by Imperial Systems | Oct 17, 2016 | Uncategorized

As of 2016, the Department of Justice (DOJ) and the Department of Labor (which includes OSHA) partnered to bring federal charges against companies who expose workers to dangerous materials and carcinogens. Hazardous fume and dust exposure in the workplace is indeed a serious offense.

Environmental Protection Laws Facilitate Prosecution

This partnership is to enable prosecutors to use powerful environmental protection laws. With these laws, they can prosecute companies for worker safety violations involving exposure to dangerous substances. This will allow prosecutors working on OSHA worker exposure cases to work with the Environmental Crimes Section of the DOJ to maximize penalties and criminal charges.

In many cases, environmental protection laws are stricter and have stronger punishments than OSHA regulations. Environmental protection has wide public support and considerably more funding than occupational health and safety. There is an entire division of the DOJ that handles environmental crimes. More effectively, these crimes may carry a much heavier fine or more serious criminal charges.

OSHA’s ability to level criminal charges is usually limited to certain situations. This is where an employer willfully and knowingly violates safety standards which cause the death of a worker. These cases can be difficult to prove and even more difficult to prosecute. Under laws regulating environmental crimes, releasing or failing to control any workplace hazard exposure to dangerous substances is a crime. This applies even if the exposure does not result in death or serious injury.

Just like with OSHA fines, the most serious criminal charges will go to employers who repeatedly violate the rules or who fail to correct problems even when they know about them. Bringing in the DOJ and their regulation of environmental laws is likely to affect companies who aren’t following the rules for controlling or cleaning up their hazardous materials.

Identifying Hazardous Fume and Dust in the Workplace

Workplace hazard exposure includes materials such as fumes and dust from many types of industrial processes. Some examples are welding, plasma or laser cutting, manufacturing of plastics and resins, printing inks and pigments, as well as production of chemicals or fertilizers.

OSHA usually sets exposure limits for employees. Environmental regulations set limits for material release into the environment, regardless of the exposure to individual employees. Under the DOJ, environmental laws can handle hazardous material release amounts inside a facility.

For metalworking facilities, hexavalent chromium, manganese, and other components of cutting and welding fumes are heavily regulated as environmental toxins. Exposing people to these materials, inside or outside, can be an environmental crime. Hexavalent chromium often contaminates drinking water, and it’s a major environmental concern.

For companies that use or produce hazardous dust or fumes, a dust collection system is very important for limiting exposure. The system will not only keep the materials away from workers but also collects them safely and allows you to dispose of them properly. A dust and fume collection system that’s maintained and used correctly is a necessary tool for controlling hazardous airborne particles or fumes. Contact us for more information.

References:

www.justice.gov

www.justive.gov

www.justice.gov

Read more

by Imperial Systems | Oct 13, 2016 | Uncategorized

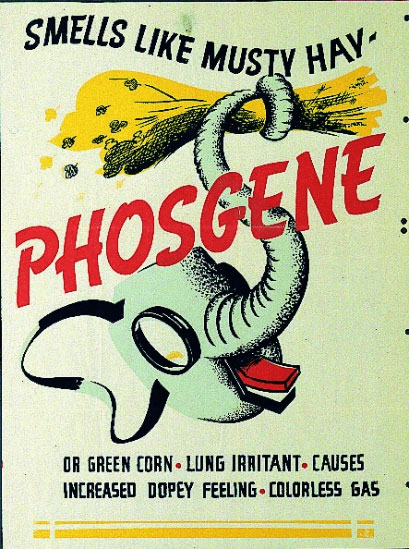

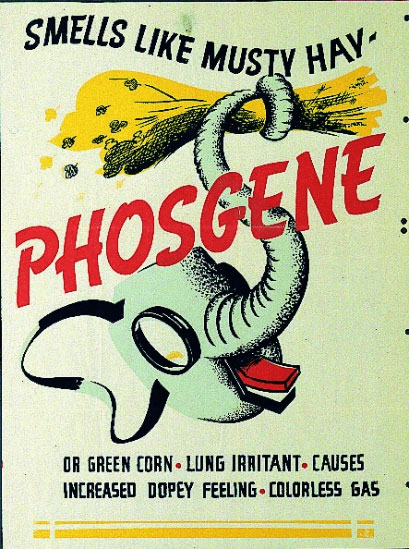

Phosgene gas became infamous during its use in chemical warfare in World War I. In numerous welding forums and opinion pieces, people share concerns about phosgene gas produced while welding.

