![The Dangers of Phosgene Exposure [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/04/featuredimage_phosgene-1080x675.jpg)

by Erin Long | Apr 10, 2019 | Uncategorized

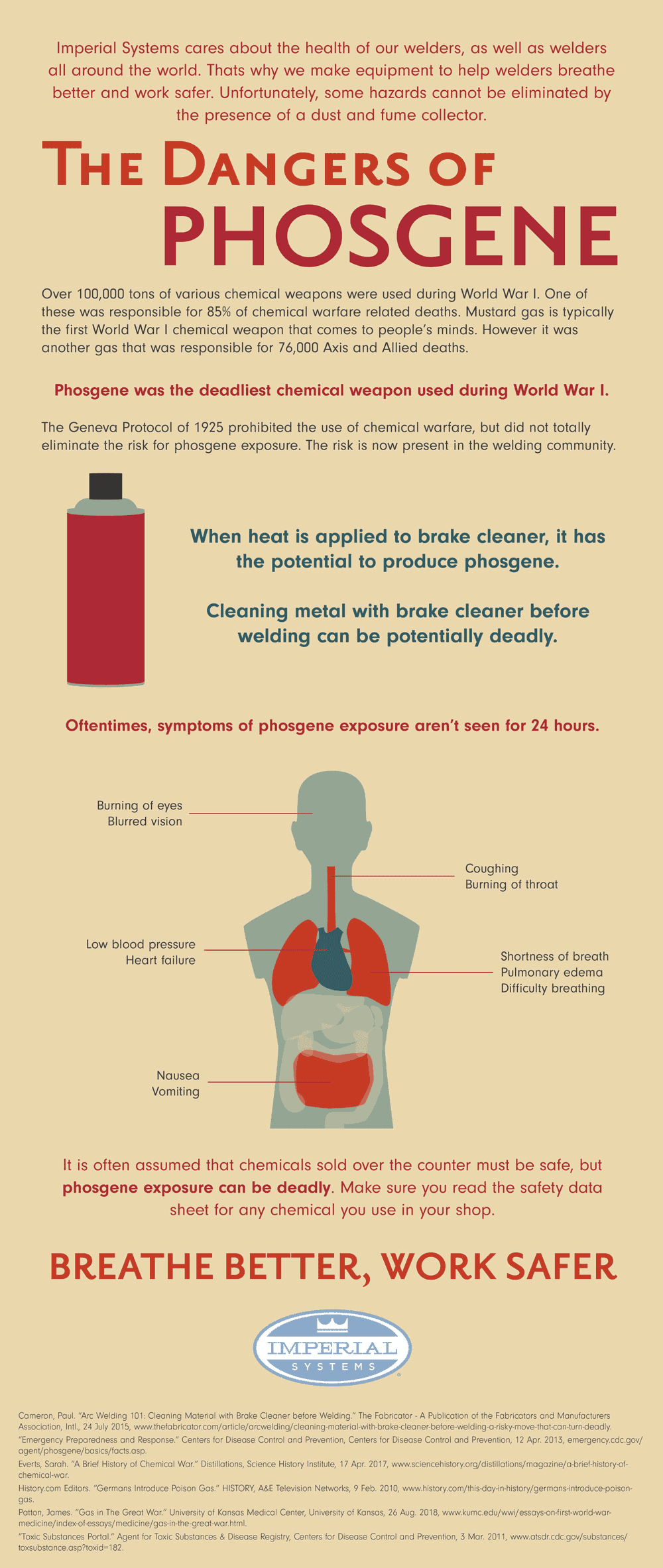

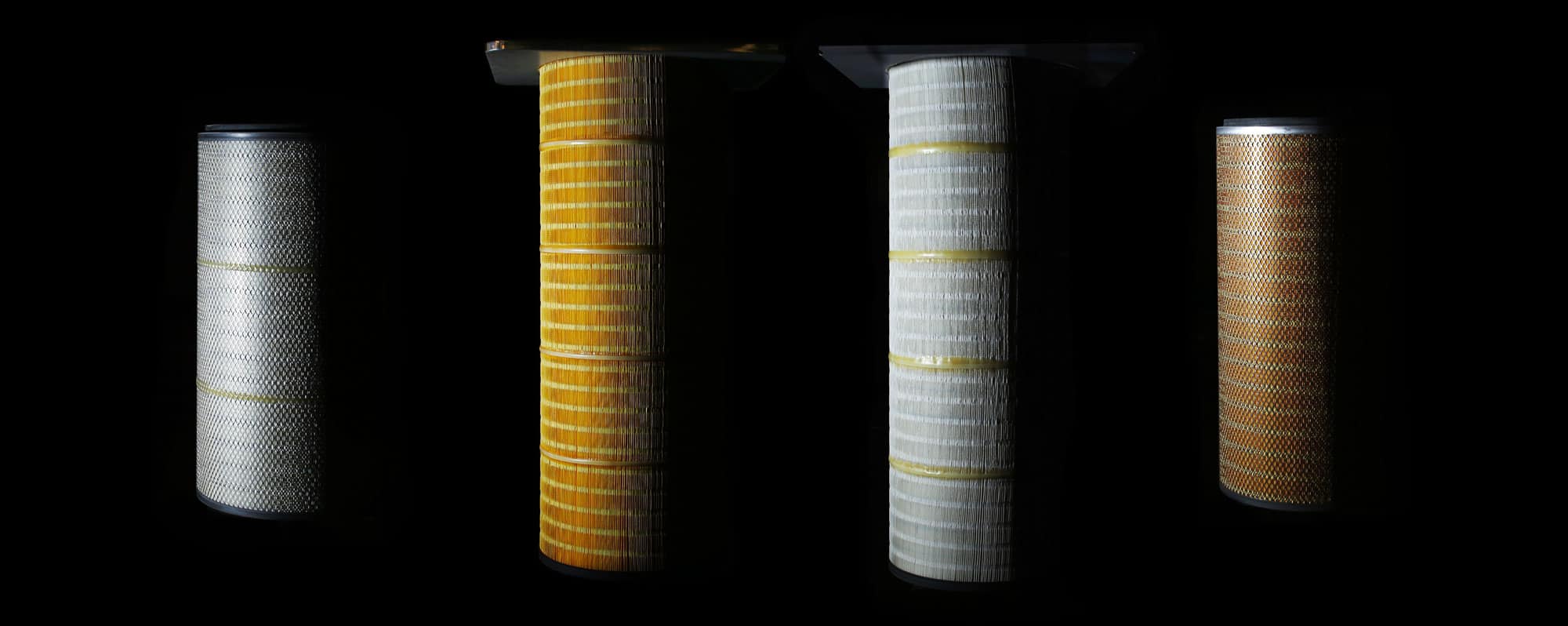

This brief infographic describes the dangers of phosgene exposure. Phosgene is a potentially deadly gas that should be avoided at all costs. Phosgene gas is created when heat is applied to brake cleaner, making it a potential hazard to welders. While a dust and fume collector will not eliminate phosgene, you can take proper precautions to avoid it.

Over 100,000 tons of various chemical weapons were used during World War I. One of these was responsible for 85% of chemical warfare-related deaths. Mustard gas is typically the first World War I chemical weapon that comes to people’s minds. However, it was another gas that was responsible for 76,000 Axis and Allied deaths.

Phosgene exposure was the deadliest chemical weapon used during World War I

The Geneva Protocol of 1925 prohibited the use of chemical warfare but did not totally eliminate the risk of phosgene exposure. The risk is now present in the welding community. When heat is applied to brake cleaner, it has the potential to produce phosgene. Cleaning metal with brake cleaner before welding can be potentially deadly.

Oftentimes, symptoms of phosgene exposure are not seen for 24 hours. These include burning of the eyes and throat, blurred vision, coughing, difficulty breathing, pulmonary edema, nausea, vomiting, low blood pressure, and heart failure. It is often assumed that chemicals sold over the counter must be safe, but phosgene exposure can be deadly. Make sure you read the safety data sheet for any chemical you use in your shop.

Imperial Systems cares about the health of our welders, as well as welders all around the world. That’s why we make equipment to help welders breathe better and work safer. Unfortunately, some hazards cannot be eliminated by the presence of a dust and fume collector.

Learn more about phosgene gas in this related blog post.

Read more

by Erin Long | Mar 25, 2019 | Uncategorized

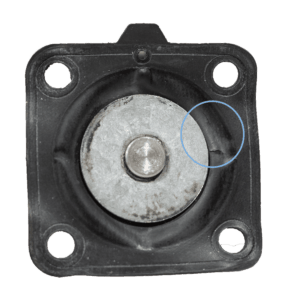

Does everything with your dust collector look like it’s working properly? That doesn’t mean there aren’t problems you can’t see. Dust collector valves are often the culprits of hidden costs due to internal damage.

