by Imperial Systems | May 1, 2015 | Dust Collection Filters

Don’t let your employees become a statistic. Put your trust in Imperial Systems.

Providing quality machinery in the metalworking industry is imperative in keeping a safe working environment. According to the International Labour Association*, there are reported to be more than 160 million people a year who suffer from a work-related disease. Every 15 seconds, a worker dies because of a work-related disease or illness. Don’t let your employees become a part of that statistic.

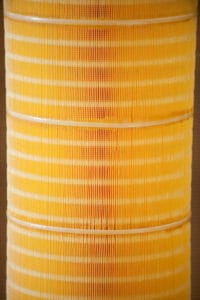

Replacement filters recently installed in a CMAXX dust collector

With a purchase as simple as our DeltaMAXX replacement filters from Imperial Systems, you can help lead your employees in the right direction towards a healthier life.

You must be sure that your dust collector system is running at it’s best by using our DeltaMAXX replacement filters. Your employees will be able to work in a safe environment, decreasing their risk of diseases such as lung cancer and mesothelioma.These diseases can take decades to show up in our bodies, so make sure that you get started today in keeping your environment free of dust and debris.

Why Choose Imperial Systems for Replacement Filters?

One word. Quality.

Imperial Systems provides quality that is above reproach. We only seek standards of honesty and integrity when it comes to our products and services. With our company you will find the highest standard of quality in our replacement filters because they are made with:

- Nanofiber technology, stopping submicron particles from becoming embedded into the media, before they even enter the filter.

- The highest quality pleated media having a 99.9% efficiency

- Reduced dust collector operational costs

- The industry’s best surface loading technology

- Lower operational mass emissions

- The best in the industry, MERV15 filtration

- Less pulse cleaning

- and more..

Along with our quality replacement dust collector filters, you will also experience our excellent customer service.

Read more

by Imperial Systems | Apr 30, 2015 | Dust Collection Filters

Did you know that materials and nanotechnology could make the difference for your filter life?

What are the advantages of Camfil FARR cartridge filters?

You have probably heard of Camfil FARR cartridge filters as being long lasting, and standing up to the worst conditions. You certainly don’t want filter distortion or blowouts when it comes to metalworking. These types of errors in products can create major health and security concerns.

But are Camfil FARR cartridge filters all that they claim to be? Or could you possibly find a company that offers the same product at a lower cost, while boasting higher quality in material and technology innovation?

We’d like to answer that question for you.

Yes.

Imperial Systems has been rated above Camfil Farr in satisfaction surveys with the product, which breaks down to higher quality development processes, materials, and advanced technology.

We offer double the filter life for our air filter bags. We use advanced nanofiber technology and offer MERVE 15 filtration efficiency for a higher quality product.

Camfil FARR filters use an exclusive media bonded to a welded wire grid for filtration technology, which they claim will hold more dirt/dust for longer. However, this means that their product is made of several materials, which is still not optimal. We have innovated in the industry, offering the most advanced NanoFiber technology available in filters (which is how we can guarantee a filter life double that of most other companies in the industry). The nanofiber stops submicron particles from becoming embedded. We also use a heat sealed airbag, so that fine particles can’t leak out. Our loading technology operationalizes dust take release, another factor leading to our longer filter life. Last, our pleated media is also of the highest quality. We offer 99.9% efficiency .3 to .5 micron –hard to find in most parts!

If you want to know what it feels like to work with the best in the dust collection and air filtration industry, talk to us. Our representatives are available to talk anytime and answer any questions you have. Our goal is to ensure that you have the safest and most economical dust filtration experience possible. For safety, quality, and value, call 800-918-3013.

camfil farr cartridge filters | cartridge filters camfil farr

Read more

by Imperial Systems | Apr 24, 2015 | Dust Collection Filters

Find out how this top dust collector stays ahead of the competition…and how it can help you do the same!

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well.

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well.

This is especially true of safety equipment, such as your industrial dust collection systems. But if your systems can’t hold up to the heavy load, or harsh conditions, it is time to find an alternative. Begin by discovering what sets the top dust collector apart from the competition.

From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At Imperial Systems, we take these concerns and needs seriously. So, when it came time to design and manufacture our innovative dust collection system, we incorporated the latest technology with unique designs to create the top dust collector in the industry.

