by Imperial Systems | Aug 2, 2016 | Uncategorized

Whether you are a new manufacturing business or just branching out into new territory, if you are going to get into the metalworking field, addressing industrial dust control solutions demand some serious consideration. Not only do you have the safety of your work space to think about, but unchecked dust and fumes can also pose health hazards to those working in it. We’ve spent nearly 15 years considering the challenges of industrial dust accumulation and control, and we have developed the solutions our customers need. Discover the facts you need about dust control for your business so things run safely and smoothly.

Meet Safety Standards

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update HERE. When you look for an industrial dust control system, begin by ensuring that it meets these and other industry standards.

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update HERE. When you look for an industrial dust control system, begin by ensuring that it meets these and other industry standards.

Anticipate Dust And Fumes

As you consider a system to provide dust control for your workspace, make sure you take fumes into account as well. In many metalworking processes, noxious fumes are created which are more than unpleasant; they can be increasingly harmful when inhaled. Not all industrial dust control systems are created to handle this dual threat, so it is vital to choose a collector that can manage both dust and fume generated by metalwork manufacturing.

Your Industrial Dust Control Solutions Experts

Whether you need dust and fume filtration or just a dust collection system, Imperial Systems is your industrial dust control headquarters. We manufacture the most efficient, strongest, and longest-lasting systems and filters in the industry. Through these products, we have become well-known for our dedication to quality, value, and safety. Our outstanding line of equipment includes:

- CMAXX™ Dust Collector System

- DeltaMAXX™ Cartridge Filters

- CMAXX™ Laser Fume Extraction System

- Spark Arrestor

- Explosion Isolation Valve

- Custom Ductwork & Fittings

- Heavy Duty Abort Gates

- and more!

Most of our products are available to ship within 24 hours. For more information about our products and how we can support your metalworking business, contact us today.

Read more

by Imperial Systems | Jul 26, 2016 | Uncategorized

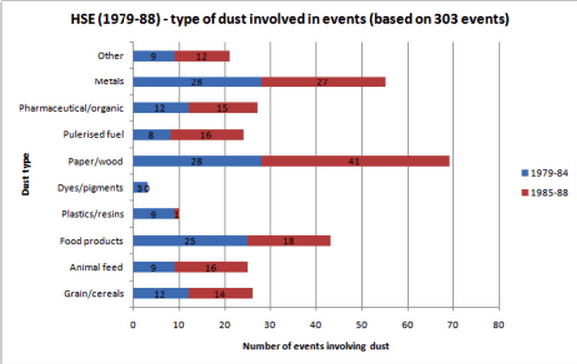

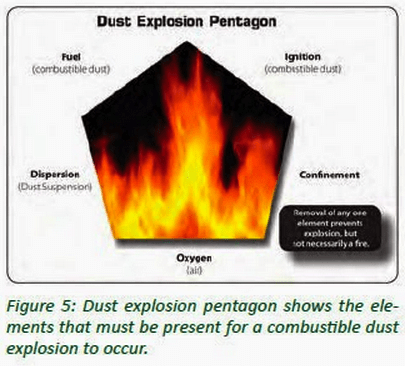

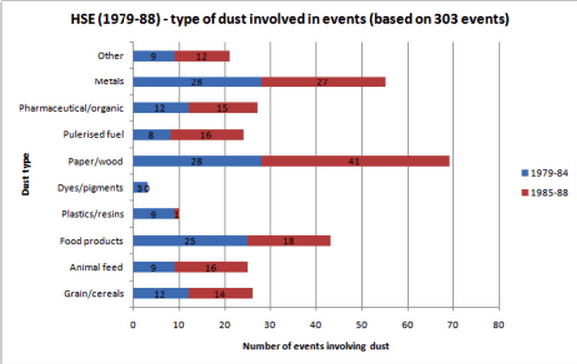

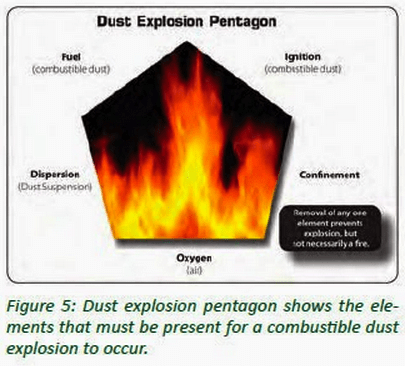

Dust explosions are bad to begin with, but what do you know about secondary explosions? There are many factors that determine how likely a particular type of dust causes deflagration. When you think of combustible dust, do you think of the explosions you’ve heard about at grain handling facilities? Maybe you think of the explosive potential of aluminum dust.

