by Scott Stearns | Sep 13, 2018 | Uncategorized

By now, if you deal with combustible dust in your facility, you have probably heard about NFPA 652, the new Standard on the Fundamentals of Combustible Dust. According to this new standard, your company must have completed a Dust Hazard Analysis by October 2018. OSHA inspectors making overall safety checks can ask for a company to present its DHA and may fine any company that hasn’t conducted one if the dust is a safety hazard.

How do you know if NFPA 652 applies to you and if you need to conduct a dust hazard analysis?

This standard applies to both new installations and existing facilities, so if your process produces dust of any type, it might apply to you. The first step is to conduct safety testing on your dust or particulate if you haven’t already. Because NFPA 652 is a combustible dust standard, the first step is to have a dust test performed. This will give you key information about whether your dust is combustible, how dangerous it is, and what steps you may have to take to address it.

A dust hazard analysis is a review process that looks at each part of the facility’s processes and evaluates any fire, deflagration, or explosion hazards that are present anywhere in the facility as the result of combustible dust. By this standard, it is not good enough to be able to show that you had your dust tested and that you have a dust collection system in place. The entire hazard analysis must be documented. This includes checking for the following hazards and documenting them completely:

- Is the dust in this process or area combustible?

- Is there dust accumulation in any part of the area?

- At any point in this process, is the dust airborne or in a cloud (where it is easier to ignite)?

- Are there any ignition sources that could ignite the dust?

- Is there enough dust present during the process to allow a deflagration?

Once all these factors have been assessed, the dust hazard analysis needs to answer some very important questions about what’s being done currently and what needs to change in managing the hazards.

- What hazard management is in place right now to deal with the combustible dust hazard in each area or process?

- Does the current hazard management address all the issues that the hazard analysis uncovered?

- If current hazard management isn’t enough or doesn’t cover everything, what steps need to be taken to improve it?

Keep in mind that this is necessary for each area or process in your facility, even if you have one centrally located dust collection system. For example, if your metalworking facility has plasma cutting, welding, and grinding or other fabrication processes, the DHA has to assess the hazards for each one. The weld fumes present a different type of risk than the dust from grinding, for example, and some processes produce a fine airborne fume instead of a heavy accumulating dust.

It’s possible that your DHA will find that you have your combustible dust and fume hazards under good control. If that’s the case, conducting the DHA will give you a full hazard report that meets NFPA 652 standards and that you can present to an OSHA inspector.

If your DHA identifies hazards that still need to be addressed, it’s still very important that you’ve done your work, documented all the combustible dust hazards, and are taking steps to fix problems. Contacting a dust and fume collection professional like Imperial Systems will help you identify your options. We can help you make sure that every area of your facility passes the dust hazard analysis.

NFPA 652 is the organization’s new attempt to prevent combustible dust damage, injury, and death in the workplace. A dust hazard analysis may take time and require good documentation, but it might help you catch a potentially dangerous problem. Take the time to conduct a dust hazard analysis, or have professionals come in and assist you. Address problems if you find them, and you’ll have a safer and healthier workplace.

Download our Dust Testing Sheet and call our team to have your dust tested for a KST value.

Read more

by Scott Stearns | Jul 20, 2018 | Uncategorized

A fire or an explosion can destroy expensive equipment, damage, or even wreck your building. It can certainly cause injury or death to workers. Dust and fume collection systems are often collecting some type of combustible material. So, these systems often require fire or explosion control systems as well as other types of safety systems.

Difference Between Fire and Explosion Control

It’s important to understand how a fire and an explosion are different. Fire is caused is when a substance rapidly consumes oxygen to produce heat and light. An explosion is an event where energy rapidly expands outward from the source, often creating a damaging shock wave. A fire may not cause an explosion, and explosions can happen without fire. For example, logs in a fireplace can slowly burn for a long time, producing flames and heat. Also, a pressurized tank of gas can explode if the material inside expands.

