by Scott Stearns | Nov 26, 2018 | Uncategorized

Dusty Jobs Issue 7 is the third quarter of the year. Check out the articles! Charlie is back with an article about food, and we interview one of our welders, Richard Matters. If you would like a printed hard copy of this issue of the quarterly newsletter, contact your Imperial System Sales Rep.

Click the cover to download and print the newsletter.

CLICK THE ARTICLE TO READ.

Read more

by Scott Stearns | Nov 26, 2018 | Hidden from Archive

For several years, I worked as a Sales Rep for a large, European‑owned dust and fume collection company. Like most of the big companies in this industry, they had an aggressive way of doing business that was not consistent with how I believed things should be done. They called it “filling holes,” which was the practice of sizing dust and fume collection equipment large enough to perform well, but not at a capacity that would minimize periodic filter replacement. Regrettably, I condoned it for far too long. How did I reach the tipping point where I decided to start my own business? My story starts with my granddad.

I grew up in a family-owned and operated sheet metal shop. My granddad, a loving and driven man, had me slagging parts and sorting hardware by age seven. I spent every minute of every summer in and around the shop. It was a noisy, greasy and busy place – and I loved it! At an early age, I was fascinated to learn what a cyclone and baghouse were and how they were built. Warm family gatherings always included shop talk and I would eagerly sit in on those conversations, listening to every word. Today is no different. I still love fabrication and never pass up an opportunity to tour a fabrication facility. Dust and fume filtration is truly in my blood.

I started as a sales rep in my early 20’s. At the time, the industry was led by a couple of company giants who promoted the practice of filling holes. I was quickly taught to stretch the limits, get the orders and move on to more projects. This philosophy was fundamentally against what I had learned growing up in the family business. Unfortunately, top dust and fume collection companies continue with this practice today. But being ambitious and eager to please, I unwisely suppressed my opinion of it and sold collectors in this manner for years. Increasingly unhappy with my circumstance, conviction compelled me to start my own business.

In October 2001, I founded Imperial Systems with the mission that my company would build the best dust and fume collection equipment on earth. Our collectors would be designed and built from an end user’s point of view, last longer and filter better than any other collector on the market. Growing up in manufacturing, I knew that one of our strongest attributes was that we were a company that knew how to design, build and install complete systems from start to finish. This was a distinct advantage over the big companies and still holds true today. Every one of our sales engineers has spent time in the field installing systems so that they understand what they’re selling and what it takes to get equipment properly designed for a dependable installation.

For years we successfully built and sold cyclones, baghouses, ducting and airlocks. In 2010, I decided to expand the company by building cartridge style dust collectors. When we started, we copied a major brand’s collector almost exactly. Unfortunately, this was a mistake for several reasons. For one, it did not differentiate us from our competitors. The technology was old, and by replicating it we made ourselves a “me-too” brand. The only way to compete was on price, which immediately put us at a disadvantage. We were the smallest industrial dust collector manufacturer in the industry. Why would someone buy from us over one of the larger, more established companies? When it was all about price, we would win a job but lost money as a consequence. Regrettably, I realized that copying a competitor was a short-sided strategy. Being a “me-too” company is not what I had envisioned as our future.

So, we regrouped and made some innovative design changes. We committed to build a better cartridge dust collector and differentiate ourselves from our competitors. It was then that I realized that our strength was in our differences. From that point on, we reminded ourselves of this insight at every design and engineering meeting. It became a mantra as we insisted on being innovators, not copiers. That’s when our business started to thrive. Independent sales reps started calling us unexpectedly to represent our product line. We started winning the majority of the quotes that we were working on. It was a new beginning for the newly designed CMAXX, now the flagship of Imperial Systems.

I am proud of the new approach and success that Imperial Systems has had with the CMAXX. The innovations came from customers reporting to us the problems with other equipment that they have had for years. They spoke and we listened. Because of these innovations and loyal customers, Imperial Systems is now the most progressive dust and fume collection company in the industry today. Ironically, CMAXX is now the most copied collector on the market!

