by Erin Long | Apr 15, 2019 | Uncategorized

Some Interesting Welding Facts As We Recognize National Welding Month

Some Interesting Welding Facts As We Recognize National Welding Month

- Welding started in the Bronze Age when people first began using different types of metals. Blacksmiths mastered the art of forge welding, or heating pieces of metal to red heat and then hammering them together.

- Welding using electricity started in the 1800s, but the welds were often brittle because the metal oxidized. Welded seams at this time were prone to failure.

- The 1920’s saw research into shielding the welding arc with various gases to prevent welds from becoming brittle from exposure to oxygen. Eventually, this research would lead to early versions of all shielded welding processes.

- The first industrial robot ever put into use was a spot welder used by General Motors. It weighed two tons.

- In space, there’s no oxygen. Because metals can’t form their usual layer of oxidation, two different types of metal that touch each other in space will instantly weld themselves together.

- According to the Bureau of Labor Statistics, the average pay for welders across the United States is $19.35 per hour. Most welders have a high school education.

There are an estimated 410,000 welders, cutters, solderers, and brazers working today. The average age of these welders is 54 years old, suggesting that not as many young people are choosing it as a career.

There are an estimated 410,000 welders, cutters, solderers, and brazers working today. The average age of these welders is 54 years old, suggesting that not as many young people are choosing it as a career.- Welding jobs are expected to grow at a rate of 6% to 10% over the next twenty years, not including the need to replace retiring workers.

- 50% of all manufactured products, from bridges to computers, go through some type of welding during their manufacturing.

- Welders with special skills, like underwater welding, can make up to $100,000 per year. These jobs require extensive training in the special challenges of the work.

- Welding as an art form has led to some amazing metal sculptures that are on display all over the world. Welded art has become a growing industry.

- Besides standard welding methods, some applications use ultrasonic vibrations to cause metal molecules to bond together. Others use explosions to create enough pressure to force metals to bond.

- Many industries, including the automotive industry, use robot welders in their manufacturing process. While the robot welders can repeat the same welding tasks over and over, they are no substitute for an adaptable human welder.

Share your count!

So how many of these welding facts did you know? Share your answer in the comments of our Facebook post now.

Got a welding fume extraction problem in your shop? Contact us here at Imperial Systems!

Read more

![The Dangers of Phosgene Exposure [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/04/featuredimage_phosgene-1080x675.jpg)

