by Imperial Systems | Nov 8, 2016 | Uncategorized

Your dust and fume collector can save you money on heating this winter. But to make the most of those savings, your system might need some winter maintenance. It’s that time of year when your dust collector system needs a little attention to make sure it’s ready for the demands of colder weather.

Winter Maintenance Checklist

Replace Those Filters

Winter maintenance means starting the new year with clean new filters… and you’re not going to want to change them in the middle of a snowstorm.

Changing the Magnahelic Gauge Filter

It’s easy to forget about this little filter, but it’s necessary to keep the gauge readings accurate. You should replace it whenever you replace your other filters.

Check for Accumulated Dust

If you’ve been working with the doors open during the warmer months and not running the dust collector as much, you might have dust accumulated, especially in high places or flat surfaces. For safety, try to remove as much of it as possible.

Check Airlock Wipers and Bearings

Usually, you should change airlock wipers once a year. Worn-out wipers don’t do their job properly. Winter maintenance is a good time to check them. When you replace wipers, you should also plan to replace the bearings.

Check Heaters on Pulse Valves

If you’re in a cold area and your pulse valves have heaters to keep them from freezing up, make sure they’re working. Frozen pulse valves are an inconvenience nobody needs to deal with in frigid weather.

Check Solenoid and Diaphragm Valves

Again, these are not things you want to have broken in the middle of nasty cold weather. A quick check and some preventative maintenance if necessary can save you a headache later during winter.

Check Compressed Air Hoses

Cold can make hoses more brittle and likely to break. If your compressed air hoses have any weak spots or look worn or damaged, now is a good time to make sure they get fixed or replaced.

Check Seals and Gaskets

As with the hoses, cold can make seals and gaskets crack or develop leaks. If needed, replacing them before the weather gets cold can save you from dealing with downtime from an unexpected leak.

Calibrate Differential Pressure Gauge

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

Check Your Dust Collector Roof

If you’re a CMAXX owner, lucky you! Your domed CrownTech roof will keep snow or ice from piling up on top of the collector. If you don’t have a CMAXX, make sure you keep an eye on the amount of snow or ice buildup, since that can cause leaks into the collector.

Read more

by Imperial Systems | Jun 14, 2016 | Uncategorized

Dust collection management is one of the main investments that those in the timber industry must face in the near future. In fact, Timber Processing Magazine (www.timberprocessing.com), which conducts research on industry production, supply, and investments, notes that many facilities will need to plan for additional equipment needs above and beyond those they have already planned for.

Areas where facilities may need to plan for investments include:

Complete BRF System Installation

- Loading equipment

- Drying kilns

- Planer mill sorting and packaging

- Forklifts

- Conveyors

- Dust control

Because of the highly combustible nature of wood production dust and OSHA’s increasingly strict regulations on combustible dust collection management, dust collection equipment is one of several investments that companies in this industry may need to consider.

Modernization of equipment is often essential to streamline production and materials handling. According to the surveys conducted by Timber Processing Magazine, almost 75% of facilities rated their return on investments in 2015 as “good” or “excellent.”

Investing in Reliability, Safety

When considering where to put that investment, dust control equipment should definitely be top on the list. Processing more product creates more dust, and nothing can shut your production down faster than a malfunctioning dust collection system or, worse, a fire.

Even if your current dust collection system is handling your dust adequately, equipment such as explosion isolation valves, spark arrestors, and backdraft dampers can be a valuable investment in fire and explosion prevention. Wood processing dust has unique demands on dust collection and fire suppression systems, and an experienced systems engineer should be consulted to ensure equipment is optimized for your particular application.

Good news for the timber industry is also good news for manufacturers who produce dust collection management equipment for this industry. This recent report makes it clear that this industry is alive and well, and that companies are likely to see long-term benefits from investments they make in new equipment.