I guess you can say we are now doing things right. We’ve emerged with dignity from being an ambitious imitator to an industry thought leader. We are transparent about the solutions we provide to fill needs, not holes. I’m so grateful to my granddad for his influence on my life. And I thank every member of the Imperial Systems team for fulfilling my true vision of this company.

Read more

by Imperial Systems | May 16, 2018 | Uncategorized

Sometimes it’s necessary to cut or weld, or hot work in the vicinity of your dust collector. However, this can be extremely dangerous if your dust is explosive. A dust collector, after all, is an accumulation of dust. If that material is combustible, careless hot work could lead to a catastrophic explosion.

“Hot work” is defined by OSHA as “welding, brazing, cutting, soldering, thawing pipes, using heat guns, torch applied roofing and chipping operations, or the use of spark-producing power tools, such as drilling or grinding”. Most of us would think twice about welding or cutting in near a dust collector or any other combustible dust. But some tools, even ones that shouldn’t produce sparks, may have faulty wiring. This can lead to a fire or explosion.

Hot Work Procedures

No hot work should be done near the dust collector without the correct procedures (see NFPA 51B). This NFPA standard specifically defines the procedures for conducting this type of work anywhere that it might cause an explosion.

Hot work near or on a dust collector might include repairs or adding/removing a piece of equipment or ductwork. It may include any number of other projects. Before doing this kind of work around the dust collector, you must have a hot work procedure IN WRITING:

- Shall be in writing and available to anyone conducting hot work in the area

- It must require an inspection of the work area before the work starts

- Must have a permit signed to show that all phases of the work have been inspected and approved

The program should assess safety equipment in the area. On a dust collector that might include a spark arrestor, spark detector, fire suppression or sprinkler system, abort gate, explosion venting, or other types of fire and explosion safety devices.

Hot work may require completely blocking the ductwork to the dust collector, or if the work is on or close to the collector, may require removing the filters, emptying or removing the hoppers, and thoroughly cleaning the entire dirty air side of the dust collector. a strong g recommendation is that a fire suppression system is in place before hot work begins. This will suppress any fire that might start. Further, remove as much of the dust as possible if it is explosively combustible.

Permits Ensure Safety

NFPA 51B specifies that the company safety specialist will issue a permit for work to proceed once achieving an inspection and determination of safety for hot work. It’s the job of this designated safety specialist to inspect the area of hazards. The specialist ensures the removal of all combustible dust. They confirm the isolation of all sparks and heat and establish safety procedures in the event of a fire.

No one should be allowed to perform ANY type of hot work, including the use of spark-producing power tools, in the vicinity of the dust collector without a permit. However, it happens all the time and puts lives at risk if the dust is combustible. Take the time to assess this hazard in your own workplace. If the hazard exists, your safety professional should set up hot work procedures to make sure no one puts themselves or the facility at risk.

Read more

by Imperial Systems | May 2, 2018 | Uncategorized

1. What information do we need to start designing a system and what are the considerations for ductwork?

- First, you need to know about your dust. Important details: how it’s being generated, how toxic or hazardous it is, what exposure levels OSHA considers to be too high, whether it is combustible and/or explosive, particulate size, physical characteristics.

- Combustible dust will certainly require special precautions in the system design to protect the facility and workers from deflagration or explosion. Dust testing can determine how explosive dust is and the needed precautions.

- A general layout of the facility and each location generating dust.

- A sketch of the ductwork layout, including the location of the dust collector, fans, and ductwork branches.

- A plan for the type of hood to use at each of the dust capture locations. Also, how much CFM each one will require.

2. What are the basic components of a dust collection system?

- Hoods: must be the correct design for each type of machine. They must also be efficient at removing the produced dust by that machine.

- Ducts: must be the correct size to allow proper airflow and keep air moving. They also must not have too many bends or elbows to slow down the airflow. This can allow particulates to drop out of the airflow. It can also create a point for wear and tear on the ductwork.

- Fan: the fan must be powerful enough to keep air moving through all the ductwork at a high enough velocity. Drops in velocity or not enough velocity can allow dust to fall out of the air stream.

