Our Story

The Imperial Systems Story

Finding strength in our differences to fill needs, not holes

By Jeremiah Wann, President

For several years I worked as a sales rep for a large, European-owned dust and fume collection company. Like most of the big companies in this industry, they had an aggressive way of doing business that was not consistent with how I believed things should be done. They called it “filling holes,” which was the practice of sizing dust and fume collection equipment large enough to perform well, but not at a capacity that would minimize periodic filter replacement. Regrettably, I condoned it for far too long. How did I reach the tipping point where I decided to start my own business? My story starts with my granddad.

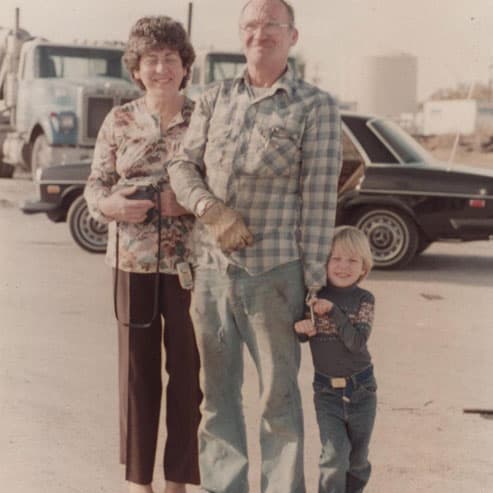

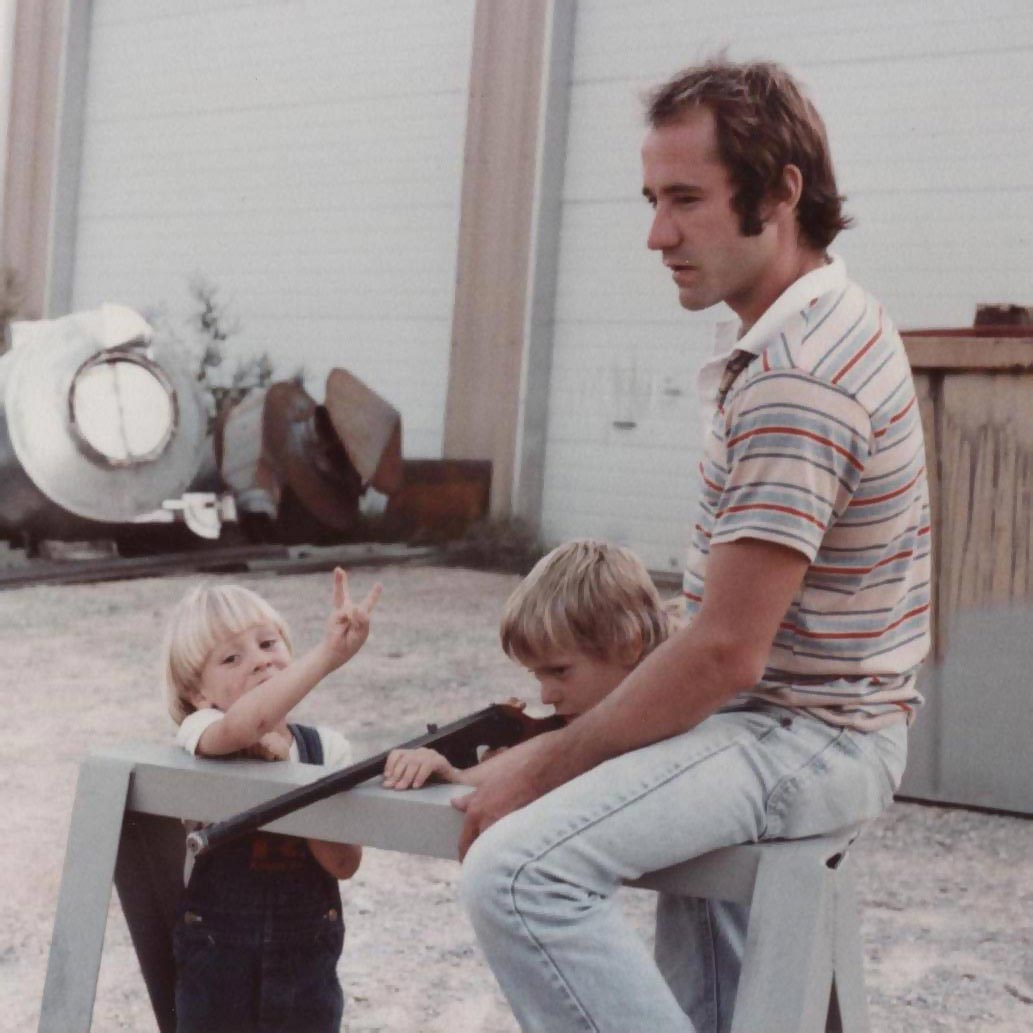

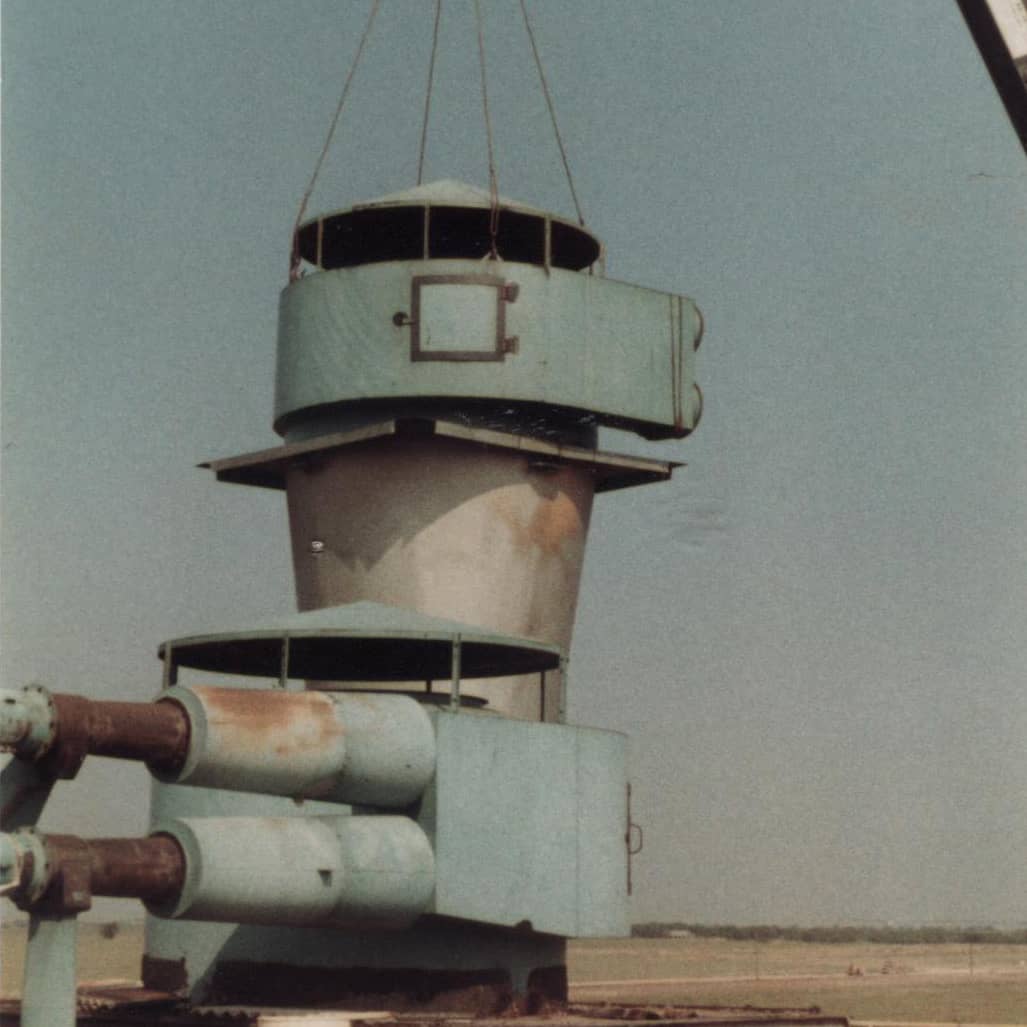

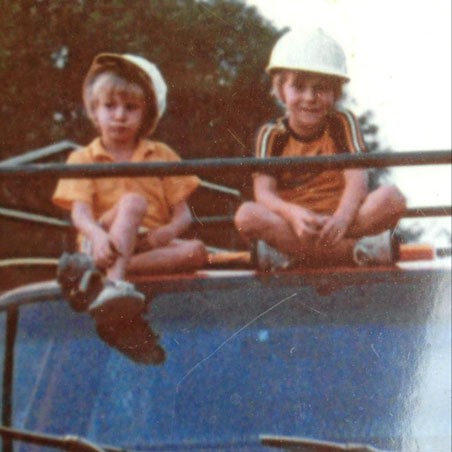

I grew up in a family-owned and operated sheet metal shop. My granddad, a loving and driven man, had me slagging parts and sorting hardware by age seven. I spent every minute of every summer in and around the shop. It was a noisy, greasy and busy place – and I loved it! At an early age, I was fascinated to learn what a cyclone and baghouse were and how they were built. Warm family gatherings always included shop talk and I would eagerly sit in on those conversations, listening to every word. Today is no different. I still love fabrication and never pass up an opportunity to tour a fabrication facility. Dust and fume filtration is truly in my blood.

