by Imperial Systems | Apr 3, 2015 | Dust Collection Filters

What don’t you know about the dust you’re producing? Learn about it from your local professional dust collector firm.

Dust collection is an important process to protect your employees and keep your work environment accident-free. Who would ever guess that dust could be so dangerous? While the general public won’t be aware of this issue, as a manufacturing or metalworking company, you realize that it’s vital—especially in today’s regulatory climate. A professional dust collector firm can help you by ensuring that you have the correct systems in place to prevent dust-initiated accidents.

What is the problem with dust?

Simply put, dust can be a highly flammable substance that may result in fires. Because of dust’s combustible properties, it can become a fuel when it has been accumulated over time from industrial processes. Oftentimes it may travel down pipes or remain within the operations systems, creating an entire chain of dust fuel!

This possesses serious risks for employees working around the dust. Since the year 2000, there have been many documented explosions within factories that did not take proper precautions in regards to dust collection and education of employees.

What is a dust collector?

What do we mean when we talk about dust collectors? We’re referring to the system utilized to improve air quality that is released from industrial processes. The dust collector should handle dust loads by removing dust from the air—different from air cleaners, which have the filter.

A professional dust collector firm should provide you with a comprehensive system that goes beyond a simple air cleaner. This system is comprised of a blower, dust filter, filter-cleaning system, and a dust receptacle. It is also referred to as an air pollution control device, which is understood to maintain air quality.

What do dust collectors do?

Dust collectors recover valuable granular solids from process streams or remove solid contaminants before they are ventilated into the atmosphere. They are distinguished from mist collectors, which are used for metal working to remove liquid from the air. Dust collectors also function differently from fume/smoke collectors, which remove particulate matter from the air during industrial processes such as welding, rubber making, tempering, and quenching.

How to tell if my dust is dangerous?

Two types of dust testing help you to pinpoint the particular properties of dust, including its potential combustibility. These are: bench testing, and explosibility testing.

Bench testing requires a series of tests. Particle size analysis shows the dust’s particle size to decide the filtration intensity required to follow emissions regulations. This test reveals the count, or number of particles of that size, and the volume/mass spread of the dust. Many dusts are mixed, making this an important testing standard.

You can also use moisture analysis by using a humidity chamber to see how rapidly dust absorbs moisture. This is a good test to use in case of moisture problems, but it is not important 100% of the time.

On the other hand, the explosibility testing should never be skipped. A lab will use a screening test to measure if your dust could be combustible. If that possibility exists, the test will continue forward, measuring dust cloud parameters to determine the rate of pressure rise and the maximum pressure of a contained explosion.

Who can help?

Imperial Systems is a well-established professional dust collector firm within the industry of dust protection for over a decade. We are equipped with every system part you should require to ensure maximal dust safety in your workplace. Our consultants are professionals who can help you improve your systems by learning about your particular business. To get in contact with us, please call 800.918.3013 today.

professional dust collector firm | collector firm professional dust

Read more

by Imperial Systems | Mar 27, 2015 | Common Industrial Dust Collection System Problems, Dust Collection Filters

The importance of dust collection can’t be underestimated when your life is in danger.

Dust collection has become an important issue in many industries that must produce raw materials, such as metalworking or wood pellet manufacturing. The importance of dust collection cannot be understated, especially since employers must now abide by OSHA standards for dust procedures.

What are the dangers of dust? Dust accumulates in the produced material during operations and because of its large quantity and combustible properties, may become a fuel—leading to accidental fires and explosions. The combustible nature of dust has made it hazardous in work environments as we have seen through several unfortunate incidents in factories around the US documented over the past 10 years. OSHA defines combustible dusts as “fine particles that present an explosion hazard when suspended in air in certain conditions.”

Dust that accumulates at wood pellet plants during the production process can end up being a fuel source itself, fueling unwanted fires or explosions. Effective dust management must be an integral aspect of all manufacturing plants as a continual prevention process. “Essentially we are taking a woody product, reducing its particle size and drying it into its most combustible form, and then densifying it afterward,” says Shawn Bells, general manager with Pacific BioEnergy. “So with regard to what we do, we’re probably doing the exact opposite of what you are supposed to be doing—we are creating a fuel—so then we have to deal with it.”

