by Imperial Systems | Dec 20, 2017 | Uncategorized

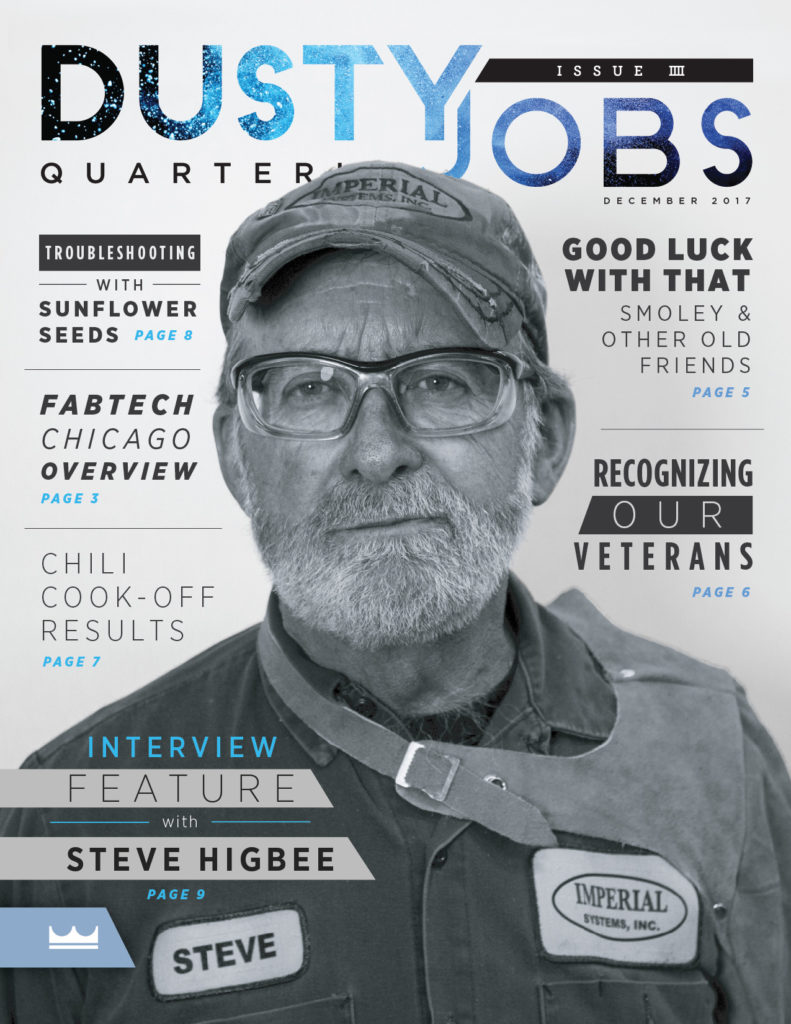

Imperial Systems Newsletter Issue 4 is the last one of the year and the best issue to date. Make sure to check out all of the articles and interview.

Click Cover To Download and Print Newsletter

CLICK THE ARTICLE TO READ

BECCA THE EDITOR

BECCA THE EDITOR

It’s not in my official job title. It’s not what I was hired for. Underneath my ordinary day job in aftermarket sales, I have another responsibility. I am The Editor.

If you read our blog, our brochures, our newsletter, or our published magazine articles, you’ve read my work. It doesn’t have my name on it and I don’t care. Being The Editor has given me a chance to learn more about our products, our customers, and this industry than I ever would have learned in sales.

Just about every person who works here has a wealth of knowledge and a unique story to tell. Putting those things into written form is what I do. I tap into the incredible resources I have all around me. I ask a lot of questions. Sometimes I get blank stares, and occasionally I get a “why exactly are you asking me this” look with raised eyebrows. But in the end, someone always has an answer.

The best thing about my secret job as The Editor is the pride I feel when our company’s written material sounds professional, when our blog posts are helpful to someone, or when an industry magazine publishes an article. All of this represents the ideas and knowledge of many people; I put it in words and make it sound good.

In a way, that’s how everything works here at Imperial Systems. Everything, from the products we make to the newsletter you’re reading, is the work of a team.

