![Occupational Lung Diseases From Dust & Fumes [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2018/08/health-risk-infographic1-1080x675.jpg)

by Scott Stearns | Aug 14, 2018 | Uncategorized

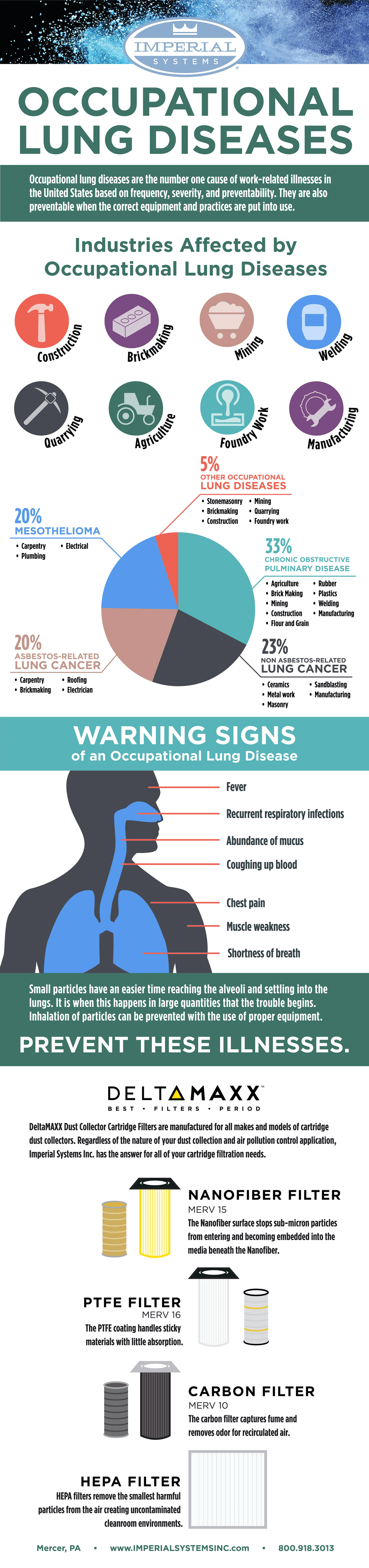

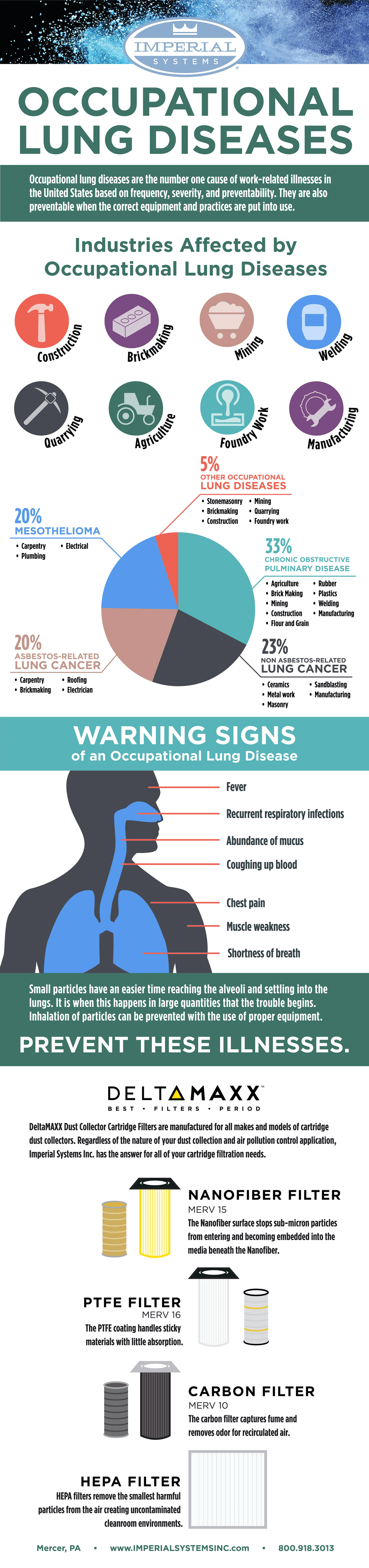

Industries Affected by Occupational Lung Diseases

There are many trades and business operations associated with respiratory illnesses. For example, construction workers are a high-risk group for occupational lung diseases, a study by the National Library of Medicine concluded. There is exposure to high concentrations of dusts in closed spaces and they breathe high levels of crystalline silica. Inhaling free crystalline silica causes a lung disease named Silicosis. Processes like brickmaking, quarrying, and foundry work for making building materials are also high risk to workers. Lung function impairment is the most common respiratory problem among workers with exposure to dusts.

Occupational lung diseases also affect the mining, agriculture, and manufacturing industries. Johns Hopkins Medicine reports that crystalline silica is found in the air of mines, foundries, blasting operations, and stone, clay, and glass manufacturing facilities. Further, people at higher risk for occupational asthma often work in manufacturing and processing operations, farming, animal care, food processing, cotton and textile industries, and refining operations.