Producers understand now that their operations must be governed strictly by dust control and management in order to abide by OSHA. President of American Wood Fibers Stephen Faeher explains that this increased awareness became prominent around 10 years ago. “OSHA became focused on dust control and management. That’s, I think, when it heightened everyone’s awareness.”

What is OSHA?

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death.

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death.

What Causes Dust Explosions?

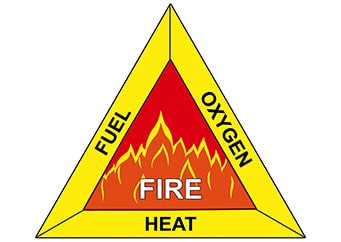

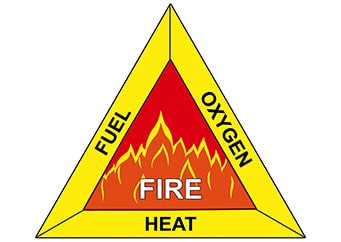

The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

- Combustible dust (fuel)

- Ignition source (heat)

- Oxygen in air (oxidizer)

In addition, a dust explosion is more likely when the dust cloud is ignited within a confined area. When that dust is further dispersed, this can cause an even more severe second explosion. This may occur after the first explosion shakes fugitive dust into other places. If you have had the warning of a first explosion, be sure to watch out. A second explosion can be more dangerous and create more widespread damage than the first.

The Employer’s Responsibility for Worker Safety

One of the most effective ways to prevent explosions is to train employees to recognize the warning signs of combustion. The importance of training the people closest to the hazard cannot be underestimated, as they can be instrumental in sighting unsafe conditions and calling on management.

Though the OSHA regulations necessitate that certain employees be trained, it is recommended that employers issue basic education on the importance of dust collection and combustion prevention procedures. Such education should include information on plant programs on dust management and ignition source controls. The training should be required in these circumstances:

- Pre-assignment training

- Periodic refreshers-i.e. every 6 month re-licensure for work in these environments

- Re-assignment training-i.e. any time work location changes, employees should receive information correspondent to that area

Training should include a practical as well as a lecture aspect. All lectures should be followed or accompanied by demonstrations of the procedures, and as much as possible, employees should be asked to repeat the procedure for the practical element. Repeating the procedure under supervision with feedback given for each practice re-enforces the most important tasks and ensures that employees have absorbed the detail given by the lectures.

It should also be noted that employers holding hazardous chemicals, which includes combustible dusts, must comply with the Hazard Communication standard, 29 CFR 1910.1200.. Included in this regulation is the law that all containers of hazardous chemicals must have labels on them, and the requirement to provide employee training.

Case Study of Dust Fire and Explosion: Massachusetts (3 killed, 9 injured)

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes.

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes.

It was discovered that the fire commenced within a shell molding machine and continued into ventilation systems, fueled by deposits of phenol formaldehyde resin dust. The small fire initiated within the ductwork and dislodged dust sitting on outside of the ducts. This caused a dust cloud to formulate, causing a second explosion (as explained above). The investigation concluded that the following were necessary to prevent such explosions in the future:

- Housekeeping to manage dust accumulation

- Ventilation system design

- Oven maintenance

- Equipment of safety devices

This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.

This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.

From 1980 to 2005 there were 281 dust fires in US businesses, causing 119 deaths that could have been prevented. Clearly, dust accumulation and dispersion is a problem that continues to plague production facilities—confirmed by the fact that since the 2003 investigation, 70 more dust fires have taken place within US businesses.

Where are companies going to ensure that their facilities are safe for the worker? What combination of dust protection products and employee training are being used to guard against fires? How are you seeking to prevent dust explosions from occurring in your facilities?

Professional Dust Collection and Management Services

If what you have read thus far is ringing alarm bells for you, you may need dust and fume collection equipment to guard your employees’ safety and the livelihood of your company assets. Over the past ten years, Imperial Systems has provided manufacturers the most advanced and reliable equipment for prevention of dust-induced explosions.

We manufacture all our materials from our own store in western Pennsylvania, so that we can ensure that you have the most quality product possible. We offer the following products:

- CMAXX Dust Collector System

- DeltaMAXX Cartridge Filters

- CMAXX Laser Fume Extraction System

- Heavy Duty Abort Gates

- Airlocks

- Backdraft Damper

- SCF Dust Collectors

- Diverter Valves

- Spark Arrestor

- Lidegates

- Flex hose

We hope that our research on the importance of dust collection and process maintenance has been helpful to you as you seek to instill the best practices in your company. At Imperial Systems, we want to bring true value to your company’s systems by using our expertise in the industry and our unique, “home-made” products. We thus hope to be a resource to you as you figure out what your needs are and how best to follow OSHA regulations as summarized above.