by Erin Long | Apr 10, 2019 | Uncategorized

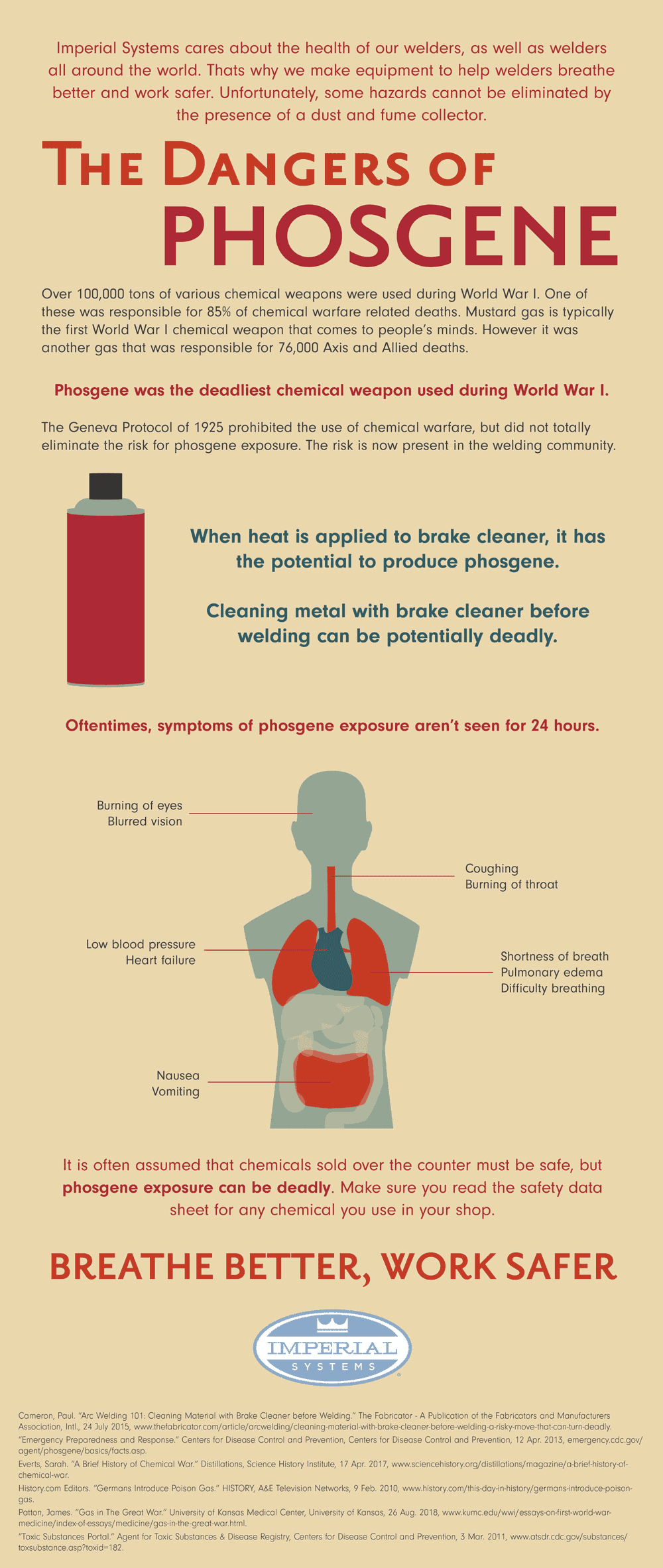

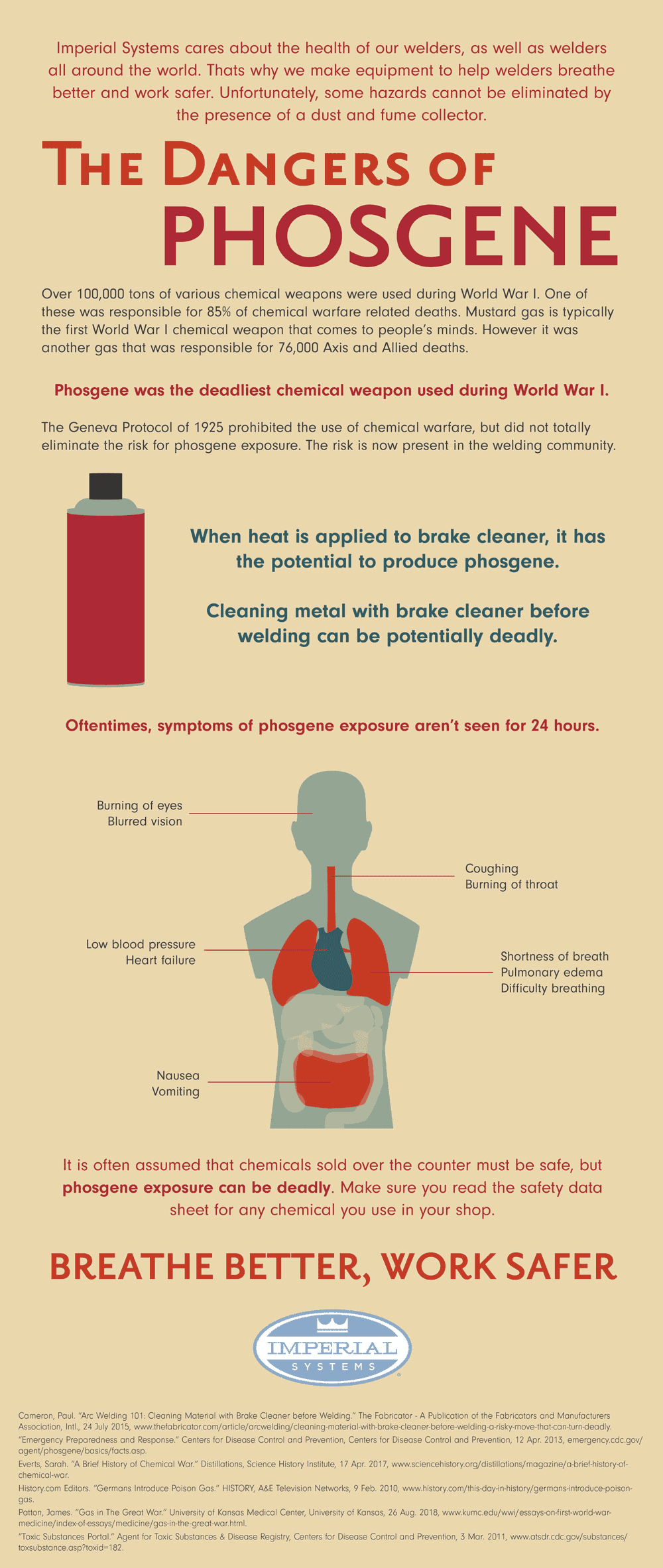

This brief infographic describes the dangers of phosgene exposure. Phosgene is a potentially deadly gas that should be avoided at all costs. Phosgene gas is created when heat is applied to brake cleaner, making it a potential hazard to welders. While a dust and fume collector will not eliminate phosgene, you can take proper precautions to avoid it.