Is this a fact or a myth?

Some industrial processes use phosgene gas. It can also occur as a breakdown product from chemicals called chlorinated hydrocarbon solvents. These have names like trichloroethylene and methylene chloride.

These are very common chemicals. Pesticides, degreasing chemicals, and solvents are all examples. Older refrigerators also still contain coolants that can convert to phosgene when heated. According to the available information, welding a metal that has a solvent or degreaser (like brake cleaner) on it produces phosgene gas as a component of the welding fumes.

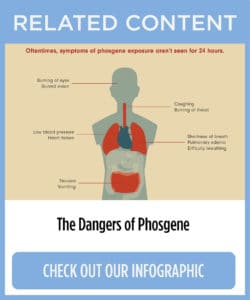

In one example, while repairing a refrigerator a man heating the coolant with a welding torch suffered exposure to phosgene. He endured extreme shortness of breath and irritation to his throat and lungs. He was admitted to intensive care and recovered. There are many other stories of people reporting that they or someone they know suffered exposure or injury by phosgene welding fumes.

So what are the facts about phosgene gas?

Some brake cleaners, degreasers, and solvents do contain chlorinated hydrocarbons. These products carry a warning label about toxic gases and fumes, and some of them specifically mention phosgene gas. Even though they are unexciting reading, always follow warning labels. So it’s absolutely possible to poison yourself with phosgene if using these chemicals incorrectly.

Some brake cleaners, degreasers, and solvents do contain chlorinated hydrocarbons. These products carry a warning label about toxic gases and fumes, and some of them specifically mention phosgene gas. Even though they are unexciting reading, always follow warning labels. So it’s absolutely possible to poison yourself with phosgene if using these chemicals incorrectly.

Is it a real danger for welders?

There doesn’t seem to be much solid information about that. The example of the man who was injured while using a welding torch to work on an old refrigerator is true (Journal of Accident and Emergency Medicine, 12 pp212-213 (1995)). Many people report that they or someone else suffered exposure to phosgene gas while welding something that had been cleaned with brake cleaner. There doesn’t seem to be a lot of reliable information about this problem, though. It’s definitely something that could happen, but there’s not much information about how often it actually does happen.

Do you know someone to whom this has happened, or has it happened to you? Have you ever experienced dangerous fumes while welding? Do you have any information about welding, phosgene gas, and brake cleaner that people should know about?

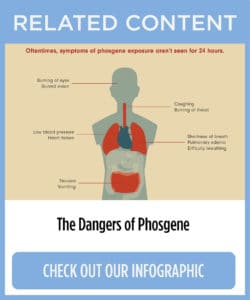

Check out our infographic on phosgene gas!

References:

Read more

by Imperial Systems | Oct 4, 2016 | Uncategorized

How Your Dust Collector Can Pay for Itself

Installing a dust collection system (or updating an old one) is a big investment. Safety, health, and compliance are all important reasons to do so. Will energy cost savings with this investment benefit your company in the long run? When looking at spending that kind of money, it helps to know about a more immediate return on your investment.

The good news is that your new system can pay for itself in as little as two years. That’s by saving you a lot of money on heating and cooling costs.

It’s hard to put a dollar amount on employee health. But it’s easy to put a dollar amount on how much you spend heating and cooling your building. If you’re spending that money and then venting heated air outside the building, you’re effectively blowing money out the window.

