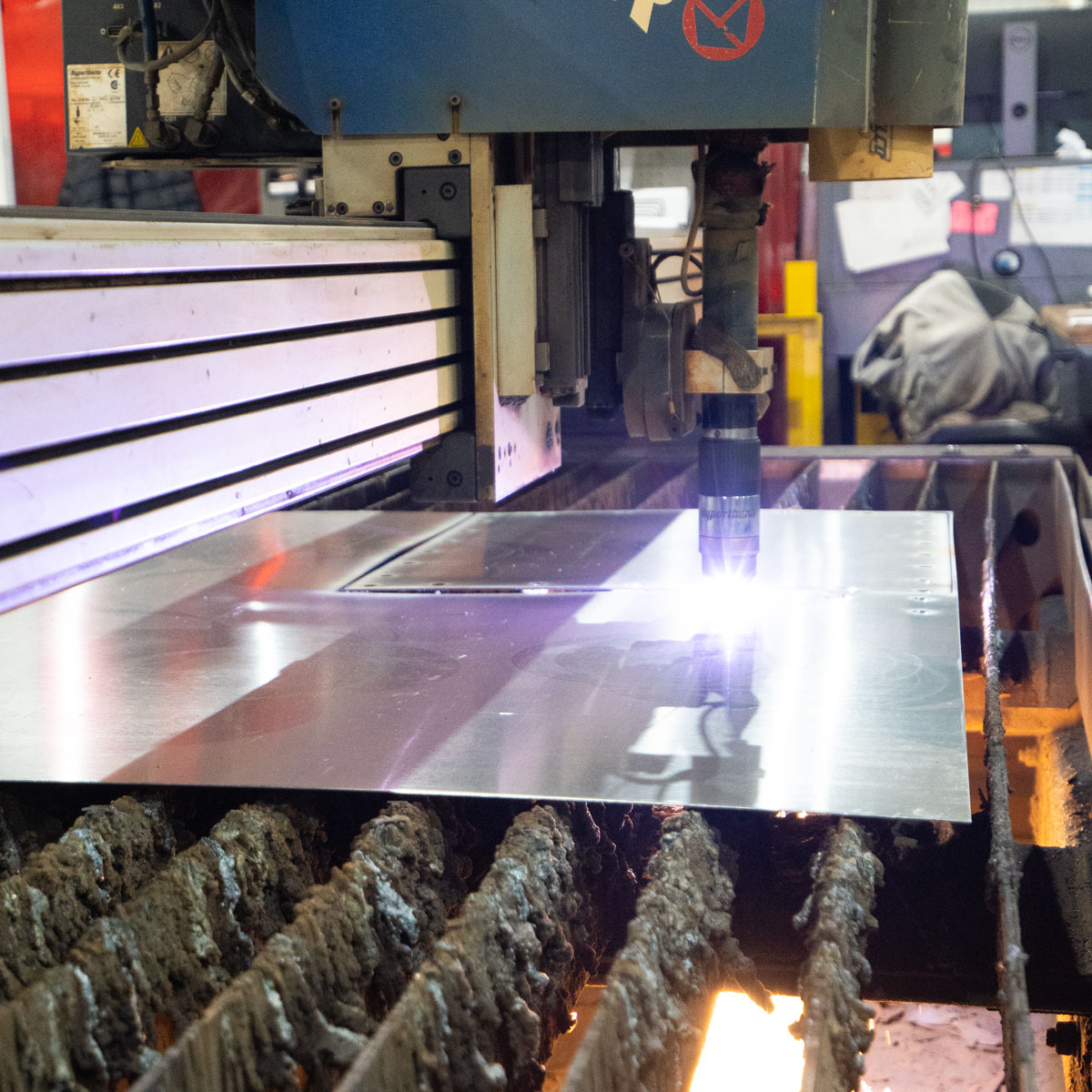

Plasma Cutting Fume Extraction

Plasma cutting is a widely used industrial process that involves using a high-temperature, ionized gas to cut through metal. Although it is a highly effective method for fast and precise cutting, it also produces hazardous fumes and smoke that can pose significant health risks to workers if proper precautions are not taken. Therefore, it is essential to have appropriate ventilation systems installed in areas where plasma cutting occurs to minimize the exposure of employees to harmful fumes.

DIFFERENT TYPES OF PLASMA CUTTERS

There are several types of plasma cutters available on the market. The choice of the best plasma cutter for a given application depends on the type of material, the thickness of the material, and the precision of the cut required.

