by Imperial Systems | Oct 24, 2016 | Uncategorized

Extinguish the Threat of Explosions with a Spark Arrestor

It’s imperative that every metalworking facility have highly efficient dust collection systems. Also, it’s crucial that metalworking facilities utilize a spark arrestor to provide even greater protection from these combustible hazards. Here’s why a Spark Trap safety system by Imperial Systems is the best choice.

We have dedicated over 15 years to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We also continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration. Our company also meets NFPA guidelines with our highly efficient dust collection systems and replacement cartridge filters.

We have dedicated over 15 years to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We also continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration. Our company also meets NFPA guidelines with our highly efficient dust collection systems and replacement cartridge filters.

If you’re asking yourself if a spark arrestor is really necessary, the answer is yes! First of all, consider the findings of OSHA’s National Emphasis Program. It shows that metal dust accounts for 20% of explosions nationwide. Also, 7% of ignition sources are ignited by fabricated metals. Further, another 8% of ignition sources are caused by primary metals. So, if you want to reduce the possibility of an accident at your metalworking facility, you MUST invest in spark arrestors!

How can Spark Trap safety systems reduce explosions?

Adding a spark arrestor to your industrial dust collection system is like adding a security system to your home. That is, you already have the proper amount of protection with locks. But installing a security system in your home provides another line of defense. Above all, it keeps you and your family safe.

