by Imperial Systems | Aug 6, 2015 | Dust Collection Filters

The competition may be close but DeltaMAXX comes in for the win!

Metalworking causes an abundance of dust and gasses to dwell in the air. Those that have professional dust collector systems in their metalworking facility understand the importance of the maintenance required for such systems. Fortunately for you, we have developed DeltaMAXX cartridge filters. As compared to Donaldson Torit cartridge filters, ours beat this competition by a landslide.

Donaldson Torit cartridge filters have certainly upheld their name for quite some time now, as one of the leading manufacturers for air purification and dust collection – until now.

Donaldson Torit cartridge filters have certainly upheld their name for quite some time now, as one of the leading manufacturers for air purification and dust collection – until now.

Why Choose Imperial Systems’ DeltaMAXX Over Donaldson Torit Cartridge Filters?

Thanks to the ever-increasing innovation in everything dust collection, Torit cartridge filters now make room for DeltaMAXX cartridge filters for these 3 main reasons.

- Quality. Thanks to the discover of Nanofiber technology, all of our cartridge filters are more efficient than ever with easier cleaning and longer filter life. Our cartridge filters are also customizable, with the ability to fit into any dust collector system. Our filters last twice the length of time as the average filter, using the highest quality pleated media. We also offer MERV15 filtration efficiency, industry-best surface loading technology and less pulse cleaning. These qualities then lead to lower operational mass emissions and reduced dust collector operational costs. Therefore, you get more bang for your buck!

- Price. Unfortunately for big-name companies like Donaldson Torit, their products have a higher price tag, rather than Imperial Systems. Imperial Systems is actually one of the top manufacturers not only in the nation, but in North America (serving Canada as well as the United States). With such a large clientele, we at Imperial Systems are able to keep our prices at a lower rate than those of Donaldson Torit.

- Service. This is where the rubber meets the road. Our service team here at Imperial Systems are the absolute best at what they do. From knowledge to respect to communication, our specialists have it all in their grasp. We are professional, friendly and best of all, an advocate for all of our clients, both current and potential.

Stop Waiting

The choice is yours. If you are a current user of Donaldson Torit cartridge filters, we hope that you have had success with their business, but have learned something new with Imperial Systems. Give us a call today at 724.662.2801 so we can show you how to get more efficiency from the dust collector systems you have.

Read more

by Imperial Systems | Aug 5, 2015 | Common Industrial Dust Collection System Problems

EvenLock Technology from Imperial Systems empowers you to effectively prevent hazardous leaks from developing anywhere across filter gaskets.

At Imperial Systems, we design and manufacture our dust collection equipment with EvenLock Technology because we understand the concerns of the metalworking industry.

Whether your manufacturing business is devoted exclusively to metalworking or that is just a part of the larger work you do, you undoubtedly have a strong understanding of one of the highest concerns in the industry: safety. Even without the multitude of variable brought on by the presence of human workers, the dust, fumes, and sparks that result from standard metalworking processes can be cause for concern. These elements, if allowed to mix without the control of high-performing safety equipment, could quickly become a recipe for disaster.