Read more

by Imperial Systems | Dec 14, 2017 | Uncategorized

Managing weld smoke risks means dealing with very small particle size, toxic metals, and the combustibility of metal dust. Weld smoke and fumes are different from other types of dust, and a system needs to be designed to deal with it. A CMAXXTM dust and fume collection system will meet any metalworking or weld smoke control needs.

WELD SMOKE RISK: HEALTH

One of the risks of weld smoke is hexavalent chromium. This compound can cause skin sores and lung damage, and cancer of the lungs, kidneys, and other organs. Many metals are alloyed with chromium to make them corrosion-resistant.

Most of the particles in welding fumes come from the welding wire, but some of them come from the material being welded. Some of them can cause allergic reactions and an immune response called “metal fume fever”. Lead and manganese can damage the brain. Others, like hexavalent chromium and nickel, are known carcinogens and increase your risk of cancer. Learn more about welding fumes and cancer.

The particles that are put into the air as fumes from welding are extremely small. Most are smaller than one micron. This means they are small enough to get inside human cells and cause damage. This also means that welding fumes are lighter than air, especially when heated. A system for collecting these fumes must be designed to handle very small particles.

MANAGING WELD SMOKE RISK: FIRE AND EXPLOSION

Welding produces metal dust and gases that may be combustible. Some metals, such as aluminum, are very explosive as a dust. Almost all metal dusts have the potential to explode. Handling welding fumes means using appropriate fire suppression and prevention measures.

Suppressing sparks to keep them from getting into the collector can help prevent explosions from welding smoke dust. Spark Arrestors are important in keeping most sparks from getting to the collector. An explosion isolation valve can prevent a fire from traveling back through the ductwork. Chemical control systems can suppress or extinguish a flame, but only certain chemicals are approved for fires involving metal dust.

Filters can also be important for fire suppression in a welding smoke system. Filters with a fire-retardant coating they will resist burning and help control a deflagration. Some collectors are designed with filters that help isolate an explosion and keep it from causing damage inside the workplace. DeltaMAXXTM filters with fire-retardant coating will prevent a fire from occurring inside a dust collector.

HANDLING WELD SMOKE

Figuring out what type of fume extraction system to use in your facility is an important decision for managing the risks from weld smoke. Our systems engineers will consult with you to help you determine the best way to manage your weld smoke risk.

If there are not very many welders and they don’t always work at the same place, portable collectors can be a solution. They can be useful for handling point of source capture. An ambient system is designed to move a volume of air out of a large area and through filters.

For managing weld smoke, portable collectors can be easily moved around, but they are not as powerful as a larger collector. Central collectors are the most efficient for large areas, but if they are inside they take up floor space. Locating the collector outside is usually recommended for safe explosion venting.

One of the biggest advantages with an ambient system that recirculates the air back into the facility is energy cost savings. When heated or air-conditioned air is vented outside, the energy used is lost. Many businesses find that a fume collection system can pay for itself within two years with the money saved in energy costs.

CMAXXTM dust and fume collectors have proven themselves in the welding and metalworking fields. Our newest product, the SHADOWTM portable collector, gives you even more options for managing weld smoke . DeltaMAXXTM nanofiber filters are the best available material for capturing metal fumes. At Imperial Systems Inc., we are committed to helping you control your weld smoke risks.

(as seen in The Fabricator Magazine)

Read more

by Imperial Systems | Dec 6, 2017 | Uncategorized

An explosion inside a dust collector can be a disaster if there is no explosion venting (also called deflagration venting). Obviously, the first priority is to make sure that no sparks or heat sources have a chance to get inside the collector. However, even the best safety precautions aren’t 100% foolproof. If a dust explosion occurs in your dust collector, how will explosion relief be handled safely?

Explosion Venting Considerations

The method you choose for venting an explosion will be based on several factors:

- Location of the dust collector inside or outside the building

- Distance of the dust collector from roof or walls

- Proximity of the dust collector or vent to other structures

- Cost efficiency

Outside Installation

The first and safest method of venting a dust explosion is to have the collector located outside the building. In this case, any explosion that occurs will be vented safely with appropriate venting.