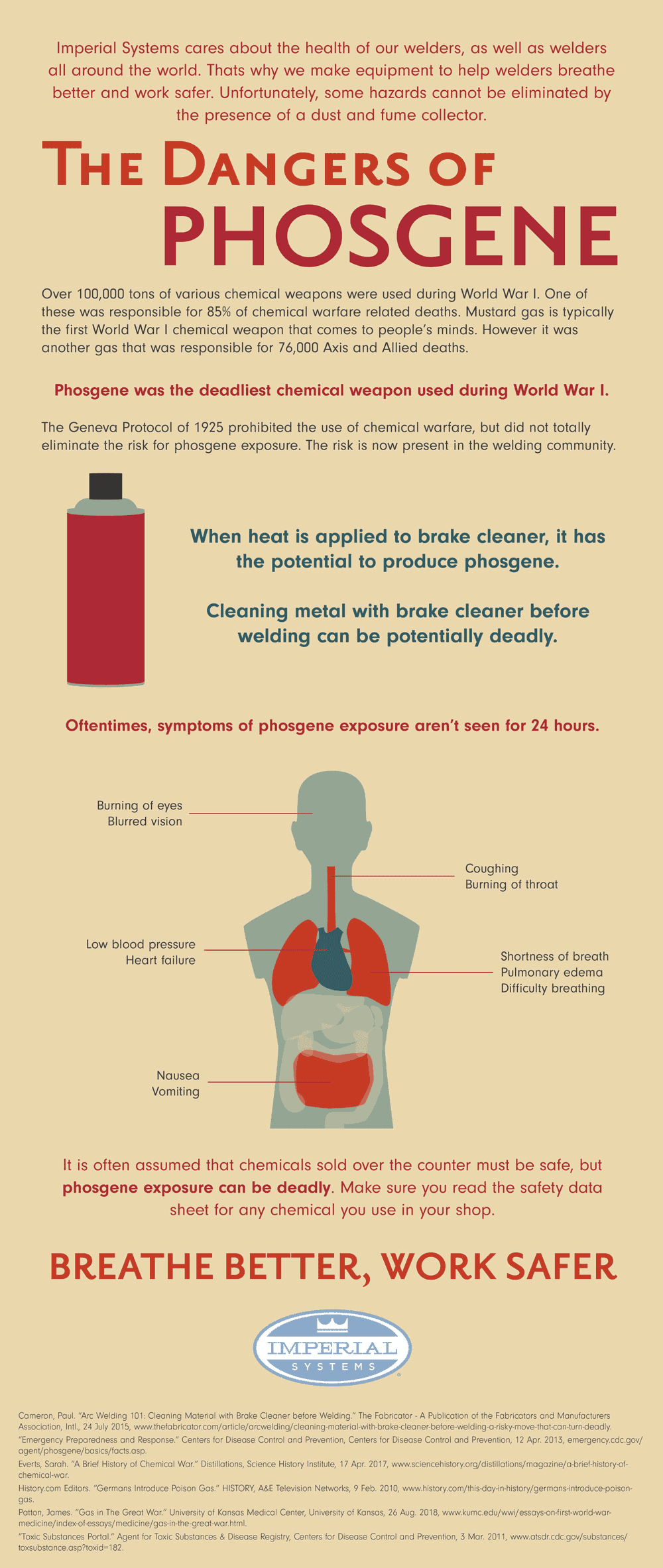

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

Because of this damaged valve, the filter that it’s cleaning is getting less compressed air than the other filters. So, each pulse is not fully cleaning it. That means that filter is going to blind off and need replacement sooner, costing you money. Multiple small valve leaks can have a major impact on shortening the life of your filters.

Springing for New Dust Collector Valves

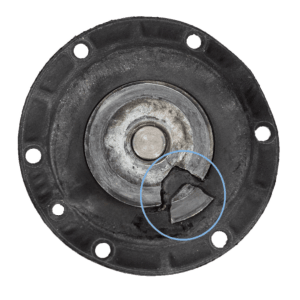

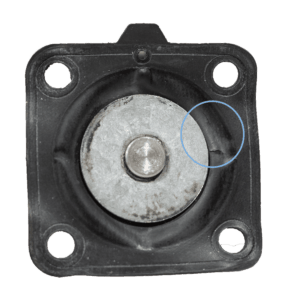

The following photo is from a ServiceMAXX visit for a problem completely unrelated to the diaphragm valves. However, when our technician did a routine inspection of the valves, he found a problem. The springs inside of them had completely fallen apart:

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

We’re Dying to Find Leaks!

Another ServiceMAXX option is a dye test. In this test, a harmless fluorescent powder runs through the dust collection system, which is then inspected with ultraviolet light. The powder glows brightly. If everything is working properly, the glow will be seen only on the outside of the filters, on the dirty air side of the collector. Any glow on the clean air side means that the dye and other dust is getting through a leak somewhere. This test identifies even very small holes in filters that can’t otherwise be seen.

ServiceMAXX technicians can also perform many other services. Please contact us to schedule a ServiceMAXX visit or a yearly maintenance program. A yearly scheduled maintenance program will give you priority scheduling during times when our technicians are very busy, and makes sure your system is always running at maximum efficiency.

Read more

by Erin Long | Mar 15, 2019 | Uncategorized

In January 2019, a facility in Indiana reported an aluminum fire. The company produces aluminum alloys for the auto industry. The fire resulted from highly combustible aluminum dust that had accumulated in the building.

The facility had a sprinkler system that certainly helped keep the fire from becoming an explosion. Fortunately, all the employees escaped without injury. Every facility that handles combustible material can take some advice from this incident.