For now, we leave you with the question: When was the last time you checked your dust collection processes? Are all your boxes checked in the areas of housekeeping (dust accumulation removal), proper ventilation, safety equipment, and oven maintenance? How often are your employees trained, and are they receiving all the information they need to prevent dust explosions in your manufacturing plant? Don’t hesitate to call us with any questions.

Read more

by Imperial Systems | Mar 4, 2015 | Uncategorized

Discover the advantages Imperial Systems’ filters have over Donaldson replacement filters and make the switch today.

Are you still buying Donaldson replacement filters for your metalworking business? If so, you are throwing away money on a product that is not providing you with the longest lasting filtration in the industry. Rather than continuing to spend more money on less performance, take the time to discover why many metalworkers like you have switched from Donaldson replacement filters to Imperial Systems’ DeltaMAXX cartridge filters. Once you discover the difference, we have no doubt that you, too, will switch to the replacement filters which can provide you the performance, lifespan, and savings you really need for your metalworking business.

DeltaMAXX Offers the Advantages You Depend On…

When you started buying Donaldson replacement filters, you were probably impressed by a number of their advantages: the latest nanofiber technology, a MERV 15 efficiency rating, and a perfect fit in your existing dust collection systems. Certainly these are all important assets to have when it comes to handling your workshop’s heavy duty metalworking dust and fumes.

When you started buying Donaldson replacement filters, you were probably impressed by a number of their advantages: the latest nanofiber technology, a MERV 15 efficiency rating, and a perfect fit in your existing dust collection systems. Certainly these are all important assets to have when it comes to handling your workshop’s heavy duty metalworking dust and fumes.

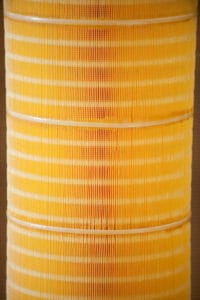

Did you know that you can find all of these same advantages from Imperial Systems’ DeltaMAXX cartridge filters? With the same nanofiber technology, you get a high performance filter which requires minimal pulse cleaning. You will also get the highest efficiency rating in the industry and can be confident that these filters will be compatible with your current dust collection system.

…With More Long Term Benefits

However, the DeltaMAXX advantages actually go above and beyond those of the Donaldson filters. Two areas that we know are important to metalworking businesses which stand out are:

- Lifespan: Using the best surface loading technology, our filters are proven to offer up to twice the filter life of the industry standard. This feature will not only save your business money, but also the time and stress of continually having to order and replace new filters.

- Fits All Makes and Models: At Imperial Systems, we understand that your needs as a business are continually changing, as technology and methods develop over time. So, you may have a Donaldson dust collector system now, but in a few years, that may be replaced by another. You need a reliable filter which you can find to fit any one of the systems you may choose. That’s why Imperial Systems manufactures our DeltaMAXX filters to fit all makes and models of dust collection systems.

Ready to Switch From Donaldson Replacement Filters?

Now that you know that you can get all of the advantages of a Donaldson cartridge filter, and more, when you switch to the DeltaMAXX filters, what more are you waiting for? Give our service representatives a call today to get more details or to place your order. Contact us at: 800.918.3013.