The issue with this method has to do with safety distance. Specifically, explosion relief vents must be located far enough away from anything that the energy vented might damage. Space around the dust collector, especially near the explosion vents, must be clear of anything that could be damaged or ignited.

Many areas have state and/or local regulations for fire safety and explosion venting. Locating the collector outside when possible is usually the easiest way to meet these standards.

Inside Installation

What if your dust collector must be inside the building? There are various reasons for this, depending on your system setup. For example, it’s possible that the collector must be centrally located. Also, it might need to be close to or attached to a certain piece of equipment.

If you can’t put the collector outside, you will have to divert the energy of an explosion. The most common way to do that is to vent the explosion to the outside, either through a wall or through the ceiling. The area outside needs to be safe just like it would need to be around a dust collector, free of anything that could be damaged by the explosion. A deflector shield can redirect the explosive force in a safe direction.

If you can’t put the collector outside, you will have to divert the energy of an explosion. The most common way to do that is to vent the explosion to the outside, either through a wall or through the ceiling. The area outside needs to be safe just like it would need to be around a dust collector, free of anything that could be damaged by the explosion. A deflector shield can redirect the explosive force in a safe direction.

What happens if your dust collector is inside the building and you’re not close enough to a wall or ceiling to vent that way? This could be a very dangerous situation, with a collector inside your building and no way to get an explosion safely outside.

In this case, a flameless dust collector explosion vent may be the only safe option. While these safety devices are not cheap, they are essential for venting an explosion safely inside a facility or anywhere else that flame from the venting could be dangerous.

A flameless explosion vent design is made of a tightly wound metal mesh. It’s designed to extinguish the flame and dissipate the heat from an explosion. It takes up less space and is less expensive than other explosion protection systems. It is ATEX certified and NFPA 68 and 61 compliant.

Venting Solution Priorities

We recommend looking at explosion venting solutions in the following order, based on cost and safety:

- Locating the collector outside

- Venting the collector through a wall or ceiling

- Installing flameless venting

We also recommend always consulting your local building codes and regulations. Some areas have very specific regulations for fire safety and environmental safety.

Read more

by Imperial Systems | Nov 29, 2017 | Uncategorized

The Penn-Northwest Development Corporation has chosen Imperial Systems for their local industry and spotlight in Mercer County. PNDC is a non-profit organization that recognizes companies bringing or expanding business and local jobs in Mercer County.

Imperial Systems was chosen for this recognition because of our expansion, which is expected to be completed in January 2018. By renovating and making drastic improvements, we have brought new life to an aging facility that might otherwise have ended up standing empty.

PNDC works to build economic development in Mercer County, an area which has experienced increased unemployment and skilled workers moving elsewhere. Their focus is on bringing new companies to Mercer County and supporting the growth of local companies.

Since its beginning, Imperial Systems has provided skilled trades jobs in Mercer County. As we have expanded, new employees have been brought into the shop to keep up with increasing demand, and new employees have also come in the form of equipment and aftermarket sales staff. Most of these careers support families who live right here in Mercer County.

Imperial Systems is proud to be recognized in PNDC’s Local Industry Spotlight, because we pride ourselves on keeping our business here, where it belongs. By keeping our expansion in Mercer County, we continue to support the jobs and families in this area.

PNDC’s annual report notes that Imperial Systems’ expansion is expected to add 15 more jobs and to retain 50 current local jobs.

Mercer County is home for many of our employees and their families, and we’re very proud to contribute to the growth and development of this area. Imperial Systems products will always be made in the USA and will always provide full-time work for local employees.

As we become one of the new biggest names in the dust collection industry, the number of employees needed can only be expected to grow over time. We plan to continue supporting industry in Mercer County, and appreciate the recognition from PNDC for our efforts.