Read more

by Imperial Systems | Feb 18, 2014 | Uncategorized

When choosing a top industrial dust collection system it’s extremely important to do your research on the product. Not only is purchasing a top industrial dust collection system a large investment, there are many different features, designs, cleaning systems, and technologies that different brands offer.

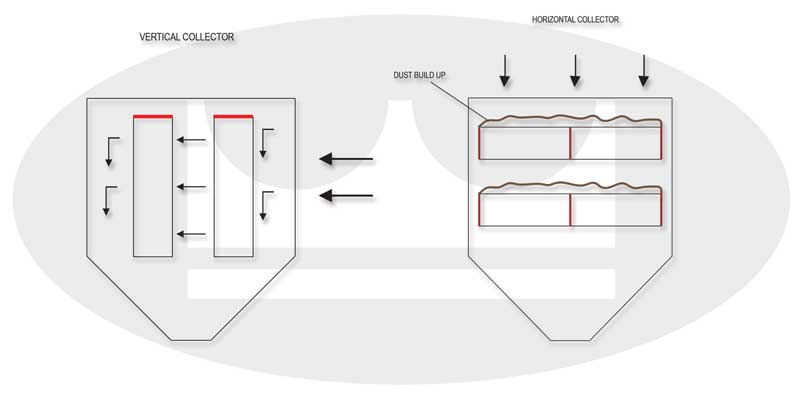

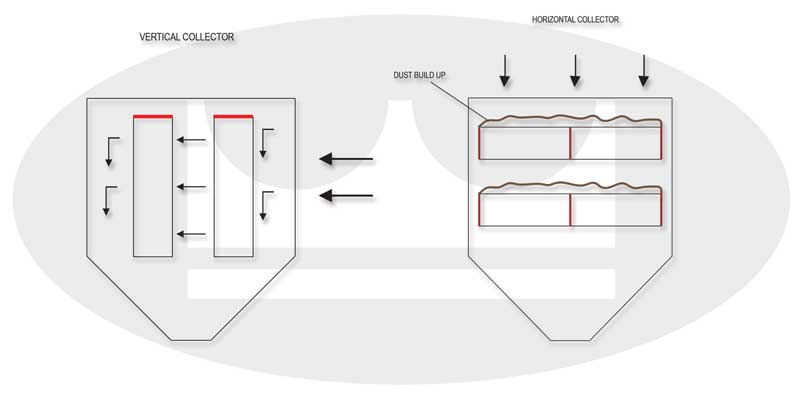

One of the most frequently asked questions among industrial dust collection system purchasers is, “What is the difference between a vertical cartridge collector and a horizontal cartridge collector?”

At Imperial Systems, our preference is the vertical cartridge industrial dust collector design and here are some reasons why:

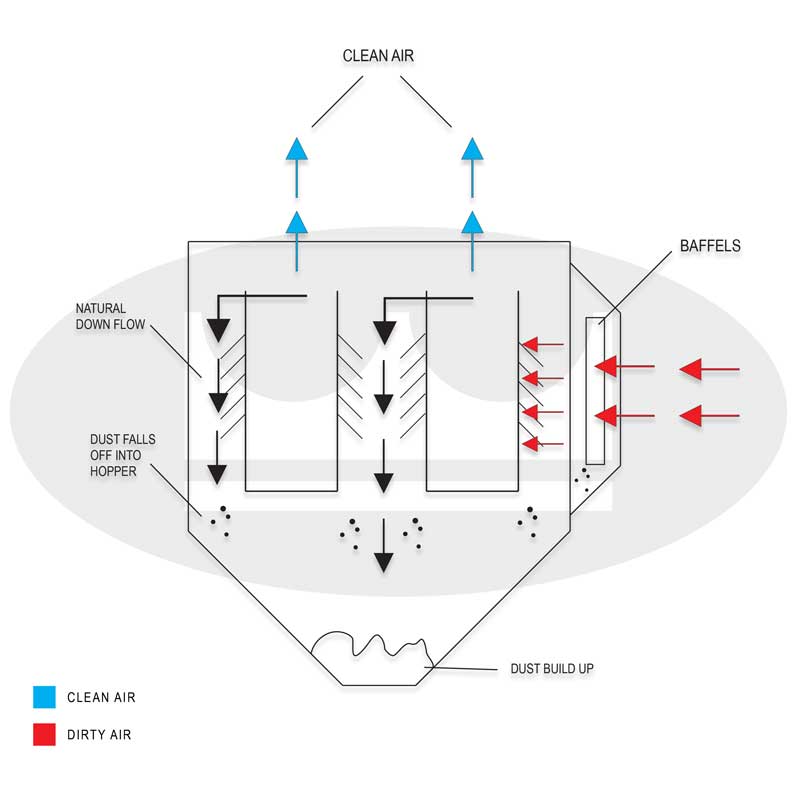

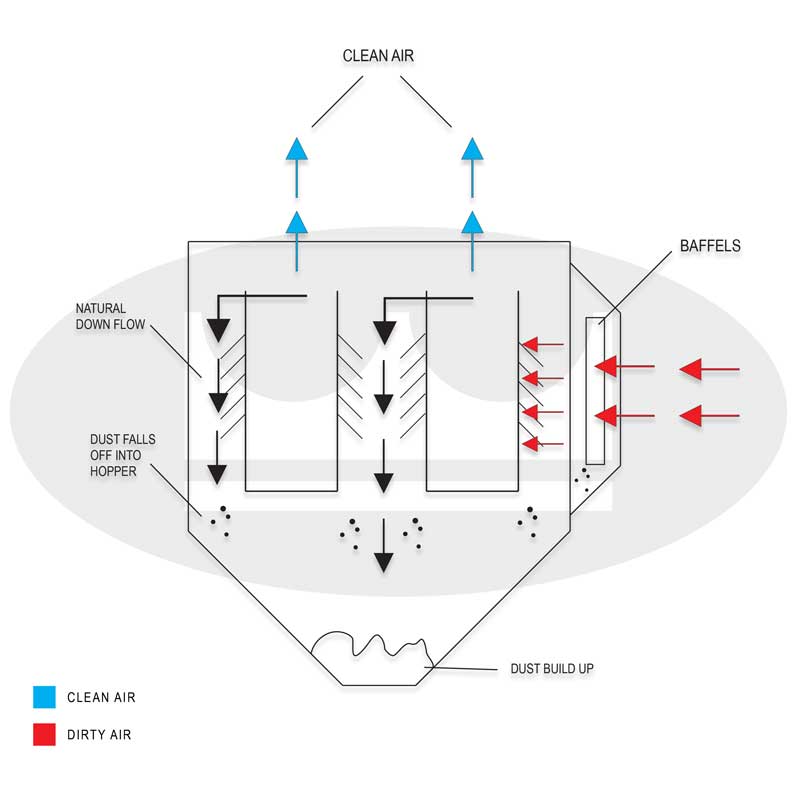

1. Gravity works in your favor

a. Dust and debris falls off of the cartridge filters instead of laying on the cartridge filter’s media.

2. When filter cleaning with pulses of compressed air, dust is blown off and into the hopper instead of on top of the filter below.

3. Natural down-flow with a high entry inlet configuration.

a. This allows for the natural flow of the air aid in, removing dust laden air from the filter chamber.

