Don’t let the sparks fly in your metalworking facility. Employee safety is a top priority at Imperial Systems

All across the globe, metalworking plants have seen an overwhelming amount of damage and fatalities caused by explosions and fires that could’ve been prevented with quality spark traps, or spark arrestors, and dust collection systems.

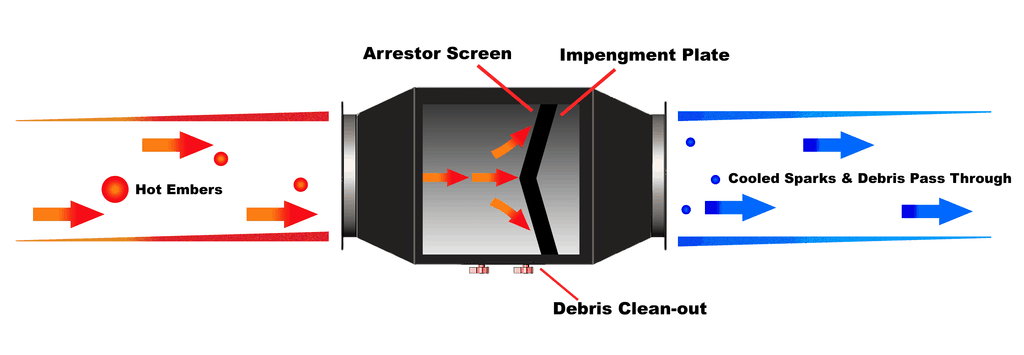

The problem that is seen in the metalworking industry is when a spark finds its way into the main component of a dust collection system causing the ignition of combustible dust, which causes devastating damage to the lives of metal fabricators and metalworking plants.

The problem that is seen in the metalworking industry is when a spark finds its way into the main component of a dust collection system causing the ignition of combustible dust, which causes devastating damage to the lives of metal fabricators and metalworking plants.

The National Fire Protection Association has a comprehensive guide on the control of ignitions sources to prevent explosions (NFPA 654):

- The use of proper electrical equipment and wiring methods.

- The control of static electricity.

- The control of sparks, open flames, and smoking.

- The control of mechanical sparks and friction.

- The use of separator devices to remove foreign materials capable of igniting combustibles from process materials.

Consider that 7% of ignitions sources are caused by fabricated metal, while metal dust accounts for 20% of explosions. It seems surprising then that spark arrestors are often overlooked as a necessary device to help prevent explosions in the metalworking industry. The initial thought is that an efficient high quality dust collection system, efficient filters, and implementation of the safety standards set by OSHA and the NFPA will be enough to prevent fires and explosions from occurring. But consider the lives at stake, and the overwhelming cost of damage to your metalworking facility when the solution to preventing fires and explosions was purchasing efficient spark traps.

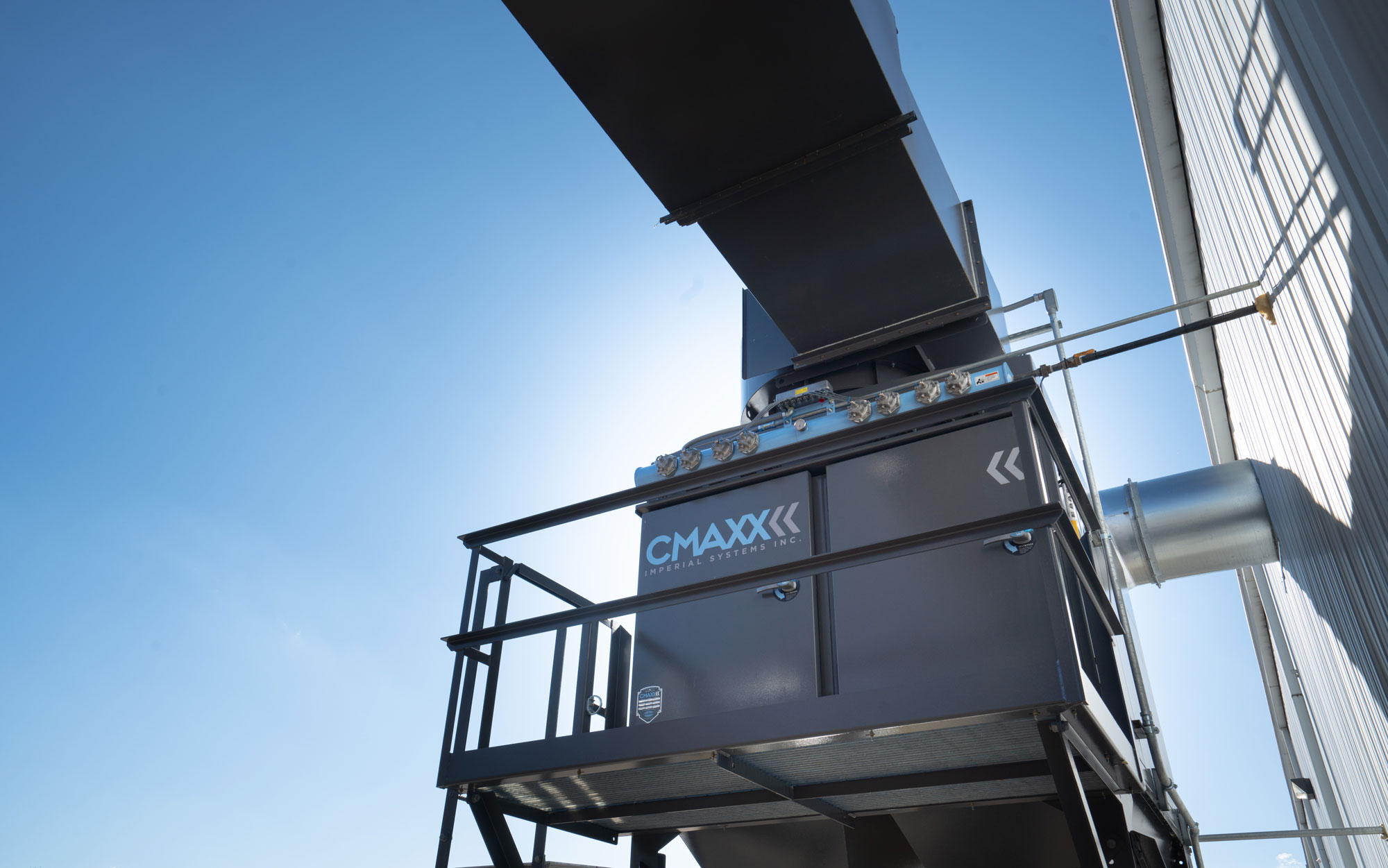

In-Line Spark Traps From Imperial Systems

- A simple installation: Our unique spark trap system does not require upkeep from their providers, meaning they are hassle-free in addition to being simple to install. They do not require any moving parts or additional welding.

- Optional sizes and features: You can choose between a carbon and stainless steel finish. In addition, you can choose to include raw inlets and outlet edges to your spark traps.

- Customized fit: With both horizontal and vertical configuration options, an Imperial Systems arrestor can be aligned to your collector without fail.

By now, you understand the importance of incorporating spark traps in your current dust collections system. At Imperial Systems, we don’t want safety to be a hassle. So we’ve made our spark arrestor easy to purchase and easy to install into any system.

Contact Imperial Systems today at 800.918.3013 or learn more by emailing us at info@isystemsweb.com to discuss the right spark arrestor for you.

Spark Traps | Spark Trap