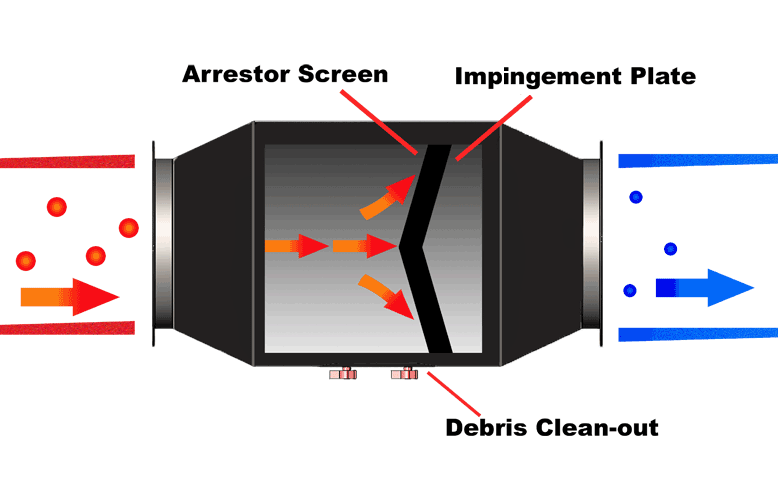

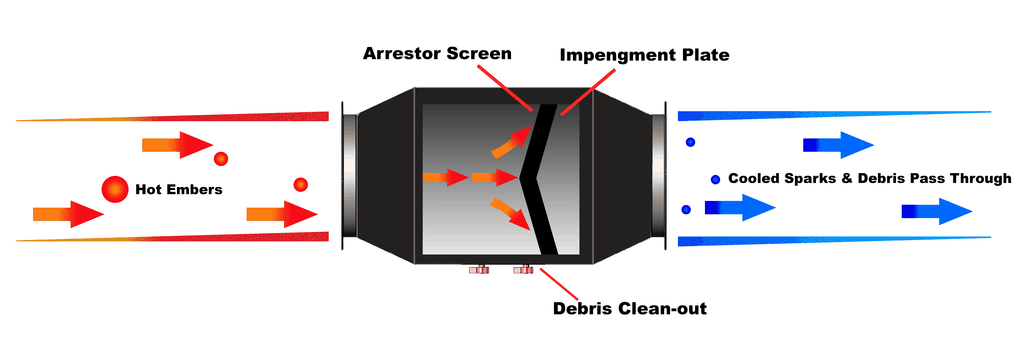

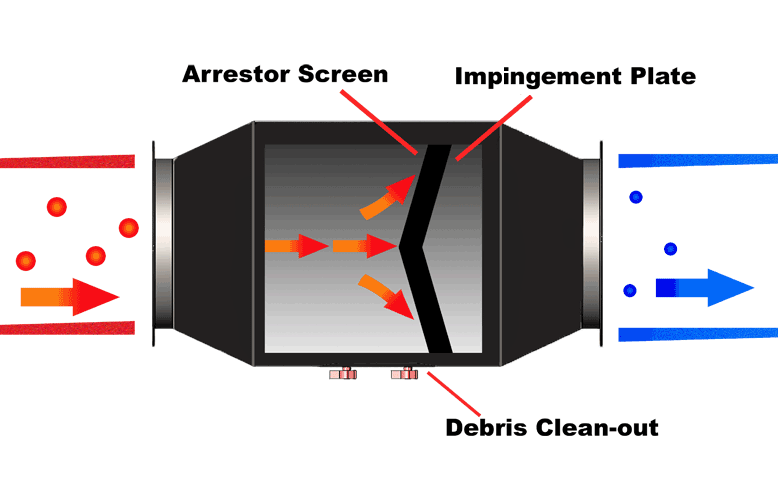

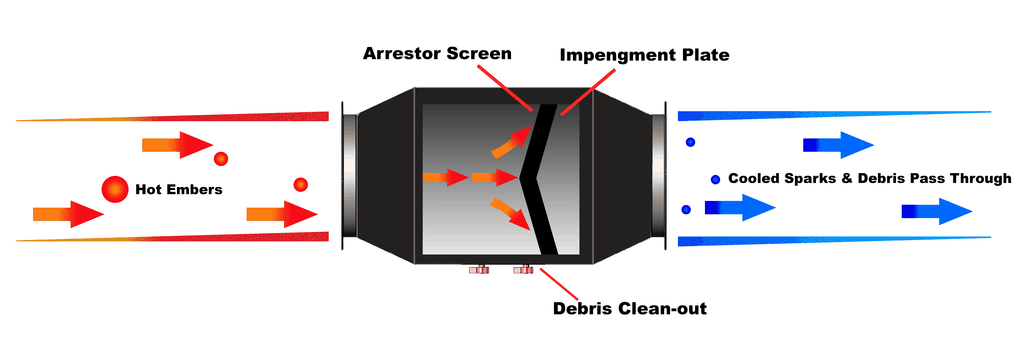

Our spark arrestor, named Spark Trap, is the first line of defense in protecting your metal fabricators and your metalworking facility from explosions. Spark Traps extinguish nearly every spark before it enters the main containment unit where combustible dust and other flammable material collect. When you choose our Spark Traps, you’ll receive a quality product. We make it with heavy-duty materials and it’s highly effective at keeping sparks from entering your industrial dust collector.

Here are some key features you’ll receive when you invest in our Spark Trap safety system:

- Maintenance free components

- Fully welded construction

- Easy install for any system

- No moving parts

- Available in carbon steel or stainless steel

- Can be installed in horizontal or vertical configurations

- Available in 6 to 40 inches

- Clean-out door

- Doesn’t require water

Spark Trap optional features include:

- Raw inlet and outlet edges

- A clamp together function for clamping duct

- Rolled angle flange for bolt-together duct

Want to know more about the Spark Trap? Check out our FAQ sheet to learn all of the benefits of our Spark Trap safety system.

Read more

by Imperial Systems | Oct 17, 2016 | Uncategorized

As of 2016, the Department of Justice (DOJ) and the Department of Labor (which includes OSHA) partnered to bring federal charges against companies who expose workers to dangerous materials and carcinogens. Hazardous fume and dust exposure in the workplace is indeed a serious offense.

Environmental Protection Laws Facilitate Prosecution

This partnership is to enable prosecutors to use powerful environmental protection laws. With these laws, they can prosecute companies for worker safety violations involving exposure to dangerous substances. This will allow prosecutors working on OSHA worker exposure cases to work with the Environmental Crimes Section of the DOJ to maximize penalties and criminal charges.

In many cases, environmental protection laws are stricter and have stronger punishments than OSHA regulations. Environmental protection has wide public support and considerably more funding than occupational health and safety. There is an entire division of the DOJ that handles environmental crimes. More effectively, these crimes may carry a much heavier fine or more serious criminal charges.

