by Imperial Systems | Nov 17, 2016 | Uncategorized

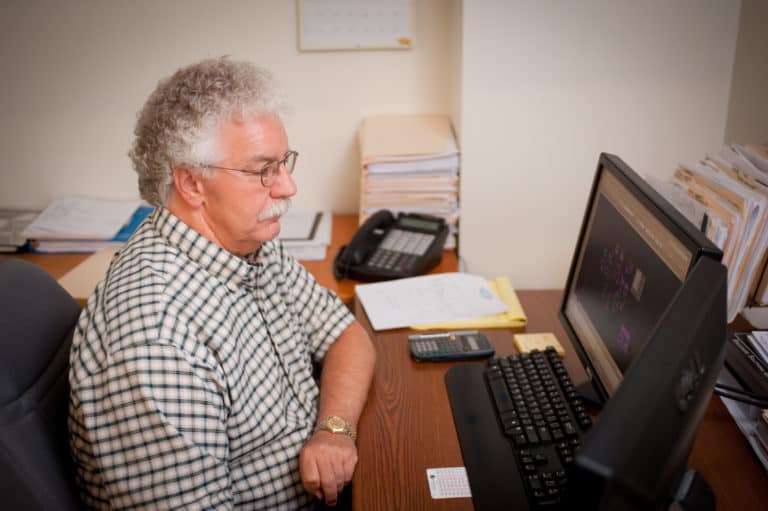

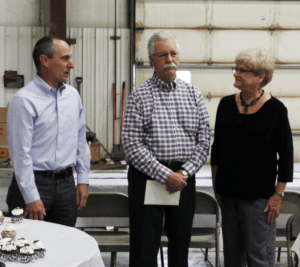

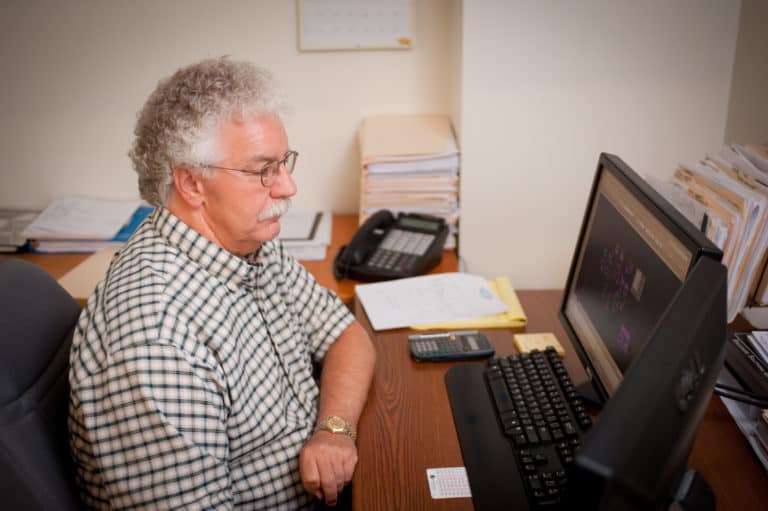

This November, with best wishes and some sadness, we celebrate the retirement of a man who didn’t just work here at Imperial Systems: Bruce Johnson helped to build it.

When you ask Bruce to tell you about his accomplishments, he seems a little confused as to why you’d even ask him. He is quiet and humble, and I’m not sure he realizes how deeply he is respected or how deeply he will be missed.

Bruce came to Imperial Systems in January of 2008. On his first day, he was helping design a ductwork system. There were no offices, just a shop with dividers, and every project was a team project. These were early days for Imperial Systems as a company stepping into larger projects and new industries, and Bruce will tell you, with a smile, “It was definitely a team effort. We were all in it together.” Whether it was Jeremiah doing some welding or Joe Moore programming the plasma table or Charlie bringing his vast experience as a draftsman, everyone took whatever role was necessary to move forward.

It was nice to get offices, Bruce says, because then the engineers didn’t have to yell at each other. From small local jobs, he has moved to working on bigger systems, bigger and more elaborate ductwork, and new industries, like coal processing, grain, rubber, and wood dust. Bruce particularly remembers the Methuen project. “There were multiple floors in the building, really complex ductwork. It was a really great project to work on. Great learning experience.”

When you listen to Bruce talk about his time at Imperial Systems, two things stand out. One is his commitment to and love of learning: “If you don’t learn something new every day here, you must have been sleeping.” The other is a powerful sense of teamwork and sharing accomplishments with others. “We complement and balance each other,” he says. “As time went on we became more and more of a team. We depended on each other.” Bruce talks about his time at Imperial Systems as a time of team building, learning to build on each person’s skills, teaching each other, and becoming more skilled and more capable together than they could ever be on their own.

Bruce doesn’t talk about his own accomplishments as much as he talks, with great pride and affection, about how he and those around him grew together and built something great. He talks about the problems they solved, jobs that just kept growing, jobs that turned out to be more complicated than expected. He talks about how the company constantly moves forward, but what he doesn’t talk about is how necessary he was in making that happen. In his small, meticulously kept records, he counts 131 jobs he has worked on since 2013.

