by Erin Long | Apr 17, 2019 | Weld Fume

Any of our competitors will sell you a weld fume collector, but how many of our competitors are welders themselves? We are proud to be a welding fume collection company. If you go out into our shop, you’ll see our CMAXX dust and fume collector right in the middle. It’s protecting a shop full of welders who are working on new dust and fume collectors.

Fume Collectors Welded, Not Bolted

While most of our competitors bolt the pieces of their dust and fume collectors together, Imperial Systems’ collectors are welded solid with no external bolt holes. Because our collectors are welded and not bolted, we understand welders’ fume collection needs. We know our weld fume collector works in the field because it works in our shop.

Our own welders test our fume collection system every day. The safety of our own employees drives us. As a welding fume collection company, our systems can’t just be good enough to sell to you. They must be good enough to put in our own shop.

Because our competitors do so much bolting and not so much welding, their systems don’t get put through the same test that ours do. If our fume collection system didn’t work for welders, our welders wouldn’t be happy with it.

By Welders, For Welders

The person who cares most about how a machine works is the person who uses it every day. For welders doing their jobs every day, a fume collection system needs to work. They care about their work environment and whether it’s clean and pleasant to work in. They care about their health and what they’re breathing.

As a welding fume collection company, it’s our responsibility to make products that welders like and trust. We always encourage and value feedback from our welders about ways our weld fume collectors could be improved. We know that if our own welders in our shop aren’t satisfied with the way our CMAXX works, people who purchase it for their own shops won’t be satisfied either.

Our welders are proud of the quality of their work. As a weld fume collection company we take pride in giving our welders the safest, most pleasant environment to work in. Our goal must always be the highest air quality possible.

What’s Wrong with Bolts

Why do we weld our fume collectors instead of bolting them together like the competitors? Bolting the panels together probably saves some time over the work of a skilled welder. When you’re choosing a weld fume collection company, however, quality beats cutting corners. Bolts can come loose, and bolt holes rust and allow water inside the collector.

As a solid welded piece with no external bolt holes, the CMAXX has no bolt holes to rust. The quality work of our welders produces the most durable, weather-resistant fume collector on the market. It allows us to offer the longest warranty in the industry.

Our competitors choose bolts over welding, probably because that’s how they’ve always done it. Some competitors, though, have started to copy our design, including the solid welding instead of bolts. Don’t fall for these CMAXX wanna-be products. The copycats will never be as good as the original. Many of these copycats aren’t even made in the USA and they don’t go through our most important test: the satisfaction and happiness of our own welders.

With NFPA standards on combustible dust, more and more dust and fume collectors are being located outside. This makes it easier and safer to vent an explosion, but it exposes the collector to the elements. After many years of rain and snow, bolt holes will show corrosion and rust. Unlike bolt holes, our welds don’t leave the metal weak to rusting.

Why We Do What We Do

We are a welding fume collection company because welders deserve to be safe and healthy at work. All welders, including those in our own shop, deserve the basic right to clean air in the workplace. Our welders test our weld fume collectors while they’re making them. Our shop relies on our systems to do a good job. If our own welders trust the product they build, that means you can trust it in your shop too. The CMAXX is a product built by welders, for welders, from our weld shop to yours.

Read more

by Erin Long | Feb 7, 2019 | Weld Fume

Welding can be a dangerous job. Specifically, weld fumes contain a mixture of metals that can cause serious health damage. However, welders can work safely and stay healthy with an industrial ventilation system keeping the air clean.

What Are Some Health Risks for Welders?

Welders work very closely to the metal they are welding. So this puts them in the path of the weld fumes that rise from the heated metal. Many components of these fumes are dangerous to inhale. But industrial ventilation systems can remove these fumes.

Welders working on iron are at risk of pulmonary siderosis, sometimes known as “welder’s disease.” This is where iron particles build up in the lungs and damage them. This disease is incurable. Welding causes another disease known as “metal fume fever”. In this case, the lungs react to inhaling metals like nickel or other metals, causing a flu-like illness. Also, cadmium and hexavalent chromium are proven to cause cancer. Further, beryllium is often alloyed with other metals and causes fatal lung disease. Meanwhile, using manganese in welding rods or alloys causes a disease looking like Parkinson’s.

With all these health dangers, ventilation solutions are necessary for welders’ health. Fortunately, an industrial ventilation system will remove weld fumes and let welders work safely.

How Should a Plant Ventilation System be Designed?

An industrial ventilation system for welding can be either an ambient or source capture system. Both provide ventilation solutions, but in different ways.

An ambient system circulates all the air in the facility through a dust collector. Then it returns clean air. This removes weld fumes from the whole space.

A source capture system has ventilation points at the areas where the welders work. Examples of these points can be fume arms, hoods, or downdraft tables. The air pulls the fumes directly away from the welder’s breathing area. The plant ventilation system filters the air through a dust collector.