From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At Imperial Systems, we take these concerns and needs seriously. So, when it came time to design and manufacture our innovative dust collection system, we incorporated the latest technology with unique designs to create the top dust collector in the industry.

How does our CMAXX dust collector stay two steps ahead of the competition? The answer lies within our unique system advantages and our latest design updates. Discover the difference today to take the next step towards a cleaner, safer, and longer lasting dust collection system.

The Challenge

Whether your manufacturing processes involve welding, woodworking, or even just moving food or grain products, dust can pose at least three major challenges. These include:

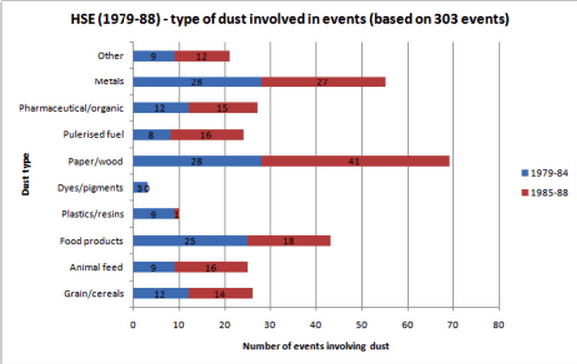

(http://www.dustexplosion.info/statistics.htm)

- Inhalation. According to the World Health Organization, regularly breathing particles in has “the potential to cause harm either locally or subsequently elsewhere in the body.” Several OSHA standards seek to address such risks.(http://www.who.int/occupational_health/ publications/en/oehairbornedust3.pdf)

- Combustion. Dust explosions are another major risk. Between 1980 and 2005, the US Chemical Safety and Hazard Investigation Board identified 281 combustible dust incidents. Collectively, these incidents were responsible for the deaths of 119 workers, 718 injured, and numerous damaged facilities. Despite new standards, OSHA still estimates that there are approximately 30,000 U.S. facilities at risk for combustible dust explosions.

(https://www.osha.gov/dsg/combustibledust/)(http://www.grainger.com/content/safety-control-combustible-dust)

- Contamination. In certain fields, especially in food processing, contamination is also a significant concern. Not only can dust affect employees and equipment, it can also harm products. (http://industrialdustcollectors.blogspot.com/2014/07/dust-collector-compliance-with_18.html)

With such high stakes, it is imperative to have an efficient, dependable, and long-lasting dust collection system.

The Competition

Other industrial dust collection manufacturers have attempted to address these concerns in their dust collection systems. They have worked hard to create dust collectors that will hold up to NFPA and OSHA standards which have continued to evolve in recent years.

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit.

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit.

A top dust collector should offer you the highest efficiency in order to help you save on costs while offering the utmost filtration. Additionally, you need a system that can withstand the heavy loads, and even the harsh elements, often involved in the world of manufacturing.

Sadly, many high performing industrial dust collection systems are not made to last. Our competitor’s unit that is closest to the CMAXX collector has close to 68 feet of sealed connection and approximately 160 bolt holes with over 1000 holes throughout the collector from the bolted panel. This outdated fabrication style puts the whole system at risk for leaks, rust, and ultimately, damaged equipment.

Top Dust Collector Advantages

At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design.

At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design.

With our vertical cartridge design and PD technology, our system offers up to twice the filter life of similar units. At the same time, we offer the cleanest plant air at a lower price with our high efficiency design that includes both manifold mounted pulse valves and 100% total pulse distribution across the filter media.

Other system advantages include:

- A space-saving, low-profile design

- The lowest internal velocities from a larger housing

- Less service time with our tool-free filter door

- Factory assembled air header and top section

- Less Internal build up because of no internal frame on the dirty air plenum

- High quality Goyen GoCo cone nozzles located closer to the filter media

Additionally, our slanted inlet design prevents water built up while more evenly distributing dust and particulates throughout the filters. Collectively, these advantages not only provide up to 40% more cleaning power than the industry standard, but they also save you time, effort, and money along the way.

