Keeping Things Clean Indoors Leads to the Better Things Outdoors

Sometimes, your search for the best solution can end in familiar territory.

Paul Arnold is the long-time Vice President of Operations for Keystone Ridge Designs in East Butler, Pennsylvania (keystoneridgdesigns.com). Since 1995, the company has supplied premium-quality steel trash receptacles, benches, bike racks, planters, and other heavy outdoor furniture to parks, campuses, municipalities, housing developments, and various retail establishments, including major shopping malls. All products are made solely in the United States, with all expert continuous-seam welding and powder coating done by hand.

“We have a sterling reputation, especially with landscape architects, for exceptionally durable, uniquely and contemporarily designed furniture that will hold up well in even the most challenging high-traffic outdoor areas,” says Arnold. “In short, we deliver great value over the life of a product. Not to mention, our look remains ‘current’ no matter how often a landscape might change – West Coast, East Coast, or wherever.”

Keystone Ridge Designs employs a continuous inseparable weld seam during its welding process. This step prevents corrosion from moisture over the life of the furniture. In addition, each bench, rack, or steel (composed of 25 percent or more recycled content) piece is protected from significant chipping, cracking, or sun damage by Keystone Ridge’s patented Keyshield® finish.

“The heart-and-soul of our fabrication excellence revolves around our powder-coating step,” claims Arnold. “After we sandblast our substrates to a white finish to remove all possible contaminants, we electrostatically apply a zinc-rich epoxy primer, followed by a coat of colored polyester powder. Both coats are oven-cured to ensure an optimal finish.”

But such elaborate production also yields a substantial amount of dust and fumes during manufacturing, particularly while workers, during two shifts per day, sandblast the substrate material.

“In any blasting environment, things get dirty and dusty in a huge way,” begins Justin Pyle, Shop Manager. “Sometimes, our worker can stay in the booth for no more than 20 minutes at a time due to the heat and dust generated. Not to mention, the refuse pot fills quickly and needs to be emptied.”

Keystone Ridge uses small dust collectors within its powder-coat booth…and had a much larger unit to remove air contaminants from the overall fabricating facility. However, Arnold, Pyle, and crew were not satisfied with the performance or some of the features of its prior larger system.

“Our basic issue was the horizontal positioning of the filters within our old collector,” begins Arnold. “The filters were literally on top of one another. That meant the top one would stay relatively clean – but would dump material, when purging, onto the filters below it, leading to what we thought was very premature filter failure throughout the system.”

Arnold then conducted a vast search into collectors that offered non-traditional vertically hanging filter placement. He also needed a unit that would fit nicely within a somewhat limited space on the firm’s property. He found the perfect – and familiar – solution not too far away.

“I kept hearing good things regarding the CMAXX® compact collector from Imperial Systems (isystemsweb.com),” says Arnold. “I then learned that one of my Grove City High School classmates, Jeremiah Wann, was president of the company.”

Wann and his installation crew soon performed an onsite inspection to ensure that the CMAXX unit would do the job for Keystone Ridge’s demanding conditions. They also needed to determine where the collector would best reside for maximum performance. Neither decision took long.

“Jeremiah made me extremely comfortable from the start,” says Arnold. “Imperial was willing – and able – to do whatever it took to meet our requirements. It also helped that I knew him. A purchase this large involves significant financial risk, obviously. But Jeremiah made me 100 percent confident that Imperial would stand behind its product.”

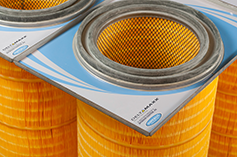

The CMAXX compact modular cartridge collector uses Imperial’s renowned DeltaMAXX™ vertically hanging filters with their unique NanoFiber Filtration Technology that incorporates a very fine surface layer of synthetic fibers to prevent particulates from embedding into the premier-quality media. As a result, the filters provide twice the service life versus competitive models, while yielding an extraordinary 15 ASHRAE MERV efficiency rating. In fact, the DeltaMAXX style pulses 94% less, and emits 97% less contaminant, when tested against other filters in its class.

“We installed our CMAXX unit and DeltaMAXX cartridge filters in September of 2012. In nine months, we have not had to change out a single filter,” begins Pyle. “Our air is remarkably clean throughout the blasting area – and the entire shop, in fact. The only maintenance I’ve had to do on the CMAXX is to apply some grease to a few screws around the compressor. And, best of all, material from one filter doesn’t fall down onto another filter because of the vertical positioning.”

None of the trouble-free operation of the Imperial products has been a surprise to Arnold, however. His thorough research had yielded only positive feedback regarding his former classmate’s company and offerings.

“A few of Imperial’s local installations were actually written about in our newspaper,” says Arnold. “All the press was completely favorable – and now you can add us to the list of completely satisfied users.”

The CMAXX dust collector has a unique Pulse Distribution technology that delivers 100% even pulsation across the DeltaMAXX filter wall – resulting in maximum dust-collection performance and filter life. It also comes with a 15-year warranty. Even though Keystone Ridge has yet to change filters, removal and replacement is fast and easy, when required.

In addition, the CMAXX dust collector has no external bolt holes. That’s especially critical for Keystone Ridge because the company’s unit is located outside.

“The CMAXX dust collector has amazing suction power…it draws air from everywhere,” states Arnold. “Its construction ensures that contaminants do not get back into the airstream and blown back at our workers. Plus, because there are no bolt holes, water cannot get into the unit to damage the filters.”

When Arnold and Pyle reflect on their Imperial purchase and brand experience, not a single negative enters the conversation:

“Consistency is the first descriptor that comes to mind,” begins Pyle. “Consistent and exceptional performance of the CMAXX collector, of the DeltaMAXX filters, and of the outstanding customer and technical support we receive from Imperial.”

Arnold connects all the key components and processes:

“We can fabricate the nicest park bench in the world…but if the finish is no good, then our final product is no good. The key to a perfect finish is proper substrate pre-treatment – leading to a superior powder topcoat. A first-class blast system is essential to such pre-treatment. Dust and fume collection is critical to keeping our blasting system operating at optimal levels. Bottom line: The Imperial products play an extremely important role in our overall production and ultimate success.”

Keystone Ridge Designs prides itself on continually exceeding customer and self-imposed expectations. It didn’t have to look far to find a partner with the same core values and reputation.

Read more