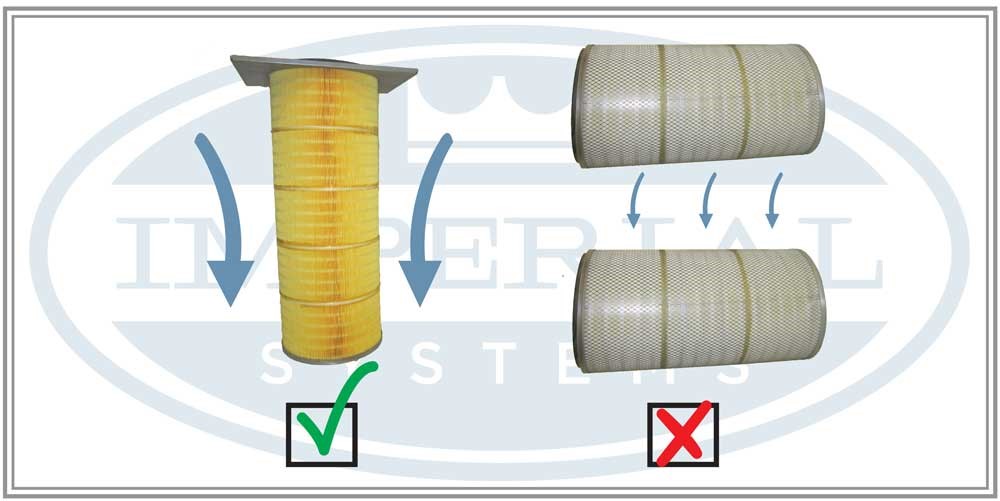

4. No need for rotating dirty filters

a. Vertical dust collector design allows for even cartridge filter loading.

