When choosing a top industrial dust collection system it’s extremely important to do your research on the product. Not only is purchasing a top industrial dust collection system a large investment, there are many different features, designs, cleaning systems, and technologies that different brands offer.

One of the most frequently asked questions among industrial dust collection system purchasers is, “What is the difference between a vertical cartridge collector and a horizontal cartridge collector?”

At Imperial Systems, our preference is the vertical cartridge industrial dust collector design and here are some reasons why:

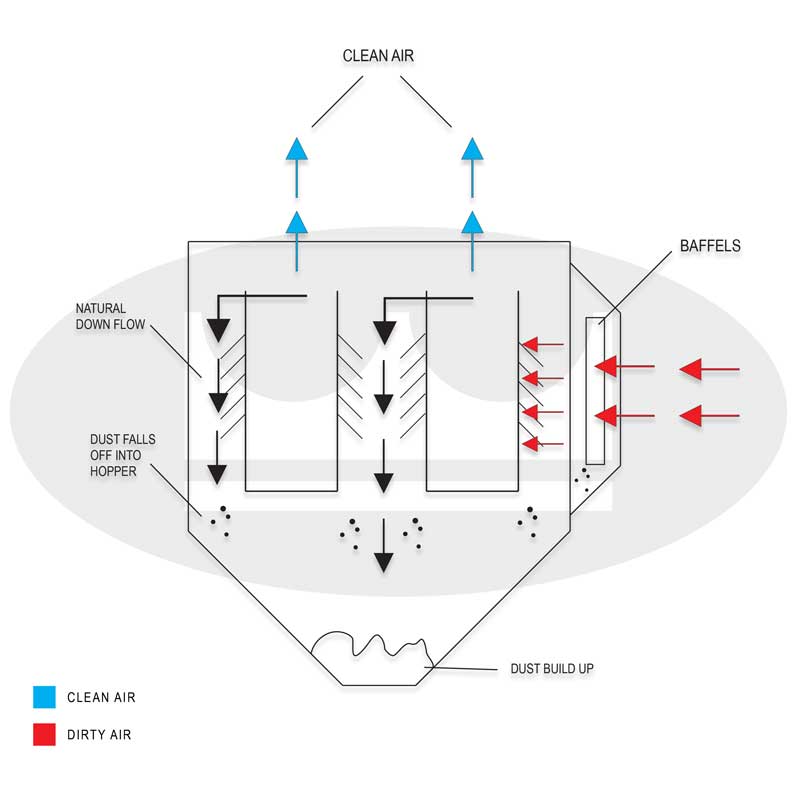

1. Gravity works in your favor

a. Dust and debris falls off of the cartridge filters instead of laying on the cartridge filter’s media.

2. When filter cleaning with pulses of compressed air, dust is blown off and into the hopper instead of on top of the filter below.

3. Natural down-flow with a high entry inlet configuration.

a. This allows for the natural flow of the air aid in, removing dust laden air from the filter chamber.

