Special Fabtech Edition with Brian Norris from Nordfab Ducting – Dusty Jobs Podcast – S3 E7

In this special episode we are recording at Fabtech Atlanta 2022 from our booth. We are talking with Brian Norris from Nordfab Ducting. He discusses what they do at Nordfab and what the different types of ducting there are and their different uses.

Narrator: Welcome to the Dusty Jobs Podcast from Imperial Systems. Industry knowledge to make your job easier and safer.

Donovan: Hello, and welcome to another episode of the Dusty Jobs Podcast. Today, Brian Norris is here from Nordfab Ducting. How are you doing?

Brian: Doing excellent! How about yourself?

Donovan: Good! And if you’re listening this and it seems a little loud, it’s because we are at Fabtech. We’re doing a big trade show this week. And you guys are here too, aren’t you?

Brian: Yeah, absolutely. So we’re over in A Hall, booth 1946.

Donovan: So guys are looking forward to the first day of the show. We’re looking forward to a lot of people coming in and I’m sure you are too.

Brian: Absolutely. We got a full team over there ready to talk to people, and it’s been really busy so far.

Donovan: How many Fabtechs have you been to Brian?

Brian: So this is going on my fifth year with Nordfab, so five years.

Donovan: Do they still have it during 2020, or no?

Brian: Well, yeah that’s a good point. I think we did kind of furlough that one.

Donovan: Yeah, I couldn’t remember.

Brian: So maybe three. Three or four.

Donovan: But it’s always a great show for us. I’m sure it is for you guys too.

Brian: Absolutely. It is a great show. And it’s the last one of the year; we’re excited about it.

Donovan: For people who aren’t familiar with Nordfab: What is Nordfab?

Brian: So Nordfab Ducting is going on forty-four years now of manufacturing ducting. We’re in Thomasville, North Carolina. It’s kind of the furniture capital of the world, so think about textiles, manufacturing, dust, things like that… that’s kind of how we got started. And we kind of revolved into our quick fit plan, which is kind of our package plan…

Donovan: You said quick fit plan…

Brian: Exactly. We call it QF. But it’s our quick fit plan. It makes insulation extremely easy…

Donovan: As opposed to a slow fit plan.

Brian: That’s right. Or let’s say, the screws went in spiraling, or even bolts on a flange product which we got to talk about later…

Donovan: Sure, sure, okay.

Brian: But yeah, quick fit is our less labor-intensive way to install tons of ducting. It’s basically modular, so our pipes come in modular sections and you just clamp them together and go.

Donovan: Gotcha. So your style of duct work is a quick… quick… I’m going to mess this up. Quick fit clamp. There we go, I finally got it!

Brian: And we can call it QF if you want.

Donovan: QF! Let’s do that. That’ll make it easier. So you guys have a QF-style duct work. You mentioned it comes in five-foot sections.

Brian: Correct.

Donovan: And you say it’s less labor intensive. So, everyone who is listening, we don’t have a piece here. Tell me how this works. Explain it to me.

Brian: It’s completely modular. So what’s great about it is you can system up. You can take a system down. You can move it across town…

Donovan: But you’re telling me there’s no screws or clamps on this.

Brian: That’s right. Just clamps together. So we have a rolled lip, and those two pieces of rolled lip are married together and then they clamp right down.

Donovan: So is it a lot like what you get on a barrel lid clamp?

Brian: Yeah, exactly. A lot like that.

Donovan: Okay. But then it holds the ductwork together.

Brian: Yeah, absolutely.

Donovan: And it’s solid enough that you don’t have to use anything else?

Brian: Nope. That’s it.

Donovan: Okay.

Brian: We do have a gasket of what we call a QFS, it’s a quick fit seal. If you have an oil mist application of where you want leakproof, we do have a gasket for that. But that would be the only real thing that you would do differently.

Donovan: Gotcha. Quick fit. QF. Is it okay to use in every application? Is it okay to use indoor, outdoor, is there spots where you should use it or shouldn’t use it?

Brian: Yeah, great question. You can use it anywhere. It’s a tried and tested product. We actually have third-party testing on it as well, so there’s leakage rates and all of that. In an outdoor application, because a system is inherently pulling moisture and there are some leakage points. You would want to add that quick UFS seal in an outdoor application, and then we’ll epoxy some of the branches and elbows as well if you tell us, so we’re not pulling moisture into the system.

