by Imperial Systems | Apr 26, 2018 | Uncategorized

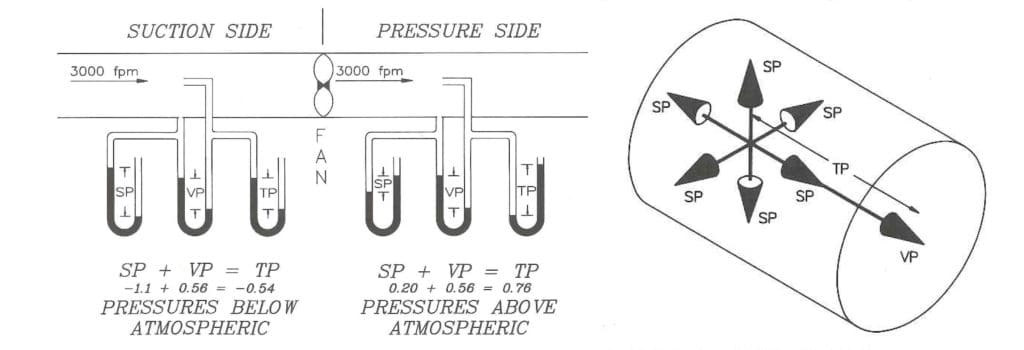

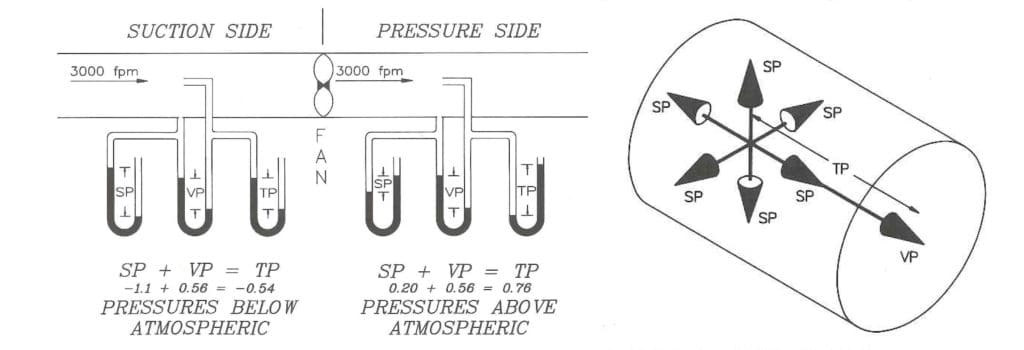

1. What do the different types of pressure measurements mean for airflow in ductwork?

- The basic behavior of airflow: it always travels through the past of least resistance, from higher pressures to lower pressures.

- STATIC PRESSURE: potential pressure exerted in all directions in the ductwork with no airflow, measured with a manometer. It can also be positive (pressure outward on the duct) or negative (pressure pulling inward on the duct)

- VELOCITY PRESSURE: pressure necessary to move air through the ductwork at a certain velocity. Further, this is kinetic energy, and the pressure is in the direction of the airflow.

- TOTAL PRESSURE: a calculation of system static pressure and velocity pressure (the formula is TP=SP+VP). It can be positive or negative. It is the overall energy content of the air stream.

2. When we do our airflow calculations to determine our fan size, what’s the difference between SCFM and ACFM?

- SCFM is Standard Cubic Feet per Minute. This is a measurement based on a standard temperature and air pressure.

- Temperature and air pressure can be significantly different in different areas (e.g. higher altitude, cold or hot climate, high humidity). Then can also vary in different applications (high/low temperature or humidity applications).

- ACFM is Actual Cubic Feet per Minute. This is a measurement of the actual airflow conditions that your system will be operating under.

- Fan manufacturers are able to make these airflow calculations. However, they need to be provided with accurate data about temperature and humidity conditions in your application.

3. What is conveying velocity and why is it important?

- The unit of measurement for conveying velocity is feet per minute (FPM). It is the required velocity to pick up dust in the air stream and move it through the ductwork.

- It is calculated by the CFM at the point of capture and the square foot cross-section of the ductwork.