What Caused the Accident?

Aluminum dust has a high Kst value, meaning that it can cause a very strong explosion. Because of how destructive an aluminum fire can be, take precautions to control and remove aluminum dust.

This facility has a dust collector. But aluminum dust had still accumulated around the building, especially on overhead beams. During routine cleanings, one can miss dust from flat surfaces in high places that accumulate it.

This facility has a dust collector. But aluminum dust had still accumulated around the building, especially on overhead beams. During routine cleanings, one can miss dust from flat surfaces in high places that accumulate it.

In the Indiana facility, they could not determine where the dust found an ignition source. First, it spread from an area near a furnace, igniting combustible aluminum dust that had accumulated in the area. Then the aluminum fire continued to spread by igniting dust piled up on the ceiling beams.

Their sprinkler system did activate. As a result, this probably prevented a dangerous explosion by keeping the dust from forming an airborne cloud. However, the fire burning on the overhead beams was above the sprinkler system.

From the overhead beams, the aluminum fire was able to spread and reached the dust collector. This caught on fire and burned until the fire department could extinguish it.

Recommendations for Prevention of an Aluminum Fire

Like many combustible dust incidents, this aluminum fire resulted from poor housekeeping. Accumulated dust in a facility can find an ignition source from a spark, faulty wiring, or machines. With a high Kst dust like aluminum, the dust can certainly cause an explosion.

The explosion can cause disturbed layers of dust to become airborne. Consequently, this leads to secondary explosions which can be devastating. However, in this aluminum fire, the dust on the beams did not get a chance to turn into a dust cloud.

Outdoor Installation

This aluminum dust did burn and continue to spread the fire throughout the building and into the dust collector. Fortunately, the collector was located outside the building. With highly combustible dust, it’s almost always the recommendation to locate the collector outside. If an explosion does happen in the dust collector, it will vent away from the building and people inside.

Safety Features

Dust with a high Kst value like aluminum requires a dust collection system with fire and explosion prevention. This company had a sprinkler system in the building. But even after the sprinkler system triggered, nothing stopped the fire from entering the dust collector. Since an explosion wasn’t reported, the collector probably had explosion vent panels or some other safety features.

Housekeeping

The most basic recommendation to prevent an aluminum fire, or any other dust fire, is good housekeeping. This means making sure there is no dust buildup around the building. So check and remove any dust from high surfaces like beams.

A dust collection system prevents a buildup of dust in the facility by capturing and removing it. This company had a dust collector, but it clearly could not handle all the dust being produced. An experienced dust collection system designer will make sure your system can capture all the dust your processes create.

The

CMAXX Dust & Fume Collector can meet all your company’s dust collection needs. With an Imperial Systems system designer working with you, your system will be able to handle even highly

combustible dust like aluminum. This will keep your building and workers safe.