Read more

by Imperial Systems | Oct 7, 2014 | Uncategorized

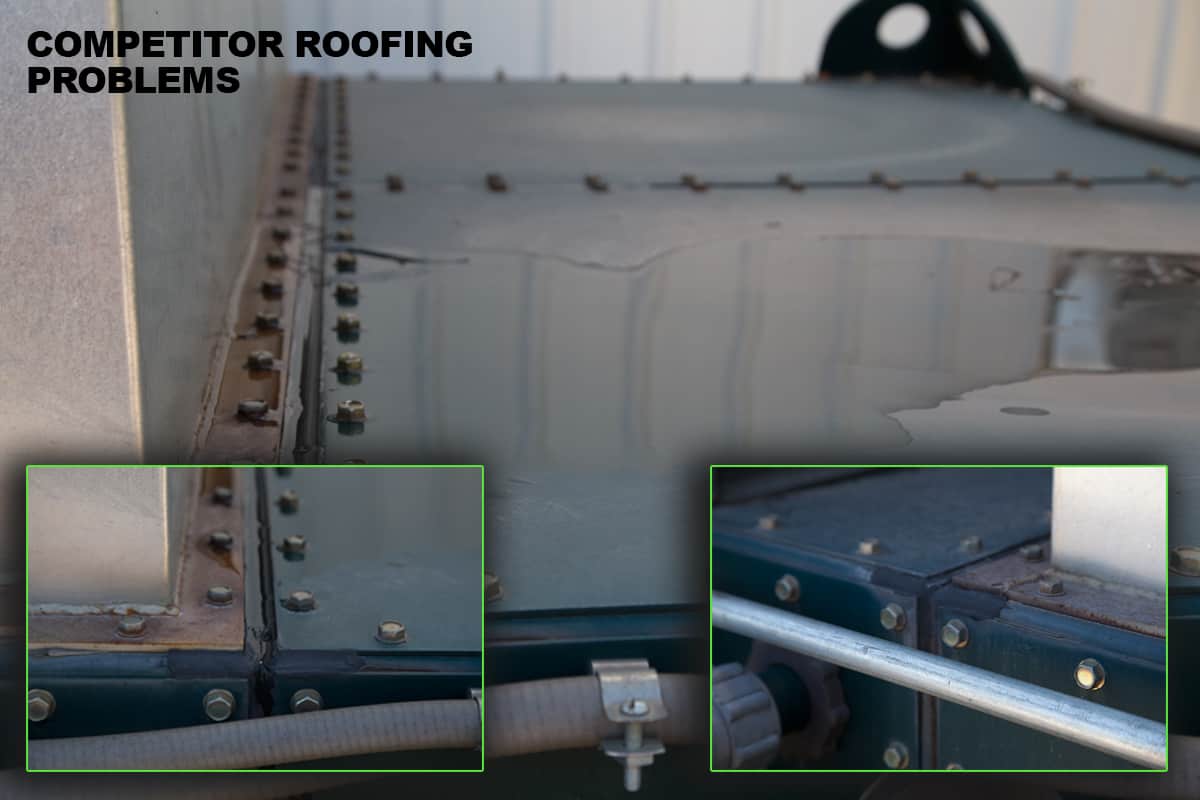

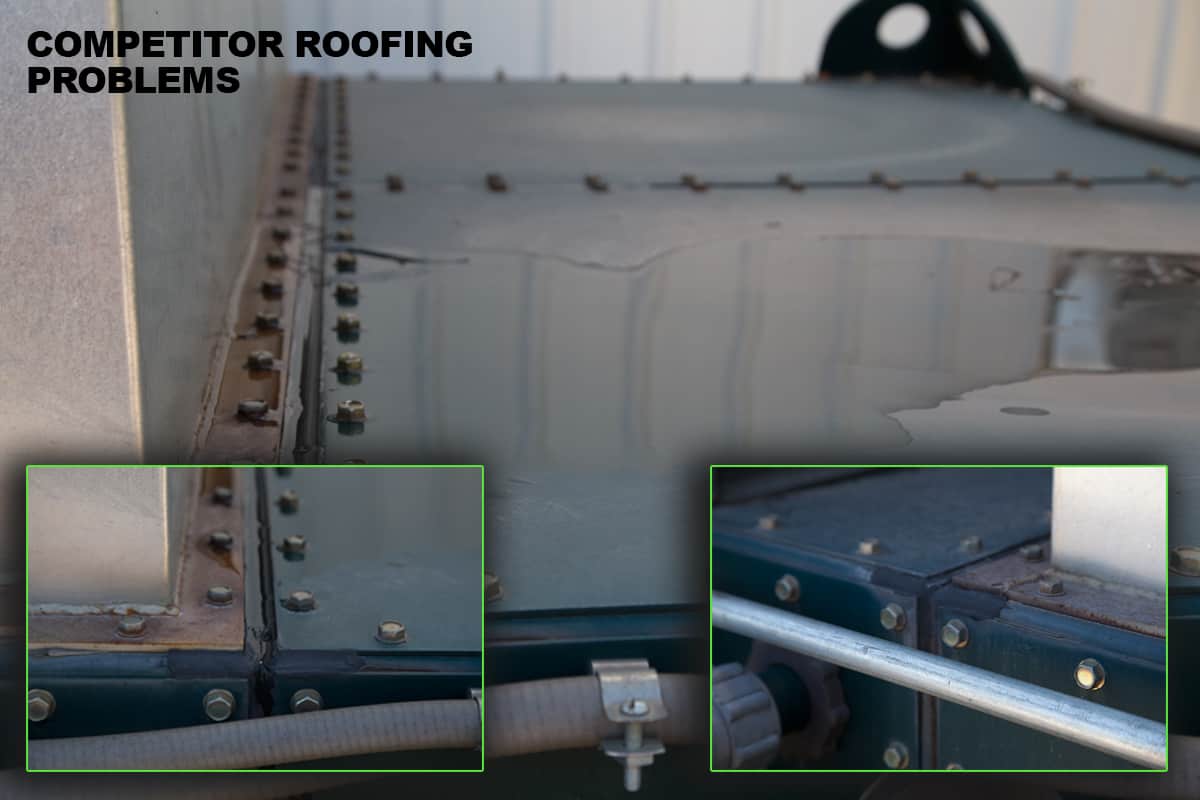

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.

The three key features of the new roof design are: 1. Zero bolt holes, 2. No individual panels, and 3. No roof seams between the modular.

Imperial System’s competitor’s similar unit, with 16 cartridges, has close to 68 feet of sealed connection and approximately 160 bolt holes with over 1000 holes throughout the collector from the bolted panel design. This old style of fabrication leads to potential leaks and holding water resulting in rust and damaged equipment from freezing.

The CMAXX Dust Collector stands tall on the claim of no external bolt holes with an industry best 15 year warranty.

The new CrownTECHTM roof is set to display this year at Fabtech 2016 in Las Vegas. Be sure to stop by booth # N1825 to check out Imperial’s products.

These pictures show how the competitors roof holds water from the panels being under vacuum. It also shows corrosion around the external bolts and bolt holes

Read more

by Imperial Systems | Jun 12, 2014 | Uncategorized

Industrial dust collector filters are crucial in a wide variety of industries, and DeltaMAXX has been shown repeatedly to be the top of the line brand of filter that our clients can trust. Our filters have over a ninety-nine percent efficiency rate for collection of 0.3 to 0.4 micron particles, and with the nanofibers at half the size of those of our competitors, they are the industry’s most efficient cartridge dust collector filters. With a significantly longer life expectancy and reduced outlet emissions, our filters will not only prove to be a wise investment from a financial standpoint, but they will also give you and everyone in your workplace a reason to be confident in the efficiency and safety provided by your dust collection system.