- This is extremely important because if the conveying velocity drops too low at any point in the dust transport, the dust will drop out of the airflow.

- There are a variety of tables to help engineers calculate the minimum conveying velocity for different kinds of dust.

- Combustible materials might need a higher minimum conveying velocity. This is because an accumulation of this material in the ductwork could cause a deflagration or dust explosion.

Read more

by Imperial Systems | Apr 18, 2018 | Uncategorized

In the agricultural industry, grain dust explosions are a hazard that must be addressed. According to a report from Purdue University, grain dust explosions have occurred at a constant rate over the last ten years, with little change in the number of explosions, injuries, and fatalities. They report an average of 9.3 explosions each year over the past decade.

Since OSHA instituted Standard 29 CFR in 1988, which specifically details safety in grain handling facilities, there has been a focus on the control of what OSHA refers to as “fugitive grain dust”. Preventing grain dust explosions was a focus, including regulations on any type of “hot work” occurring in the vicinity of grain dust. The standard requires testing for combustible dust presence in all storage containers (silos, tanks, bins). It also requires thorough housekeeping procedures to keep dust from accumulating on surfaces.

Grain dust collection systems are strongly recommended, and they must be designed to resist an explosion or deflagration. Correctly designed systems can prevent an explosion from happening or prevent it from causing damage or injury.

Purdue University’s report examines the number of grain dust explosions that occur each year. From 1995 to 1998 the number of explosions was high, reaching 18 grain dust explosions in 1998. Numbers stayed below the ten-year average until 2005, with 13 explosions, and then in 2008, with 19 explosions.

The most common months for grain dust explosions, according to the report, are April, August, and September. The report suggests that during these months, there is increased handling and moving of grain.

What’s causing these explosions? Some facilities think that they don’t need to worry about a little accumulated dust as long as there’s no ignition source. As our own Charlie Miller would say, “good luck with that”… in 67.8% of incidents, the ignition source was unknown. Only 6% could be related to fire, with less than 4% related to sparks or mechanical failures. Most of the time, nobody knows what triggered the explosion, which makes it very difficult to prevent an explosion when fugitive dust is present.

The high percentage of unknown ignition sources should be proof that the only prevention for grain dust explosion is to keep fugitive grain dust under control in all parts of the facility at all times. A dust collection system is essential to this, and can include a baghouse, a cartridge collector, or spot filters located at specific grain handling points.

Some other interesting statistics related to combustible dust explosions in the grain industry:

From 2007 to 2016, there were 91 dust explosions, and 52 of those were caused by corn dust. The second most hazardous type was mixed feed, which probably includes corn quite often, with 19 explosions. 20 explosions out of 91 were caused by other types of dust.

In 2017, there were 7 grain dust explosions, slightly below the ten-year average of 9. The locations included a pet food plant, a grain mill, and 5 grain elevators. Grain elevators move large quantities of grain and create a high risk of explosion.

In the last ten years, there have been 101 injuries and 15 fatalities due to grain dust explosions. 55 of the explosions occurred in grain elevators, with feed mills a distant second at 18.

If grain elevators are so hazardous, how can the risk be decreased? Spot filters are often a very good solution for dust control on these facilities. They can be placed almost anywhere that dust is generated and are self-cleaning, requiring only occasional maintenance. They do not require confined space permits to work in and can control fugitive grain at the source.

https://engineering.purdue.edu/FFP/research/dust-explosions/Grain_Dust_Explosions_2017.pdf

Read more

by Imperial Systems | Apr 11, 2018 | Uncategorized

Imperial Systems Newsletter Issue 5 is the first issue of the year. Make sure to check out all of the articles and interview. If you would like a Printed Hard Copy of this issue of our newsletter please contact your Imperial Sales Rep.

Click Cover To Download and Print Newsletter

CLICK THE ARTICLE TO READ

Imperial Systems has been a family business from the very beginning. Over time, though, our family has grown a lot. We have new employees as well as reps from all across the country who’ve joined our family because they believe in us and our products. Our National Sales Meeting in March showed us just how much our family has grown, and it gave everyone a chance to learn more about our products, while taking a peek behind the curtain to see what we do here and how everything works.