You can use both kinds of systems for industrial ventilation. Source capture works well when the dust comes from individual machines or work areas that don’t move around. Install a hood or arm to handle ventilation from those sources.

Applications can include fume extraction from robotic weld cells or welding stations. In other instances, they can include bin vents, blenders, and conveyors. Source capture can usually manage any process that generates dust.

Connect a hood, fume arm, or downdraft table to the general air ventilation system. Design the system with many “drops,” or source capture points. This requires a skillful system designer to balance the airflow. A badly designed system may not have consistent ventilation in all areas of the plant.

An ambient system works well for cleaning all the air in the facility. An industrial ventilation system like this might be used when people are creating fumes by welding in different areas or moving around. If source capture points can’t catch everything, an ambient strategy may be needed. This will ensure the plant ventilation system is sufficient.

Industrial Ventilation Systems for Welder Health

With so many ventilation solutions possible, you can protect welders in every type of facility from weld fume health hazards. Have your system designed by a trained pro will make sure every area of the facility has clean air.

If a hazard can’t be removed completely, OSHA and other safety groups like ACGIH recommend engineering controls. A plant ventilation system is a form of engineering control. Welders need to work around weld fumes. The best way to minimize the risk is to remove the fumes before they can cause harm.

Make sure welders in your facility stay healthy. Contact us about an industrial ventilation system designed for your needs.

Read more

![Weld Fume Extraction Guide [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/01/fume-extraction-header-1080x675.jpg)