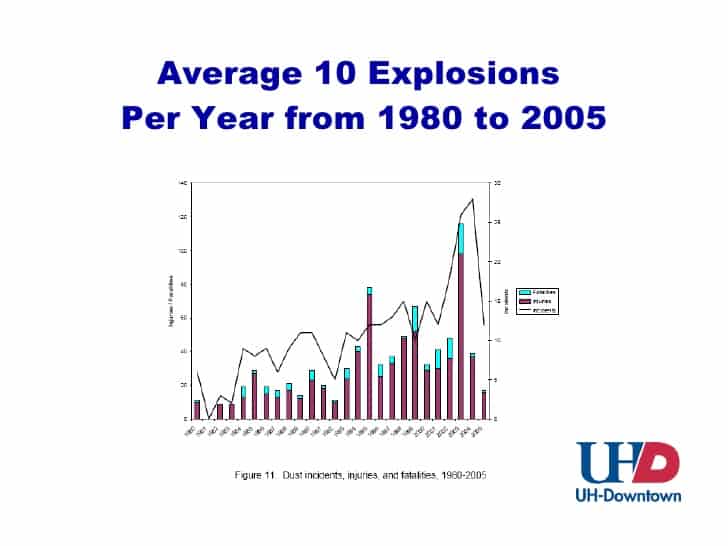

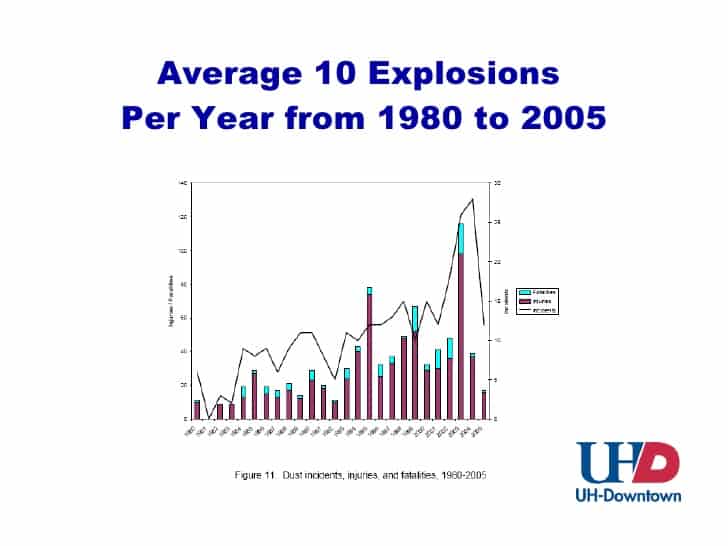

The absence of adequate safety equipment like Dust and Fume Collections Systems with Spark Arrestors can lead to some of the most dangerous work hazards in the nation. A 2008 CBS News report enumerated some of the most recent examples of this problem:

- At least 30,000 U.S. factories are vulnerable to dust explosions

- 350 dust explosions occurred in U.S. factories between 1980 and 2008

- During that time 133 people were killed and many more injured

These numbers, though staggering on their own, only begin to reflect the dangers of inadequate dust and fume collection systems. In addition to these large scale disasters, ongoing dust or fume problems can also lead to health problems in workers, malfunctioning equipment, inefficiency, and losses in time, productivity, and money for the businesses involved.

http://www.cbsnews.com/news/is-enough-done-to-stop-explosive-dust/(@CBSnews)

Many manufacturers, have taken the initiative to establish dust collection systems, spark arrestors, and other safety equipment into their work areas. However, potential danger may be lurking in these systems, disguised by the illusion that the problems of dust, sparks, and fumes has been solved:

Hazardous Leaks From Unclean Filter Gaskets

Hazardous Leaks From Unclean Filter Gaskets

As Robert Brooks of EHS Today (@EHSToday) points out, filters need regular, effective cleaning to continue operating at peak efficiency. Insufficiently cleaned filters can lead to a loss in suction which not only lowers the efficacy of the system but can also lead to uneven gasket compression on the filters. This uneven compression can lead to leaks occurring in the filter gaskets which, left unattended, can undermine the work of the system.

http://ehstoday.com/industrial-hygiene/when-dust-settles-how-choose-dust-and-fume-collector (@EHSToday)

Other industrial dust collection system manufacturers have tried to address this problem in their own products. Two of the most common approaches are:

- Individual door pans with hand crank knobs

- Cam-bars that rotate to clamp the filter in place

Although these “solutions” are common, the reality is that both of them fall short of the mark and, ultimately, are ineffective to solve the problem of hazardous leaks occurring across filter gaskets. The hand crank knobs on individual door pans can easily be lost or stripped out, leaving you in need of a potentially costly, time-consuming replacement. Cam-bars which rotate to clamp down on the filter are unable to deliver the same level of compression–if any at all–to the rear filters of the collection unit. Clearly, a new solution is necessary.