Imperial Systems has been a family business from the very beginning. Over time, though, our family has grown a lot. We have new employees as well as reps from all across the country who’ve joined our family because they believe in us and our products. Our National Sales Meeting in March showed us just how much our family has grown, and it gave everyone a chance to learn more about our products, while taking a peek behind the curtain to see what we do here and how everything works.

In this issue, you’ll meet some of our new extended family of reps from all over the country, but you’ll also meet Andy, who has been with the company almost since it began and is a long-time member of our close-knit family. As the Sales Manager, a major part of my job is helping our company grow, and it’s been really exciting to have all of these new reps and OEM’s sign on to represent Imperial Systems. Many of them left our competitors and came to work with us, not just because of the quality of our product, but because of who we are.

I’d like to invite anyone who is interested to visit us and see our new facility, get a look at all the great work getting done here, and meet some of the amazing people that make up our Imperial Systems’ family.

Read more

by Imperial Systems | Apr 5, 2018 | Uncategorized

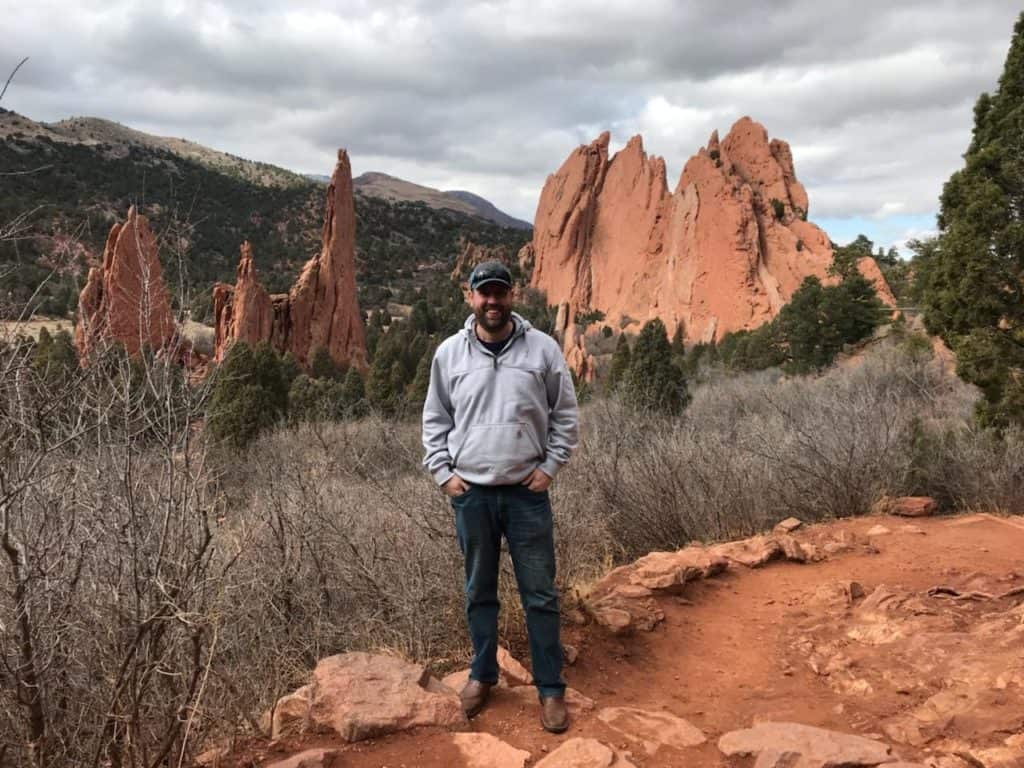

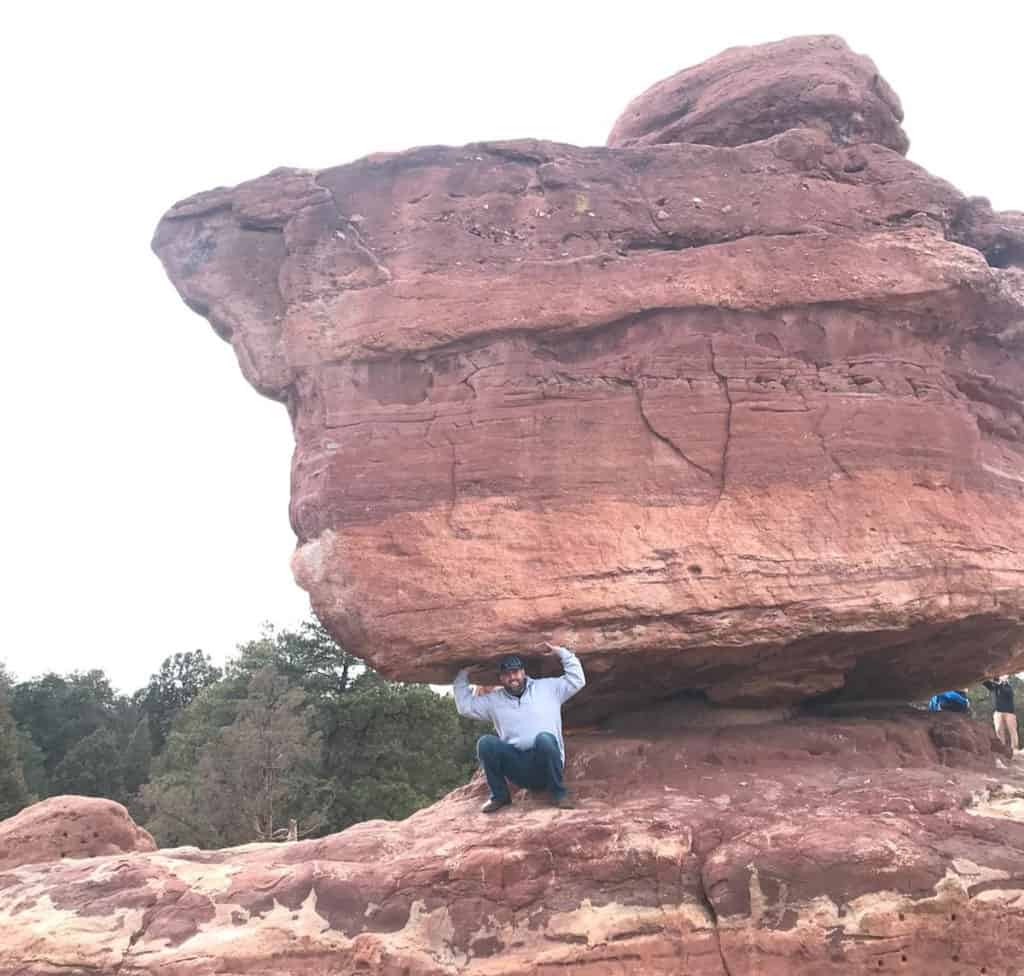

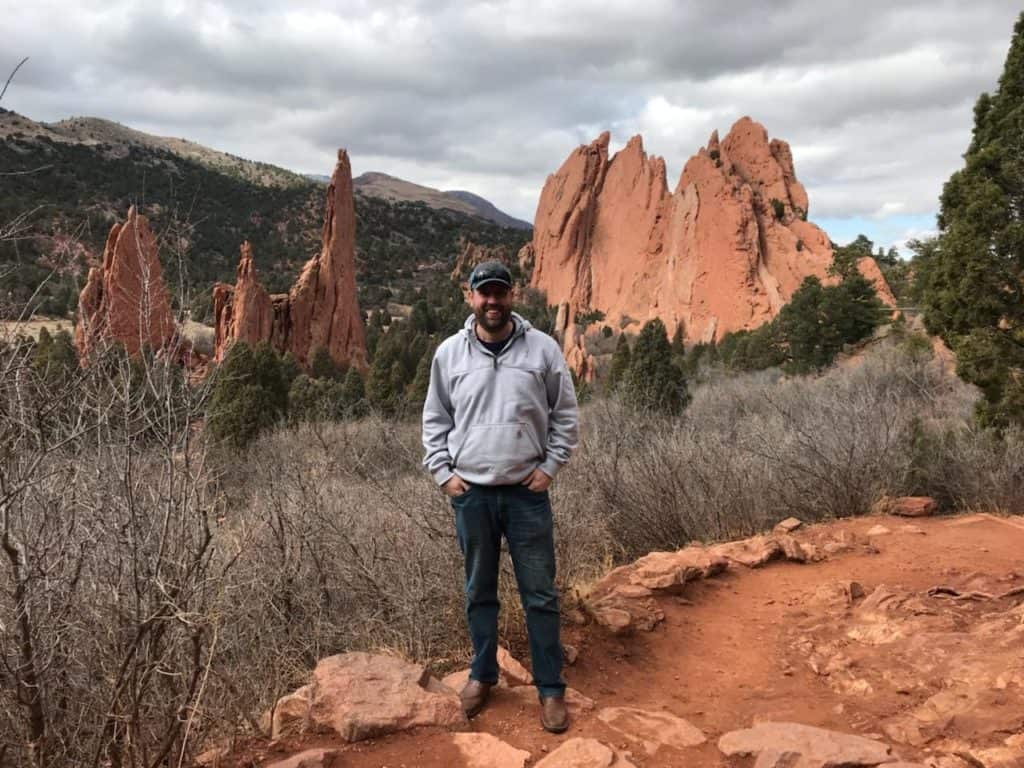

A team from Imperial Systems recently spent three days in Denver at the annual GEAPS show (Grain Elevator & Processing Society). GEAPS is “the knowledge resource for the grain industry”. Imperial Systems had a booth at the show to talk about our BRF baghouses, spot filters, and other options for grain industry dust control. Jeremiah and Mitch had a good time at the show, joined by Tommy Eastlack from Glacier Technology. They even got to appreciate some of the Colorado scenery.

Spot Filters for Grain Dust

As usual, the GEAPS show featured many types of equipment used in the grain industry. This included elevators, conveyors, screeners, and separators. All of these types of equipment are opportunities for combustible grain dust to become a hazard. Spot filters are an excellent choice for grain dust applications because they can be located anywhere along the process line, including above elevators, conveyors, hoppers, and blenders. Spot filters offer CMAXX efficiency exactly where it’s needed. This is important because grain industry applications often have multiple areas across the facility that need dust collection. Spot filters are a solution for controlling piles of dust that so often form around train moving or mixing equipment.

High Volume Dust Collection with Fire and Explosion Prevention Options

When a large collector is needed, a BRF baghouse or a CMAXX may be used, depending on the application. At this GEAPS show, Jeremiah and Mitch provided information to many potential customers and vendors about our products. Fire and explosion prevention and control are also major issues for dust collection in the grain industry, so they also offered information about our products such as abort gates, EIVs, chemical fire suppression, and other options. A representative from Fike was also at the show. They highlighted the importance of a strong fire safety program for all-grain applications.