Secondary Dust Explosion Incidents

Three dust explosions occurred in 2003. They demonstrate how many different types of production and manufacturing can produce a deflagration risk, including a secondary dust explosion. In a North Carolina plant, the application of a polyethylene coating to rubber caused accumulation of the dust. As the material dried, dust formed and accumulated above the work area. The work area was clean. But a layer of dust 1/4″ thick was enough to cause an explosion that killed six people. In this situation, a dust collection system in the production area could have captured the dust particles before they circulated through the facility.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

Aluminum dust from scrap processing fueled the explosion in Indiana. The dust collector in this case was the source of the explosion. It did not have explosion vent panels, and instead of being directed safely, the explosion traveled back into the building and ignited dust in the ductwork. A secondary explosion occurred when dust accumulated on surfaces inside the facility ignited. A dust collector designed to isolate and redirect a deflagration could have prevented this accident.

NFPA Recommendations

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

It’s often this accumulated dust, hidden on high surfaces, in corners, or inside ductwork, that ignites to cause a secondary explosion that’s far more dangerous than the original one. Witness reports of dust explosions often include descriptions of a smaller explosion followed by one or more larger ones; this is secondary ignition. Dust control throughout the facility, along with fire prevention equipment such as abort gates, spark arrestors, and explosion venting, can control a potential explosion and prevent a small fire from becoming a fatal disaster.

Read more

by Imperial Systems | May 25, 2016 | Uncategorized

Ever wonder how much facilities like yours might be paying when they don’t have proper dust control?

When a facility doesn’t have proper dust control equipment installed, or when they fail to protect their workers from welding fumes or combustible dust, fines from OSHA may be in your future. Since March of 2016, numerous fines OSHA have been handed out for respiratory hazard violations:

- A cement company in Ohio is looking at a $92,000 fine for violations that include silica dust exposure

- A company’s abrasive blasting process without proper air filtration resulted in a $121,000 fine for exposing workers to airborne lead

- Fines for a power equipment manufacturer may total $77,000 for violations including failure to evaluate dust hazards

- A pallet manufacturer is facing $152,000 in fines for safety hazards including combustible dust build-up

- Exposing workers to lead and cadmium dust at seven times the permissible limit will cost a Pennsylvania foundry $42,000

- A minerals company that failed to provide proper air quality and dust control exposed workers to lead and arsenic, which may cost them $106,000

Is your dust collection system ensuring you don’t face these kinds of fines? Imperial Systems can help! Our custom-designed dust control systems will help keep your facility and your employees safe. Call one of our knowledgeable team members today to learn more! 800-918-3013.

Read more

by Imperial Systems | Apr 24, 2015 | Dust Collection Filters

Find out how this top dust collector stays ahead of the competition…and how it can help you do the same!

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well.

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well.

This is especially true of safety equipment, such as your industrial dust collection systems. But if your systems can’t hold up to the heavy load, or harsh conditions, it is time to find an alternative. Begin by discovering what sets the top dust collector apart from the competition.

From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At Imperial Systems, we take these concerns and needs seriously. So, when it came time to design and manufacture our innovative dust collection system, we incorporated the latest technology with unique designs to create the top dust collector in the industry.

From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At Imperial Systems, we take these concerns and needs seriously. So, when it came time to design and manufacture our innovative dust collection system, we incorporated the latest technology with unique designs to create the top dust collector in the industry.

How does our CMAXX dust collector stay two steps ahead of the competition? The answer lies within our unique system advantages and our latest design updates. Discover the difference today to take the next step towards a cleaner, safer, and longer lasting dust collection system.

The Challenge

Whether your manufacturing processes involve welding, woodworking, or even just moving food or grain products, dust can pose at least three major challenges. These include:

(http://www.dustexplosion.info/statistics.htm)

- Inhalation. According to the World Health Organization, regularly breathing particles in has “the potential to cause harm either locally or subsequently elsewhere in the body.” Several OSHA standards seek to address such risks.(http://www.who.int/occupational_health/ publications/en/oehairbornedust3.pdf)

- Combustion. Dust explosions are another major risk. Between 1980 and 2005, the US Chemical Safety and Hazard Investigation Board identified 281 combustible dust incidents. Collectively, these incidents were responsible for the deaths of 119 workers, 718 injured, and numerous damaged facilities. Despite new standards, OSHA still estimates that there are approximately 30,000 U.S. facilities at risk for combustible dust explosions.

