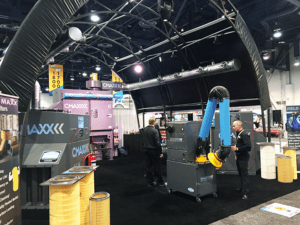

The CMAXX for managing weld smoke on display at FABTECH 2017. This install is showing an ambient filtration method.

Managing weld smoke risks means dealing with very small particle sizes, toxic metals, and the combustibility of metal dust. Weld smoke is different from other types of dust, requiring a system design to deal with it. A CMAXX dust and fume collection system will meet any metalworking or weld smoke control needs.

Managing Weld Smoke for Health

One of the risks of weld smoke is hexavalent chromium. That’s because this compound can cause skin sores and lung damage, and cancer of the lungs, kidneys, and other organs. Many metals have chromium alloy to make them corrosion resistant.

Most of the particles in welding fumes come from the welding wire, but some of them come from the welded material. Some of them can cause allergic reactions and an immune response called “metal fume fever.” Lead and manganese can damage the brain. Further, others like hexavalent chromium and nickel, are carcinogens and can increase your risk of cancer.

Welding fume particles are extremely small. Most are smaller than one micron. This means they are small enough to get inside human cells and cause damage. This also means that welding fumes are lighter than air, especially when heated. So, a system for managing weld smoke and collecting these fumes requires a design to handle very small particles.

Managing Fire And Explosion Risk

Welding produces metal dust and gases that may be combustible. Some metals, such as aluminum, are very explosive in dust form. Almost all metal dusts have the potential to explode. Handling welding fumes means using appropriate fire suppression and prevention measures.

Suppressing sparks to keep them from getting into the collector can help prevent explosions from welding smoke dust. Spark Arrestors are certainly important in keeping most sparks from getting to the collector. Also, an explosion isolation valve can prevent a fire from traveling back through the ductwork. Chemical control systems can suppress or extinguish a flame, but only certain chemicals are approved for fires involving metal dust.

Filters can also be important for fire suppression in a welding smoke system. Filters with a fire-retardant coating will resist burning and help control deflagration. Some collector designs have filters that help isolate an explosion and keep it from causing damage inside the workplace. DeltaMAXX filters with a fire-retardant coating will prevent a fire from occurring inside a dust collector.

Handling Weld Smoke

Figuring out what type of fume extraction system to use in your facility is an important decision for managing the risks from weld smoke. Our systems engineers will consult with you to help you determine the best way to manage your weld smoke risk.

If there are not very many welders and they don’t always work at the same place, portable collectors can be a solution. They can be useful for handling point-of-source capture. An ambient system design moves a volume of air out of a large area and through filters.

For managing weld smoke, portable collectors are easy to move around, but they are not as powerful as larger collectors. Central collectors are the most efficient for large areas, but if they are inside they take up floor space. We recommend locating the collector outside for safe explosion venting.

One of the biggest advantages of an ambient system that recirculates the air back into the facility is energy cost savings. When heated or air-conditioned air is vented outside, the energy used is lost. Many businesses find that a fume collection system can pay for itself within two years with the money saved in energy costs.

CMAXX dust and fume collectors have proven themselves in the welding and metalworking fields. Our newest product, the SHADOW portable collector, gives you even more options for managing weld smoke. DeltaMAXX nanofiber filters are the best available material for capturing metal fumes. At Imperial Systems Inc., we are committed to helping you control your weld smoke risks.

(as seen in The Fabricator Magazine)