I grew up in a family-owned and operated sheet metal shop. My granddad, a loving and driven man, had me slagging parts and sorting hardware by age seven. I spent every minute of every summer in and around the shop. It was a noisy, greasy and busy place – and I loved it! At an early age, I was fascinated to learn what a cyclone and baghouse were and how they were built. Warm family gatherings always included shop talk and I would eagerly sit in on those conversations, listening to every word. Today is no different. I still love fabrication and never pass up an opportunity to tour a fabrication facility. Dust and fume filtration is truly in my blood.

I started as a sales rep in my early 20’s. At the time, the industry was led by a couple of company giants who promoted the practice of filling holes. I was quickly taught to stretch the limits, get the orders and move on to more projects. This philosophy was fundamentally against what I had learned growing up in the family business. Unfortunately, top dust and fume collection companies continue with this practice today. But being ambitious and eager to please, I unwisely suppressed my opinion of it and sold collectors in this manner for years. Increasingly unhappy with my circumstance, conviction compelled me to start my own business.

In October 2001, I founded Imperial Systems with the mission that my company would build the best dust and fume collection equipment on earth. Our collectors would be designed and built from an end user’s point of view, last longer and filter better than any other collector on the market. Growing up in manufacturing, I knew that one of our strongest attributes was that we were a company that knew how to design, build and install complete systems from start to finish. This was a distinct advantage over the big companies and still holds true today. Every one of our sales engineers has spent time in the field installing systems so that they understand what they’re selling and what it takes to get equipment properly designed for a dependable installation.

In October 2001, I founded Imperial Systems with the mission that my company would build the best dust and fume collection equipment on earth. Our collectors would be designed and built from an end user’s point of view, last longer and filter better than any other collector on the market. Growing up in manufacturing, I knew that one of our strongest attributes was that we were a company that knew how to design, build and install complete systems from start to finish. This was a distinct advantage over the big companies and still holds true today. Every one of our sales engineers has spent time in the field installing systems so that they understand what they’re selling and what it takes to get equipment properly designed for a dependable installation.

For years we successfully built and sold cyclones, baghouses, ducting and airlocks. In 2010, I decided to expand the company by building cartridge style dust collectors. When we started, we copied a major brand’s collector almost exactly. Unfortunately, this was a mistake for several reasons. For one, it did not differentiate us from our competitors. The technology was old, and by replicating it we made ourselves a “me-too” brand. The only way to compete was on price, which immediately put us at a disadvantage. We were the smallest industrial dust collector manufacturer in the industry. Why would someone buy from us over one of the larger, more established companies? When it was all about price, we would win a job but lost money as a consequence. Regrettably, I realized that copying a competitor was a short-sided strategy. Being a me-too company is not what I had envisioned as our future.