Many of our CMAXX systems have paid for themselves within two years just in energy cost savings. And they will continue to save their owners money for many years of service. Some companies have even been able to find energy conservation incentives. These save them money on the immediate cost of a system.

Considerations for Recirculation

Recirculating air back into the facility can be an excellent cost-saving measure. But only if it doesn’t compromise the health of people working there. This means that the recirculated air has to be completely clean and safe.

If you’re planning to recirculate air, be sure to equip your system to handle the type of dust you’re producing. Particles from welding fumes and laser or plasma cutting smoke can be as small as half a micron. This usually requires a filter with a rating of at least MERV 15, meaning it is more than 95% effective for particles down to 0.3 microns. If there might be dangerous or highly regulated materials (such as hexavalent chromium) in the dust, a HEPA filter may be necessary for air that’s going to be returned inside.

Besides the savings on energy costs, a system that recirculates air can actually be more efficient. In some ambient systems, the clean air enters at the level where people are working. This moves the dirty air out of the work area and toward the collector. These types of systems are very effective at filtering the air in larger spaces.

Payback Through Energy Cost Savings

If a dust and fume collector is something you’re going to need anyway, the tremendous savings in your energy cost might be what it takes to get that project into the budget. After all, those heating and cooling cost savings will go back into the budget year after year, and that’s something everyone likes to hear.

