Find out how metalworkers like you can address the need of a top-quality spark

It’s no secret that the materials you work with everyday in the metalworking industry can create a serious risk for combustion. In fact, metals make up 20% of the materials involved in combustible dust incidents. And between 2008 and 2012, the United States Chemical Safety Board documented 50 combustible dust accidents, which led to a total of 29 fatalities and 161 injuries.

The spark trap is the solution to a very dangerous problem and the need to invest in the most advanced spark trap is clearly an essential safety decision that we at Imperial Systems take very seriously.

In fact, continuing customers rely on Imperial Systems when quality is of the utmost importance because they know Imperial engineers outstanding, high quality products to keep buyer’s employees and businesses safe from dust collection and the risks of combustion in the metalworking industry.

At Imperial Systems, we are dedicated to to helping metalworkers like you ensure the safety of your employees and efficiency of your workplace. We’ll discuss:

- Why a cutting-edge spark trap is of the utmost importance.

- The risks of an inefficient spark trap.

- Why the Imperial Systems spark trap keeps your employees safe from combustion hazards.

Why Invest in a Quality Spark Trap?

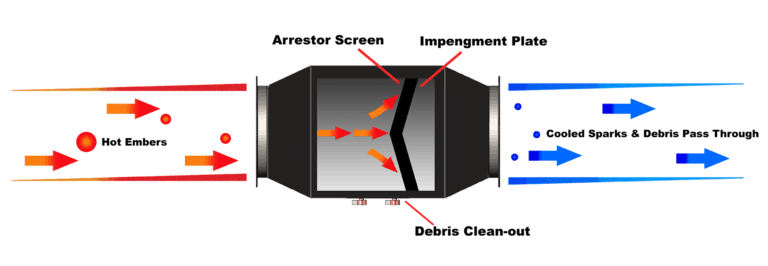

Designed primarily as a first line of defense to prevent ignition within a dust collection system, spark traps reduce the potential for fire hazard by capturing sparks before they reach the main containment unit, where dust or other flammable materials may be present.

The risk associated with a spark trap that functions inefficiently to achieve the above scenario every time is that it only takes one small failure of the system to put your employees in a deadly situation.

Companies in the metalworking industry should consider implementing ways to control the elements of a combustible dust explosion. The NFPA recommends several practices and policies to prevent combustible dust explosions, including:

- use of dust collection systems and filters and surfaces that minimize dust collection

- use appropriate electric equipment and wiring methods

- controlling static electricity, smoking, open flames, sparks, and friction

- install and use spark/ember detection, extinguishing, sprinkling, and explosion protection systems

A spark trap, or spark arrestor, is an instrumental part of these methods, working to minimize risk by cooling and thus extinguishing sparks before they reach the filter surface. In the diagram above that shows the process of an Imperial Systems spark trap, note how the hot spark enters the arrestor which both cools and collects debris, before allowing the cooled ember to pass through.

The Cost of Procrastination: Why an Imperial Systems Spark Trap is Essential to Safety

An ineffective or entire lack of a proficient spark trap leads to an increased risk in danger associated with the metalworking industry. Without it, sparks can reach the main component, where dust and flammable materials fill the air, causing an explosion.

- A simple installation: Our unique spark trap system does not require upkeep from their providers, meaning they are hassle-free in addition to being simple to install and pre-wired. With tool-free filter access and change out, they do not require any moving parts or additional welding.

- Optional sizes and features: You can choose between a carbon and stainless steel finish. In addition, you can choose to include raw inlets, outlet edges, an integrated HEPA after filter, and more to your spark traps.

- Customized fit: With both horizontal and vertical configuration options, an Imperial Systems arrestor can be aligned to your collector without fail.

Your metalworking company is not like other businesses where the environment is at increased risk with the potentially explosive combination of combustible dust and sparks flying. It is vital that you act immediately to implement all of the required and recommended OSHA and NEPA safety equipment, including dust collection systems with sealed ductwork and an effective spark trap.

Choose Imperial Systems Today

If you haven’t yet decided on a spark extinguisher for your metalworking business, what is that procrastination costing you?

From 1996-2005, 106 explosions resulted in 16 fatalities, 126 injuries, and an estimated cost of $162.8 million in damages to the facilities.

As we know, sparks are a major cause of such explosions and an Imperial Systems spark trap is an essential piece of equipment that can mitigate the fears and risk of an explosion.

Contact Imperial Systems today at 800.918.3013 or learn more by emailing us at info@isystemsweb.com.