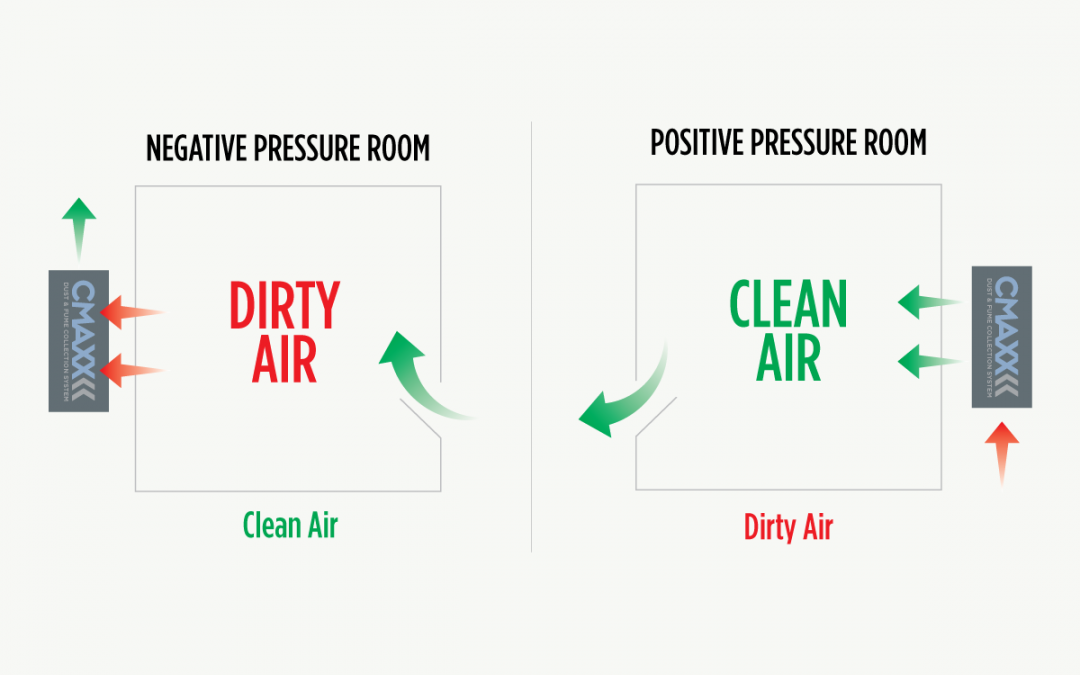

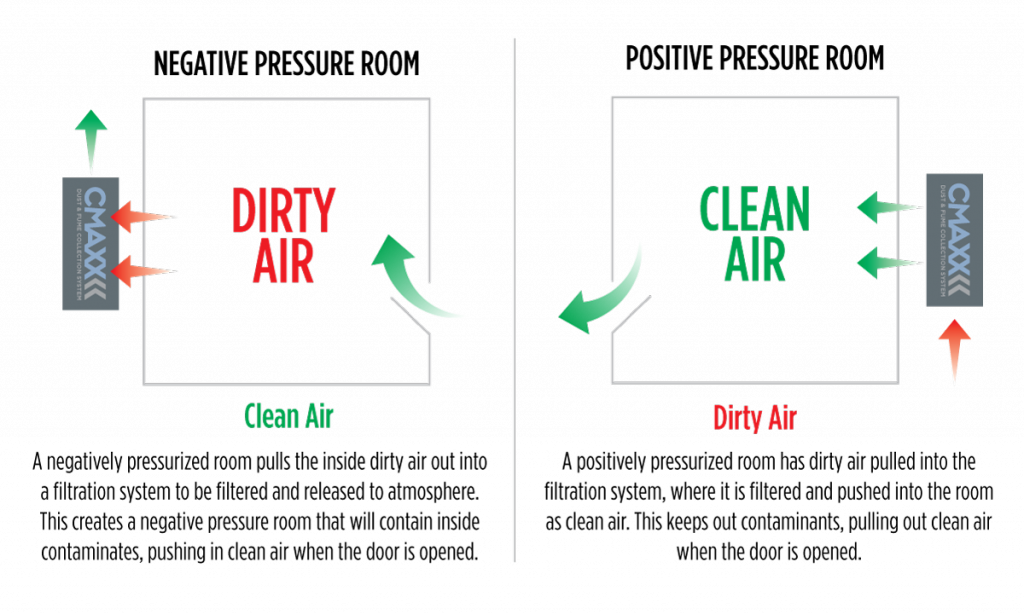

Donovan: Gotcha. Because on a dust collection HVAC, we’re going to be at negative pressure…

Brian: Exactly. It’s going to bear pulling from all different areas.