A New Solution: EvenLock Technology From Imperial Systems

A New Solution: EvenLock Technology From Imperial Systems

At Imperial Systems, we are dedicated to providing the highest level of quality, safety, and value in each one of our products. This means that we aim to design and manufacture solutions that metalworkers like you can rely on. We are not content with products that are easily broken or unreliable. So, we set out to create the best solution for the problem hazardous leaks occurring across filter gaskets within our industrial Dust And Fume Collection Systems.

We are proud to announce that EvenLock Technology is an incredible breakthrough filter cleaning technology that ensures even-gasket compression on all cartridge filters in our CMAXX Industrial Dust Collection System. By compressing the DeltaMAXX filter gaskets at a 50:1 compression rate, and by employing individual cams at each filter, from the front to the back, our system ensures 100% literal “Even-Locking” across the board. With our new EvenLock Technology, manufacturers can finally, effectively prevent hazardous leaks from occurring anywhere across the filter gaskets.

EvenLock Technology Advantages

This advanced technology comes with several advantages that set it–and Imperial Systems–apart from the competition:

- This technology eliminates the torsion effect from a rotating bar that is likely to twist in-motion and not deliver the same compression, if any, to the rear filters.

- EvenLock Technology works just as well with loaded heavy filters; if the slide rail arm is locked forward, your gaskets are protected.

- Our EvenLock Technology comes standard in every CMAXX Industrial Dust Collector, so you can have confidence in all of our equipment.

This unique approach is the solution manufacturers need to address the challenge of potentially problematic leaks in the system.

CMAXX Features and Benefits

If you are currently using an industrial dust collection system that does not have Imperial Systems’ EvenLock Technology, it may be time to make a change. This advanced technology is just one of the many advantages of our CMAXX Industrial Dust Collection Systems. This vertical cartridge dust collection system is designed with revolutionary PD Technology for Maximum Cleaning Performance. Other favorite features include:

If you are currently using an industrial dust collection system that does not have Imperial Systems’ EvenLock Technology, it may be time to make a change. This advanced technology is just one of the many advantages of our CMAXX Industrial Dust Collection Systems. This vertical cartridge dust collection system is designed with revolutionary PD Technology for Maximum Cleaning Performance. Other favorite features include:

- A low-profile design to save space

- Vertical cartridge design to promote a longer filter life

- Tool-free, heavy duty filter doors for shorter service time

- No external bolts for less chance of water and air leaks

- 100% total pulse distribution across filter media

- Spark Trap features

This system is designed to be used with our DeltaMAXX replacement cartridge filters. Made with advanced nano-fiber technology, these filters offer up to twice the filter life of the industry standard. They can also boast a MERV 15 Filtration Efficiency, the best in the industry, along with less pulse cleaning and lower operational mass emissions.

This system is designed to be used with our DeltaMAXX replacement cartridge filters. Made with advanced nano-fiber technology, these filters offer up to twice the filter life of the industry standard. They can also boast a MERV 15 Filtration Efficiency, the best in the industry, along with less pulse cleaning and lower operational mass emissions.

Together, these products have the best cleaning efficiency and offer the longest filter life in the industry, saving you time and money while still providing the highest level of service.

In Conclusion

In this blog, you found just a few examples of the types of solutions that Imperial Systems regularly provides to metalworkers and manufacturers like you.  All of the products that we design, manufacture, and install are engineered for outstanding quality, safety, and value. We also maintain a large inventory of our dust collection equipment, so that we can ship most of the products you need–including the CMAXX Dust Collection System with Evenlock Technology–within 24 hours of your order. For years, we have earned credibility and established strong relationships as a provider of customer-driven solutions.

All of the products that we design, manufacture, and install are engineered for outstanding quality, safety, and value. We also maintain a large inventory of our dust collection equipment, so that we can ship most of the products you need–including the CMAXX Dust Collection System with Evenlock Technology–within 24 hours of your order. For years, we have earned credibility and established strong relationships as a provider of customer-driven solutions.

And now, we want to hear from you. What are some of the biggest challenges you face in metalworking or in other aspects of your manufacturing work? What problems do you face regularly for which you wish you had a solution? At Imperial Systems, we are dedicated in creating products to answer the needs of manufacturers like you, so we look forward to hearing from you. Please leave your thoughts, questions, or concerns in the comments section below!