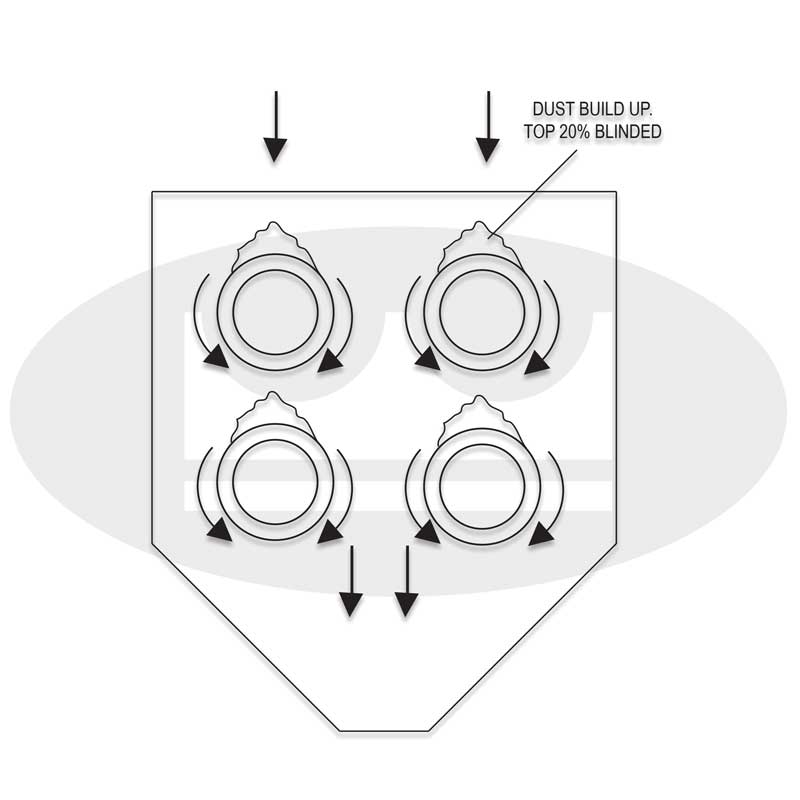

4. No need for rotating dirty filters

a. Vertical dust collector design allows for even cartridge filter loading.

5. Horizontal cartridge filters blind off the top 20% of the filters media from dust laying on top of it.

a. Since gravity is in a vertical cartridges favor, vertical cartridge filters will prevent a build-up of dust while allowing equal filter media distribution for the incoming dust.

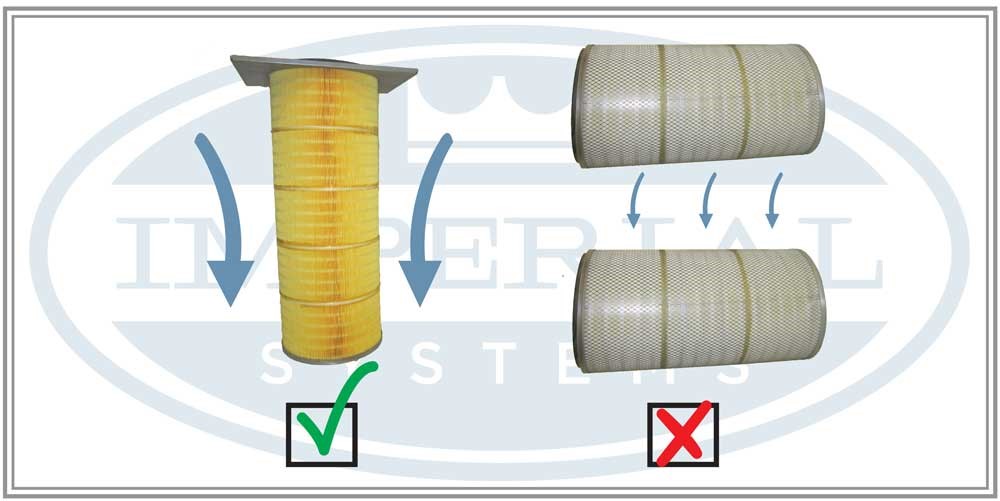

6. Changing filters takes a fraction of the time

6. Changing filters takes a fraction of the time

a. Allows for a much cleaner process as the vertical cartridge filters don’t have to be pulled out to your body.

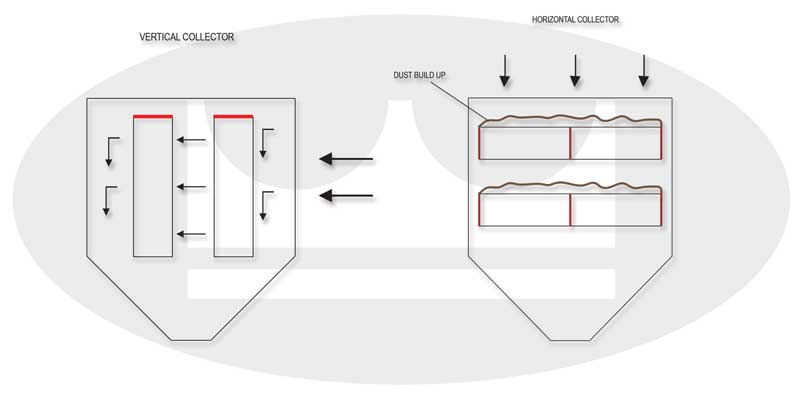

7. There is only one gasket seal point in a vertical cartridge collector..not two or three.

a. Horizontal cartridge dust collectors have to be seated properly, they have more potential for dust bypass.

Have a horizontal cartridge collector? A vertical cartridge collector may be a better option for your facility. Contact us to learn what the best option is for you.