What don’t you know about the dust you’re producing? Learn about it from your local professional dust collector firm.

Dust collection is an important process to protect your employees and keep your work environment accident-free. Who would ever guess that dust could be so dangerous? While the general public won’t be aware of this issue, as a manufacturing or metalworking company, you realize that it’s vital—especially in today’s regulatory climate. A professional dust collector firm can help you by ensuring that you have the correct systems in place to prevent dust-initiated accidents.

What is the problem with dust?

Simply put, dust can be a highly flammable substance that may result in fires. Because of dust’s combustible properties, it can become a fuel when it has been accumulated over time from industrial processes. Oftentimes it may travel down pipes or remain within the operations systems, creating an entire chain of dust fuel!

This possesses serious risks for employees working around the dust. Since the year 2000, there have been many documented explosions within factories that did not take proper precautions in regards to dust collection and education of employees.

What is a dust collector?

What do we mean when we talk about dust collectors? We’re referring to the system utilized to improve air quality that is released from industrial processes. The dust collector should handle dust loads by removing dust from the air—different from air cleaners, which have the filter.

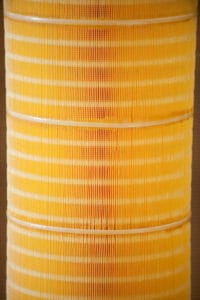

A professional dust collector firm should provide you with a comprehensive system that goes beyond a simple air cleaner. This system is comprised of a blower, dust filter, filter-cleaning system, and a dust receptacle. It is also referred to as an air pollution control device, which is understood to maintain air quality.

What do dust collectors do?

Dust collectors recover valuable granular solids from process streams or remove solid contaminants before they are ventilated into the atmosphere. They are distinguished from mist collectors, which are used for metal working to remove liquid from the air. Dust collectors also function differently from fume/smoke collectors, which remove particulate matter from the air during industrial processes such as welding, rubber making, tempering, and quenching.

How to tell if my dust is dangerous?

Two types of dust testing help you to pinpoint the particular properties of dust, including its potential combustibility. These are: bench testing, and explosibility testing.

Bench testing requires a series of tests. Particle size analysis shows the dust’s particle size to decide the filtration intensity required to follow emissions regulations. This test reveals the count, or number of particles of that size, and the volume/mass spread of the dust. Many dusts are mixed, making this an important testing standard.

You can also use moisture analysis by using a humidity chamber to see how rapidly dust absorbs moisture. This is a good test to use in case of moisture problems, but it is not important 100% of the time.

On the other hand, the explosibility testing should never be skipped. A lab will use a screening test to measure if your dust could be combustible. If that possibility exists, the test will continue forward, measuring dust cloud parameters to determine the rate of pressure rise and the maximum pressure of a contained explosion.

Who can help?

Imperial Systems is a well-established professional dust collector firm within the industry of dust protection for over a decade. We are equipped with every system part you should require to ensure maximal dust safety in your workplace. Our consultants are professionals who can help you improve your systems by learning about your particular business. To get in contact with us, please call 800.918.3013 today.

professional dust collector firm | collector firm professional dust