Is Combustible Dust Flammable or Explosive?

The answer is often both, depending on the conditions. If you try to light a block of metal on fire, not enough of the titanium is exposed to the air to start a fire. However, if you grind up that metal or turn it into gas with a welder, those tiny particles are exposed to plenty of air, and if there is an ignition source, they can catch on fire. Some metals, like titanium, burn so hot that once they are ignited, they can actually use water to burn even more, so using water to put them out just makes it worse.

Another example is sugar. Most of us use sugar all the time without realizing that it’s even flammable. However, an airborne cloud of sugar can combine with oxygen so quickly that it causes a violent explosion. Many other materials behave like sugar: once they become airborne, they can cause dangerous explosions because a fire can ignite the material so quickly.

A dust collector can be a perfect environment for a fire or explosion. Lots of dust inside an enclosed space can be very dangerous if it starts to burn, and it can be explosive. So how do you protect your dust collection system from fire or explosions?

Dust Fire and Explosion Control Devices

Spark detectors, spark trap, and abort gates can all act as fire prevention devices. One common choice for fire prevention is a spark detector. A spark detector will sense a spark before it gets into the dust collector, and it can activate other devices.

The spark detector might activate an abort gate. This will drop and deflect any sparks, fire, or smoke away from the facility and divert it safely. A spark trap installed in the ductwork and purposefully creates turbulence in the airflow. This knocks a spark around until it loses so much heat that it can’t start a fire.

These are devices that protect you and your facility from a fire. There are also chemical suppression systems that can be activated by the spark detector and extinguish a spark before it can start a fire. These systems can also put out a fire once it has started to keep it from spreading and prevent damage.

An in-line deflagration arrestor (IDA) is a type of system design. It protects your facility from explosions by stopping a flame front and preventing it from traveling back into the facility. IDA dust collectors include special filters that help extinguish a flame front and prevent it from going any further.

Explosion isolation valves are triggered by pressure to close off and prevent the explosion from traveling any further. A fast-acting slide gate can also be triggered to contain the explosion inside the dust collector. Once an explosion has occurred, there’s one, primary safety concern. That’s preventing it from getting back into the building or from causing damage or injury.

Devices like explosion vent panels or flameless explosion venting do not prevent explosions. But they do vent the explosion safely if one does occur.

Let’s Figure It Out

Sometimes a dust collector upgrade makes the most sense to protect a facility from fire damage. Contact us here at Imperial Systems to help determine your best options.