The CMAXX dust collector is also built to last. We have designed it with military grade door latches, rather than the less dependable truck trailer hardware. We also added corrosive resistant paint inside and out and heavy duty nickel plated hardware. With such dependability, not to mention our 15 year warranty, you can have confidence in your CMAXX Dust Collection System.

More Advantages With The Latest Update

Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.

Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.

Many dust collection systems are subject to the potentially harsh external elements. For many years, rust, leaks, and warping have been common results. These resulting defects, however, can compromise the integrity of the unit, undermining the very safety it is supposed to provide. Clearly, a change is needed.

And change is exactly what you will find in the new, domed roof design of the CMAXX dust collection system. We’ve taken not just one stand, but four, against the potential dangers of water damage and leaking:

- Solid, One-Piece Roof. With no individual panels, this innovation offers a stronger design while eliminating the risks of warping and leaks through the roof.

- Positive Bow. This shape allows water and debris to run off more easily, making the whole unit easier to clean. Additionally, there is no chance for freezing water to pool up on top of the unit and cause potential damage.

- No Bolt Holes. Without any external bolt holes, our system is completely sealed. This guarantees against both leaks and rusty bolts which may break or loosen.

- Heavy Duty Construction. Our 3/16” thick roof is fully welded with all welds ground smooth. Additionally, ¼” plate internal stiffeners offer further reinforcement.

With the latest advantages offered by our innovative roof and exterior design, Imperial Systems has taken a significant leap forward in dust collection system design. Combined with previously existing features, this system will continue to perform at the top of the industry today, and for years to come.

Are You Ready To Invest In Your Future Safety?

How long have you had your current industrial dust collection system? How is it holding up? Share your stories with us in the comments section below.

Then, if you want more information, or if you are ready to make the change and install a system that is uniquely designed for high-efficiency and longevity, give us a call at Imperial Systems. You can reach us at 800.918.3013.

Read more

by Imperial Systems | Apr 16, 2015 | Dust Collection Filters

These problems can be avoided with the aid of a professional dust control firm.

Hire a professional dust control firm? Like many others, you might scoff at the idea. Really, what is dust, anyway? Surely, dust could not pose any serious problems in your workplace.

According to most definitions, dust is the fine, dry particles of earth or waste matters which combine to form a light, dry powder. You may see this powder lying on the ground, other surfaces, or floating in the air. Could this often barely visible material really cause hazards and other problems in your workplace, though? The short answer: Absolutely yes.

According to the World Health Organization (WHO), “Year after year, both in developed and in developing countries, overexposure to dusts causes disease, temporary and permanent disabilities and deaths. Dusts in the workplace may also contaminate or reduce the quality of products, be the cause of fire and explosion, and damage the environment.”

If these facts give you cause for any concern at all about the conditions in your workplace, we highly recommend reconsidering the services of a professional dust control firm. A professional dust control firm can help you tackle dust management and thereby the potential problems of dust in your place of business or production.

Professional Dust Control Firm Services

A reliable, professional dust control firm such as Imperial Systems will be able to provide you with multiple dust control services. Some of those services may include:

- Extraction of these hazardous dusts, identified by WHO:

- mineral dusts from the extraction and processing of minerals (these often contain silica, which is particularly dangerous);

- metallic dusts, such as lead and cadmium and their compounds;

- other chemical dusts, such as bulk chemicals and pesticides;

- vegetable dusts, such as wood, flour, cotton and tea, and pollens;

- moulds and spores.

- Ease of safe waste disposal

- Maintenance of dust removal equipment

- Integrated dust management systems which provide comprehensive coverage of dust control in your workplace

- Choices of dust control equipment designed to efficiently extract certain dust materials

- Specific combinations of equipment to take care of your dust control needs

Compliance with World Health Organization workplace safety standards is one way to vastly improve the conditions in your workplace, even if it means controlling dust. To understand more about why you may need to hire a professional dust control company, contact Imperial Systems today.

Imperial Systems is among the top dust collection equipment manufacturing businesses in North America, and will be sure to take care of your dust problem. One of our representatives will be happy to schedule an assessment and provide a quote for you, at your convenience.

Professional Dust Control Firm | Professional Dust Control Company

Read more

by Imperial Systems | Apr 3, 2015 | Dust Collection Filters

What don’t you know about the dust you’re producing? Learn about it from your local professional dust collector firm.