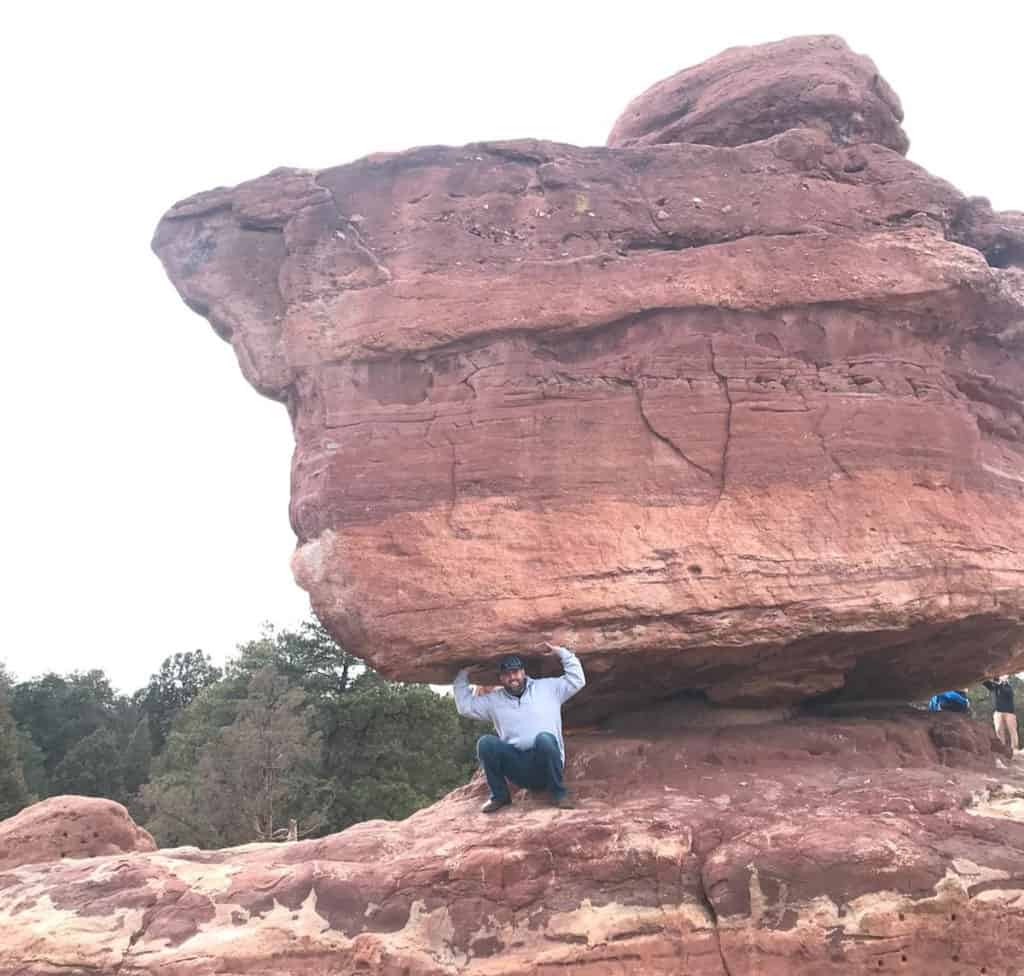

From GEAPS to Rocky Leaps

During their time in Denver, Jeremiah and Mitch also took the opportunity to do some site seeing. They visited Table Mountain in Golden, Colorado, and the aptly named “Garden of the Gods” park in Colorado Springs. One of the special things about trade shows like GEAPS is getting to visit new places. Such was last year’s Fabtech trip to Mexico. Next year the GEAPS show will be in New Orleans. We expect that along with a successful trade show, there will also be some extracurricular adventures.

Read more

by Greg | Feb 8, 2018 | Uncategorized

The switch to powder coating is one of the most exciting changes about our move to our new building. The booth is big enough to accommodate our largest pieces of equipment. This equips us to powder coat everything that we produce.

Why the switch to powder coating? There are so many reasons!

Going Green

This paint application technology is much healthier for people and the environment. Liquid paint contains solvents and volatile organic compounds (VOCs). Therefore, it creates many dangerous emissions that can damage the environment and harm people’s health. The powder coat process creates almost no pollution, so it’s a much greener process than solvent-based liquid paints. The EPA considers powder coating a much better option for environmental health.

Efficiency

It is extremely efficient. The metal attracts the powder which adheres to it. Collect and reuse any powder that doesn’t stick. Because there are no produced VOCs, a powder coating booth does not require expensive, complicated air cleaning systems. The technique is faster and easier than many other processes. Also, temperature and humidity don’t affect the process as much. This means it’s easier for us to ship finished products regardless of the weather.

Durability

This process produces a durable, tough surface that’s resistant to scratches, chips, and rust. It is used on everything from household items to metal equipment that needs to last many years outdoors in all conditions. It will give our equipment a finish that makes it even more weather-resistant than before, and protect it from rust, scratches, and other damage. We are currently the only company in the USA powder coating a round baghouse, so if you want a collector that’s going to stand up to almost anything, ours is the one to go with.

Appearance

If you’re looking for an attractive finish, powder coating is definitely one of the best options. Because it coats evenly and doesn’t streak, run, or smear, it produces a smooth and good-looking finish. Items that are powder coated will look better and have a cleaner-looking surface than items painted with liquid paint. We want the appearance of our products to be as good as the performance, so getting a great finish is the perfect finishing touch.

Freshly powder-coated CMAXX Dust and Fume Collectors are ready to be shipped out.