Donovan: And I can say from the dust collector’s side, we don’t want to be sucking the rain in from outside.

Brian: That’s not a good thing. Exactly.

Donovan: So now that we’re putting it all together and it’s real simple and easy, how big of a piece can I get in this quick fit?

Brian: Great question. In our QF system we can do three inches in diameter all the way up to twenty-four inches in diameter. Anything larger than that, which we can go up to 84 inches in ducting.

Donovan: So your duct can be 84 inches from Nordfab…

Brian: But not in QF.

Donovan: QF goes to…

Brian: Twenty-four.

Donovan: Gotcha.

Brian: And then anything over twenty-four, we will do a flange on. So we vance on it, put a flange on it. And you can up anywhere from twenty-five to eighty-four.

Donovan: So we’re talking about a flange together, ductwork. That’s one that you actually have to bolt.

Brian: That’s right. So you got bolt pattern all around the flange. You got to put an individual roll with a nut on it, which is a little bit time-consuming.

Donovan: I can see how… when you get up to that size, how many bolts do you have to put in there?

Brian: I mean, an eighty-four-inch, we’re talking about a huge piece of ducting. It could be twenty, forty bolts.

Donovan: What about on like a twenty-eight-inch piece?

Brian: Ah, well that’s the other thing. We do custom bolt patterns. You could do as little as three or four, or as many as twenty if you wanted.

Donovan: So you could have twenty in that, but if you did a quick fit, it’s just one clip, and you’re done.

Brian: Less than ten seconds. Throw the clamp on. Put the carter pin in. Move on to the next one.

Donovan: So to put these systems together, do you have to come to you guys to get a specific training on how this goes together? Is this something that someone who owns their own woodshop or their own weld shop… could they do it on their own?

Brian: Yeah, in theory anyone could put this together. There are Youtube videos out there on how to put it together. It’s super simple. We have woodshop guys do their own installations all the time.

Donovan: Okay. Are there other companies out there that also have this system in place.

Brian: Yeah absolutely. We have competitors that try to copy and mirror what we do, if you will. But we still think we do it a lot better.

Donovan: So what’s different about you guys and them?

Brian: A little bit of history about Nordfab: We’re ISO-certified 9001 to 14001, okay? We laser cut. We laser weld. And we build quality into the product. We’re trying to give you the very best product we can, built into the product. And we think we do it better than others, and we have a ton of tools that can go along with that. But we think we do a really good job at manufacturing that. And we are a global company. Majority of our corporate headquarters is in Thomasville, NC. The majority of what we sell globally is out of that facility. But we have other locations around the world as well and we’ve been doing it for a long time and we really take a lot of pride in what we do.

Donovan: That’s great! So, let’s take a little bit of a shift here. Obviously, you guys sell ductwork. But if I’m a shop owner, or a business owner, or a weld shop… I know it’s not as simple as buying some ductwork and putting it up there. I mean, there’s got to be some type of formula. I’ve been in a lot of facilities and you don’t just have one piece of ductwork that’s the side of… well, actually you do see that in some places. But from the dust collection side we know that that’s not the best way to do that. So do you guys help at all with someone who just wants to size that system out?

Brian: Yeah. Absolutely. So, one thing we see a lot of people coming to us wanting the help. So we go to market through dealers and distributors. We don’t sell direct. But we do like to take and foster those leads and work with those individuals through a specific dealer in their market and try to help them out. Now we have some tools that help load the in-user end, our dealer out, and one of those that we just launched… and we love our acronyms, so I apologize here. It’s QFV, which is quick fit vid. So that’s our 3-D drawing tool that we’re very proud of. It’s a proprietary tool that Nordfab had developed to incorporate our ducting, our clamps, our accessories, all the things we sell along with our product reference playbook, if you will. So that tool’s very helpful, because what is different about that tool from our competitors is that it will do sizing for you, it will give you pressure loss calculations, and it kind of takes a lot of the guesswork out for someone who’s kind of a novice, and doesn’t understand all that.