Over 100,000 tons of various chemical weapons were used during World War I. One of these was responsible for 85% of chemical warfare-related deaths. Mustard gas is typically the first World War I chemical weapon that comes to people’s minds. However, it was another gas that was responsible for 76,000 Axis and Allied deaths.

Phosgene exposure was the deadliest chemical weapon used during World War I

The Geneva Protocol of 1925 prohibited the use of chemical warfare but did not totally eliminate the risk of phosgene exposure. The risk is now present in the welding community. When heat is applied to brake cleaner, it has the potential to produce phosgene. Cleaning metal with brake cleaner before welding can be potentially deadly.

Oftentimes, symptoms of phosgene exposure are not seen for 24 hours. These include burning of the eyes and throat, blurred vision, coughing, difficulty breathing, pulmonary edema, nausea, vomiting, low blood pressure, and heart failure. It is often assumed that chemicals sold over the counter must be safe, but phosgene exposure can be deadly. Make sure you read the safety data sheet for any chemical you use in your shop.

Imperial Systems cares about the health of our welders, as well as welders all around the world. That’s why we make equipment to help welders breathe better and work safer. Unfortunately, some hazards cannot be eliminated by the presence of a dust and fume collector.

Learn more about phosgene gas in this related blog post.

Read more

by Erin Long | Apr 2, 2019 | Weld Fume

About the School and Their Challenge

About the School and Their Challenge

Located in northern Texas, the Community College offers comprehensive two-year educational programs – including a welding technology program. The school offers Associate of Art, Associate of Science, and Associate of Applied Science Degrees. The Welding Technology Program was interested in more cost-effective cartridge filters for welding fume in their Lincoln Statiflex 6000 dust collector.

Solution: DeltaMAXX Filters for Welding Fume

An Imperial Systems aftermarket member was making daily cold calls to businesses in the industrial realm. They struck a sale with the community college while talking with the instructor of the Welding Technology Program. The aftermarket member learned that the school was shopping around for replacement dust collector cartridge filters for the upcoming school year. Due to the budget, it was a top priority that the filters for welding fume were cost-effective and reliable.

After reviewing the DeltaMAXX filter literature and cross-referencing the filters on Imperial System’s website, the welding technology instructor purchased four DeltaMAXX replacement cartridge filters for the upcoming school year.

Results Beyond Customer Expectations

After running the filters in the dust collector for the fall semester, the welding school instructor was “really impressed” with the DeltaMAXX Replacement Dust Collector Filters.

“The System is running very smooth, not much back blow. When turning on the dust collector in the past we have had problems with smoke blowing out of the back. That problem went away when we installed the DeltaMAXX filters”, said the Texas welding school instructor.

“Imperial Systems’ dust collector filters for welding fume are very durable and they are lasting much longer for us. My expectations were exceeded and you can count on us to be a returning customer.”

Learn more about how Imperial Systems can provide better performing, long-lasting replacement cartridge filters for your existing dust collector. Contact us today.

Read more

by Erin Long | Mar 25, 2019 | Uncategorized

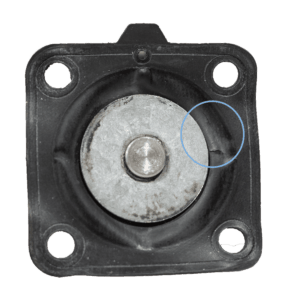

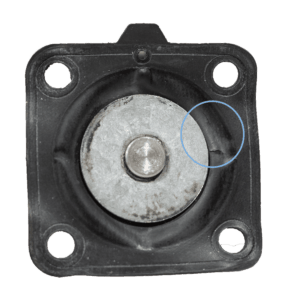

Does everything with your dust collector look like it’s working properly? That doesn’t mean there aren’t problems you can’t see. Dust collector valves are often the culprits of hidden costs due to internal damage.

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

Because of this damaged valve, the filter that it’s cleaning is getting less compressed air than the other filters. So, each pulse is not fully cleaning it. That means that filter is going to blind off and need replacement sooner, costing you money. Multiple small valve leaks can have a major impact on shortening the life of your filters.

Springing for New Dust Collector Valves

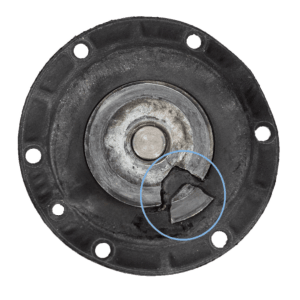

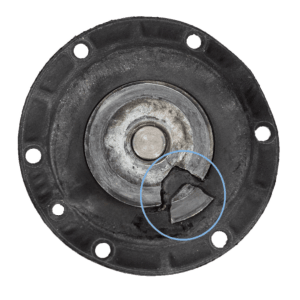

The following photo is from a ServiceMAXX visit for a problem completely unrelated to the diaphragm valves. However, when our technician did a routine inspection of the valves, he found a problem. The springs inside of them had completely fallen apart:

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

We’re Dying to Find Leaks!