Dust collection is an important process to protect your employees and keep your work environment accident-free. Who would ever guess that dust could be so dangerous? While the general public won’t be aware of this issue, as a manufacturing or metalworking company, you realize that it’s vital—especially in today’s regulatory climate. A professional dust collector firm can help you by ensuring that you have the correct systems in place to prevent dust-initiated accidents.

What is the problem with dust?

Simply put, dust can be a highly flammable substance that may result in fires. Because of dust’s combustible properties, it can become a fuel when it has been accumulated over time from industrial processes. Oftentimes it may travel down pipes or remain within the operations systems, creating an entire chain of dust fuel!

This possesses serious risks for employees working around the dust. Since the year 2000, there have been many documented explosions within factories that did not take proper precautions in regards to dust collection and education of employees.

What is a dust collector?

What do we mean when we talk about dust collectors? We’re referring to the system utilized to improve air quality that is released from industrial processes. The dust collector should handle dust loads by removing dust from the air—different from air cleaners, which have the filter.

A professional dust collector firm should provide you with a comprehensive system that goes beyond a simple air cleaner. This system is comprised of a blower, dust filter, filter-cleaning system, and a dust receptacle. It is also referred to as an air pollution control device, which is understood to maintain air quality.

What do dust collectors do?

Dust collectors recover valuable granular solids from process streams or remove solid contaminants before they are ventilated into the atmosphere. They are distinguished from mist collectors, which are used for metal working to remove liquid from the air. Dust collectors also function differently from fume/smoke collectors, which remove particulate matter from the air during industrial processes such as welding, rubber making, tempering, and quenching.

How to tell if my dust is dangerous?

Two types of dust testing help you to pinpoint the particular properties of dust, including its potential combustibility. These are: bench testing, and explosibility testing.

Bench testing requires a series of tests. Particle size analysis shows the dust’s particle size to decide the filtration intensity required to follow emissions regulations. This test reveals the count, or number of particles of that size, and the volume/mass spread of the dust. Many dusts are mixed, making this an important testing standard.

You can also use moisture analysis by using a humidity chamber to see how rapidly dust absorbs moisture. This is a good test to use in case of moisture problems, but it is not important 100% of the time.

On the other hand, the explosibility testing should never be skipped. A lab will use a screening test to measure if your dust could be combustible. If that possibility exists, the test will continue forward, measuring dust cloud parameters to determine the rate of pressure rise and the maximum pressure of a contained explosion.

Who can help?

Imperial Systems is a well-established professional dust collector firm within the industry of dust protection for over a decade. We are equipped with every system part you should require to ensure maximal dust safety in your workplace. Our consultants are professionals who can help you improve your systems by learning about your particular business. To get in contact with us, please call 800.918.3013 today.

professional dust collector firm | collector firm professional dust

Read more

by Imperial Systems | Mar 27, 2015 | Common Industrial Dust Collection System Problems, Dust Collection Filters

The importance of dust collection can’t be underestimated when your life is in danger.

Dust collection has become an important issue in many industries that must produce raw materials, such as metalworking or wood pellet manufacturing. The importance of dust collection cannot be understated, especially since employers must now abide by OSHA standards for dust procedures.

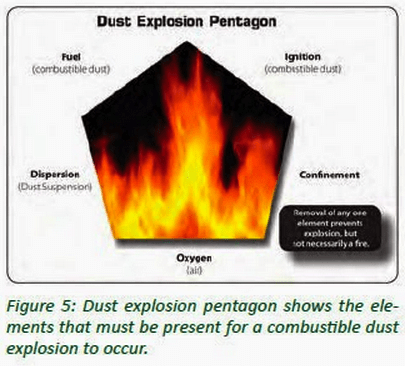

What are the dangers of dust? Dust accumulates in the produced material during operations and because of its large quantity and combustible properties, may become a fuel—leading to accidental fires and explosions. The combustible nature of dust has made it hazardous in work environments as we have seen through several unfortunate incidents in factories around the US documented over the past 10 years. OSHA defines combustible dusts as “fine particles that present an explosion hazard when suspended in air in certain conditions.”