by Erin Long | Mar 5, 2019 | Uncategorized

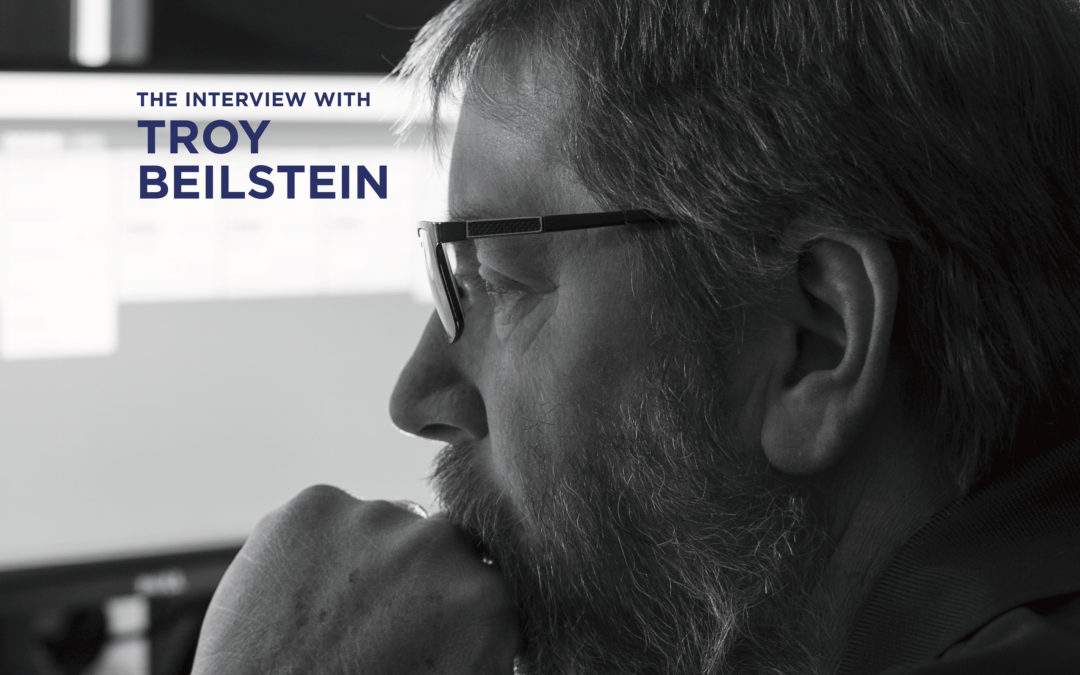

Dusty Jobs Issue 8 is here! Charlie teaches us a card game, we talk about our latest new product, the Rhino Drum, and we interview one of our engineers. If you would like a printed hard copy of this issue of the quarterly newsletter, contact your Imperial System Sales Rep.

Click the cover to download and print the newsletter.

Click the article to read

A Letter from the Director of Sales & Marketing

Several years ago I had the pleasure of visiting VIR (Virginia International Raceway) in Alton, VA. This is a historic road course originally developed in the 1950s and resurrected in 2000. I was visiting a friend who was CART racing at the time and he invited us to come watch him race. Upon arrival, we were asked if we were interested in a ride around the course. “Sure!” we exclaimed, and then proceeded to pile into a Ford Econoline van with a professional driver behind the wheel. While the spin around the track was fun and even at times exhilarating as this driver pushed the large van to its limits, I couldn’t help but to think that with the right vehicle this trial spin could have been a lot more effective, and fun.

Several years ago I had the pleasure of visiting VIR (Virginia International Raceway) in Alton, VA. This is a historic road course originally developed in the 1950s and resurrected in 2000. I was visiting a friend who was CART racing at the time and he invited us to come watch him race. Upon arrival, we were asked if we were interested in a ride around the course. “Sure!” we exclaimed, and then proceeded to pile into a Ford Econoline van with a professional driver behind the wheel. While the spin around the track was fun and even at times exhilarating as this driver pushed the large van to its limits, I couldn’t help but to think that with the right vehicle this trial spin could have been a lot more effective, and fun.

You might now be thinking, “That’s nice, but what in the world does this story have to do with Imperial Systems?” Let me explain. I came on board as Director of Sales and Marketing for Imperial Systems about seven months ago. Over the years I have worked for a couple of medium size companies and one fairly large international organization approaching $1 billion on total sales. This large company had many great people and great products but, like most large companies, if you wanted to get something done it required a lot of planning, consensus from many, and copious amounts of time. In other words, it was like trying to handle a road race track in a full-size van.

Imperial Systems has been a refreshing and fun change for me. Like the other companies I have worked with, we have great people, great products and great ideas. The difference is that we have clear, concise and quick discussions and brain storming sessions with ideas that get engineered, tested, and manufactured in a fraction of the time it takes in most companies. I have been a part of this experience for our newest product, The Rhino Drum, along with all of the current improvements we are making to our cartridge line, our flagship CMAXX collector, our BRF Medium Pressure unit, and many others to come. I also witnessed this in our approach to Fabtech in the way in which we created a plan and implemented that plan, which lead to a very successful trade show eliciting many viable leads.

Imperial Systems has been a refreshing and fun change for me. Like the other companies I have worked with, we have great people, great products and great ideas. The difference is that we have clear, concise and quick discussions and brain storming sessions with ideas that get engineered, tested, and manufactured in a fraction of the time it takes in most companies. I have been a part of this experience for our newest product, The Rhino Drum, along with all of the current improvements we are making to our cartridge line, our flagship CMAXX collector, our BRF Medium Pressure unit, and many others to come. I also witnessed this in our approach to Fabtech in the way in which we created a plan and implemented that plan, which lead to a very successful trade show eliciting many viable leads.

At Imperial Systems there is an awareness that we are on that race track and we are surrounded by competitors who want to be first at the finish line. The difference is that we not only have the right drivers but also the right vehicle to ensure we finish first and best. Drivers, start your engines!!

– Tomm Frungillo, Director of Sales & Marketing

Read more

by Erin Long | Jan 30, 2019 | Uncategorized

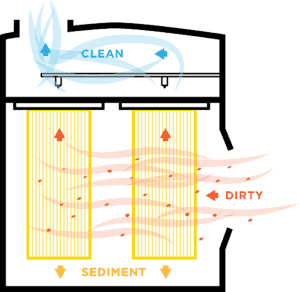

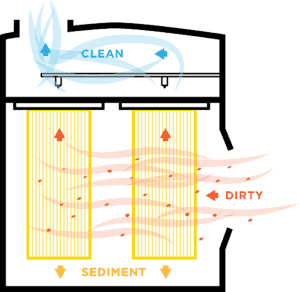

The CMAXX is a vertical pulse-jet dust collection system. So how does a dust collector work? What’s going on inside there, and why is it designed the way it is?