Read more

by Scott Stearns | Jul 18, 2018 | Uncategorized

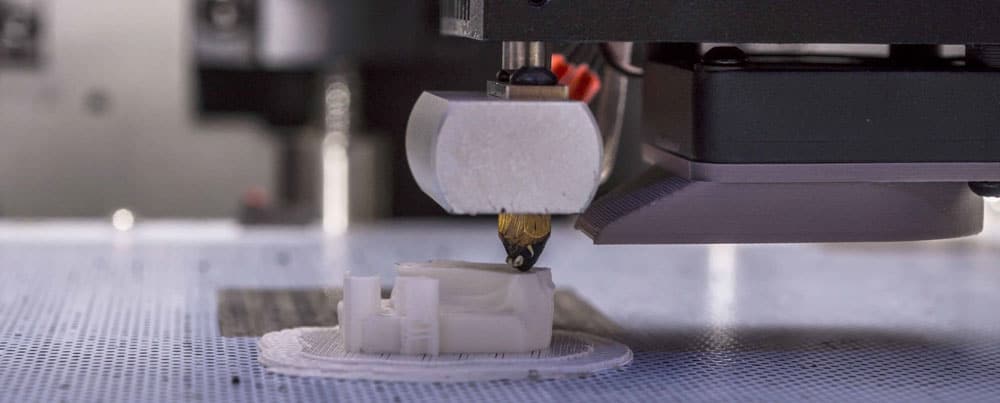

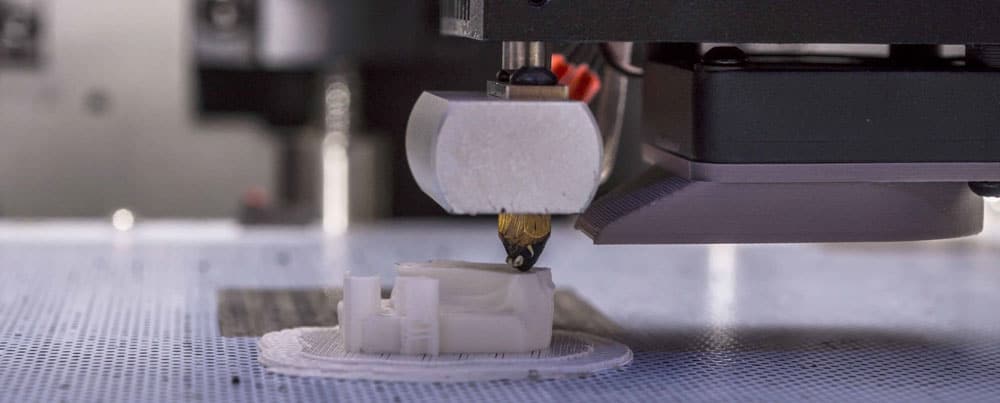

With the exploding popularity of 3D printing, it’s inevitable that combustible dust hazards would become part of the process. After all, 3D printing uses materials from plastics and nylon to aluminum and titanium. Almost all of them are combustible and can form explosive airborne dust around the work area.

3D printing is also called additive manufacturing, and it works by fusing layers and layers of extremely fine dust to create the final shape. When using metals, plastics, or ceramics, the layers are often fused by a laser that has the precision to carry out computer-guided designs.

The term “additive manufacturing” is most often found in applications like metalworking, where it is used as an opposite of manufacturing that involves removal of material, like cutting or grinding. 3D printing is a much broader term and can apply to a wide variety of processes.

If the combination of combustible dusts and high-powered ignition sources doesn’t sound like an explosion hazard, consider the fact that this is still a new technology, and many dust collection systems on the market aren’t equipped to handle this kind of hazard. OSHA has already cited at least one company for an explosion that occurred when combustible aluminum and titanium metal powers from their 3D printing process ignited, causing serious injuries.

Besides the risks of a combustible dust explosion, the extremely fine powders needed for 3D printing or additive manufacturing are often hazardous to human health. In other blog posts we’ve discussed the health risks of inhaling these particles, which can be as fine as welding fume dust. With the materials being fused by lasers or other high-heat techniques, harmful particulates are being released into the air along with the dust from the manufacturing process.

These harmful particles can include plastic particles, known toxins like hexavalent chromium, or even byproducts of high-tech aircraft alloys like beryllium. Many of them are health hazards and almost all of them are explosive if the conditions are right. Additive manufacturing or 3D printing often creates perfect conditions for a combustible dust explosion.

How do you mitigate the risk of combustible dust in your 3D printing operation? Proper dust collection will remove all excess dusk from the work area, preventing an explosive situation from occurring. With the CMAXX dust and fume collector, the most efficient filtration and best explosion protection are on your side to make sure your 3D printing areas, expensive pieces of equipment, and workers all stay safe.

Imperial Systems is ahead of the game in designing custom solutions for 3D printing and additive manufacturing applications. If you’re looking for a solution for the combustible dust problem that your application creates, contact the company that’s already designing systems to handle exactly these kinds of problems.

With the best design and quality on the market along with unbeatable fire and explosion protection options, the Imperial Systems CMAXX is the solution 3D printers need to keep their process efficient and safe. High efficiency filters allow for the capture and reuse of expensive powders and keep your work area clean of combustible dust. They also keep your air clear of dangerous byproducts and toxic substances your process might use or produce.

