by Imperial Systems | May 4, 2016 | Common Industrial Dust Collection System Problems, Uncategorized

The metalworking industry is compromised many different aspects of metal fabrication encompassing welding, thermal spraying, sanding and shot blasting, and plasma cutting. Thermal spraying is is used for repairing damaged surfaces, temperature/oxidation protection, corrosion protection, crankshaft reconditioning and conditioning, and altering thermal conductivity. The process of thermal spraying comes in many applications from cold spraying, plasma spraying, wide arc spraying, high velocity oxygen fuel spraying, and warm spraying. While there may be variations in the applications of thermal spraying they all have similar risks.

Because the process of thermal spraying involves the atomization of molten metals, this produces large amounts of combustible dust and toxic fumes according to the publication of the Fabricators & Manufacturers Association, Intl. Other dangers involved with warm spraying are the fine metal particles that are possibly pyrophoric and can be very harmful when accumulated in the body, and the constant inhalation of highly toxic metal dust particles. The constant exposure to these fumes and vapors can produce serious respiratory diseases such as a coughs, pulmonary edema, asthma, or contact dermatitis. Some metals that are used such as nickel, chromium, or cobalt are considered to be potentially carcinogenic to humans.

Because the process of thermal spraying involves the atomization of molten metals, this produces large amounts of combustible dust and toxic fumes according to the publication of the Fabricators & Manufacturers Association, Intl. Other dangers involved with warm spraying are the fine metal particles that are possibly pyrophoric and can be very harmful when accumulated in the body, and the constant inhalation of highly toxic metal dust particles. The constant exposure to these fumes and vapors can produce serious respiratory diseases such as a coughs, pulmonary edema, asthma, or contact dermatitis. Some metals that are used such as nickel, chromium, or cobalt are considered to be potentially carcinogenic to humans.

In order to avoid or limit any of these hazards, there are certains standards and guidelines set by the Occupational Safety and Health Administration. Safety being the priority, OSHA suggests your metalworking facility be fitted with the appropriate dust and fume extraction system to avoid any explosions and reduce metal fabricators exposure to metal air pollutants.

The Solution to Thermal Spraying Hazards

Imperial Systems CMAXX™ Dust Collector System can provide your metalworking facility with the protection it needs because our dust collector systems are designed for our DeltaMAXX™ Replacement Cartridge Filters. Our DeltaMAXX™ Replacement Cartridge Filters have the longest filter lifer, provide you with a greater cost in savings, and the cleanest air for your facility. Here are more outstanding features the CMAXX™ Dust Collector System can provide for your metal facility:

- Vertical cartridge design for a longer filter life.

- 100% Total pulse distribution.

- Best in class internal velocities.

- Increased cleaning power with an energy efficient and high-performance manifold mounted pulse valves.

- 15 Year manufacturer warranty

- 10% More filter media than other same-sized vertical cartridge collectors.

At Imperial Systems, we know the hazards that metalworkers face each day, and we continue to go above and beyond the standards set by OSHA and the NFPA.

Contact us today, and let us help you get fitted with the CMAXX™ Dust Collector System to combat the hazards of thermal spraying.

Read more

by Imperial Systems | May 3, 2016 | Uncategorized

You probably already know that combustible dust comes in many varieties. You’ve probably heard reports of explosions at industrial facilities caused when built-up dust ignited, causing a deflagration in the dust collector system. While Imperial Systems’ CMAXXTM DUST COLLECTION SYSTEM and other safety products can help prevent this in your facility, it’s hard to tell exactly how dangerous your dust might be. Take this pop quiz to see what you know:

Rate the FOUR TYPES OF DUST below, from most explosive to least explosive:

- Sugar

- Cellulose

- Silica

- Aluminum

Combustible dust test on a CMAXX

Many people are aware that metal dusts are dangerously combustible. Cellulose (in the form of paper dust, sawdust, or other wood dust) is also very combustible. Sugar, along with dry milk and egg products, is combustible and has caused fatal explosions.

If you chose the option that silica isn’t explosive, you were correct! But you’re not out of the woods yet… OSHA’s NEW REGULATIONS on silica dust mean that even if you don’t have to worry about combustible dust explosions, you do have to worry about whether your dust collection system meets the newer regulations on how to handle silica dust at your facility.