The concept is basic: dirty air goes in, dust or particulate gets removed, and clean air comes out. However, the details become important when you’re looking for the right central vacuum system for your machinery.

Considering a shop dust collector system for your business? If so, this information may be helpful for you.

Dust Collection System Design

The CMAXX is a reverse pulse-jet cartridge dust collector. The best way to explain what this means is to go on a tour of the path that air follows through the dust collection system.

Dirty Air

- Dirty air containing particles of dust enters the collector through the ductwork. Fans either push or pull the air through the ducts.

- The air hits a set of baffles, which are angled pieces of metal that slow it down. As a result, this keeps the dust from hitting the filters at full speed.

- Then the air enters what we call the dirty air plenum. This just means the side of the collector where the air is dirty. At the bottom of this space, collected dust drops out into a drum or hopper.

Dust Capture

- Next, the air passes through the dust collector’s cartridge filters. In the CMAXX, these hang vertically from the tube sheet, which is the metal sheet separating the dirty and clean air spaces.

- Pleating the filters gives them more surface area. DeltaMAXX filters are also coated with a nanofiber material. This makes the spaces that the air must go through smaller.

- The filters capture the dust. Some of it falls off. Some of it sticks to the filters. Gaskets at the top of each filter seal it to the tube sheet to keep dust from sneaking through.

Filter Cleaning

- A pulse of compressed air blows into the filters. Because the pulse of compressed air goes in the reverse direction of the regular airflow, we call it a reverse pulse-jet collector.

- The pulse of compressed air blows the accumulated dust off the filters. The dust drops out of the collector and the filters are ready to collect more dust.

- On the other side of the filters, filtered air enters the clean air plenum. From there, it can go back into the facility or vented outside.

How Does the Pulse-jet Dust Collection System Clean the Cartridge Filters?

A pulse-jet collector is a very effective type of industrial dust collection system. Diaphragm valves control the compressed air in a pulse-jet collector. Often a timer controls the diaphragm valves. To make the cleaning more efficient, the pulses can also be controlled by differential pressure sensors.

Differential pressure sensors read the air pressure on the dirty air and clean air sides of the filters. The dirtier the filters are, the more resistance they have to air going through them. When the difference in the two pressure readings gets too high, it signals the filter cleaning mechanism.

Using differential pressure sensors makes a pulse-jet dust collector more efficient because it reduces the use of compressed air. It also helps the cartridge filters last longer, because the pulses of compressed air cause wear and tear on them.

Pulse-jet dust collection systems are efficient because of this filter cleaning. With an industrial dust collection system, replacement filters can be a big expense. By making filters last longer, a pulse-jet collector is the most cost-efficient shop dust collection system. Read about offline cartridge filter cleaning.

How Does a Vertical Pulse-jet Dust Collection System Work Better?

Cartridge collectors have the filters in either a horizontal or vertical arrangement. In horizontal dust collection system design, the filters lay on their sides and are stacked on top of each other. The filters hang down from the tube sheet in a vertical filter dust collector.

In a horizontal pulse-jet dust collector, the pulse cleaning causes dust to be blown off the filters. However, because they’re on top of each other, the dust from the top filters falls on top of the others.

In a vertical pulse-jet collector, the dust that pulses off of the filters drops directly down into the hopper. The dust falls free and doesn’t land on the other filters.

Most CMAXX competitors on the market are horizontal dust collectors. Only a few companies make vertical pulse-jet cartridge collectors. Vertical systems are the most effective shop dust collection systems.

In conclusion…

If you’re looking for a central machinery dust collector for your facility, make sure it has a self-cleaning, pulse-jet system. To get a good idea of how the CMAXX works, check our product page. If you still have questions, please feel free to ask us!