Read more

by Imperial Systems | Jul 31, 2015 | Common Industrial Dust Collection System Problems

The Imperial Systems Spark Arrestor is your best choice for an in-line spark trap that you can rely on for quality, value, and safety.

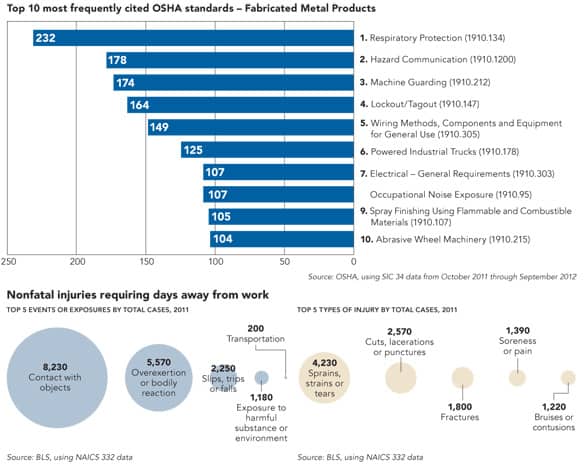

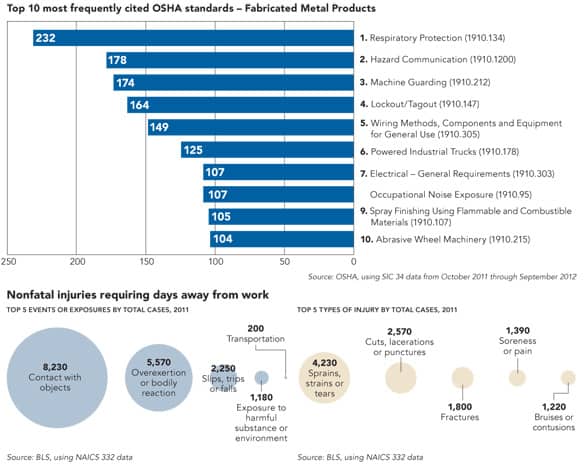

Just over a decade ago, metal fabricators were considered the third-highest at-risk group in a lineup of metalworking industry safety statistics by the U.S. Department of Labor’s Bureau of Labor Statistics. One of the major risk factors posing a hazard to workers is the combination of dust, fumes, and sparks that are all put off during manufacturing processes. However, with the right dust collection equipment, you can significantly reduce the chances of illness, injury, or accident occurring in the workspace. So, an important question to ask yourself right now is: do I have the right in-line spark trap to keep my workers safe?

At Imperial Systems, we are acutely aware of the importance of an in-line spark trap, or spark arrestor, that you can rely on to extinguish all sparks before they enter your industrial dust collector. This is why we have designed and manufactured two different options to help your business stay safe.

At Imperial Systems, we are acutely aware of the importance of an in-line spark trap, or spark arrestor, that you can rely on to extinguish all sparks before they enter your industrial dust collector. This is why we have designed and manufactured two different options to help your business stay safe.

Dust Collectors With An In-Line Spark Trap

Our CMAXX Laser and Plasma Fume Extraction System incorporates all of the latest metalworking safety technology and is easy to use. It comes with a built in in-line spark trap to ensure that any spark which enters the collector is immediately extinguished. Additionally, this system also offers the following advantages:

- Premium reverse air cleaning

- DeltaMAXX fire retardant filters

- Fan silencer

- Tool-free filter access and change out

- Pre-wired setup: all you have to do is plug it in and push start!

Additional Spark Arrestors

Of course, at Imperial Systems, we acknowledge that you may not be prepared to purchase and install a new system, no matter how easy it is, in order to get the in-line spark trap you need. So, we also sell individualized spark traps, called Spark Arrestors, which are customized to fit your unique needs.

Manufactured with the same attention to quality, safety, and value as all of our products, these offer the following features:

-

- Heavy duty construction

- No maintenance

- Clean-out door

- Fully welded construction

- Easy install into any system

- Can be installed in horizontal or vertical configurations

- No moving parts

- Carbon steel or stainless steel available

- No water required

- Available sizes: 6in. to 40in.