(https://www.osha.gov/dsg/combustibledust/)(http://www.grainger.com/content/safety-control-combustible-dust)

- Contamination. In certain fields, especially in food processing, contamination is also a significant concern. Not only can dust affect employees and equipment, it can also harm products. (http://industrialdustcollectors.blogspot.com/2014/07/dust-collector-compliance-with_18.html)

With such high stakes, it is imperative to have an efficient, dependable, and long-lasting dust collection system.

The Competition

Other industrial dust collection manufacturers have attempted to address these concerns in their dust collection systems. They have worked hard to create dust collectors that will hold up to NFPA and OSHA standards which have continued to evolve in recent years.

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit.

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit.

A top dust collector should offer you the highest efficiency in order to help you save on costs while offering the utmost filtration. Additionally, you need a system that can withstand the heavy loads, and even the harsh elements, often involved in the world of manufacturing.

Sadly, many high performing industrial dust collection systems are not made to last. Our competitor’s unit that is closest to the CMAXX collector has close to 68 feet of sealed connection and approximately 160 bolt holes with over 1000 holes throughout the collector from the bolted panel. This outdated fabrication style puts the whole system at risk for leaks, rust, and ultimately, damaged equipment.

Top Dust Collector Advantages

At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design.

At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design.

With our vertical cartridge design and PD technology, our system offers up to twice the filter life of similar units. At the same time, we offer the cleanest plant air at a lower price with our high efficiency design that includes both manifold mounted pulse valves and 100% total pulse distribution across the filter media.

Other system advantages include:

- A space-saving, low-profile design

- The lowest internal velocities from a larger housing

- Less service time with our tool-free filter door

- Factory assembled air header and top section

- Less Internal build up because of no internal frame on the dirty air plenum

- High quality Goyen GoCo cone nozzles located closer to the filter media

Additionally, our slanted inlet design prevents water built up while more evenly distributing dust and particulates throughout the filters. Collectively, these advantages not only provide up to 40% more cleaning power than the industry standard, but they also save you time, effort, and money along the way.

The CMAXX dust collector is also built to last. We have designed it with military grade door latches, rather than the less dependable truck trailer hardware. We also added corrosive resistant paint inside and out and heavy duty nickel plated hardware. With such dependability, not to mention our 15 year warranty, you can have confidence in your CMAXX Dust Collection System.

More Advantages With The Latest Update

Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.

Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.

Many dust collection systems are subject to the potentially harsh external elements. For many years, rust, leaks, and warping have been common results. These resulting defects, however, can compromise the integrity of the unit, undermining the very safety it is supposed to provide. Clearly, a change is needed.

And change is exactly what you will find in the new, domed roof design of the CMAXX dust collection system. We’ve taken not just one stand, but four, against the potential dangers of water damage and leaking:

- Solid, One-Piece Roof. With no individual panels, this innovation offers a stronger design while eliminating the risks of warping and leaks through the roof.

- Positive Bow. This shape allows water and debris to run off more easily, making the whole unit easier to clean. Additionally, there is no chance for freezing water to pool up on top of the unit and cause potential damage.

- No Bolt Holes. Without any external bolt holes, our system is completely sealed. This guarantees against both leaks and rusty bolts which may break or loosen.

- Heavy Duty Construction. Our 3/16” thick roof is fully welded with all welds ground smooth. Additionally, ¼” plate internal stiffeners offer further reinforcement.

With the latest advantages offered by our innovative roof and exterior design, Imperial Systems has taken a significant leap forward in dust collection system design. Combined with previously existing features, this system will continue to perform at the top of the industry today, and for years to come.

Are You Ready To Invest In Your Future Safety?

How long have you had your current industrial dust collection system? How is it holding up? Share your stories with us in the comments section below.

Then, if you want more information, or if you are ready to make the change and install a system that is uniquely designed for high-efficiency and longevity, give us a call at Imperial Systems. You can reach us at 800.918.3013.

Read more

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update HERE. When you look for an industrial dust control system, begin by ensuring that it meets these and other industry standards.

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update HERE. When you look for an industrial dust control system, begin by ensuring that it meets these and other industry standards.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well.

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well. From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At

From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit.

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit. At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design.

At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design. Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.

Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.