Donovan: Right. So if I’m moving into my new woodwork shop, right? And I’m looking at everything, and I know where my equipment is going to be. Then I’ve got to figure out how to make sure all the ducts get sized properly, and I call up Nordfab. Next thing you’re going to do is send me to someone that you guys have already trained on how to do this, is that right?

Brian: That’s correct. So we have dealers all over the country that know how to use this tool and are using this tool to help generate those drawings and those quotes for those customers.

Donovan: And then that person will help work through the design and get my order together.

Brian: Absolutely.

Donovan: And then send it to you guys and then you guys get it out the door.

Brian: Exactly.

Donovan: Gotcha. Gotcha. So, you’ve been doing this for a while. What do you think the biggest mistake is that you see a lot of people when they’re doing this… what do you think it is?

Brian: Well, what we see is, you got a piece of pipe, and then you got to drop down to a machine. People love T-branches. They think ‘Aw, that’s so easy. I’ll just run a T-branch down to that machine. A ninety-degree bend for airflow is not great, right? Contrary to popular belief. So we’ll incorporate elbows that may be on a thirty or forty-five degree and gently roll into that flow, rather than be on a ninety. So, we see that a lot. People want to throw Ts in there and they really aren’t that great for airflow.

Donovan: Might look like the right idea, but it’s not the right idea.

Brian: Exactly. And then the other thing we see is balancing flow. We sell manual and automatic blast gates. And so what a lot of guys will do with our manual blast gates… you get a lot of negative pressure in there… and they’ll actually use the blast gates… you can open them as much or as little as you want…

Donovan: Now you’re using the word blast gates…

Brian: It’s a little misconceiving. It’s more of just a gate that closes, we don’t actually use them for anything blasting.

Donovan: So it’s almost like a knife valve that’s in the pipe?

Brian: Exactly. It looks like a guillotine almost. So it’s sliding up and down inside of the pipe…

Donovan: And the point of that is to…

Brian: Well, there’s multiple uses. One that I was getting at is you can regulate airflow, right? So if you’re not getting the airflow you need, you can open it a little and bleed some air in to help regulate your airflow. And you can also put it as a capture point. So let’s say you’re a small woodshop, you’ve only got maybe a five-horsepower collector but you’ve got eight machines. Well, you’re one guy. You can’t run all eight machines at one time. So let’s close seven of them off, and only open one of them while you’re operating. So your collectors are working at full efficiency.

Donovan: And I know on our dust collector’s side that if you can do that, it actually allows you to buy a smaller unit which then can save you money and energy in the end.

Brian: Absolutely. So that’s another use for that.

Donovan: Now, one of the things I see people, in woodworking at least… they love the flex stuff.

Brian: They do.

Donovan: So what’s your opinion on flex stuff?

Brian: Less is more.

Donovan: Less is more?

Brian: Try to use less flex stuff. The more hard piping you can use, the better flow you’re going to get, in our opinion. We see a lot of people wanting to run all kinds of flex stuff and it’s never straight. It’s got a bend in it and it’s curled up, and it is challenging when you’re trying to collect dust and things like that.

Donovan: On our side, we say that really makes the system work a lot harder.

Brian: It does.

Donovan: Where it could be more efficient to pull more dust away from the process.

Brian: Right. Absolutely.

Donovan: Now we were talking about the slide piece. You started to say that’s how you would balance the system. Let’s say I have this much money this year, and I know I’m going to buy this piece of equipment. But I know that next year I’m going to have more money, and I’m going to buy more equipment. Does it make sense to buy the ductwork for the future? Or does it make sense to buy it later?

Brian: The good thing about quick fit is, you could buy an end cap. You can run a section twenty feet and put an end cap on it and stop the flow of air, right? Put them in the ends. You want to buy two machines later, the quick fix is you just unclamp it and start adding your pipes. So, with our modular quick-fix system, it makes it super simple to add another drop pretty efficiently later if you want to do that.

Donovan: We’ve experienced that too. We have a lot of people who you can go in and help adjust things later down the line. Hopefully peoples’ businesses keep growing, or they just get that new piece of equipment that’s going to help them and they’re not so locked into a framework that it makes it impossible for them to adjust or costs them a lot of money to adjust.