Read more

by Imperial Systems | Dec 20, 2017 | Uncategorized

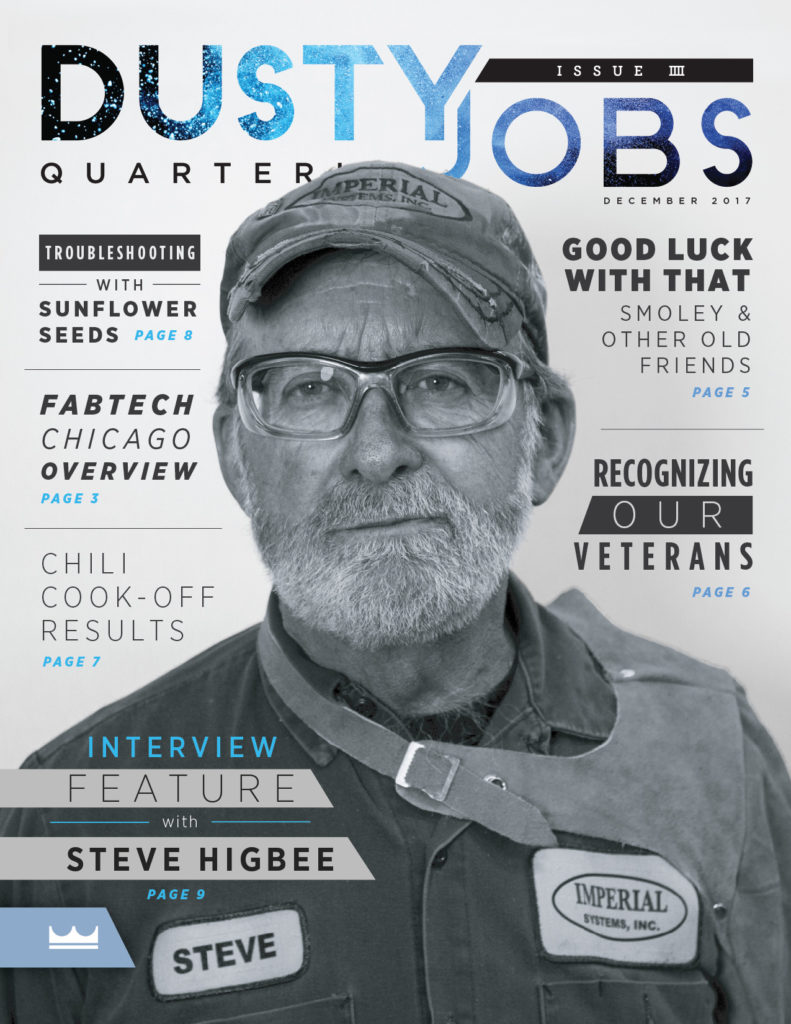

Imperial Systems Newsletter Issue 4 is the last one of the year and the best issue to date. Make sure to check out all of the articles and interview.

Click Cover To Download and Print Newsletter

CLICK THE ARTICLE TO READ

BECCA THE EDITOR

BECCA THE EDITOR

It’s not in my official job title. It’s not what I was hired for. Underneath my ordinary day job in aftermarket sales, I have another responsibility. I am The Editor.

If you read our blog, our brochures, our newsletter, or our published magazine articles, you’ve read my work. It doesn’t have my name on it and I don’t care. Being The Editor has given me a chance to learn more about our products, our customers, and this industry than I ever would have learned in sales.

Just about every person who works here has a wealth of knowledge and a unique story to tell. Putting those things into written form is what I do. I tap into the incredible resources I have all around me. I ask a lot of questions. Sometimes I get blank stares, and occasionally I get a “why exactly are you asking me this” look with raised eyebrows. But in the end, someone always has an answer.

The best thing about my secret job as The Editor is the pride I feel when our company’s written material sounds professional, when our blog posts are helpful to someone, or when an industry magazine publishes an article. All of this represents the ideas and knowledge of many people; I put it in words and make it sound good.

In a way, that’s how everything works here at Imperial Systems. Everything, from the products we make to the newsletter you’re reading, is the work of a team.

Read more

BECCA THE EDITOR

BECCA THE EDITOR