Warning Signs and Best Prevention

Common symptoms include fever, recurrent respiratory infections, an abundance of mucus, coughing up blood, chest pain, muscle weakness, and shortness of breath. However, occupational lung diseases can be prevented. Avoiding the inhalation of dust and fumes that cause lung diseases is the best thing you can do. Small particles have an easier time reaching the alveoli and settling into the lungs. Trouble begins when this happens in large quantities.

The infographic below illustrates the lung diseases found in various industries and denotes their warning signs in the body. It also presents how an Imperial Systems CMAXX dust and fume collector with DeltaMAXX filters can help save your life.

Contact Imperial Systems today for a review of your dust and fume collection challenges. We will design a system to help keep your employees safe from occupational lung diseases.

Read more

by Imperial Systems | Nov 8, 2016 | Uncategorized

Your dust and fume collector can save you money on heating this winter. But to make the most of those savings, your system might need some winter maintenance. It’s that time of year when your dust collector system needs a little attention to make sure it’s ready for the demands of colder weather.

Winter Maintenance Checklist

Replace Those Filters

Winter maintenance means starting the new year with clean new filters… and you’re not going to want to change them in the middle of a snowstorm.

Changing the Magnahelic Gauge Filter

It’s easy to forget about this little filter, but it’s necessary to keep the gauge readings accurate. You should replace it whenever you replace your other filters.

Check for Accumulated Dust

If you’ve been working with the doors open during the warmer months and not running the dust collector as much, you might have dust accumulated, especially in high places or flat surfaces. For safety, try to remove as much of it as possible.

Check Airlock Wipers and Bearings

Usually, you should change airlock wipers once a year. Worn-out wipers don’t do their job properly. Winter maintenance is a good time to check them. When you replace wipers, you should also plan to replace the bearings.

Check Heaters on Pulse Valves

If you’re in a cold area and your pulse valves have heaters to keep them from freezing up, make sure they’re working. Frozen pulse valves are an inconvenience nobody needs to deal with in frigid weather.

Check Solenoid and Diaphragm Valves

Again, these are not things you want to have broken in the middle of nasty cold weather. A quick check and some preventative maintenance if necessary can save you a headache later during winter.

Check Compressed Air Hoses

Cold can make hoses more brittle and likely to break. If your compressed air hoses have any weak spots or look worn or damaged, now is a good time to make sure they get fixed or replaced.

Check Seals and Gaskets

As with the hoses, cold can make seals and gaskets crack or develop leaks. If needed, replacing them before the weather gets cold can save you from dealing with downtime from an unexpected leak.

Calibrate Differential Pressure Gauge

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

Check Your Dust Collector Roof

If you’re a CMAXX owner, lucky you! Your domed CrownTech roof will keep snow or ice from piling up on top of the collector. If you don’t have a CMAXX, make sure you keep an eye on the amount of snow or ice buildup, since that can cause leaks into the collector.

Read more

by Imperial Systems | Sep 6, 2016 | Uncategorized

Weld Smoke and Fume Dangers

Weld smoke is a direct cause of Pneumosiderosis, also known as welder’s lung. Inhaling iron dust or fumes, usually from welding, is a serious health issue. While it’s one of the most common occupational lung diseases of welders, it’s not the only one. Welders are also at risk of chronic bronchitis and cancer. Fortunately, a properly designed dust and fume collector, like our CMAXX™, can prevent these problems.

A case study from the publication Cases Journal gives an example of how welder’s lung can occur. It follows the case of a 64-year-old man who went to his doctor with a cough. He had worked as a welder in an automobile factory for 15 years, welding steel frames. The work area was small and enclosed, without a proper dust collection system to remove weld smoke and fumes.

The man’s doctor found that his lung X-ray was abnormal. Tests showed that his lungs contained many white blood cells full of iron. White blood cells remove things from your lungs that don’t belong there, but large amounts of inhaled iron are too much for them to handle. This buildup of iron causes coughing, shortness of breath, and eventually chronic lung disease.

They advised the man to stop working as a welder. His doctor treated him for his symptoms, and after some time his lung function returned to normal. However, he remains at an increased risk of lung cancer as a result of his long exposure to hexavalent chromium present in the steel.

Along with welder’s lung, inhaled welding dust or fumes also causes an increased risk of cancer. Hexavalent chromium, found in the steel the man in the case study worked on, is a known carcinogen. Welding, in general, increases cancer risk.

How Do You Prevent These Risks?

Because the fumes and smoke from welding contain iron and other metals in very, very small particles, inhalation deep into the lungs is easy. Because these particles are so small, our DeltaMAXX™ nanofiber filters are efficient at removing dust as small as .3 microns, making them an excellent choice for welding and other metalworking applications.

While pneumosiderosis most often affects welders because they are usually very close to the materials they’re working with, the same problem can affect people who are exposed to fumes from laser or plasma cutting. Dust from these applications also may contain hexavalent chromium and other health hazards. Our CMAXX™ system for cutting tables can remove fumes from the air before employees are exposed to them.

The most basic way to prevent welder’s lung is to remove weld smoke and fumes from the air that welders are breathing. A dust and fume collection system like the CMAXX™ can be designed to capture fumes from individual welding stations or from the ambient air. Our systems work with you to keep welders safe and healthy. Learn more about welding fumes and cancer.