- Collector: must be the correct size for the system. It must have an air-to-cloth ratio that makes it able to filter all the air coming into the collector. Must have correct filter material to handle the size and type of particulate. This could be DeltaMAXX nanofiber for most applications, or spunbond, PTFE, or other specialized filters for particular applications. Further, filters must be fire-retardant if the dust is flammable.

- Fire Prevention: devices such as spark arrestors can help keep sparks from entering the dust collector. A water or chemical fire suppression system can extinguish sparks or flame when a sensor detects them.

- Venting/Exhaust: If returning air to the building, it must be clean enough to meet all health and safety standards. If dust is toxic, it may necessitate an extra layer of safety in the form of HEPA filters. A backdraft damper can prevent backdrafts from allowing dust back into the system. An abort gate with spark detector can sense a spark or flame, diverting the flame in a safe direction.

3. What is the process for designing a ductwork system?

- System design should start with identifying each place that a hood or other source capture point needs to go. In other words, anywhere that generates dust.

- Use appropriate calculations to figure out how much CFM you need at each of these points

- Determine the minimum duct velocity. This is based on the transport velocity (the airflow needed to keep your particular dust moving in the air stream).

- Calculate the size of duct for each branch. This is based on the CFM and the transport velocity and will be different for different spots along the ductwork.

- Increase duct velocity at each branch to maintain transport velocity until all branches are connected to the main duct.

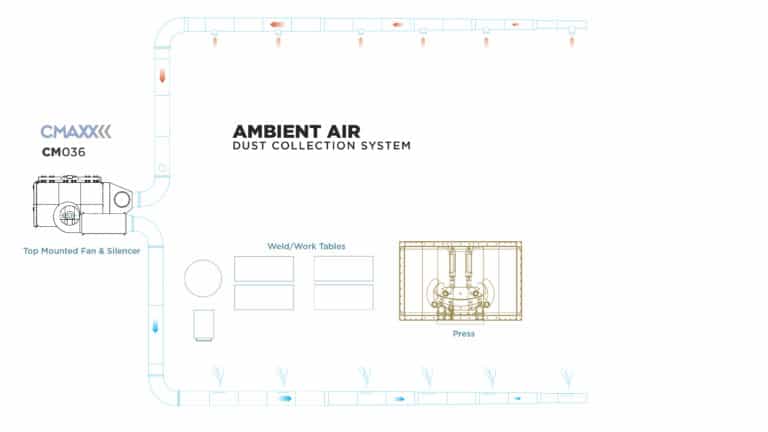

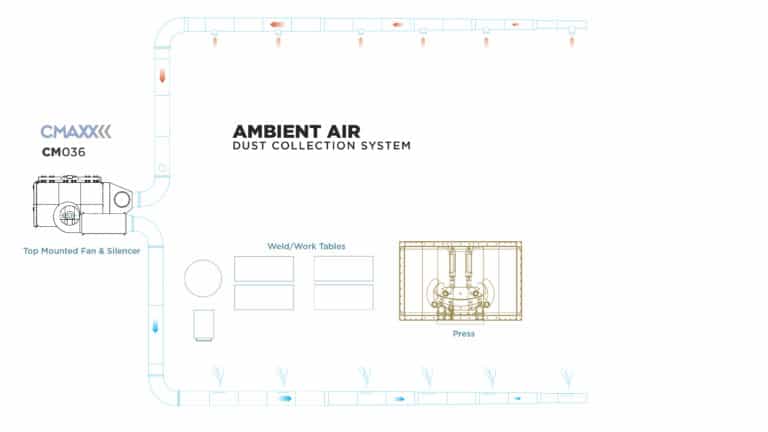

4. Will this be an ambient system or source capture system?

- Ambient system: removes air from the entire work area. It filters and recirculates it back into the area, diluting contaminated air with clean air.

- Air changes per hour: the number of times per hour that the total amount of air in the area changes. This is from old/contaminated air to new/clean. The calculation is made with the cubic volume of the work area and the number of required air changes to maintain air quality.