Read our white paper on combustible dust.

http://www.ehstoday.com/industrial-hygiene/additive-manufacturing-and-combustible-dust-hazards-3d-printing

https://www.osha.gov/news/newsreleases/region1/05202014

Read more

by Imperial Systems | May 2, 2018 | Uncategorized

1. What information do we need to start designing a system and what are the considerations for ductwork?

- First, you need to know about your dust. Important details: how it’s being generated, how toxic or hazardous it is, what exposure levels OSHA considers to be too high, whether it is combustible and/or explosive, particulate size, physical characteristics.

- Combustible dust will certainly require special precautions in the system design to protect the facility and workers from deflagration or explosion. Dust testing can determine how explosive dust is and the needed precautions.

- A general layout of the facility and each location generating dust.

- A sketch of the ductwork layout, including the location of the dust collector, fans, and ductwork branches.

- A plan for the type of hood to use at each of the dust capture locations. Also, how much CFM each one will require.

2. What are the basic components of a dust collection system?

- Hoods: must be the correct design for each type of machine. They must also be efficient at removing the produced dust by that machine.

- Ducts: must be the correct size to allow proper airflow and keep air moving. They also must not have too many bends or elbows to slow down the airflow. This can allow particulates to drop out of the airflow. It can also create a point for wear and tear on the ductwork.

- Fan: the fan must be powerful enough to keep air moving through all the ductwork at a high enough velocity. Drops in velocity or not enough velocity can allow dust to fall out of the air stream.

- Collector: must be the correct size for the system. It must have an air-to-cloth ratio that makes it able to filter all the air coming into the collector. Must have correct filter material to handle the size and type of particulate. This could be DeltaMAXX nanofiber for most applications, or spunbond, PTFE, or other specialized filters for particular applications. Further, filters must be fire-retardant if the dust is flammable.

- Fire Prevention: devices such as spark arrestors can help keep sparks from entering the dust collector. A water or chemical fire suppression system can extinguish sparks or flame when a sensor detects them.

- Venting/Exhaust: If returning air to the building, it must be clean enough to meet all health and safety standards. If dust is toxic, it may necessitate an extra layer of safety in the form of HEPA filters. A backdraft damper can prevent backdrafts from allowing dust back into the system. An abort gate with spark detector can sense a spark or flame, diverting the flame in a safe direction.

3. What is the process for designing a ductwork system?

- System design should start with identifying each place that a hood or other source capture point needs to go. In other words, anywhere that generates dust.

- Use appropriate calculations to figure out how much CFM you need at each of these points

- Determine the minimum duct velocity. This is based on the transport velocity (the airflow needed to keep your particular dust moving in the air stream).

- Calculate the size of duct for each branch. This is based on the CFM and the transport velocity and will be different for different spots along the ductwork.

- Increase duct velocity at each branch to maintain transport velocity until all branches are connected to the main duct.