Read more

by Imperial Systems | Sep 29, 2016 | Uncategorized

The Surprising OSHA Game That’s Actually Fun

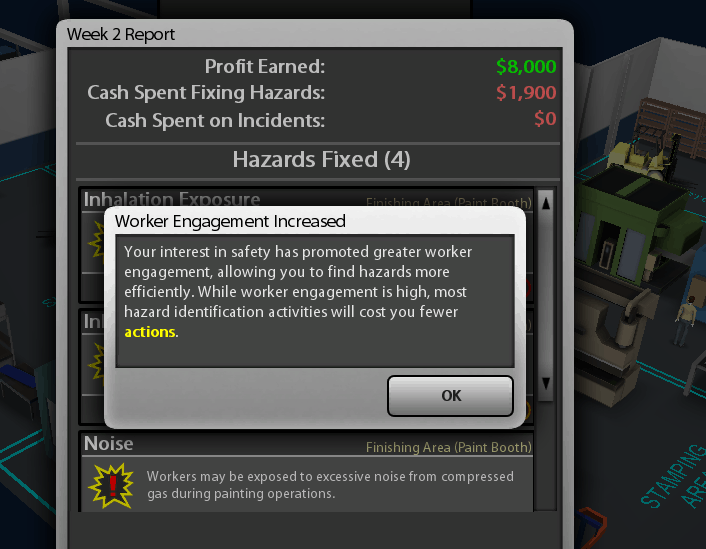

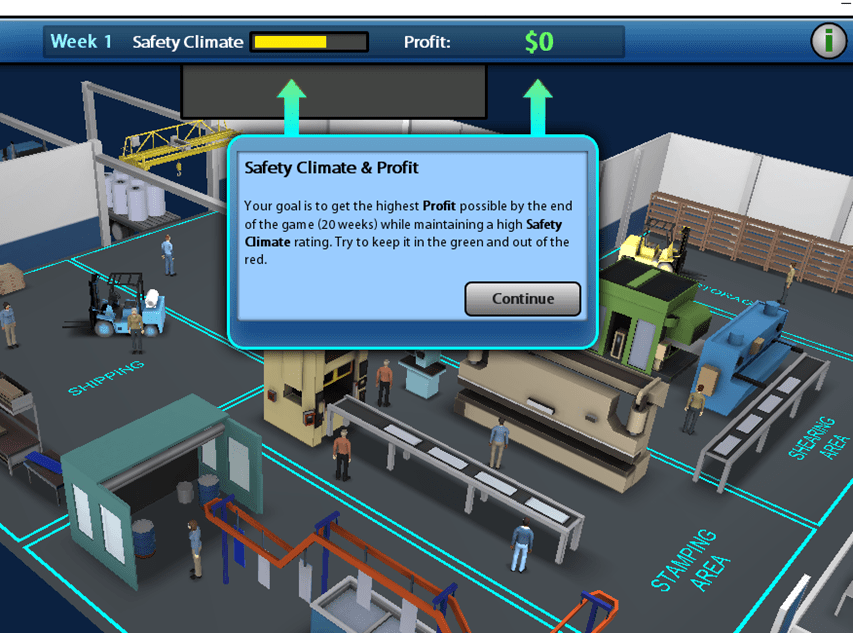

You might actually find yourself playing this just to try for a high score. I’m not kidding. For the sake of accurate reporting, I forced myself to test out this OSHA Hazard Identification Training Tool. I even forced myself to test it more than once after I managed to crash my profits on the first try. This was solely for testing purposes and had nothing to do with being annoyed about losing.

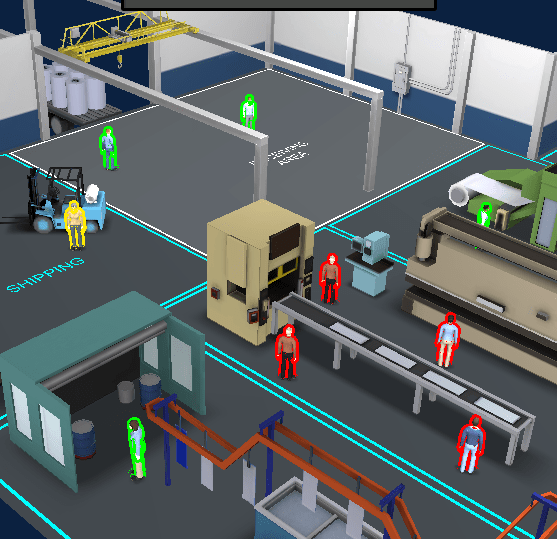

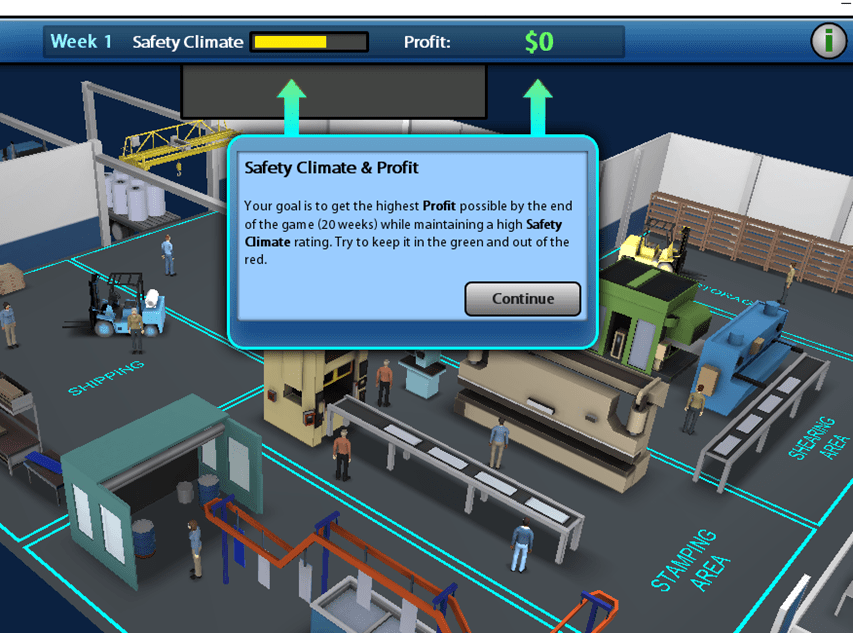

Apparently, someone at OSHA is a fan of farm or city management games, because their Hazard Identification Training Tool is really a time and resource game. This OSHA training tool focuses on three different workplaces: construction, manufacturing, and an emergency room. Most relevant for most of the companies we work with would be manufacturing, which allows you to play as either an owner or a worker in a facility that manufactures metal parts.