Imperial Systems can make sure your dust management system is keeping you safe, regardless of the type of dust you have. Call us today and discover how we can help you! 800-918-2803

Read more

by Imperial Systems | Apr 25, 2016 | Uncategorized

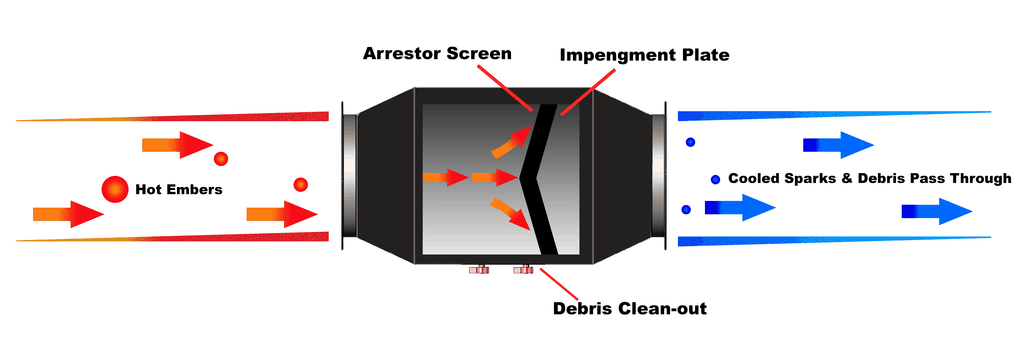

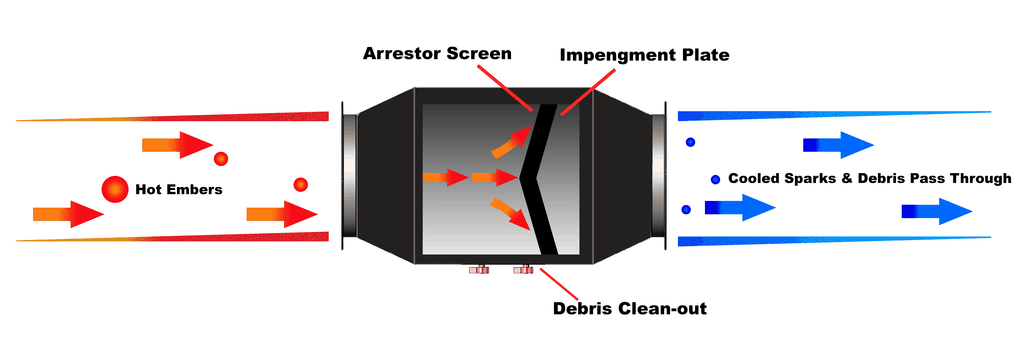

Extinguish the threat of explosions with an Imperial Systems spark trap.

While it is imperative that every metalworking facility have highly efficient dust collection systems, it is just as crucial that metalworking facilities utilize a spark trap to provide even greater protection from these combustible hazards.

Imperial Systems has dedicated over a decade to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration, and the guidelines set out by the National Fire Protection Association with our highly efficient dust collection systems and replacement cartridge filters.

Imperial Systems has dedicated over a decade to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration, and the guidelines set out by the National Fire Protection Association with our highly efficient dust collection systems and replacement cartridge filters.

If you’re asking yourself if a spark trap is really necessary– the answer is yes! Consider the findings of the OSHA’s National Emphasis Program, which shows that metal dust accounts for 20% of explosions nationwide, and that 7% of ignition sources are ignited by fabricated metals while another 8% of ignition sources are caused by Primary metals. If you want to reduce the possibility of an accident at your metalworking facility, you MUST invest in spark arrestors!

How Can Imperial Systems Spark Trap Reduce Explosions?

Adding a spark trap to your industrial dust collection system is like adding a security system to your home. You already have the proper amount of protection with locks, but installing a security system in your home provides another line of defense, keeping you and your family safe.