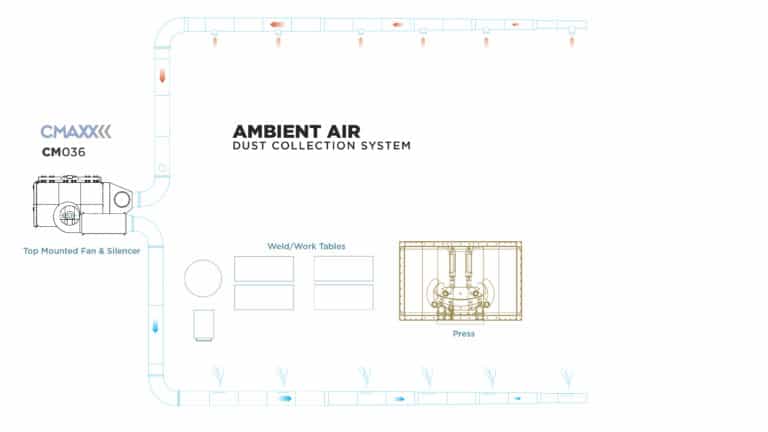

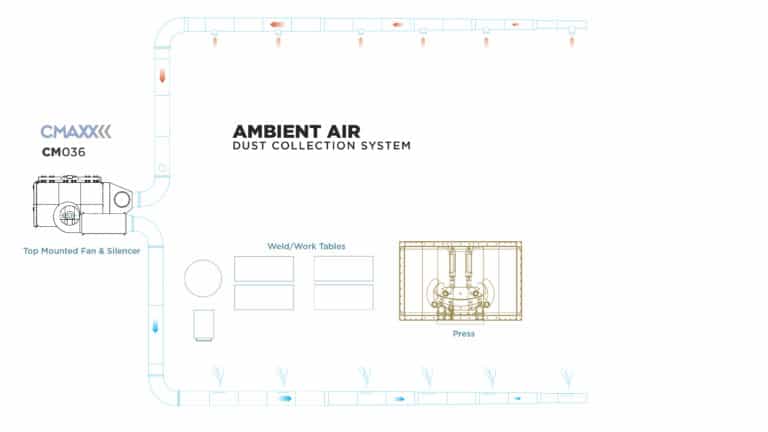

4. Will this be an ambient system or source capture system?

- Ambient system: removes air from the entire work area. It filters and recirculates it back into the area, diluting contaminated air with clean air.

- Air changes per hour: the number of times per hour that the total amount of air in the area changes. This is from old/contaminated air to new/clean. The calculation is made with the cubic volume of the work area and the number of required air changes to maintain air quality.

- Source capture/close capture: captures generated dust at each point throughout the facility.

- This type of system must have properly designed hoods at every capture point. Perform and double-check your airflow calculations. Specialty hoods can be designed for almost any application.

- Static pressure in these systems is an algebraic formula. It includes a loss at hoods, flex ducts, transitions, and straight ductwork runs. Minimal use of elbows and flex ducts in the ductwork runs will greatly improve system efficiency.

- For dangerous or toxic dust where exposure must be kept to an absolute minimum, a close capture system will keep the material from entering the air of the general workplace.

We hope this set of articles about ductwork help to answer some of your questions. Please thank the knowledgeable and experienced Charlie Miller for providing so much valuable information and sharing his wisdom.

Read more

by Imperial Systems | Jul 26, 2016 | Uncategorized

Dust explosions are bad to begin with, but what do you know about secondary explosions? There are many factors that determine how likely a particular type of dust causes deflagration. When you think of combustible dust, do you think of the explosions you’ve heard about at grain handling facilities? Maybe you think of the explosive potential of aluminum dust.

Secondary Dust Explosion Incidents

Three dust explosions occurred in 2003. They demonstrate how many different types of production and manufacturing can produce a deflagration risk, including a secondary dust explosion. In a North Carolina plant, the application of a polyethylene coating to rubber caused accumulation of the dust. As the material dried, dust formed and accumulated above the work area. The work area was clean. But a layer of dust 1/4″ thick was enough to cause an explosion that killed six people. In this situation, a dust collection system in the production area could have captured the dust particles before they circulated through the facility.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

Aluminum dust from scrap processing fueled the explosion in Indiana. The dust collector in this case was the source of the explosion. It did not have explosion vent panels, and instead of being directed safely, the explosion traveled back into the building and ignited dust in the ductwork. A secondary explosion occurred when dust accumulated on surfaces inside the facility ignited. A dust collector designed to isolate and redirect a deflagration could have prevented this accident.

NFPA Recommendations

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

It’s often this accumulated dust, hidden on high surfaces, in corners, or inside ductwork, that ignites to cause a secondary explosion that’s far more dangerous than the original one. Witness reports of dust explosions often include descriptions of a smaller explosion followed by one or more larger ones; this is secondary ignition. Dust control throughout the facility, along with fire prevention equipment such as abort gates, spark arrestors, and explosion venting, can control a potential explosion and prevent a small fire from becoming a fatal disaster.

Read more

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An