by Imperial Systems | Apr 18, 2018 | Uncategorized

In the agricultural industry, grain dust explosions are a hazard that must be addressed. According to a report from Purdue University, grain dust explosions have occurred at a constant rate over the last ten years, with little change in the number of explosions, injuries, and fatalities. They report an average of 9.3 explosions each year over the past decade.

Since OSHA instituted Standard 29 CFR in 1988, which specifically details safety in grain handling facilities, there has been a focus on the control of what OSHA refers to as “fugitive grain dust”. Preventing grain dust explosions was a focus, including regulations on any type of “hot work” occurring in the vicinity of grain dust. The standard requires testing for combustible dust presence in all storage containers (silos, tanks, bins). It also requires thorough housekeeping procedures to keep dust from accumulating on surfaces.

Grain dust collection systems are strongly recommended, and they must be designed to resist an explosion or deflagration. Correctly designed systems can prevent an explosion from happening or prevent it from causing damage or injury.

Purdue University’s report examines the number of grain dust explosions that occur each year. From 1995 to 1998 the number of explosions was high, reaching 18 grain dust explosions in 1998. Numbers stayed below the ten-year average until 2005, with 13 explosions, and then in 2008, with 19 explosions.

The most common months for grain dust explosions, according to the report, are April, August, and September. The report suggests that during these months, there is increased handling and moving of grain.

What’s causing these explosions? Some facilities think that they don’t need to worry about a little accumulated dust as long as there’s no ignition source. As our own Charlie Miller would say, “good luck with that”… in 67.8% of incidents, the ignition source was unknown. Only 6% could be related to fire, with less than 4% related to sparks or mechanical failures. Most of the time, nobody knows what triggered the explosion, which makes it very difficult to prevent an explosion when fugitive dust is present.

The high percentage of unknown ignition sources should be proof that the only prevention for grain dust explosion is to keep fugitive grain dust under control in all parts of the facility at all times. A dust collection system is essential to this, and can include a baghouse, a cartridge collector, or spot filters located at specific grain handling points.

Some other interesting statistics related to combustible dust explosions in the grain industry:

From 2007 to 2016, there were 91 dust explosions, and 52 of those were caused by corn dust. The second most hazardous type was mixed feed, which probably includes corn quite often, with 19 explosions. 20 explosions out of 91 were caused by other types of dust.

In 2017, there were 7 grain dust explosions, slightly below the ten-year average of 9. The locations included a pet food plant, a grain mill, and 5 grain elevators. Grain elevators move large quantities of grain and create a high risk of explosion.

In the last ten years, there have been 101 injuries and 15 fatalities due to grain dust explosions. 55 of the explosions occurred in grain elevators, with feed mills a distant second at 18.

If grain elevators are so hazardous, how can the risk be decreased? Spot filters are often a very good solution for dust control on these facilities. They can be placed almost anywhere that dust is generated and are self-cleaning, requiring only occasional maintenance. They do not require confined space permits to work in and can control fugitive grain at the source.

https://engineering.purdue.edu/FFP/research/dust-explosions/Grain_Dust_Explosions_2017.pdf

Read more

by Imperial Systems | Oct 19, 2016 | Uncategorized

When Water Turns a Fire Into an Explosion

A combustible dust explosion is an ever-present danger for workers in many industries. These two examples show that despite increased awareness, explosive dust still puts lives at risk. One thing they both have in common: water may have actually made them much worse.

Case #1: Grain Dust

The first example shows how even things that seem like safe and practical fire-fighting measures can lead to disaster. In May, a grain dust explosion occurred in a silo. It injured a worker who was attempting to put out a dust fire with water.

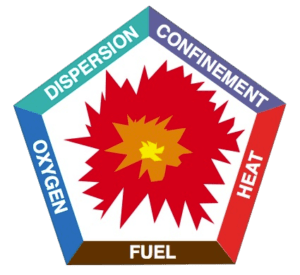

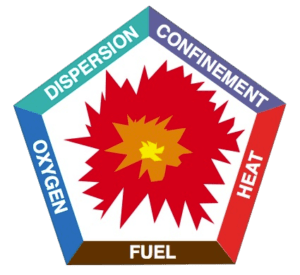

Because the very fine dust was contained in the silo, all the criteria for an explosion were present… except for one. The dust provided fuel for a fire, and the open silo hatch provided oxygen. With the material confined in the closed space of the silo and an ignition source in the form of a grain dryer, the dust explosion danger was high.

Ironically, it was the worker spraying water onto the fire that created the explosion by adding the last element: dispersal of the dust. Water hitting the dust added more air and also raised a cloud of dust. Dust suspended in the air turns the situation from a fire into an explosion. In this case, it blew the roof off the silo and caused serious injuries.

Case #2: Fish Meal Dust

The second example is in some ways a classic industrial dust explosion, except that the material isn’t one you’d expect. In September, a seafood processing plant was seriously damaged and had to be shut down because of an explosion caused by the ignition of fish meal dust.

Fish meal is a fine, dry powder that manufacturers often make into fish food. A local official noted that this is the third time he knows of that fish meal has caused an explosion at a local plant. In this case, a burst pipe may have created an explosion by causing dust to become airborne.

While people don’t think of fish as being explosive, they usually don’t think of metal as being explosive either. Both of them pose an explosion danger when in dust form.

While we talk a lot about combustible metal dust and fumes because many of the industries we work with use metals, organic dusts like grain, spices, powdered milk and egg, sugar, tobacco, and yes, even fish are dangerously explosive if all the right elements are present.

Secondary Explosions from Airborne Dust

While many places that produce metal dust are aware of the risks, some places that produce organic dust don’t realize the danger it poses, or how important a dust collection system is for controlling and handling dust. The most catastrophic damage is often done by secondary explosions: a small dust explosion causes accumulated dust to be dispersed in the air, causing a much larger explosion. Spraying water on a dust fire can do the same thing, sending dust into the air.

Minimize Dust Explosion Danger

Removing dust from the facility and collecting it with a dust collection system designed to prevent or safely control explosions is an important safety strategy. Making sure that dust will not disperse in the air is another key to explosion prevention. In any situation with combustible dust, equip the system with safety features. Spark arrestors, explosion vent panels, and chemical suppressors can curtail the dust explosion danger in your factory.

Reference:

http://www.ktoo.org/2016/09/20/explosion-westward-seafoods-sparks-police-investigation/

http://www.adn.com/alaska-news/rural-alaska/2016/09/21/official-blames-fish-meal-dust-in-100k-explosion-at-dutch-harbor-seafood-plant/

https://www.commerce.wa.gov.au/sites/default/files/atoms/files/5-2016_grain_fire_and_dust_explosion_in_silo.pdf

http://content.safetyculture.com.au/news/index.php/10/safety-alert-issued-grain-fire-dust-explosion-silo/#.V_-WMugrKM-

Read more