For more information about either of these quality spark trap options, you can give us a call today. One of our experienced service representatives will help you to find the perfect solution for your metalworking business. Begin the conversation by calling 800.918.3013.

In-Line Spark Trap | In-Line Spark Traps

Read more

by Imperial Systems | Jul 22, 2015 | Dust Collection Filters

Imperial wants you to choose the right manufacturer that best suits your specific needs.

It is absolutely necessary that when you are choosing which dust collector filters manufacturer to go with for your metalworking company, that you make the right decision the first time. Too many chances are taken when you choose the wrong manufacturer. Some of those chances include:

- Causing long-term illness in yourself or your employees

- Allowing an explosion in your facility

- Losing money over low-quality materials and machines

So what can you do to make sure none of the above happen to you? Research. According to the 2014 State of B2B Procurement study, 94% of business owners research before they purchase. That still leaves 6% that purchase without research, and lack of research increases the chance that you may have purchased a lesser quality product which will affect your business, possibly causing you to lose your business.

How Do You Know You’ve Chosen The Right Dust Collector Filters Manufacturer For Your Business?

With so many manufacturers to choose from, there are many companies that offer something special. There are also many companies that offer things that you don’t need, and would love for you to purchase those unnecessary products.

The best thing to do is abide by the 3 R’s….

- Relevance – Specific to your industry, you must be sure that you are getting the product that will benefit you. As far as a metalworking facility, you will be working with combustible gasses and dust particles, requiring the need of a DeltaMAXX filter with Nanofiber technology, and quite possibly our CMAXX Laser Fume Extraction System.

- Reliability – Be sure the dust collection filters manufacturer you are interested in has a dependable customer service department, and a list of reviews for each product so you know they have a product you can depend on.

- Reputation – Who will stand behind the products and service of your choice dust collector filters manufacturer? If they do not have a list of clients on their website, you can give them a call and ask them for a list. Look up their reviews online and do your research to discern their reputation wisely.

Remember with all the sanding, buffing, grinding, polishing and cutting there will be a great deal of dust that will settle and remain airborne in your metalworking facility. Consider the quality products Imperial Systems brings to your front door.

For more information on how Imperial Systems is a relevant, reliable and reputable dust collector filters manufacturer, contact us today.

Dust Collector Filters Manufacturer | Dust Collector Filter Manufacturer

Read more

by Imperial Systems | Jun 19, 2015 | Dust Collection Filters

In the same way that Stanford’s Yi Cui is confronting the effects of China’s pollution, Imperial Systems strives to reshape the future of North American industries.

In recent decades, sociologists have speculated about the population growth of cities and the coinciding rapid development of urban industry. Air quality has been definitively compromised by industrial growth, and is a major concern for politicians and businesses alike. This is because dust generation is a universal problem for manufacturers, affecting industries such as:

- Recycling

- Agriculture

- Woodworking

- Steel

- Mining

- Biofuels

- Food processing

- Pet food

- Chemical processing

- Paper scrap

- & Fiberglass, to name a few.

The need for an industrial air purification service grew out of people’s’ desire for safer societal conditions. Engineers and manufacturers at Imperial Systems are leaders in the designing, manufacturing, and installing premiere dust collection systems for industrial air purification within North America. Imperial Systems is working for a safer future.

A Growing Economy Needs an Industrial Air Purification Service

Globalization will continue to reshape the economy and the development of industry. Imperial Systems established themselves as North America’s dust collection and air pollution control experts because they want to help invest in future manufacturing and industry. Products and services offered by Imperial Systems are of the highest caliber and include:

- CMAXX Dust and Fume Cartridge Collectors

- BRF Reverse Air Baghouses

- Pulse Jet Baghouses

- Cyclones

- Airlocks

- Slide Gates

- Diverter Valves

- Abort Gates

- SCF After Filters

- Backdraft Dampers

- DeltaMAXX Cartridge and Bag Filters

- & Flex Hose components.

