OSHA just released the first guidelines and recommended practices list in more than twenty years. Is it something you need to know about? Probably. But you probably don’t have a few hours to spend browsing their website for information. Save yourself some time. Here’s a summary of the important parts, and links to get you to the ones you want to know more about.

OSHA Guidelines and Recommended Practices

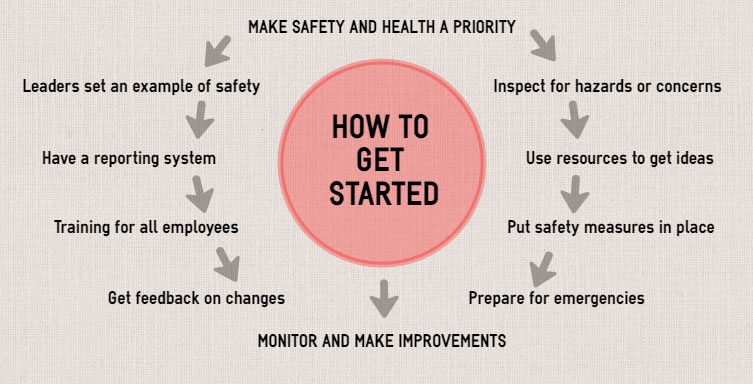

Getting Started

First off, here’s a quick guide to the process of implementing recommended practices:

There are two areas of focus here: preparing and training people, and inspecting and improving facilities, equipment, and practices. If you need some more details, head to this link: https://www.osha.gov/shpguidelines/ten-easy-things.html

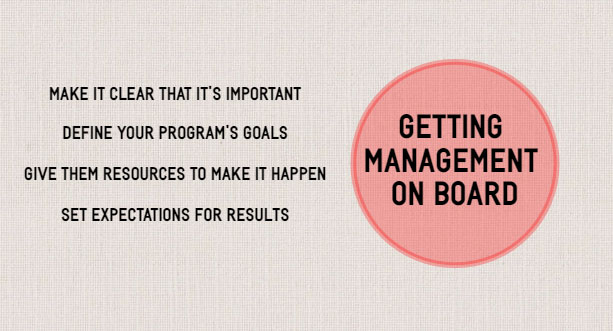

Getting Management to Work With You

You’re going to have a hard time getting a safety program off the ground if management isn’t buying in. The OSHA guidelines recommend four basic steps below to make sure they’re with you:

If you need more details about things you should do to get management and leadership engaged, this is your place to look: https://www.osha.gov/shpguidelines/management-leadership.html

Getting Workers Involved

If getting your workers to be involved and serious about your safety program is a concern, here are suggested steps in the OSHA guidelines to make sure you have genuine worker investment:

So what does it take to get workers to care about and want to participate in your safety program? And what are some of the barriers to their participation? If this is a topic you’re interested in, here’s the place to go: https://www.osha.gov/shpguidelines/worker-participation.html

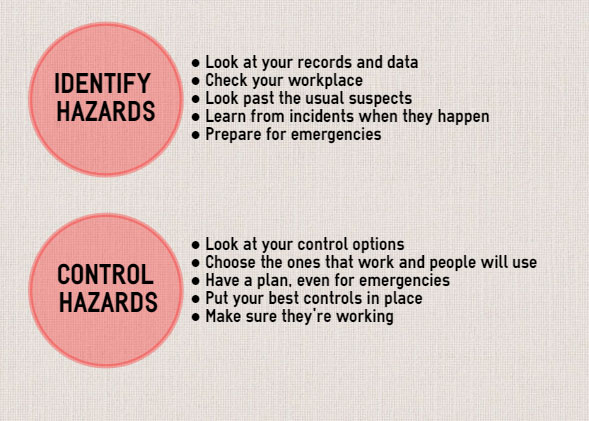

Hazard Identification, Control, and Prevention

Before you can do anything about hazards in your workplace, you have to find them. Not just the obvious ones, either: there may be hazards that only people who use a particular machine or work in a particular area are aware of, for example.