An Imperial Systems, our spark trap is the first line of defense in protecting your metal fabricators and your metalworking facility from explosions. Imperial Systems Spark Arrestors extinguish nearly every spark before it enters into the main containment unit where combustible dust and other flammable material collects. When you choose our Spark Arrestors, you’ll receive a quality product made with heavy duty materials that is highly effective at keeping sparks from entering your industrial dust collector.

Here are the quality features you’ll receive when you invest in our spark traps:

- Maintenance free components

- Fully welded construction

- Easy install for any system

- No moving parts

- Available in carbon steel or stainless steel

- Can be installed in horizontal or vertical configurations

- Available in 6in. – 40in.

- Clean out door

- Doesn’t require water

Spark Trap Optional Features include:

- Raw inlet and outlet edges

- A clamp together function for clamping duct

- Rolled angle flange for bolt together duct

If want more information about our spark traps, and you want to elevate the security for your metalworkers, contact Imperial Systems at 800-918-3013 to speak with one of our representatives today!

Spark Trap | Spark Traps

Read more

by Imperial Systems | Apr 21, 2016 | Uncategorized

Imperial Systems helps you find the best dust collector system for your manufacturing facility.

You already know that air quality can have a profound impact on the health, safety, productivity, and profitability of any industrial work facility. That’s why you and other leaders from a wide range of industries and processes – including agriculture, manufacturing, pharmaceuticals, textiles, power generation, recycling, and 3D printing, invest in Imperial Systems dust collectors and filters to manage dust before it becomes an active hazard in your facilities. But, did you also know that successful combustible dust management may actually make your building smarter?

A new study released in October of last year indicated that improved IEQ (indoor environmental quality) had the effect of doubling workers’ cognitive function test scores. Known as the Impact of Green Buildings on Cognitive Function Study, the experiment subjected 24 participants to 6 full work days in an environmentally controlled space, in which they were unaware of the test conditions. Throughout the test, participants were exposed to IEQ conditions representative of high VOC (volatile organic compound) concentration – labeled Conventional days – and low VOC concentration buildings in the U.S., as well as a high outdoor air ventilation rate and artificially elevated carbon dioxide (CO2) levels – labeled Green and Green+ days.

A new study released in October of last year indicated that improved IEQ (indoor environmental quality) had the effect of doubling workers’ cognitive function test scores. Known as the Impact of Green Buildings on Cognitive Function Study, the experiment subjected 24 participants to 6 full work days in an environmentally controlled space, in which they were unaware of the test conditions. Throughout the test, participants were exposed to IEQ conditions representative of high VOC (volatile organic compound) concentration – labeled Conventional days – and low VOC concentration buildings in the U.S., as well as a high outdoor air ventilation rate and artificially elevated carbon dioxide (CO2) levels – labeled Green and Green+ days.

The result was that, on average, cognitive scores were 61% higher on the Green day and 101% higher on the two Green+ building days than on the Conventional building day. After only 6 hours in the COGfx Study, the workers in the green building environment showed substantial improvements in cognitive performance versus those in the conventional environment. And, while cognitive function is not the sole root of productivity, decision-making faculties are an important component.

The implications for IEQ and combustible dust management as related to productivity and health/safety are significant. As the study reports, most people spend about 90 percent of their time indoors and 10 percent of their time outdoors. Conversely, 90 percent of the costs associated with a building are due to the people inside it (salaries and benefits, illnesses, etc.) while just 10 percent come from mortgage/rent and other operating costs. Therefore, combustible dust management can substantially improve your workers’ cognitive function as well as the business’s overall health and performance.

If you’ve been researching ways to increase productivity, improve your IEQ and related functions, or are simply wondering how different systems compare and measure up, we have the solution for you: the Ultimate Dust Collector Comparison Chart, featuring Imperial Systems’ CMAXX™ Dust Collector.

Compare collectors, filters, warranties, services and benefits, and more with one simple click. Or, contact Imperial Systems today at 800-918-3013 for more information on dust collectors and filters that will improve your combustible dust management processes…and maybe even your facility’s IQ!

Combustible Dust Management | Managing Combustible Dust

Read more

by Imperial Systems | Apr 11, 2016 | Uncategorized

Find out how metalworkers like you can address the need for a high-quality spark trap for explosion prevention.

Why Invest in a Spark Trap for Explosion Prevention?

