major brands of industrial cartridge dust collectors. Learn more on our DeltaMAXX dust collector replacement cartridge filters page. Many of our loyal metalworking customers permanently rely on Imperial Systems for all dust and fume collector systems and products.

We want to help make your business as clean, healthy, and efficient as possible. For more information, contact us today!

Read more

by Imperial Systems | Sep 17, 2015 | Dust Collection Filters

Never settle for anything less than the best.

It’s that time again! It’s time to re-order your dust collector filter cartridges to keep your dust collection system running smoothly. Have you noticed any lag in your system use? Perhaps your filters get dirty faster than you remember – or you are noticing more dust accumulating around your facility.

It’s time to take charge of your dust collector by checking off your needs in your filter cartridges re-order.

What Do I Need To See In My Dust Collector Filter Cartridges?

That’s a great question. Here at Imperial Systems, we want to make sure that you are receiving the best care necessary. Did you know that due to lack of maintenance or quality products, your facility may experience a combustible dust explosion? According to OSHA, from 1980 to 2005, there were:

- 281 dust explosions

- 119 deaths

- 718 injuries

Those bulleted stats are 3 major reasons why you need to be sure you are investing in quality filter cartridges.

Those bulleted stats are 3 major reasons why you need to be sure you are investing in quality filter cartridges.

5 Characteristics Of Quality Dust Collector Filter Cartridges

High Efficiency

With an average filter, the filter needs time to warm up before it works most efficiently because the surface level must become more sustainable to collect the dust. But, a filter built with Nanofiber Technology does not need time to warm up because the surface level was already created to be sustainable and substantial from the beginning.

Cleaning Is Easy

Who likes to take time cleaning a filter, anyway? Talk about productivity time wasted. Be sure that the filters you are using have tight-knit surfaces, you don’t need to waste your time any longer. Tight-knit surfaces prevent dust from getting deep into the filter, allowing you to clean up quicker and easier. No more working lunch breaks, cleaning the filters!

Customizable Filters

Other companies’ filters come in specific shapes and sizes, not allowing you to get filters that fit your needs. Imperial Systems offers customizable filters that come in any shape and size dust collector cartridge.

Long Filter Life

Perhaps one of the most important characteristics, filter life can either burn a hole in your pocket or put money back in. Standard filters may only last a short time, while filters with Nanofiber Technology last twice as long as standard filters.

What do all of these characteristics and Imperial Systems have in common? Our premium dust collector filter cartridges. DeltaMAXX filter cartridges come with all of this, and more. Along with our quality product, we also bring you superb customer service that not only makes you feel like a high-class customer, you also feel like part of the family.

For more information about Imperial Systems’ DeltaMAXX dust collector filter cartridges, give us a call today at 800.918.3013.

Read more

by Imperial Systems | Sep 1, 2015 | Dust Collection Filters

Cartridge filter replacement is an essential part of preventing accidents in your manufacturing plant.

Cartridge filter replacement is an important step in eliminating potential causes of ignition if you are in metalworking, manufacturing, or woodwork.

What are cartridge filters?

What are cartridge filters?

Cartridge filters are applied in a variety of contexts as a tool to filter water, chemicals, hydraulic fluid, and other types. They include the media for filtration, the receptacle, and the liquid filter. Since cartridges are porous, they can be made from many types of media such as carbon, polythermoplastics, metal mesh, nylon, and even paper.

If you require a cartridge filter replacement that will filter media of large sizes, this type will have a faster rate of flow than those that filter only small impurities. Filters’ very disposability is one of their benefits in metalworking and other industrial manufacturing. They can be removed with ease and replaced with an exact replica.

For this reason, a disposable cartridge filter replacement will come to you pre-filled with the required filter media and have a set duration. Then the cartridge should be thrown away and replaced with a new cartridge. There are also refillable cartridges which can be re-used a number of times. In the case of refillable cartridges, only the filter media needs to be replaced while the actual filter can be washed out.

Why it’s important

-

- 1. Safety

Everyone agrees that prevention is the key to ensuring that serious hazards are eliminated, but oftentimes, industrial dust collection may be a subject that just…slips through the cracks for many manufacturing managers. The dust collector or cartridge filter may not be used on a regular day-to-day basis by the person deciding when to have it checked or replaced, so the subject is easily forgotten or, relegated to the bottom of the priority list because it seems like an extra cost. But forgetting about dust collection until it is too late is not an option when the health and livelihood of your employees is at stake. As an employer, you can encounter serious problems with the law if you allow an accident of this sort to occur on your watch.

-

- 2. Equipment life

The life of your equipment, whether that’s a welding table, CNC cutting table, laser/plasma cutting table, etc., will be extended through your good care of it. Using proper filtration media in your industrial plant to ensure that all impurities are blocked during production will ensure longer life. Don’t forget to check your cartridge filter and research whether you are using the right type of media for your needs. You can talk to us at Imperial Systems at 724-662-2801 for advice pertaining to your particular industry.

- 3. Save Money

If ensuring proper filtration extends the life of your equipment, you can be sure that taking this step will also help save your company money in the long haul. If you bought a $60,000 car, you’d be sure to buy the correct parts and maintenance tools. Why not take care of your $60,000 machine that produces your revenue? A cartridge filter replacement is an investment that will help you avoid future costs and problems.

For more information on cartridge filter replacements, our professionals are glad to assist you with the needs pertaining to your particular industry and business. Visit the Imperial Systems website or call us at 724-662-2801 to get started.

Cartridge filter replacement | filter cartridges relevant

Read more

Dust collection equipment offered by Imperial Systems such as the CMAXX™ Dust Collection System and the DeltaMAXX™ Cartridge Filters are designed to provide many years of air filtration and air pollution control. Cleaner air means a healthier workplace environment––decreasing employee and production downtime. Using advanced and superior technology to provide our clients with the highest-quality pollution and particulate control is what Imperial Systems does best.

Dust collection equipment offered by Imperial Systems such as the CMAXX™ Dust Collection System and the DeltaMAXX™ Cartridge Filters are designed to provide many years of air filtration and air pollution control. Cleaner air means a healthier workplace environment––decreasing employee and production downtime. Using advanced and superior technology to provide our clients with the highest-quality pollution and particulate control is what Imperial Systems does best.

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing

Are you the owner of a metalworking facility? If so, you are aware the importance of dust collection. Dust collection involves protecting you, your employees and your products. Implementing

So how do our DeltaMAXX

So how do our DeltaMAXX

What are cartridge filters?

What are cartridge filters?