Once you’ve identified the hazards that need to be addressed, what do you do about them? You look for ways to control them, starting with the most dangerous or the ones that can be easily eliminated. Getting workers involved in deciding what controls you’ll use is also a great step to get them more active in the program.

These are obviously the nuts and bolts of a safety program, but they don’t work if you haven’t gotten managers and workers on board and involved. Workers are probably the people most likely to know where the real hazards are and where things might go wrong, but they’re not likely to want to talk about it with management you’ve established a program where reporting a hazard is encouraged, not punished.

If hazard identification is your topic, check here: https://www.osha.gov/shpguidelines/hazard-Identification.html

If you’re moving past identification and ready to tackle prevention and control, this is your destination: https://www.osha.gov/shpguidelines/hazard-prevention.html

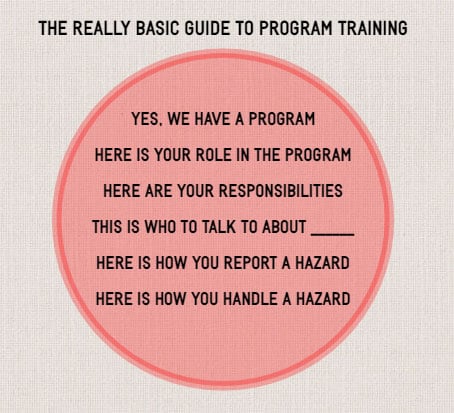

Education and Training

You can have a great program, but if nobody knows what to do or who should handle what part, you’re not going to get anywhere. Here’s the very basic breakdown:

OK, you’re probably going to need to get a little more in-depth than this. Fortunately, OSHA has some handy resources available, including training tools to help people get better at spotting hazards: https://www.osha.gov/shpguidelines/education-training.html

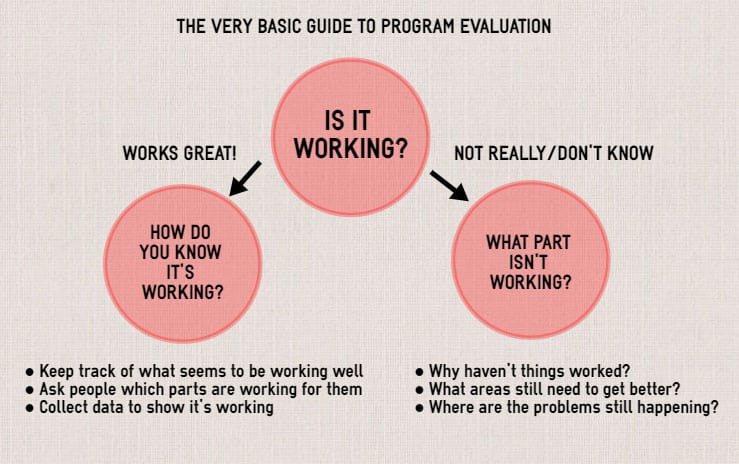

Program Evaluation and Improvement

So you started a program, and you got everyone to participate, and things seem to be going really well. Or perhaps your program, for whatever reason, isn’t doing what you hoped it would do. Evaluation is the part where you figure out what’s going well and what’s not. And improvement is the part where you do more of what’s working and less of what isn’t.

If you’re working on a safety program and need to be able to report on how it’s going and what it’s doing for the company, check out OSHA’s suggestions and tools for figuring it out: https://www.osha.gov/shpguidelines/program-evaluation.html

Additional OSHA Guidelines Information and Assistance

There’s your very quick summary of OSHA Guidelines and Recommended Practices! If you need lots and lots more information, OSHA makes sure you have tons of links and helpful tools to check out on their “additional resources” page here: https://www.osha.gov/shpguidelines/program-evaluation.html.

As always, if you are looking for dust and fume collection or fire and explosion safety controls, we are here to help you with any information you need. Using this equipment is a best practice for dealing with combustible dust, including spark arrestors, abort gates, and fire retardant dust collector filters.

DISCLAIMER: This guide is not intended to be used in place of OSHA guidelines or actual recommendations. We hope it helps you get an overview of what’s available, but while we are dust and fume collection experts, we defer to those more knowledgeable when it comes to safety program design.