Understanding that the metalworking industry is among the most susceptible in terms of a dangerous working environment is paramount to our goal at Imperial Systems to provide the highest-quality products for dust collection, including explosion prevention.

The CMAXX™ Dust Collection System is already geared towards reducing a chance of a combustible dust explosion along with having the best cleaning efficiency and longest filter life in the industry. But an added measure that should be implemented especially if your facility operates at consistently high volumes is a spark trap from Imperial Systems to compliment your current dust collection system as well as maximizing explosion prevention.

Designed primarily as a first line of defense to prevent ignition within a dust collection system, spark traps reduce the potential for fire hazard by capturing sparks before they reach the main containment unit, where dust or other flammable materials may be present.

Designed primarily as a first line of defense to prevent ignition within a dust collection system, spark traps reduce the potential for fire hazard by capturing sparks before they reach the main containment unit, where dust or other flammable materials may be present.

What Explosion Prevention Looks Like With an Imperial Spark Arrestor

An ineffective or entire lack of a quality spark trap leads to an increased risk in danger associated with the metalworking industry. Without one, sparks can reach the main component where dust and flammable materials fill the air, causing an explosion.

Our spark traps for explosion prevention are:

- Heavy duty

- Maintenance free

- Fully welded

- Easy to install with both horizontal and vertical configurations

- Available in 6in.-40in.

- Waterless

- Available in carbon steel or stainless steel

- Optional raw inlet and outlet edges

- Optional clamping duct

- Bolts together for bolted ducts

- Requires no moving parts

If you haven’t yet decided on a spark trap for your metalworking business for dust explosion prevention, what is that procrastination costing you?

From 1996-2005, 106 explosions resulted in 16 fatalities, 126 injuries, and an estimated cost of $162.8 million in damages to the facilities.

All of our products including spark traps are always built by NFPA and OSHA guidelines and standards. Don’t trust anyone else except Imperial Systems to deliver a quality spark trap for an added and essential layer to maximum explosion prevention.

Contact Imperial Systems today at 800.918.3013 or learn more by emailing us at info@isystemsweb.com.

Read more

Because the process of thermal spraying involves the atomization of molten metals, this produces large amounts of combustible dust and toxic fumes according to the publication of the Fabricators & Manufacturers Association, Intl. Other dangers involved with warm spraying are the fine metal particles that are possibly pyrophoric and can be very harmful when accumulated in the body, and the constant inhalation of highly toxic metal dust particles. The constant exposure to these fumes and vapors can produce serious respiratory diseases such as a coughs, pulmonary edema, asthma, or contact dermatitis. Some metals that are used such as nickel, chromium, or cobalt are considered to be potentially carcinogenic to humans.

Because the process of thermal spraying involves the atomization of molten metals, this produces large amounts of combustible dust and toxic fumes according to the publication of the Fabricators & Manufacturers Association, Intl. Other dangers involved with warm spraying are the fine metal particles that are possibly pyrophoric and can be very harmful when accumulated in the body, and the constant inhalation of highly toxic metal dust particles. The constant exposure to these fumes and vapors can produce serious respiratory diseases such as a coughs, pulmonary edema, asthma, or contact dermatitis. Some metals that are used such as nickel, chromium, or cobalt are considered to be potentially carcinogenic to humans.

Imperial Systems has dedicated over a decade to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration, and the guidelines set out by the National Fire Protection Association with our highly efficient dust collection systems and replacement cartridge filters.

Imperial Systems has dedicated over a decade to preventing and reducing fires and explosions in metalworking and manufacturing facilities. We continually strive to meet and exceed the standards recommended by the Occupational Safety and Health Administration, and the guidelines set out by the National Fire Protection Association with our highly efficient dust collection systems and replacement cartridge filters.  A

A Designed primarily as a first line of defense to prevent ignition within a dust collection system, spark traps reduce the potential for fire hazard by capturing sparks before they reach the main containment unit, where dust or other flammable materials may be present.

Designed primarily as a first line of defense to prevent ignition within a dust collection system, spark traps reduce the potential for fire hazard by capturing sparks before they reach the main containment unit, where dust or other flammable materials may be present.