Dust that accumulates at wood pellet plants during the production process can end up being a fuel source itself, fueling unwanted fires or explosions. Effective dust management must be an integral aspect of all manufacturing plants as a continual prevention process. “Essentially we are taking a woody product, reducing its particle size and drying it into its most combustible form, and then densifying it afterward,” says Shawn Bells, general manager with Pacific BioEnergy. “So with regard to what we do, we’re probably doing the exact opposite of what you are supposed to be doing—we are creating a fuel—so then we have to deal with it.”

Producers understand now that their operations must be governed strictly by dust control and management in order to abide by OSHA. President of American Wood Fibers Stephen Faeher explains that this increased awareness became prominent around 10 years ago. “OSHA became focused on dust control and management. That’s, I think, when it heightened everyone’s awareness.”

What is OSHA?

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death.

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death.

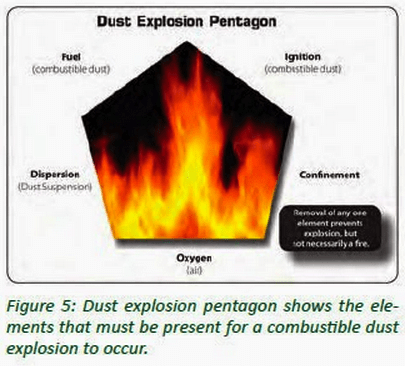

What Causes Dust Explosions?

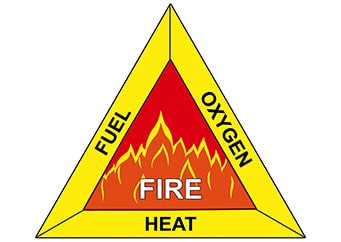

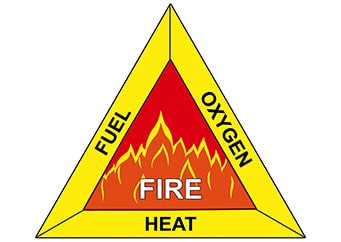

The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

- Combustible dust (fuel)

- Ignition source (heat)

- Oxygen in air (oxidizer)

In addition, a dust explosion is more likely when the dust cloud is ignited within a confined area. When that dust is further dispersed, this can cause an even more severe second explosion. This may occur after the first explosion shakes fugitive dust into other places. If you have had the warning of a first explosion, be sure to watch out. A second explosion can be more dangerous and create more widespread damage than the first.

The Employer’s Responsibility for Worker Safety

One of the most effective ways to prevent explosions is to train employees to recognize the warning signs of combustion. The importance of training the people closest to the hazard cannot be underestimated, as they can be instrumental in sighting unsafe conditions and calling on management.

Though the OSHA regulations necessitate that certain employees be trained, it is recommended that employers issue basic education on the importance of dust collection and combustion prevention procedures. Such education should include information on plant programs on dust management and ignition source controls. The training should be required in these circumstances:

- Pre-assignment training

- Periodic refreshers-i.e. every 6 month re-licensure for work in these environments

- Re-assignment training-i.e. any time work location changes, employees should receive information correspondent to that area

Training should include a practical as well as a lecture aspect. All lectures should be followed or accompanied by demonstrations of the procedures, and as much as possible, employees should be asked to repeat the procedure for the practical element. Repeating the procedure under supervision with feedback given for each practice re-enforces the most important tasks and ensures that employees have absorbed the detail given by the lectures.

It should also be noted that employers holding hazardous chemicals, which includes combustible dusts, must comply with the Hazard Communication standard, 29 CFR 1910.1200.. Included in this regulation is the law that all containers of hazardous chemicals must have labels on them, and the requirement to provide employee training.

Case Study of Dust Fire and Explosion: Massachusetts (3 killed, 9 injured)

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes.

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes.

It was discovered that the fire commenced within a shell molding machine and continued into ventilation systems, fueled by deposits of phenol formaldehyde resin dust. The small fire initiated within the ductwork and dislodged dust sitting on outside of the ducts. This caused a dust cloud to formulate, causing a second explosion (as explained above). The investigation concluded that the following were necessary to prevent such explosions in the future:

- Housekeeping to manage dust accumulation

- Ventilation system design

- Oven maintenance

- Equipment of safety devices

This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.