- Source capture/close capture: captures generated dust at each point throughout the facility.

- This type of system must have properly designed hoods at every capture point. Perform and double-check your airflow calculations. Specialty hoods can be designed for almost any application.

- Static pressure in these systems is an algebraic formula. It includes a loss at hoods, flex ducts, transitions, and straight ductwork runs. Minimal use of elbows and flex ducts in the ductwork runs will greatly improve system efficiency.

- For dangerous or toxic dust where exposure must be kept to an absolute minimum, a close capture system will keep the material from entering the air of the general workplace.

We hope this set of articles about ductwork help to answer some of your questions. Please thank the knowledgeable and experienced Charlie Miller for providing so much valuable information and sharing his wisdom.

Read more

by Imperial Systems | Apr 18, 2018 | Uncategorized

In the agricultural industry, grain dust explosions are a hazard that must be addressed. According to a report from Purdue University, grain dust explosions have occurred at a constant rate over the last ten years, with little change in the number of explosions, injuries, and fatalities. They report an average of 9.3 explosions each year over the past decade.

Since OSHA instituted Standard 29 CFR in 1988, which specifically details safety in grain handling facilities, there has been a focus on the control of what OSHA refers to as “fugitive grain dust”. Preventing grain dust explosions was a focus, including regulations on any type of “hot work” occurring in the vicinity of grain dust. The standard requires testing for combustible dust presence in all storage containers (silos, tanks, bins). It also requires thorough housekeeping procedures to keep dust from accumulating on surfaces.

Grain dust collection systems are strongly recommended, and they must be designed to resist an explosion or deflagration. Correctly designed systems can prevent an explosion from happening or prevent it from causing damage or injury.

Purdue University’s report examines the number of grain dust explosions that occur each year. From 1995 to 1998 the number of explosions was high, reaching 18 grain dust explosions in 1998. Numbers stayed below the ten-year average until 2005, with 13 explosions, and then in 2008, with 19 explosions.

The most common months for grain dust explosions, according to the report, are April, August, and September. The report suggests that during these months, there is increased handling and moving of grain.

What’s causing these explosions? Some facilities think that they don’t need to worry about a little accumulated dust as long as there’s no ignition source. As our own Charlie Miller would say, “good luck with that”… in 67.8% of incidents, the ignition source was unknown. Only 6% could be related to fire, with less than 4% related to sparks or mechanical failures. Most of the time, nobody knows what triggered the explosion, which makes it very difficult to prevent an explosion when fugitive dust is present.

The high percentage of unknown ignition sources should be proof that the only prevention for grain dust explosion is to keep fugitive grain dust under control in all parts of the facility at all times. A dust collection system is essential to this, and can include a baghouse, a cartridge collector, or spot filters located at specific grain handling points.

Some other interesting statistics related to combustible dust explosions in the grain industry:

From 2007 to 2016, there were 91 dust explosions, and 52 of those were caused by corn dust. The second most hazardous type was mixed feed, which probably includes corn quite often, with 19 explosions. 20 explosions out of 91 were caused by other types of dust.

In 2017, there were 7 grain dust explosions, slightly below the ten-year average of 9. The locations included a pet food plant, a grain mill, and 5 grain elevators. Grain elevators move large quantities of grain and create a high risk of explosion.

In the last ten years, there have been 101 injuries and 15 fatalities due to grain dust explosions. 55 of the explosions occurred in grain elevators, with feed mills a distant second at 18.

If grain elevators are so hazardous, how can the risk be decreased? Spot filters are often a very good solution for dust control on these facilities. They can be placed almost anywhere that dust is generated and are self-cleaning, requiring only occasional maintenance. They do not require confined space permits to work in and can control fugitive grain at the source.

https://engineering.purdue.edu/FFP/research/dust-explosions/Grain_Dust_Explosions_2017.pdf

https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9874

http://www.grainnet.com/article/140120/purdue-university-annual-report-shows-seven-reported-grain-dust-explosions-nationwide-in-2017

https://engineering.purdue.edu/FFP/research/dust-explosions

Read more