What is air filter differential pressure in a dust collector? It’s the difference in air pressure between the dirty and clean air sides of the filters. Most manufacturers recommend that you keep a regular log of the differential pressure measurements. But did you know it might also be a requirement in your air quality operating permit?

Each state issues its own air permits to any business that is going to create any kind of air contaminant. There are different types of permits, depending on the state, the type of pollutant, and the size of the facility. Sometimes businesses can operate without a permit as long as they comply with certain regulations.

Do air permits require monitoring?

The EPA’s Clean Air Act applies to operations that are major sources of air pollution or particularly dangerous kinds of air pollution. If your company is required to have a Title V Permit, you have very strict regulations to follow and are required to certify your compliance yearly. If you use baghouses, cartridge collectors, or similar types of particulate collection, take note. This often requires a record of differential pressure monitoring.

What if you have a state-issued permit, though? Does it say you have to keep a log of your differential pressure? And what happens if you don’t?

Your state’s air permits may require that companies using baghouses keep a differential pressure log. (The EPA and many state agencies refer to all fabric filter particulate collectors as “baghouses.”) Others may not require you to keep a log. But they might require that you take certain actions if the differential pressure indicates a problem.

If there’ no log of your system’s normal differential pressure changes, you may not know when there’s a change indicating a problem. Unusually high differential pressure might indicate that dust is blinding off your filters, and they need changing. If the differential pressure is much lower than expected, it could mean a couple of things. You could have a leak in your filters or somewhere else in the system.

Keep a log of what your differential pressure normally is. Because if you don’t, you won’t have a record to show a state or EPA inspector who comes to renew a permit or to look into a problem. Even if your permit doesn’t specify that you keep a log, it’s good documentation. It shows that you’ve been diligently monitoring your system function.

Recommended Air Filter Differential Pressure Monitoring

Dust collector manufacturers recommend keeping a differential pressure log, regardless of permits or regulations. Monitoring your differential pressure over time will allow you to see when your filters are getting close to needing changing. This lets you order and stock replacements on hand. It’s much more efficient than having to shut down a collector because the blinded filters are not working.

Monitoring can also alert you to other problems. For example, leaks in the system that let the air take a shortcut around or through holes in the filters. Any sudden or big changes from your normal differential pressure should be a warning that something might be wrong.

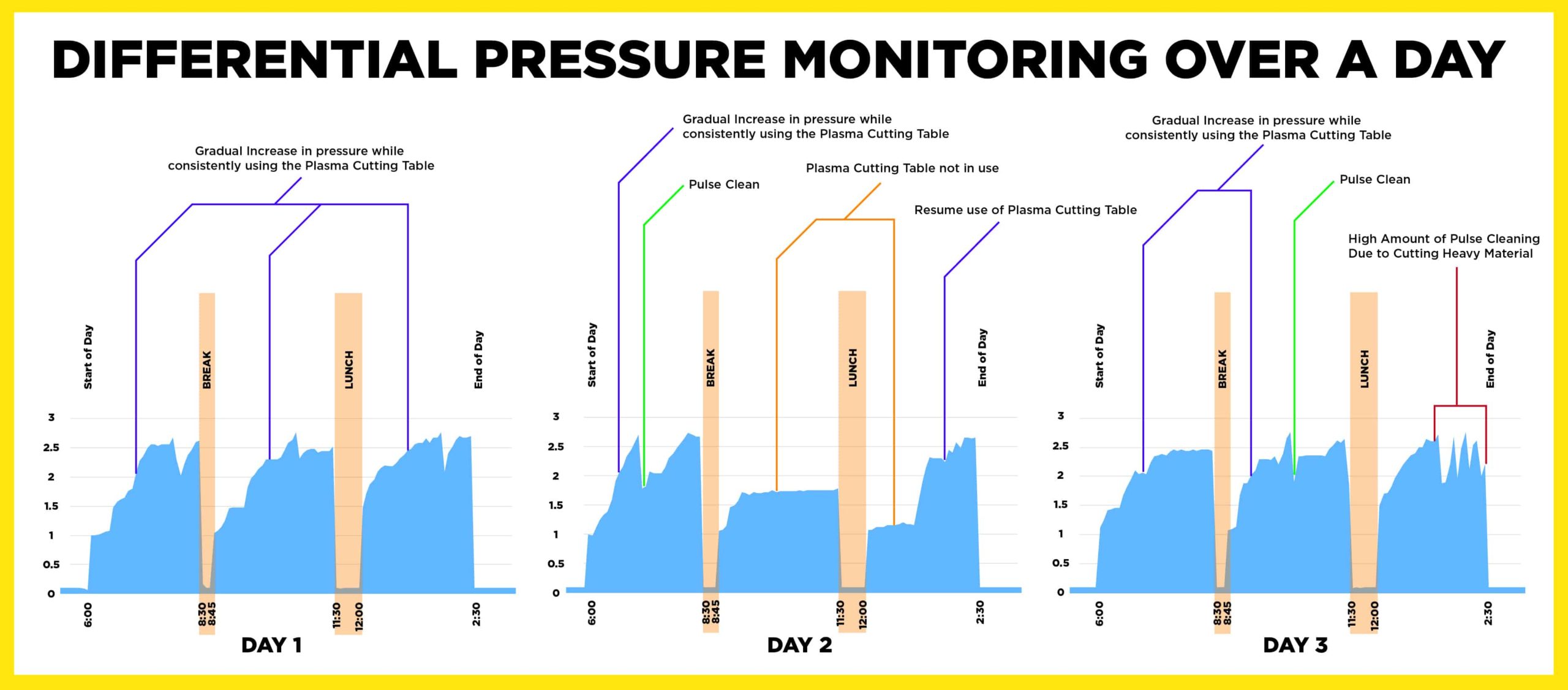

Here’s an example chart from an electronic differential pressure recorder. Every application would have a chart that would look different. The system in this sample chart below only runs for one shift each day. It does off-line pulse cleaning during breaks and lunch. You can see the pressure drop after each of these off-line cleanings during the day.

How you record and monitor the differential pressure depends on your system. Have someone monitor and record the number at specified times every day. Alternatively, set up an electronic differential pressure monitoring device to track it. Each system’s normal differential pressure graph will look different. The point is to know what your system’s “normal” is so you can tell if anything changes.

If you do have an air permit, review it. It probably contains some statement that you’re responsible for monitoring and maintaining your equipment to prevent air contamination. It might not specifically say that you have to keep a differential pressure record… but keeping that record is a great way to show that you have the monitoring and maintenance bases covered.