Read more

by Erin Long | Jan 28, 2019 | Uncategorized

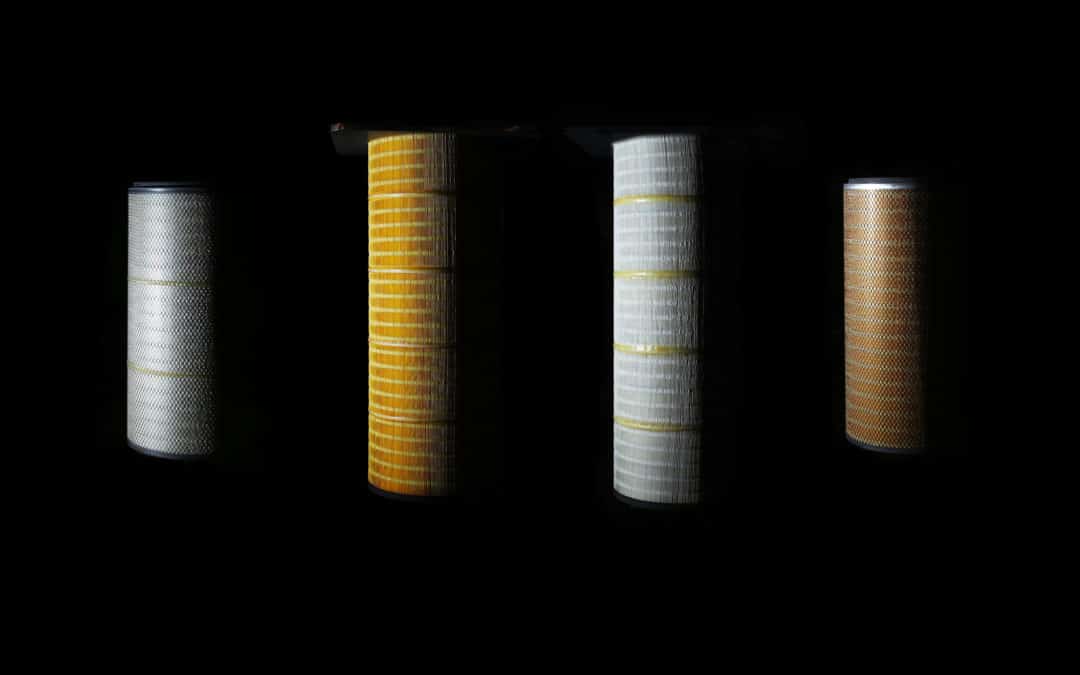

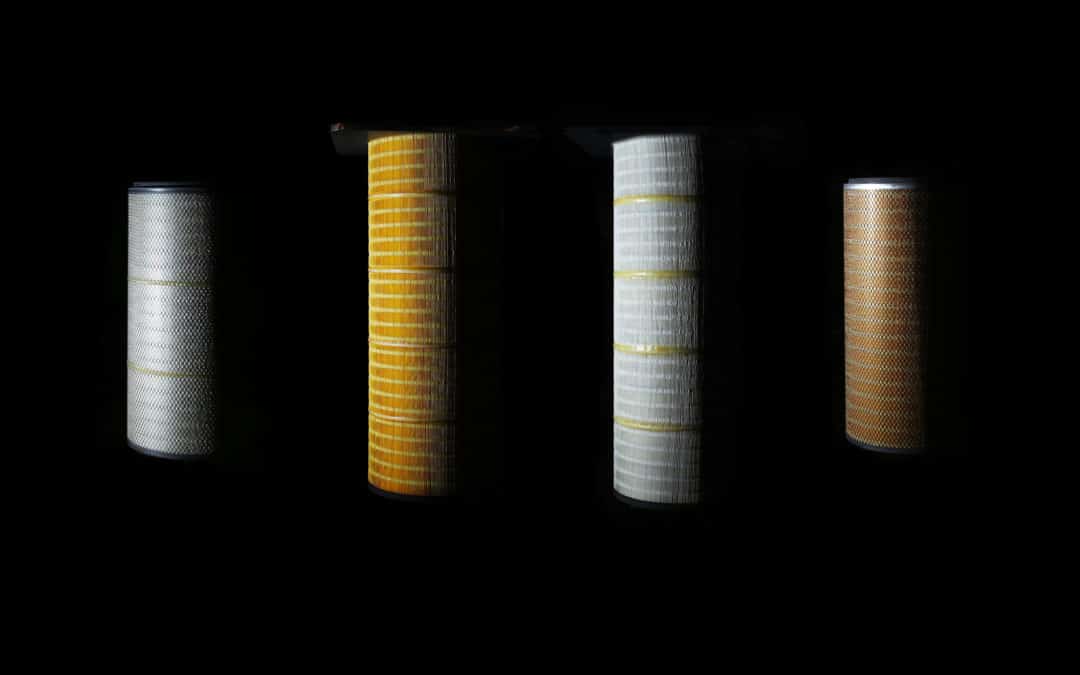

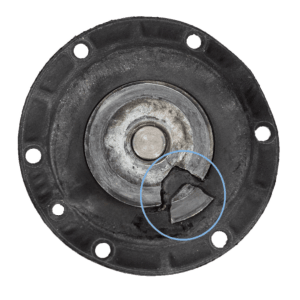

After you’ve installed your dust collection system, the big initial expense is over. However, you need to plan for your system’s regular maintenance, like replacing the industrial dust collector cartridge filters. Dust collectors that use cartridge filters have become very popular, partly because cartridge filter changes are easier.

Dust collector filters are the part of the system that clean the air traveling through the system. In a pulse jet collector with dust cartridge filters, the filter cleaning system removes dust from the surface of the filters.

All filters, though, will eventually become overloaded with particles and will need to be replaced.

Do they really have to be replaced? Why can’t you just clean them?

Can’t you just take out and clean the dust collector cartridge filters so they’ll work better again?

You can, and people do. But you shouldn’t, and here’s why.