OSHA Training Tool Simulates Realistic Company Challenges

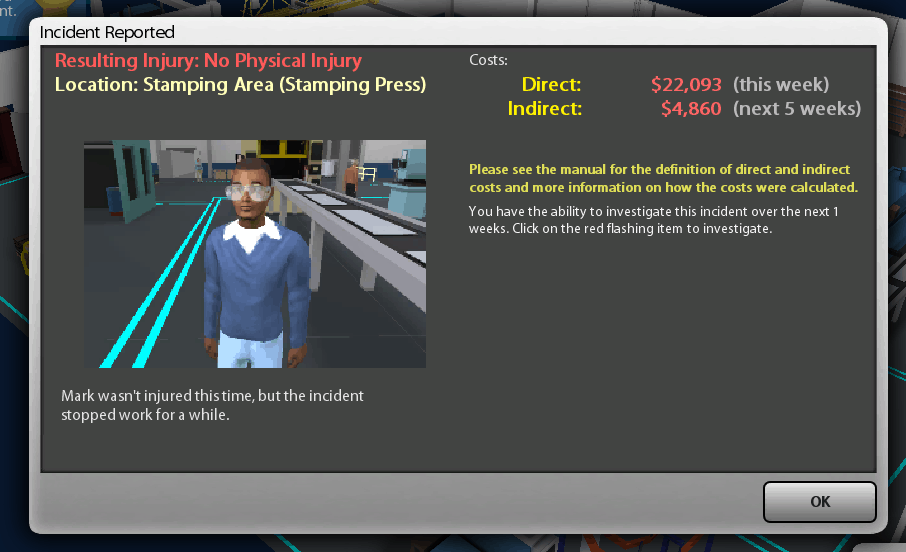

In the game… err, OSHA training tool … you are challenged to balance profit and safety. You have a certain number of points to spend each week on safety tasks like inspecting machines, interviewing workers, and doing research. Any points you do not use contribute to your profit. However, major safety failures also wreck your profits, so you have to make your safety investments wisely.

Wait a minute. A government agency actually recognizes that companies have to balance their safety efforts with trying to make a living?

Yes, it seems like they do. And this game provides a lot of information, with each safety step you choose getting a rating of the hazard and a choice of whether or not to spend safety points fixing it. Since there are far more possible hazards than you have safety points for each week, you have no choice but to prioritize which safety issues to deal with first and which can probably wait.

Wait another minute. They’re not telling you that you have to fix all the hazards right this minute?

No. This OSHA training tool requires you to budget both time and money. It sounds almost like real life. Fixing hazards will cost money. An incident because of a safety hazard you didn’t fix will also cost money.