OSHA’s ability to level criminal charges is usually limited to certain situations. This is where an employer willfully and knowingly violates safety standards which cause the death of a worker. These cases can be difficult to prove and even more difficult to prosecute. Under laws regulating environmental crimes, releasing or failing to control any workplace hazard exposure to dangerous substances is a crime. This applies even if the exposure does not result in death or serious injury.

Just like with OSHA fines, the most serious criminal charges will go to employers who repeatedly violate the rules or who fail to correct problems even when they know about them. Bringing in the DOJ and their regulation of environmental laws is likely to affect companies who aren’t following the rules for controlling or cleaning up their hazardous materials.

Identifying Hazardous Fume and Dust in the Workplace

Workplace hazard exposure includes materials such as fumes and dust from many types of industrial processes. Some examples are welding, plasma or laser cutting, manufacturing of plastics and resins, printing inks and pigments, as well as production of chemicals or fertilizers.

OSHA usually sets exposure limits for employees. Environmental regulations set limits for material release into the environment, regardless of the exposure to individual employees. Under the DOJ, environmental laws can handle hazardous material release amounts inside a facility.

For metalworking facilities, hexavalent chromium, manganese, and other components of cutting and welding fumes are heavily regulated as environmental toxins. Exposing people to these materials, inside or outside, can be an environmental crime. Hexavalent chromium often contaminates drinking water, and it’s a major environmental concern.

For companies that use or produce hazardous dust or fumes, a dust collection system is very important for limiting exposure. The system will not only keep the materials away from workers but also collects them safely and allows you to dispose of them properly. A dust and fume collection system that’s maintained and used correctly is a necessary tool for controlling hazardous airborne particles or fumes. Contact us for more information.

References:

www.justice.gov

www.justive.gov

www.justice.gov

Read more

by Imperial Systems | Oct 4, 2016 | Uncategorized

How Your Dust Collector Can Pay for Itself

Installing a dust collection system (or updating an old one) is a big investment. Safety, health, and compliance are all important reasons to do so. Will energy cost savings with this investment benefit your company in the long run? When looking at spending that kind of money, it helps to know about a more immediate return on your investment.

The good news is that your new system can pay for itself in as little as two years. That’s by saving you a lot of money on heating and cooling costs.

It’s hard to put a dollar amount on employee health. But it’s easy to put a dollar amount on how much you spend heating and cooling your building. If you’re spending that money and then venting heated air outside the building, you’re effectively blowing money out the window.

Many of our CMAXX systems have paid for themselves within two years just in energy cost savings. And they will continue to save their owners money for many years of service. Some companies have even been able to find energy conservation incentives. These save them money on the immediate cost of a system.

Considerations for Recirculation

Recirculating air back into the facility can be an excellent cost-saving measure. But only if it doesn’t compromise the health of people working there. This means that the recirculated air has to be completely clean and safe.

If you’re planning to recirculate air, be sure to equip your system to handle the type of dust you’re producing. Particles from welding fumes and laser or plasma cutting smoke can be as small as half a micron. This usually requires a filter with a rating of at least MERV 15, meaning it is more than 95% effective for particles down to 0.3 microns. If there might be dangerous or highly regulated materials (such as hexavalent chromium) in the dust, a HEPA filter may be necessary for air that’s going to be returned inside.

Besides the savings on energy costs, a system that recirculates air can actually be more efficient. In some ambient systems, the clean air enters at the level where people are working. This moves the dirty air out of the work area and toward the collector. These types of systems are very effective at filtering the air in larger spaces.

Payback Through Energy Cost Savings

If a dust and fume collector is something you’re going to need anyway, the tremendous savings in your energy cost might be what it takes to get that project into the budget. After all, those heating and cooling cost savings will go back into the budget year after year, and that’s something everyone likes to hear.

Read more

by Imperial Systems | Sep 6, 2016 | Uncategorized

Weld Smoke and Fume Dangers

Weld smoke is a direct cause of Pneumosiderosis, also known as welder’s lung. Inhaling iron dust or fumes, usually from welding, is a serious health issue. While it’s one of the most common occupational lung diseases of welders, it’s not the only one. Welders are also at risk of chronic bronchitis and cancer. Fortunately, a properly designed dust and fume collector, like our CMAXX™, can prevent these problems.