This February 2015, a breakthrough in air purification was made by Stanford engineers working to address air pollution in China. Associate professor of materials science and engineering Yi Cui developed an inexpensive, personal and hand-held air filter for citizens to combat daily air pollution consumption. Nature Communications published the findings, in which polyacrylonitrile (PAN), a material found in surgical gloves, was made into a filter through the method of electrospinning. The fibers are the size of a thousandth of a human hair and resemble a web.

The function of PAN, a polymer, is to attract PM2.5 particles found in smog. The material will possibly be used for smaller applications initially, such as for window screens. Yi Cui explains, “It works really well, and it might be a game-changer.” There is potential that it could be utilized in an industrial scale in the future after extensive testing.

Imperial Systems applauds the incredible contribution Yi Cui has made to the industrial air purification field, and looks forward to the ensuing development of the polyacrylonitrile filter. In the same way that Cui is confronting the effects of China’s pollution, Imperial Systems—an industrial air purification service, strives to reshape the future of North American industries through the production of safe and cutting-edge dust collection systems.

If you would like more information about the services provided by Imperial Systems, we invite you to reach out to us at 1-800-918-3013.

Industrial Air Purification Service | Air Purification Industrial Service

Read more

Donaldson Torit cartridge filters have certainly upheld their name for quite some time now, as one of the leading manufacturers for air purification and dust collection – until now.

Donaldson Torit cartridge filters have certainly upheld their name for quite some time now, as one of the leading manufacturers for air purification and dust collection – until now.

Hazardous Leaks From Unclean Filter Gaskets

Hazardous Leaks From Unclean Filter Gaskets A New Solution: EvenLock Technology From Imperial Systems

A New Solution: EvenLock Technology From Imperial Systems If you are currently using an industrial dust collection system that does not have Imperial Systems’ EvenLock Technology, it may be time to make a change. This advanced technology is just one of the many advantages of our CMAXX Industrial Dust Collection Systems. This vertical cartridge dust collection system is designed with revolutionary PD Technology for Maximum Cleaning Performance. Other favorite features include:

If you are currently using an industrial dust collection system that does not have Imperial Systems’ EvenLock Technology, it may be time to make a change. This advanced technology is just one of the many advantages of our CMAXX Industrial Dust Collection Systems. This vertical cartridge dust collection system is designed with revolutionary PD Technology for Maximum Cleaning Performance. Other favorite features include: This system is designed to be used with our DeltaMAXX replacement cartridge filters. Made with advanced nano-fiber technology, these filters offer up to twice the filter life of the industry standard. They can also boast a MERV 15 Filtration Efficiency, the best in the industry, along with less pulse cleaning and lower operational mass emissions.

This system is designed to be used with our DeltaMAXX replacement cartridge filters. Made with advanced nano-fiber technology, these filters offer up to twice the filter life of the industry standard. They can also boast a MERV 15 Filtration Efficiency, the best in the industry, along with less pulse cleaning and lower operational mass emissions. All of the products that we design, manufacture, and install are engineered for outstanding quality, safety, and value. We also maintain a large inventory of our dust collection equipment, so that we can ship most of the products you need–including the CMAXX Dust Collection System with Evenlock Technology–within 24 hours of your order. For years, we have earned credibility and established strong relationships as a provider of customer-driven solutions.

All of the products that we design, manufacture, and install are engineered for outstanding quality, safety, and value. We also maintain a large inventory of our dust collection equipment, so that we can ship most of the products you need–including the CMAXX Dust Collection System with Evenlock Technology–within 24 hours of your order. For years, we have earned credibility and established strong relationships as a provider of customer-driven solutions. At Imperial Systems, we are acutely aware of the importance of an in-line spark trap, or spark arrestor, that you can rely on to extinguish all sparks before they enter your industrial dust collector. This is why we have designed and manufactured two different options to help your business stay safe.

At Imperial Systems, we are acutely aware of the importance of an in-line spark trap, or spark arrestor, that you can rely on to extinguish all sparks before they enter your industrial dust collector. This is why we have designed and manufactured two different options to help your business stay safe.