Jeremiah Wann doesn’t hold back when he talks about what Bruce has meant to the company and to him personally:

“Guys like Bruce are truly a dying breed. Good work ethic, pride in quality and workmanship today is really hard to come by. I have mixed feelings about his retirement. There is a part of me that wants to celebrate with him over his retirement but there is a huge part of me that wishes we could keep him forever. It’s a real life lesson for me in that, we have to train not only in skill but in work ethic and principles. Bruce has been one of my best all-time team members and I am really going to miss him. My biggest fear is that it’s going to be impossible to completely replace him.”

No matter how humble he is or how much credit he gives to those around him, Bruce has been a critical part of making Imperial Systems what it is and set an amazing example for all those who will take up his work after him. His work ethic and his willingness to celebrate the achievements of others makes Bruce a truly special person and he will be deeply missed.

All of us at Imperial Systems wish Bruce a wonderful, happy retirement. It is certainly earned and well-deserved.

Read more

by Imperial Systems | Nov 11, 2016 | Uncategorized

For some of us, FABTECH 2016 in Las Vegas is one of the biggest events of the year! Here’s a quick preview of the things you’ll see at our booth this year.

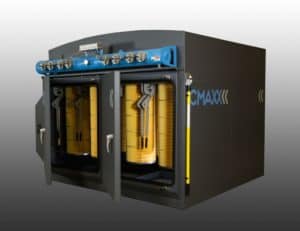

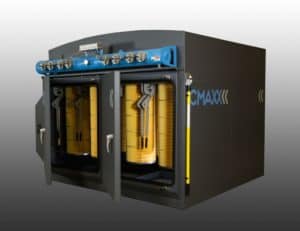

A CMAXXTM model CMoo8, fully operational and running, demonstrating a push-pull system:

A Spark Arrestor, one of the simplest and most important components of a fire safety system:

Spark Arrestor

Two CMAXXTM models (CM004), featuring our explosion venting and new FireTrace fire extinguishing system.

The official debut of our new portable dust and fume collector, the SHADOW:

FABTECH 2016 Debut

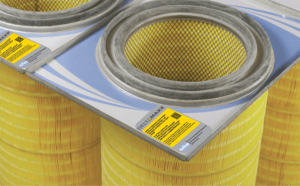

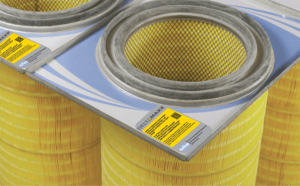

Imperial’s superior MERV 15 nanofiber DeltaMAXXTM filters:

DeltaMAXX cartridge filters

FREE STUFF! Stop by and get a stylish Imperial Systems hat!

What happens in Las Vegas doesn’t have to stay in Vegas! We have 4 show specials that you can take with you!

Our three CMAXXTM Demos and the SHADOW Portable Collector are available for sale at the show. Stop by our booth and talk to an Imperial Representative to get the full details at the FABTECH 2016 show!

Visit us at booth N1825 and see why everybody at FABTECH 2016 is going to be talking about us!

Read more

by Imperial Systems | Nov 8, 2016 | Uncategorized

Your dust and fume collector can save you money on heating this winter. But to make the most of those savings, your system might need some winter maintenance. It’s that time of year when your dust collector system needs a little attention to make sure it’s ready for the demands of colder weather.

Winter Maintenance Checklist

Replace Those Filters

Winter maintenance means starting the new year with clean new filters… and you’re not going to want to change them in the middle of a snowstorm.

Changing the Magnahelic Gauge Filter

It’s easy to forget about this little filter, but it’s necessary to keep the gauge readings accurate. You should replace it whenever you replace your other filters.

Check for Accumulated Dust

If you’ve been working with the doors open during the warmer months and not running the dust collector as much, you might have dust accumulated, especially in high places or flat surfaces. For safety, try to remove as much of it as possible.

Check Airlock Wipers and Bearings

Usually, you should change airlock wipers once a year. Worn-out wipers don’t do their job properly. Winter maintenance is a good time to check them. When you replace wipers, you should also plan to replace the bearings.

Check Heaters on Pulse Valves

If you’re in a cold area and your pulse valves have heaters to keep them from freezing up, make sure they’re working. Frozen pulse valves are an inconvenience nobody needs to deal with in frigid weather.

Check Solenoid and Diaphragm Valves

Again, these are not things you want to have broken in the middle of nasty cold weather. A quick check and some preventative maintenance if necessary can save you a headache later during winter.

Check Compressed Air Hoses

Cold can make hoses more brittle and likely to break. If your compressed air hoses have any weak spots or look worn or damaged, now is a good time to make sure they get fixed or replaced.

Check Seals and Gaskets

As with the hoses, cold can make seals and gaskets crack or develop leaks. If needed, replacing them before the weather gets cold can save you from dealing with downtime from an unexpected leak.

Calibrate Differential Pressure Gauge

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

Check Your Dust Collector Roof

If you’re a CMAXX owner, lucky you! Your domed CrownTech roof will keep snow or ice from piling up on top of the collector. If you don’t have a CMAXX, make sure you keep an eye on the amount of snow or ice buildup, since that can cause leaks into the collector.

Read more

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information

If you have the tools to do it, this is a good time to calibrate the differential pressure gauge and make sure you’re getting accurate readings. These gauges need to be calibrated occasionally to give you the most accurate information