- Conventional plasma cutters: These are the most common type of plasma cutters and use compressed air as the plasma gas. They can cut through a variety of materials, including stainless steel, aluminum, and mild steel.

- High-definition plasma cutters: These cutters produce a narrower kerf and smoother edge than conventional plasma cutters. Their precision makes them suitable for intricate or exact shapes and designs.

- CNC plasma cutters: Controlled by computer numerical control (CNC) software, these cutters allow for precise and automated cutting of complex shapes and designs.

- Handheld plasma cutters: These cutters are portable and can be carried to different job sites and work stations. They are ideal for smaller tasks.

- Dual gas plasma cutters: A mixture of gases, such as nitrogen and hydrogen, is used to cut through thick materials that are difficult to cut with conventional plasma cutters.

Here’s how a plasma cutter works. First of all, a gas is heated until it reaches the fourth state of matter, plasma. Secondly, molecules in this plasma state are electrically charged to conduct electricity. After that, an electric arc contacts the gas to produce a plasma jet. Meanwhile, forcing the gas through a nozzle forms the plasma jet, putting it under high pressure. The temperature of the plasma can reach 40,000 degrees Fahrenheit or even hotter.

The cutting temperature is much higher than the melting point of the metal being cut. Due to this, the plasma jet blasts through the metal. As a result, this turns the metal into very fine smoke or fume. Plasma cutter fume extraction is essential to protect workers from the dangers posed by these fumes.

A plasma cutting table uses a downward air flow. This pulls smoke and fumes from the cutting process. After that, the air passes through a dust collection system that filters out the contaminants. Finally, the air usually returns inside the building. This is because heated or cooled air would otherwise be lost in the process. There’s another consideration if the facility is cutting stainless steel. In this case, the dust collection system may need to have special filters to manage hexavalent chromium emissions.

How Does Plasma Cutting Produce Hazardous Fume?

All types of plasma cutting produce hazardous fumes to some extent. When the plasma arc cuts through metal, it vaporizes and ionizes the metal, creating a plasma plume that contains metal particulate and other harmful substances. The exact composition of the fumes can vary depending on the type of metal being cut and the type of plasma cutter being used. For example, cutting stainless steel can produce hexavalent chromium, which is a carcinogen, and cutting aluminum can produce aluminum oxide, which can cause respiratory irritation.

WHY ARE PLASMA CUTTING FUMES DANGEROUS?

Because plasma cutting can produce a different fume depending on a variety of factors, it can also affect employee health in many different ways.

- Metal particles: The plasma cutting process vaporizes and ionizes the metal being cut, creating metal particles that can be inhaled by workers. These particles can cause respiratory irritation, lung damage, and other health problems.

- Carbon monoxide: Plasma cutting can produce carbon monoxide, a colorless, odorless gas that can be deadly at high concentrations.

- Hexavalent Chromium: Cutting materials containing chromium, such as stainless steel, can produce hexavalent chromium, a carcinogenic substance that can cause lung cancer and other health problems.

Chemical Isolation Systems

A rapid discharge of a chemical explosion suppressant prevents the flame from continuing to other ares of your dust collection system. This is best used when explosion venting is not an option.

Spark Trap

A Spark Trap creates a tortuous path that slows sparks and embers down and causes them to loose heat. This prevents sparks from entering the dust collector and creating a fire. Spark Traps are recommended by NFPA as part of a complete fire prevention system.

Rhino Drum

The Rhino Drum Explosion Tested Drum Kit is a cost efficient alternative to a rotary airlock, and can withstand an explosion up to 7 psi. With a tool free design and no moving parts, the Rhino Drum can be quickly emptied for easier maintenance.

Abort Gate

An Abort Gate is typically situated on the return air side of the dust collector and diverts clean air, sparks, and fumes. An Abort Gate can also be trigged by a spark detector or broken bag detector, preventing harmful material like fire and smoke from entering the building.

Explosion Venting

Explosion venting allows a flame front and pressure wave to escape from within a collector and dissipate into the atmosphere. Explosion vents include a burst indicator that alert in the event of a deflagration.

Explosion Isolation Valve

This system is installed on the ductwork and detects any sparks that are present in the duct. Once detected, sparks are extinguished downstream before they can continue on and cause further damage to equipment or reenter the facility.

Airlock

Our Airlocks maintain a consistent seal at the outlet of the dust collector while allowing material to continuously pass through. This seal also allows discarded material to be properly discharged, and prevents it from returning to the dust collector.