References:

www.casesjournal.biomedcentral.com

www.oem.bmj.com

www.onlinelibrary.wiley.com

www.sjweh.fi

Read more

by Imperial Systems | Aug 2, 2016 | Uncategorized

Whether you are a new manufacturing business or just branching out into new territory, if you are going to get into the metalworking field, addressing industrial dust control solutions demand some serious consideration. Not only do you have the safety of your work space to think about, but unchecked dust and fumes can also pose health hazards to those working in it. We’ve spent nearly 15 years considering the challenges of industrial dust accumulation and control, and we have developed the solutions our customers need. Discover the facts you need about dust control for your business so things run safely and smoothly.

Meet Safety Standards

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update HERE. When you look for an industrial dust control system, begin by ensuring that it meets these and other industry standards.

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update HERE. When you look for an industrial dust control system, begin by ensuring that it meets these and other industry standards.

Anticipate Dust And Fumes

As you consider a system to provide dust control for your workspace, make sure you take fumes into account as well. In many metalworking processes, noxious fumes are created which are more than unpleasant; they can be increasingly harmful when inhaled. Not all industrial dust control systems are created to handle this dual threat, so it is vital to choose a collector that can manage both dust and fume generated by metalwork manufacturing.

Your Industrial Dust Control Solutions Experts

Whether you need dust and fume filtration or just a dust collection system, Imperial Systems is your industrial dust control headquarters. We manufacture the most efficient, strongest, and longest-lasting systems and filters in the industry. Through these products, we have become well-known for our dedication to quality, value, and safety. Our outstanding line of equipment includes:

- CMAXX™ Dust Collector System

- DeltaMAXX™ Cartridge Filters

- CMAXX™ Laser Fume Extraction System

- Spark Arrestor

- Explosion Isolation Valve

- Custom Ductwork & Fittings

- Heavy Duty Abort Gates

- and more!

Most of our products are available to ship within 24 hours. For more information about our products and how we can support your metalworking business, contact us today.

Read more

by Imperial Systems | Jul 26, 2016 | Uncategorized

Dust explosions are bad to begin with, but what do you know about secondary explosions? There are many factors that determine how likely a particular type of dust causes deflagration. When you think of combustible dust, do you think of the explosions you’ve heard about at grain handling facilities? Maybe you think of the explosive potential of aluminum dust.

Secondary Dust Explosion Incidents

Three dust explosions occurred in 2003. They demonstrate how many different types of production and manufacturing can produce a deflagration risk, including a secondary dust explosion. In a North Carolina plant, the application of a polyethylene coating to rubber caused accumulation of the dust. As the material dried, dust formed and accumulated above the work area. The work area was clean. But a layer of dust 1/4″ thick was enough to cause an explosion that killed six people. In this situation, a dust collection system in the production area could have captured the dust particles before they circulated through the facility.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An abort gate with spark or flame detection could have identified and stopped the fire from spreading, and dust collectors designed to stop deflagration fronts could have prevented the dust collectors from becoming sites of secondary explosions.

Aluminum dust from scrap processing fueled the explosion in Indiana. The dust collector in this case was the source of the explosion. It did not have explosion vent panels, and instead of being directed safely, the explosion traveled back into the building and ignited dust in the ductwork. A secondary explosion occurred when dust accumulated on surfaces inside the facility ignited. A dust collector designed to isolate and redirect a deflagration could have prevented this accident.

NFPA Recommendations

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

The National Fire Protection Association, which establishes many of the codes and standards for handling potential fire hazards recommends that all dust collection systems should have explosion venting to redirect explosions and abort gates or other equipment to stop flame fronts from spreading. It also recommends improved housekeeping measures to prevent dust from accumulating. Accomplish this by collecting dust at the source so there’s no accumulation in difficult-to-reach places.

It’s often this accumulated dust, hidden on high surfaces, in corners, or inside ductwork, that ignites to cause a secondary explosion that’s far more dangerous than the original one. Witness reports of dust explosions often include descriptions of a smaller explosion followed by one or more larger ones; this is secondary ignition. Dust control throughout the facility, along with fire prevention equipment such as abort gates, spark arrestors, and explosion venting, can control a potential explosion and prevent a small fire from becoming a fatal disaster.

Read more

![Occupational Lung Diseases From Dust & Fumes [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2018/08/health-risk-infographic1-1080x675.jpg)

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update

An accumulation of dust in any industrial setting poses a threat to the health and safety of those working there. This is especially true in the world of metalworking where the fine dust particles may be especially toxic. In light of this threat, the Occupational Safety and Health Administration (OSHA) has established standards of safety that must be followed in any such industrial setting. These address not only inhaled dust but also the threat of combustibility through its accumulation. Check out the latest combustible dust update  The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An

The explosion in Kentucky was caused by combustible dust that resulted from a resin used to treat fiberglass. Workers were aware of the large quantities of dust. But cleaning processes often just caused more of the dust to become airborne. So, it accumulated in the ductwork and in dust collection equipment. There were no safeguards in place to prevent a flame front from traveling through the ductwork or getting into the dust collector. An