You can measure the efficiency of a dust cartridge filter by its differential pressure. This means measuring the pressure on the dirty air side of the filter and then on the clean air side. This tells you how much the airflow is slowing down across the filters.

If your differential pressure is higher than the recommendation for your system, it’s time for a change. The filter cleaning system is not able to clean your dust collector filters anymore. It’s time to replace the filters.

There are companies that offer to clean your industrial dust collector filters instead of changing them. Usually, they do this by blasting them with high-pressure compressed air to blow the accumulated dust out of the filters. The problem is that dust collector cartridge filters are made of cellulose and polyester, which means a large part of the filter is cardboard. When you try to clean industrial dust collector filters this way, the high-pressure air will create holes in the filter material.

You might not be able to see the holes. It may seem like the filter cleaning worked perfectly. The filters get put back in the dust collector, and the differential pressure is much lower.

The pressure isn’t lower because the filters are clean, though. It’s lower because air is going straight through the little holes torn in your filter.

How big a problem are those little holes in the cartridge filters?

Cleaning your dust collector filters can put holes in them, but how much dust is really going to get through those tiny holes? The answer is “a lot”. Air follows the path of least resistance. The filter material has resistance. The holes don’t. The air going through the dust collector cartridge filters will go through the holes, taking dust with it.

This is a serious problem for several reasons.

First, dust will be getting through your dust collector filters. Depending on where your air is venting, it’s going out into the environment or back into your facility. Either way, this could result in fines or health problems for employees.

Second, dust that gets through the filters can build up in the clean air plenum. There should never be dust in this part of the collector. The dust in there will keep blowing out into the facility even if you fix the filters.

Third, the differential pressure will be lowered because air can easily get through the holes. This could make it look like the filters are clean and working well, even though they are damaged. This makes it hard to recognize that the dust collector filters are not doing their job.

You’re Not Saving Money by Cleaning Your Dust Collector Cartridge Filters

Industrial dust collector filters are made of a cardboard-based material that is not made to be cleaned and re-used. While it looks like the filters are cleaned and working better, what you’re really seeing is filters that have been damaged. Learn more about filter cleaning versus installing new filters and offline cartridge filter cleaning.

Instead of trying to save money by having your filters cleaned, contact Imperial Systems and ask us about DeltaMAXX filters. They last longer than the competitors’ filters, so you’ll save money on your industrial dust collector filters over time.

Read more

![The Dangers of Phosgene Exposure [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/04/featuredimage_phosgene-1080x675.jpg)

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one. The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems. Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

Several years ago I had the pleasure of visiting VIR (Virginia International Raceway) in Alton, VA. This is a historic road course originally developed in the 1950s and resurrected in 2000. I was visiting a friend who was CART racing at the time and he invited us to come watch him race. Upon arrival, we were asked if we were interested in a ride around the course. “Sure!” we exclaimed, and then proceeded to pile into a Ford Econoline van with a professional driver behind the wheel. While the spin around the track was fun and even at times exhilarating as this driver pushed the large van to its limits, I couldn’t help but to think that with the right vehicle this trial spin could have been a lot more effective, and fun.

Several years ago I had the pleasure of visiting VIR (Virginia International Raceway) in Alton, VA. This is a historic road course originally developed in the 1950s and resurrected in 2000. I was visiting a friend who was CART racing at the time and he invited us to come watch him race. Upon arrival, we were asked if we were interested in a ride around the course. “Sure!” we exclaimed, and then proceeded to pile into a Ford Econoline van with a professional driver behind the wheel. While the spin around the track was fun and even at times exhilarating as this driver pushed the large van to its limits, I couldn’t help but to think that with the right vehicle this trial spin could have been a lot more effective, and fun. Imperial Systems has been a refreshing and fun change for me. Like the other companies I have worked with, we have great people, great products and great ideas. The difference is that we have clear, concise and quick discussions and brain storming sessions with ideas that get engineered, tested, and manufactured in a fraction of the time it takes in most companies. I have been a part of this experience for our newest product, The Rhino Drum, along with all of the current improvements we are making to our cartridge line, our flagship CMAXX collector, our BRF Medium Pressure unit, and many others to come. I also witnessed this in our approach to Fabtech in the way in which we created a plan and implemented that plan, which lead to a very successful trade show eliciting many viable leads.

Imperial Systems has been a refreshing and fun change for me. Like the other companies I have worked with, we have great people, great products and great ideas. The difference is that we have clear, concise and quick discussions and brain storming sessions with ideas that get engineered, tested, and manufactured in a fraction of the time it takes in most companies. I have been a part of this experience for our newest product, The Rhino Drum, along with all of the current improvements we are making to our cartridge line, our flagship CMAXX collector, our BRF Medium Pressure unit, and many others to come. I also witnessed this in our approach to Fabtech in the way in which we created a plan and implemented that plan, which lead to a very successful trade show eliciting many viable leads.