Keep Safety in the Green

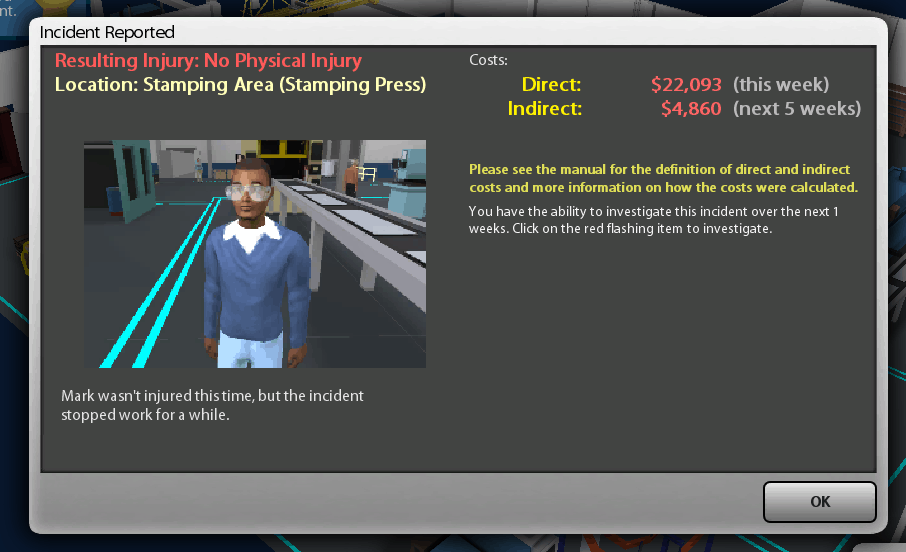

(Mark made it out OK this time, but it still took a chunk out of my profits.)

Some safety issues you’re presented with in the game are very simple to fix, like rearranging power cords so they’re not where people can trip over them. Others are more complicated, like installing machine guards, and some go all the way up to replacing broken machinery or installing engineering controls (such as a dust and fume collection system).

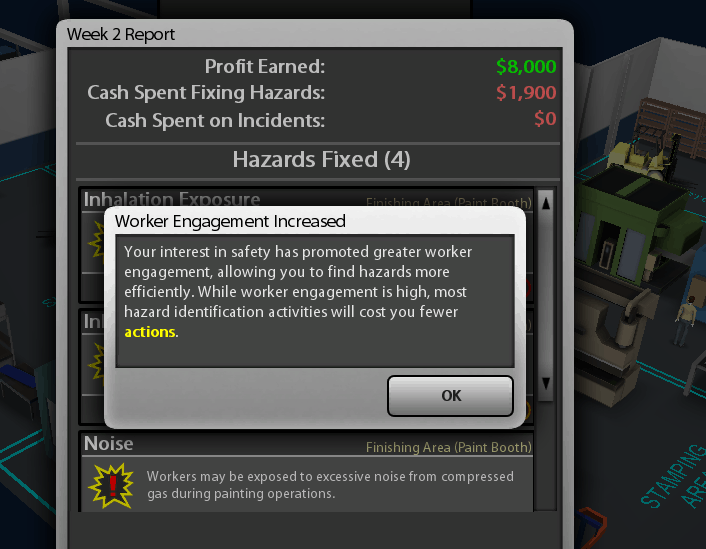

The best choices keep both your safety rating and your profit margin in the green. And some of them even make your job easier.

Talking to workers about the things they’re concerned about makes you better at finding hazards, so you can turn more points into profit. Workers will even report things to you so you can fix them, which is easier than finding them yourself.

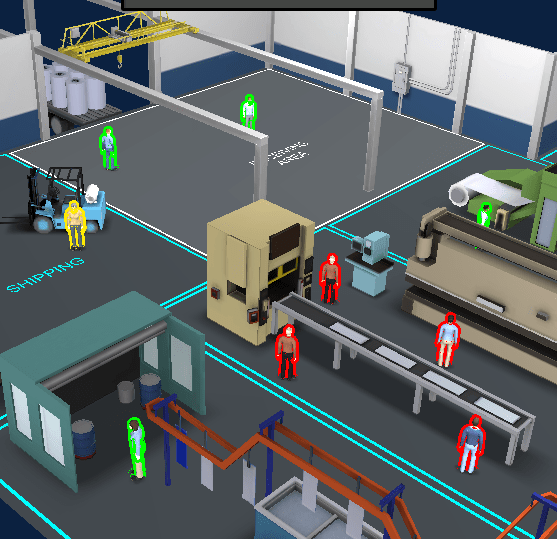

(Uh-oh… there’s apparently a hazard in the stamping area. The folks in the receiving area are pretty happy, though.)

Some of the hazards you find are minor, and some aren’t. Each of them costs money to fix but improves your safety rating. You can visually inspect a machine, watch people using it, or check the owner’s manual. You spend your money repairing exposed electrical wiring, putting up new shelving to store boxes properly, or fixing the air quality control in the paint booth. Or you can just tell them to quit playing football in the loading dock.