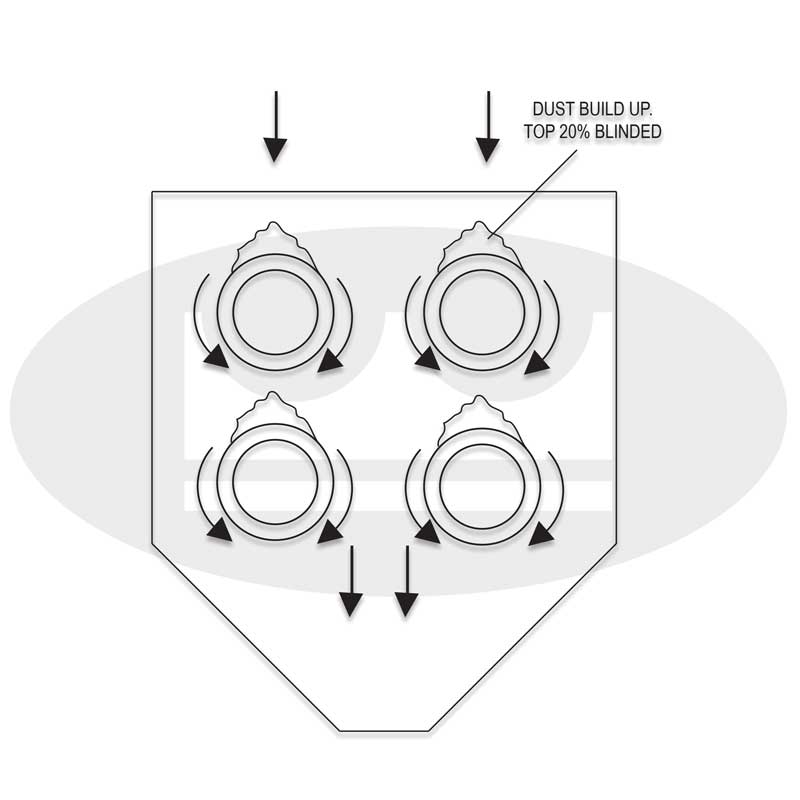

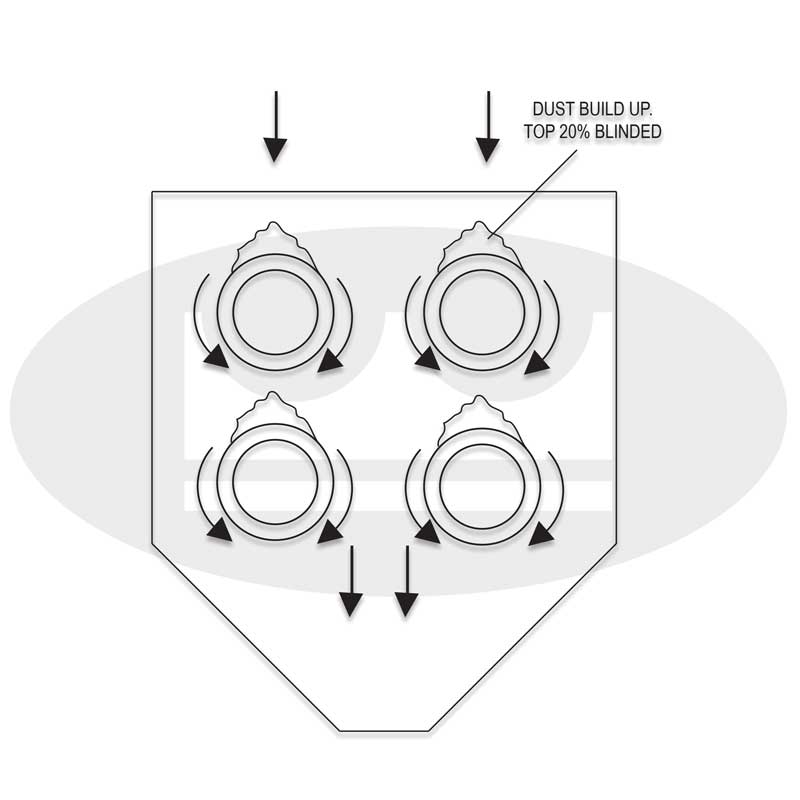

5. Horizontal cartridge filters blind off the top 20% of the filters media from dust laying on top of it.

a. Since gravity is in a vertical cartridges favor, vertical cartridge filters will prevent a build-up of dust while allowing equal filter media distribution for the incoming dust.

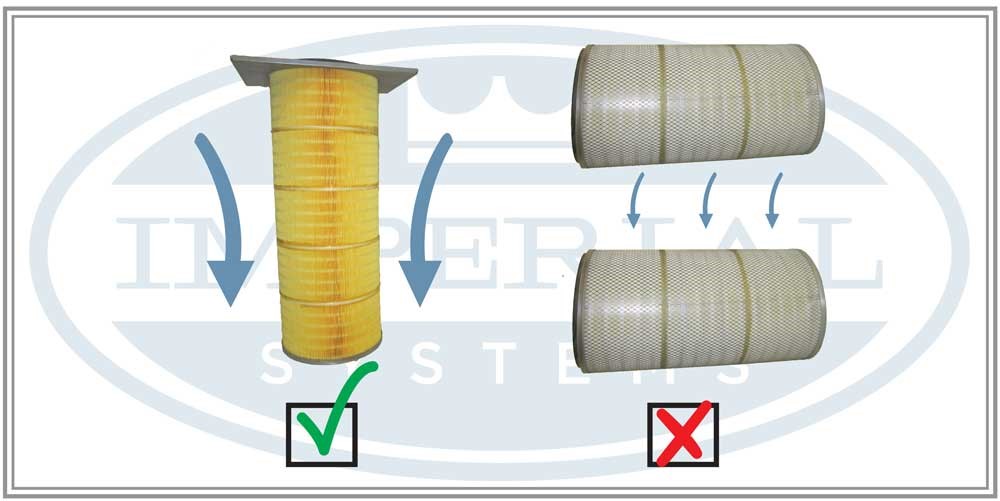

6. Changing filters takes a fraction of the time

6. Changing filters takes a fraction of the time

a. Allows for a much cleaner process as the vertical cartridge filters don’t have to be pulled out to your body.

7. There is only one gasket seal point in a vertical cartridge collector..not two or three.

a. Horizontal cartridge dust collectors have to be seated properly, they have more potential for dust bypass.

Have a horizontal cartridge collector? A vertical cartridge collector may be a better option for your facility. Contact us to learn what the best option is for you.

Read more

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information