Brian: Exactly. And that’s why this is so great. You decide you want your machine on the left or the right, you just unclamp it, spin your ducting and you plant the back. That’s what makes the quick fit so great. You’re not stuck to one position or place.

Donovan: I’ve also been in places where the whole process has changed, and then they have to rearrange for where their machines are.

Brian: We see that a lot. A lot of companies change machines all the time. They don’t like it there, or they need more space. Things like that.

Donovan: So those are some things maybe if someone is trying to think ahead, they’re thinking about buying a machine. That’s what a lot of people are doing here at Fabtech.

Brian: Absolutely.

Donovan: And when they start getting into that design phase, it might be something to consider, what’s coming up down the line.

Brian: For sure.

Donovan: Well, since we’re talking about other companies’ future growth and what they think is coming down the line, what about you guys? What about Nordfab? What’s coming up for you down the line?

Brian: We’re growing year over year ever since I’ve been down there and even before that, but it’s pretty exciting this year. We broke ground on a fifty-five thousand square foot addition.

Donovan: Wow.

Brian: So we should be under a roof here before Christmas on that. And we got some warehouse automation we’re incorporating next year. So our goal is to have more products and more standard products readily available on the shelf, ready to go so we can ship faster and provide the very best products as quickly as possible.

Donovan: So you’re going to keep doing what you’re doing, but you’re going to be doing it faster and trying to get the product out sooner? Sounds great!

Brian: And what we’re doing with that is we’re incorporating our quote tools and our drawing tools to point you in the right direction with more standard product that’s on the shelf. So when you’re drawing those drawings it’s going to…

Donovan: Let you know what’s available?

Brian: Yeah. It’s going to lead you down the right path so you can get the product faster. We’re working a lot of that stuff and it’s going to be really impressive. We’re excited about that.

Donovan: That does sound great. That sounds like a really good thing you have going on there.

Brian: Absolutely.

Donovan: Well, is there anything else that you think is important to tell people about ductwork, other than probably don’t use spiral duct if you’re going to be in a high-pressure situation?

Brian: Do not! I mean, we had a conversation about that earlier about a guy that turned his collector on and his spiral duct collapsed.

Donovan: We did! We had a guy do that!

Brian: You know our product is twenty gauge, all the way down to ten gauge. So it’s a really robust product. Again, it’s laser cut, laser welded. Our clamps are the very best clamps. We keep reinventing the wheel and squeaking that clamp, and we’re on three or four iterations in the past few years just tweaking and making it that much better. And I think that’s what separates us from our competitors. We keep notching up the intensity every year and trying to do better.

Donovan: Not that the old one was bad, but the new one is better.

Brian: Yeah. And we talk to our dealers. We get feedback. They tell us what they like and they don’t like, and we try to incorporate that and make it better.

Donovan: Same here at Imperial. Well Brian, I want to say thanks for joining us, I appreciate it. I hope you guys have a great show.

Brian: Thank you guys for having us. You’re a great partner with Nordfab and we appreciate the business, and for having us here today.

Donovan: Yeah, yeah! So everybody out there who’s listening, thanks for tuning in, thanks for listening. We’ll be trying to do a few more of these from Fabtech, and hopefully, you guys enjoy them. Until next time, stay healthy and stay safe. You can find us on Instagram and Twitter… we’re on every social media platform. You guys are too, right?

Brian: Absolutely.

Donovan: Check them out.

Brian: And again, we’re at booth A-1946, we’re at Fabtech. Stop by and see us.

Donovan: There you go. All right, thanks so much.

Brian: Thanks guys.

Donovan: Have a great day. Bye.

Narrator: Thanks for listening to the Dusty Jobs Podcast. Breathe better, work safer.

Read more

One of our goals at Imperial Systems is to continuously improve our products so they are easier for our customers to use. This past year, we introduced a touch screen control panel interface, the Keystone Controller, and we are eager to share this improvement with attendees at FABTECH.

One of our goals at Imperial Systems is to continuously improve our products so they are easier for our customers to use. This past year, we introduced a touch screen control panel interface, the Keystone Controller, and we are eager to share this improvement with attendees at FABTECH.