And best of all, how can anyone complain that OSHA training on hazard assessment is a waste of time? Clearly, this is valuable information.

Now, if they’d just improve the graphics a little… Find it here: https://www.osha.gov/hazfinder/

Read more

by Imperial Systems | Sep 27, 2016 | Uncategorized

WILL A 500% TARIFF ON CHINESE STEEL HELP OR HURT AMERICAN JOBS?

There are no easy answers. We work with many companies in the steel industry, but we also work with many companies that use steel in their manufacturing. We manufacture our own CMAXX dust and fume collectors with steel, so things that affect these industries affect us directly and indirectly. We feel that it’s important to understand all sides of this issue, since many of our customers are impacted by it.

In the struggle to help American steel compete against cheaper foreign imports, the government has imposed tariffs and taxes on steel imports. With rising tensions between the US and China, the tariff on some types of imported Chinese steel has been raised to nearly 500%. It’s another round in a fight that’s been going on for decades.

When steel from overseas is made more expensive, American-made steel can be more competitive. This allows the steel industry to keep jobs that might otherwise have been lost.

On the other hand, this makes steel more expensive for industries that buy and use it. Many companies argue that while jobs in the steel production industry have been saved, more jobs in the manufacturing and construction industries may be lost due to higher costs.

It’s this conflict that led the Wall Street Journal to call the tariffs “a double-edged sword”. The steel industry supports them. Other industries, such as automotive manufacturers, feel that raising the price of steel hurts US jobs and makes products more expensive for consumers. If overseas companies have access to cheaper steel, they can make cheaper products.

It’s not just the US imposing these tariffs. The European Union did the same when China and Russia “dumped” steel into the international market, selling it at an artificially low cost to drive market prices down. The EU imposed tariffs on China, Russia, South Korea, and several other countries in response to what some people have called economic warfare.

How can China afford to “dump” steel into the market at such low prices?

China manufactures a huge chunk of the world’s steel supply. While their economy was growing and needed steel to sustain that growth, they produced a lot of steel. With the economy slowing down, China found itself producing more steel than it could use. Their solution has been to flood the market, forcing other countries to either cut production or cut prices.

Automotive manufacturers and representatives of other industries that buy and use steel have to pay more as prices go up. Representatives argue that driving up the cost of steel hurts companies and forces them to cut jobs or close their doors. The Consuming Industries Trade Action Coalition Steel Task Force announced in 2002 that the US economy lost $4 billion in jobs and wages over a ten-month period because of increased steel prices due to tariffs. The long-term effects of the more recent tariffs remain to be seen, but many are concerned that more job losses are coming. Small businesses struggle more than larger ones to handle increased costs, and many jobs lost are from this area.

The steel industry, however, needs this economic protection in order to save jobs, both in the United States and in Europe. U.S. Steel lost $1.5 billion in 2015, and there are hopes that the new tariffs will help the company and others survive. People who support the tariffs argue that prices were only low before because of the over-production of steel internationally, and that the tariffs stabilize prices where they should be.

There is not one simple answer for these problems. In a global economy, there’s no way to escape the constantly changing forces of supply and demand. If there is more steel in the worldwide market than the market demands, prices drop and countries where production is cheaper often have an advantage. Protecting jobs is a challenge when competing with countries around the world, and there isn’t one clear solution to the problem.

http://www.bloomberg.com/news/articles/2016-08-04/china-russia-hit-with-5-year-eu-anti-dumping-tariffs-on-steel

http://www.wsj.com/articles/u-s-steel-tariffs-create-a-double-edged-sword-1464740256

http://money.cnn.com/2016/03/30/news/economy/tata-steel-china/?iid=EL

http://money.cnn.com/2016/05/18/news/us-steel-china-trade/

http://www.cnbc.com/2016/05/20/china-steel-overcapacity-war.html

http://triblive.com/business/headlines/10263460-74/steel-workers-salaried

Read more