by Erin Long | Jan 23, 2019 | Weld Fume

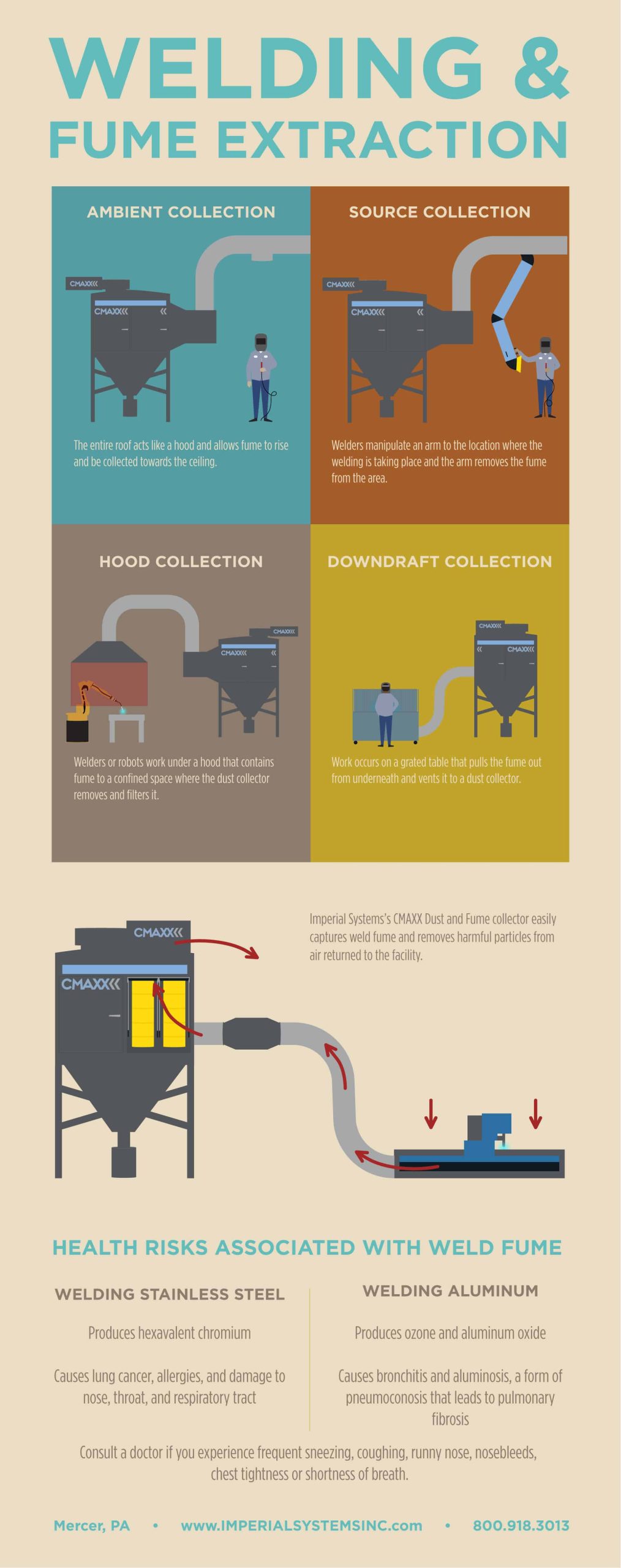

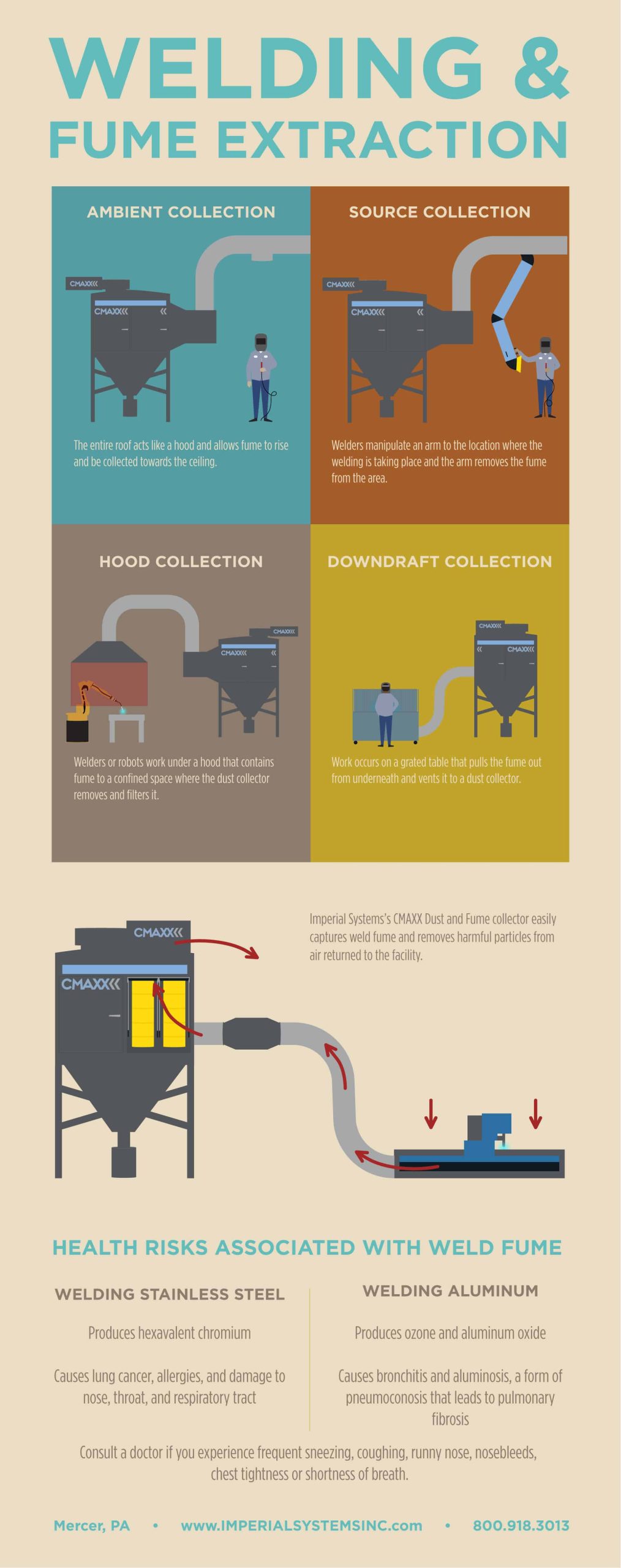

This weld fume extraction guide takes a look at the many ways to collect and remove weld fume from a facility. When not properly taken out of the work area, weld fume can cause some serious health issues for welders.

Weld Fume Extraction Methods

- Ambient Collection – The entire roof acts like a hood and allows fume to rise and be collected towards the ceiling. Ductwork runs with inlets above the work area to clear the fumes.

- Source Collection – Welders manipulate an arm to the location where the welding is taking place and the arm removes the fume from the area.

- Hood Collection – Welders or robots work under a hood that contains fume to a confined space where the dust collector removes and filters it.

- Downdraft Collection – Work occurs on a grated table that pulls the fume out from underneath and vents it to a dust collector.

Health Risks Associated with Weld Fume

Welding Stainless steel

- Produces hexavalent chromium, a dangerous valence state of the element chromium. Chromium metal is added to alloy steel to increase hardenability and corrosion resistance.

- Causes lung cancer, allergies, and damage to the nose, throat, and respiratory tract

Welding Aluminum

- Produces ozone and aluminum oxide. TIG, MIG, and plasma-arc welding typically produce ozone, a highly toxic gas. Aluminum oxide forms from the base and filler materials and exists in the welding fumes.

- Causes bronchitis and aluminosis (aluminum lung), a form of pneumoconiosis that leads to pulmonary fibrosis

Consult a doctor if you experience frequent sneezing, coughing, runny nose, nosebleeds, chest tightness, or shortness of breath.

Weld Fume Extraction Equipment and Experts

The CMAXX Dust & Fume Collector by Imperial Systems is the best choice for removing weld fume from your facility and keeping your employees safe. Our sales and product engineers will design and dust and weld fume collector specifically for your application. Contact us today.

Read more

![Weld Fume Extraction Guide [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/01/fume-extraction-header-1080x675.jpg)