A case study from the publication Cases Journal gives an example of how welder’s lung can occur. It follows the case of a 64-year-old man who went to his doctor with a cough. He had worked as a welder in an automobile factory for 15 years, welding steel frames. The work area was small and enclosed, without a proper dust collection system to remove weld smoke and fumes.

The man’s doctor found that his lung X-ray was abnormal. Tests showed that his lungs contained many white blood cells full of iron. White blood cells remove things from your lungs that don’t belong there, but large amounts of inhaled iron are too much for them to handle. This buildup of iron causes coughing, shortness of breath, and eventually chronic lung disease.

They advised the man to stop working as a welder. His doctor treated him for his symptoms, and after some time his lung function returned to normal. However, he remains at an increased risk of lung cancer as a result of his long exposure to hexavalent chromium present in the steel.

Along with welder’s lung, inhaled welding dust or fumes also causes an increased risk of cancer. Hexavalent chromium, found in the steel the man in the case study worked on, is a known carcinogen. Welding, in general, increases cancer risk.

How Do You Prevent These Risks?

Because the fumes and smoke from welding contain iron and other metals in very, very small particles, inhalation deep into the lungs is easy. Because these particles are so small, our DeltaMAXX™ nanofiber filters are efficient at removing dust as small as .3 microns, making them an excellent choice for welding and other metalworking applications.

While pneumosiderosis most often affects welders because they are usually very close to the materials they’re working with, the same problem can affect people who are exposed to fumes from laser or plasma cutting. Dust from these applications also may contain hexavalent chromium and other health hazards. Our CMAXX™ system for cutting tables can remove fumes from the air before employees are exposed to them.

The most basic way to prevent welder’s lung is to remove weld smoke and fumes from the air that welders are breathing. A dust and fume collection system like the CMAXX™ can be designed to capture fumes from individual welding stations or from the ambient air. Our systems work with you to keep welders safe and healthy. Learn more about welding fumes and cancer.

References:

www.casesjournal.biomedcentral.com

www.oem.bmj.com

www.onlinelibrary.wiley.com

www.sjweh.fi

Read more

by Imperial Systems | Jul 26, 2016 | Uncategorized

Dust explosions are bad to begin with, but what do you know about secondary explosions? There are many factors that determine how likely a particular type of dust causes deflagration. When you think of combustible dust, do you think of the explosions you’ve heard about at grain handling facilities? Maybe you think of the explosive potential of aluminum dust.

Secondary Dust Explosion Incidents

Three dust explosions occurred in 2003. They demonstrate how many different types of production and manufacturing can produce a deflagration risk, including a secondary dust explosion. In a North Carolina plant, the application of a polyethylene coating to rubber caused accumulation of the dust. As the material dried, dust formed and accumulated above the work area. The work area was clean. But a layer of dust 1/4″ thick was enough to cause an explosion that killed six people. In this situation, a dust collection system in the production area could have captured the dust particles before they circulated through the facility.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

Aluminum dust from scrap processing fueled the explosion in Indiana. The dust collector in this case was the source of the explosion. It did not have explosion vent panels, and instead of being directed safely, the explosion traveled back into the building and ignited dust in the ductwork. A secondary explosion occurred when dust accumulated on surfaces inside the facility ignited. A dust collector designed to isolate and redirect a deflagration could have prevented this accident.

NFPA Recommendations

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

It’s often this accumulated dust, hidden on high surfaces, in corners, or inside ductwork, that ignites to cause a secondary explosion that’s far more dangerous than the original one. Witness reports of dust explosions often include descriptions of a smaller explosion followed by one or more larger ones; this is secondary ignition. Dust control throughout the facility, along with fire prevention equipment such as abort gates, spark arrestors, and explosion venting, can control a potential explosion and prevent a small fire from becoming a fatal disaster.

Read more

We have dedicated over 15 years to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We also continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration. Our company also meets NFPA guidelines with our highly efficient dust collection systems and replacement cartridge filters.

We have dedicated over 15 years to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We also continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration. Our company also meets NFPA guidelines with our highly efficient dust collection systems and replacement cartridge filters.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An