At Imperial Systems we understand that monitoring the performance of your dust collector is not usually at the top of your priority list, as you have many other responsibilities to fulfill and customers to satisfy. For that reason, we have made it one of our priorities to make it simple for our clients to stay on top of maintaining their dust collectors in prime working condition. One way we do this is by making it easy for you to install your replacement filters quickly and hassle free. We check up on our customers on a regular basis, so when the time comes to switch out your industrial dust collector filters, we can have them delivered to you before you need them.

Can We Clean Our Industrial Dust Collector Filters Instead of Replacing Them?

Some of our clients have asked us about cleaning their filters to cut back on the frequency of replacing them. All industrial dust collection filters must be replaced at some point, but naturally, everyone wants to extend the lifespan of their filters in order to save money. Unfortunately, we have no reason to believe that you can actually cut down on your expenses by cleaning your dust collector filters, as opposed to ordering replacements. In addition, and more importantly, if you remove the filter and attempt to have it cleaned in-house or by a third party, you may jeopardize the integrity of the nanofibers on your filters, which can lead to more problems and additional costs in the long run.

Here are just a few reasons why we encourage our customers to stick with replacing their filters on a regular basis instead of having their used filters cleaned:

- With our cleaning processes built into your dust collection system, you can extend the life of your industrial dust collector filters.

- The nano-sized interfiber pores in our filters allows caked dust to fall off easily with a reverse pulse cleaning system.

- If you remove and clean your filters, our emission statement is null and void, and it cannot be used for DEP/OSHA permits.

Contact us if you have any questions about our DeltaMAXX filters or dust collection systems in general. We look forward to helping you maximize the efficiency and safety of your dust collection system without any hassle.

Read more

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death.

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death. The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes.

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes. This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.

This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.