Another ServiceMAXX option is a dye test. In this test, a harmless fluorescent powder runs through the dust collection system, which is then inspected with ultraviolet light. The powder glows brightly. If everything is working properly, the glow will be seen only on the outside of the filters, on the dirty air side of the collector. Any glow on the clean air side means that the dye and other dust is getting through a leak somewhere. This test identifies even very small holes in filters that can’t otherwise be seen.

ServiceMAXX technicians can also perform many other services. Please contact us to schedule a ServiceMAXX visit or a yearly maintenance program. A yearly scheduled maintenance program will give you priority scheduling during times when our technicians are very busy, and makes sure your system is always running at maximum efficiency.

Read more

by Erin Long | Mar 15, 2019 | Uncategorized

In January 2019, a facility in Indiana reported an aluminum fire. The company produces aluminum alloys for the auto industry. The fire resulted from highly combustible aluminum dust that had accumulated in the building.

The facility had a sprinkler system that certainly helped keep the fire from becoming an explosion. Fortunately, all the employees escaped without injury. Every facility that handles combustible material can take some advice from this incident.

What Caused the Accident?

Aluminum dust has a high Kst value, meaning that it can cause a very strong explosion. Because of how destructive an aluminum fire can be, take precautions to control and remove aluminum dust.

This facility has a dust collector. But aluminum dust had still accumulated around the building, especially on overhead beams. During routine cleanings, one can miss dust from flat surfaces in high places that accumulate it.

This facility has a dust collector. But aluminum dust had still accumulated around the building, especially on overhead beams. During routine cleanings, one can miss dust from flat surfaces in high places that accumulate it.

In the Indiana facility, they could not determine where the dust found an ignition source. First, it spread from an area near a furnace, igniting combustible aluminum dust that had accumulated in the area. Then the aluminum fire continued to spread by igniting dust piled up on the ceiling beams.

Their sprinkler system did activate. As a result, this probably prevented a dangerous explosion by keeping the dust from forming an airborne cloud. However, the fire burning on the overhead beams was above the sprinkler system.

From the overhead beams, the aluminum fire was able to spread and reached the dust collector. This caught on fire and burned until the fire department could extinguish it.

Recommendations for Prevention of an Aluminum Fire

Like many combustible dust incidents, this aluminum fire resulted from poor housekeeping. Accumulated dust in a facility can find an ignition source from a spark, faulty wiring, or machines. With a high Kst dust like aluminum, the dust can certainly cause an explosion.

The explosion can cause disturbed layers of dust to become airborne. Consequently, this leads to secondary explosions which can be devastating. However, in this aluminum fire, the dust on the beams did not get a chance to turn into a dust cloud.

Outdoor Installation

This aluminum dust did burn and continue to spread the fire throughout the building and into the dust collector. Fortunately, the collector was located outside the building. With highly combustible dust, it’s almost always the recommendation to locate the collector outside. If an explosion does happen in the dust collector, it will vent away from the building and people inside.

Safety Features

Dust with a high Kst value like aluminum requires a dust collection system with fire and explosion prevention. This company had a sprinkler system in the building. But even after the sprinkler system triggered, nothing stopped the fire from entering the dust collector. Since an explosion wasn’t reported, the collector probably had explosion vent panels or some other safety features.

Housekeeping

The most basic recommendation to prevent an aluminum fire, or any other dust fire, is good housekeeping. This means making sure there is no dust buildup around the building. So check and remove any dust from high surfaces like beams.

A dust collection system prevents a buildup of dust in the facility by capturing and removing it. This company had a dust collector, but it clearly could not handle all the dust being produced. An experienced dust collection system designer will make sure your system can capture all the dust your processes create.

The

CMAXX Dust & Fume Collector can meet all your company’s dust collection needs. With an Imperial Systems system designer working with you, your system will be able to handle even highly

combustible dust like aluminum. This will keep your building and workers safe.

Some Interesting Welding Facts As We Recognize National Welding Month

Some Interesting Welding Facts As We Recognize National Welding Month There are an estimated 410,000 welders, cutters, solderers, and brazers working today. The average age of these welders is 54 years old, suggesting that not as many young people are choosing it as a career.

There are an estimated 410,000 welders, cutters, solderers, and brazers working today. The average age of these welders is 54 years old, suggesting that not as many young people are choosing it as a career.![The Dangers of Phosgene Exposure [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/04/featuredimage_phosgene-1080x675.jpg)

About the School and Their Challenge

About the School and Their Challenge In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one. The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems. Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.