So, we regrouped and made some innovative design changes. We committed to build a better cartridge dust collector and differentiate ourselves from our competitors. It was then that I realized that our strength was in our differences. From that point on, we reminded ourselves of this insight at every design and engineering meeting. It became a mantra as we insisted on being innovators, not copiers. That’s when our business started to thrive. Independent sales reps started calling us unexpectedly to represent our product line. We started winning the majority of the quotes that we were working on. It was a new beginning for the newly designed CMAXX, now the flagship of Imperial Systems.

I am proud of the new approach and success that Imperial Systems has had with the CMAXX. The innovations came from customers reporting to us the problems with other equipment that they have had for years. They spoke and we listened. Because of these innovations and loyal customers, Imperial Systems is now the most progressive dust and fume collection company in the industry today. Ironically, CMAXX is now the most copied collector on the market!

I guess you can say we are now doing things right. We’ve emerged with dignity from being an ambitious imitator to an innovation leader. We are transparent about the solutions we provide to fill needs, not holes. I’m so grateful to my granddad for his influence on my life. And I thank every member of the Imperial Systems team for fulfilling my true vision of this company.

Why We Do What We Do

As an impressionable child, I was blessed by my attentive and affectionate great grandmother. She generously spent her time babysitting me, my brother, and my cousins. As both protector and storyteller, she would care for us while my hardworking family was busy during the summers. She had the most captivating stories and most of them traced back to her days growing up as a child in Southeast Kentucky. Her impressions on me as a child at play contributed to forming the character I would develop as a man with a business.

Her brothers were coal miners and so was my great grandfather. They worked hard in challenging conditions of the coal mines. When they got home every night, my great grandmother would routinely wash their work clothes which were covered in coal dust. As a result of that ongoing dust exposure, my great grandfather contracted black lung disease. Consequently, my great grandmother was also affected and suffered from severe lung problems her entire life. It makes me sad to know that these illnesses trace back to the poor working conditions and unhealthy air quality in the mines.

I have shared this personal story with countless people. About 9 out of 10 of them shared with me a similar story of someone in their family who suffered or died from lung disease caused by poor air quality in the workplace. It both depresses and angers me that so many have been stricken in these common circumstances. Fortunately, the industry is changing and companies are providing better working conditions today.

When I was just starting this business at age 24, people often complimented me when I told them that I was in the air filtration control business. I usually got some comment like, “Wow, that’s really cool that you are taking care of the environment” or, “It’s good to hear that someone is cleaning up the air.” I remember that many times I would think to myself, “Yeah, I’m no saint. I’m just doing it because it’s what I grew up doing and it’s simply what I do.” While those comments to me were true at that point, I never really given it any thought. I was focused on growing the business and working on payroll from week to week.

Since that time, we have grown into a much larger and much more mature company. As our business has grown, so have our families. My wife and I now have two beautiful children and I’m very focused on them as well as our faith. With family comes more responsibility. Focus in life changes to a more outward concern once you realize that it’s not all about you (funny how having children does this to a person). I experienced new levels of gratitude and ambition to protect those around me.

Today, the culture of our company is such that we care deeply about one another and those connected to us. We want to make sure that we have a good and safe place to work at every day. I always tell our employees that at work we are also a family and that we spend more time with each other than we do at home with our individual families. It only makes sense that our work place should have a clean, friendly and a healthy environment. It’s our responsibility to make sure that our workers are breathing clean air and not taking dust and debris home to their families. That’s something that I have become deeply convicted about.

Given our family history and today’s caring culture in our company, it’s no wonder that we feel the same way about the people who need our products. Our team takes great pride when selecting the right air filtration equipment for our customers. We are conscientious when designing new products, making design changes, welding equipment or simply applying gasketing to ensure that no dust or fume escapes our filtration units. We believe that everyone should work in a clean, healthy and safe environment. That’s how we produce each and every dust and fume collector. Our life experiences develop who we become. That’s why we do what we do.