This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.

From 1980 to 2005 there were 281 dust fires in US businesses, causing 119 deaths that could have been prevented. Clearly, dust accumulation and dispersion is a problem that continues to plague production facilities—confirmed by the fact that since the 2003 investigation, 70 more dust fires have taken place within US businesses.

Where are companies going to ensure that their facilities are safe for the worker? What combination of dust protection products and employee training are being used to guard against fires? How are you seeking to prevent dust explosions from occurring in your facilities?

Professional Dust Collection and Management Services

If what you have read thus far is ringing alarm bells for you, you may need dust and fume collection equipment to guard your employees’ safety and the livelihood of your company assets. Over the past ten years, Imperial Systems has provided manufacturers the most advanced and reliable equipment for prevention of dust-induced explosions.

We manufacture all our materials from our own store in western Pennsylvania, so that we can ensure that you have the most quality product possible. We offer the following products:

- CMAXX Dust Collector System

- DeltaMAXX Cartridge Filters

- CMAXX Laser Fume Extraction System

- Heavy Duty Abort Gates

- Airlocks

- Backdraft Damper

- SCF Dust Collectors

- Diverter Valves

- Spark Arrestor

- Lidegates

- Flex hose

We hope that our research on the importance of dust collection and process maintenance has been helpful to you as you seek to instill the best practices in your company. At Imperial Systems, we want to bring true value to your company’s systems by using our expertise in the industry and our unique, “home-made” products. We thus hope to be a resource to you as you figure out what your needs are and how best to follow OSHA regulations as summarized above.

For now, we leave you with the question: When was the last time you checked your dust collection processes? Are all your boxes checked in the areas of housekeeping (dust accumulation removal), proper ventilation, safety equipment, and oven maintenance? How often are your employees trained, and are they receiving all the information they need to prevent dust explosions in your manufacturing plant? Don’t hesitate to call us with any questions.

Read more

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well.

In the industrial manufacturing business, you need to be tough. As you balance hard work, demanding clients, and the highest safety standards, there is a lot at stake every day. And just as much as you depend upon your hardworking team, you also expect your equipment to hold up under pressure as well. From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At

From metalworking to food processing, each of these unique industries brings its own challenges, but all share the same demands for the utmost safety and long-lasting equipment. At

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit.

However, at Imperial Systems, we believe that simply meeting these standards is the bare minimum. After all, every industrial dust collection unit ought to be offering you such certifiable protection. The differentiation, then, begins with the performance of the unit. At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design.

At Imperial Systems, we are proud to say that our CMAXX Dust Collector System is one of the top dust collectors on the market. In addition to satisfying all of the latest NFPA and OSHA standards, it also outperforms the competition. But really, it is no surprise that this is one of the highest performing units available when you consider the many advantages built into its advanced design. Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.

Of course, at Imperial Systems, we’re never content with the status quo. We believe that there is always something we can be doing to innovate and improve our products to better serve manufacturers like you. We value the safety, efficiency, and durability of our products and we know that you do too. So, we’ve made some updates to our already outstanding dust collection system based on one of the most common challenges in the field; weather.

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death.

The Occupational Safety and Health Administration governs employment safety by providing employers with hazard-specific safety and health standards. The Occupational Safety and Health Act requires that employers comply with health standards given by OSHA or a state-approved plan. The General Duty Clause of the Act (Section 5 (a) (1)) requires that employers maintain a work environment free from recognized hazards which could cause serious harm or death. The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

The importance of dust collection as a preventative measure is seen in the FIRE TRIANGLE: the elements needed for a fire. In our case, dust comprises the “fuel”:

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes.

In 1999 there was a deadly fire explosion in a foundry in Massachusetts which killed 3 and injured 9 employees. The Occupational Safety Health Administration (OSHA), supported by state and local officials, conducted an investigation of the happening to determine its causes. This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.

This case study shows the necessity for laws surrounding the proper use and disposal of dust types. Other incidences of dust explosions have still been common since 1999, as most standards of national and international safety bodies have been only recommended. But in 2003 alone, there were three dust explosions that caused 14 deaths. The US Chemical Safety & Hazard Investigation Board launched a study of industrial dust explosions.