Read more

by Imperial Systems | Sep 28, 2017 | Uncategorized

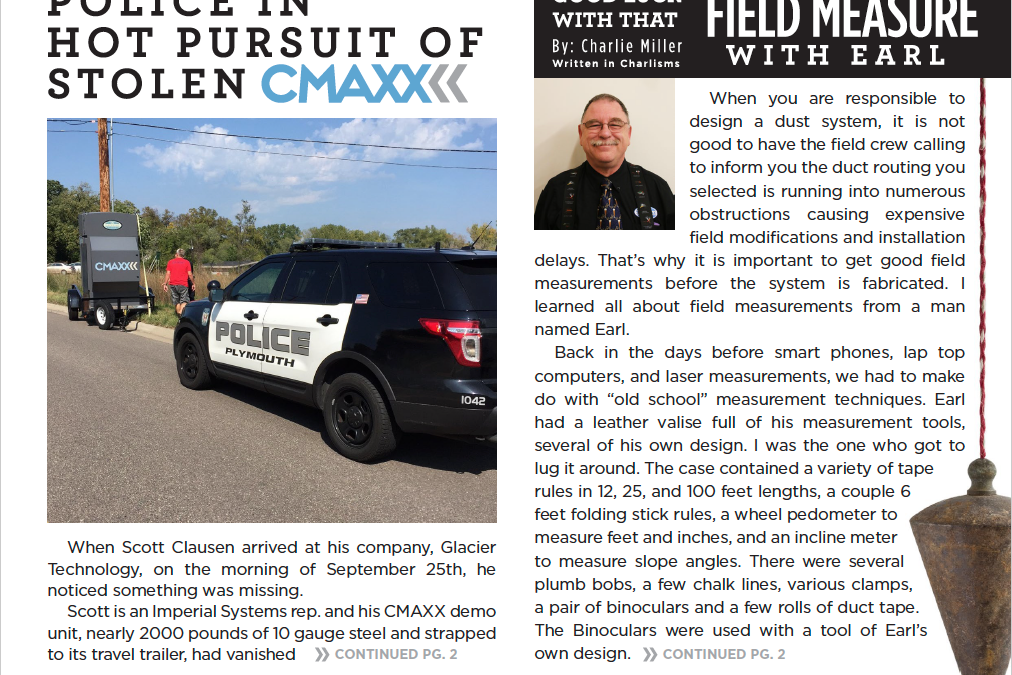

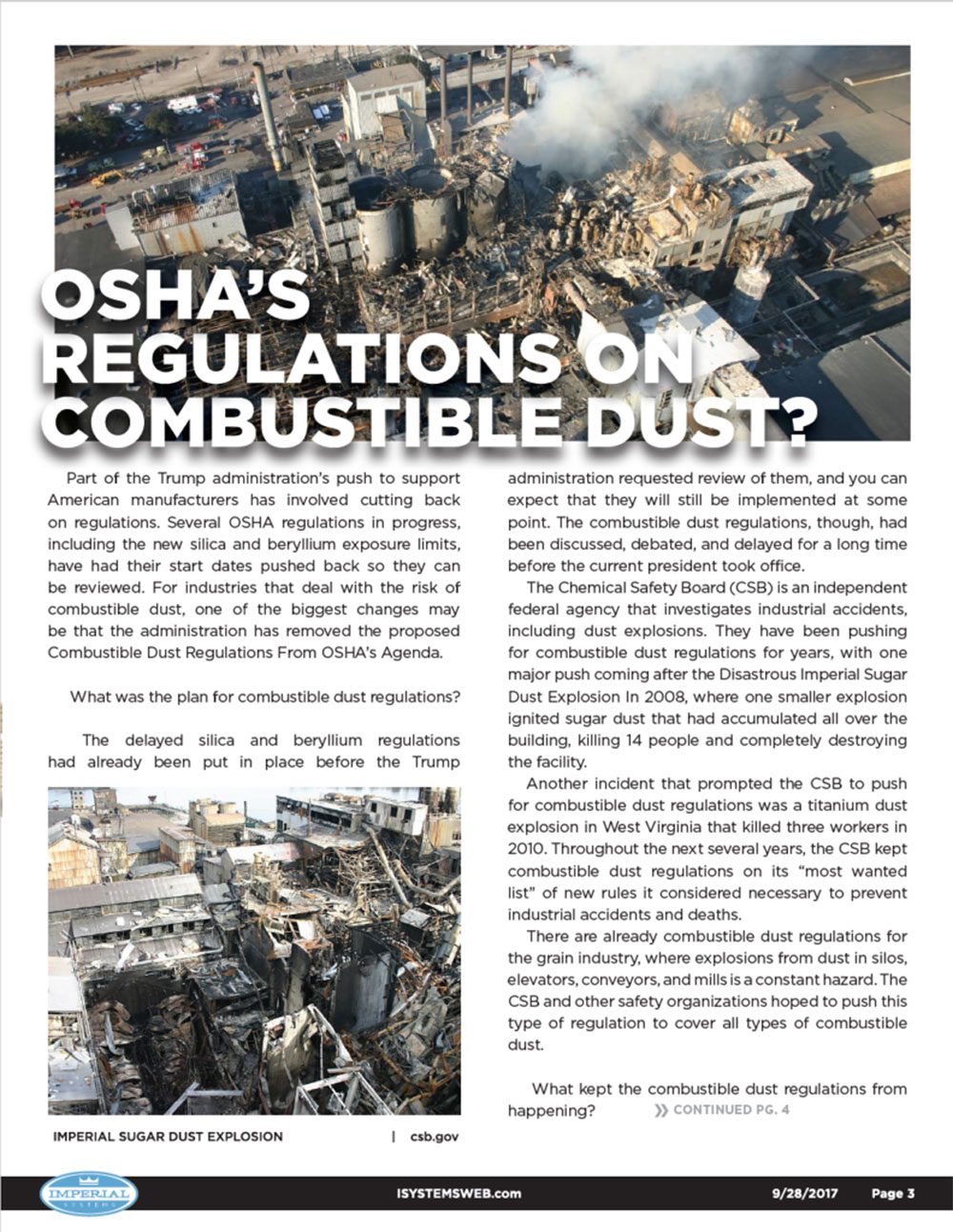

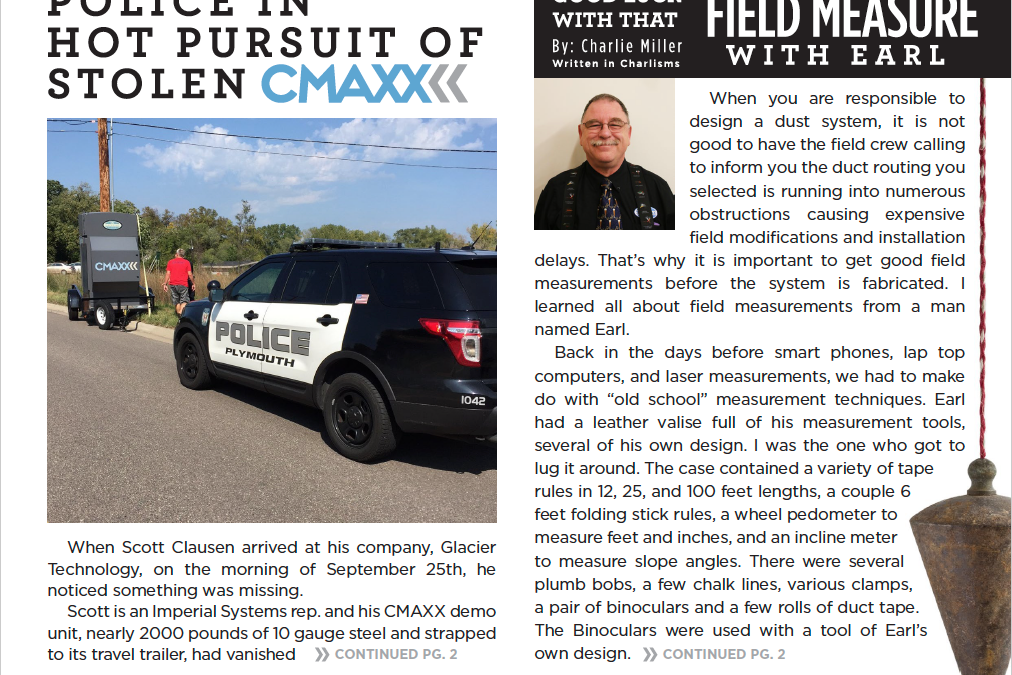

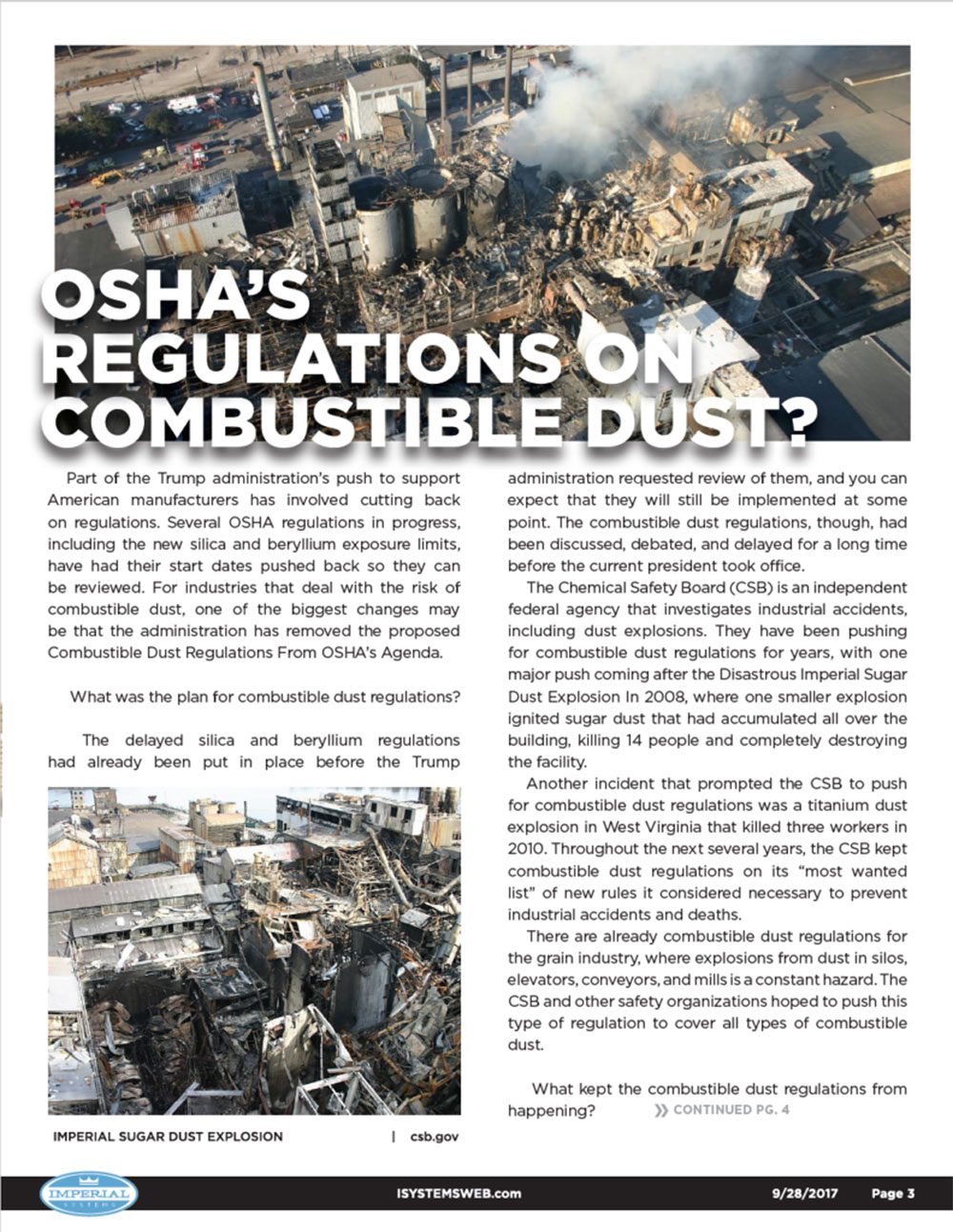

The Third Issue of Dusty Jobs Newsletter. Articles include an attempt at stealing a CMAXX, Charlie with learning to Field Measure and also OSHA on their regulations on combustible dust.

Download DUSTY JOBS | Issue 3 PDF CLICK HERE

Read more

by Imperial Systems | Sep 8, 2017 | Uncategorized

Over the past few months, there’s been a lot of excitement at Imperial Systems Inc, because we’re in the process of preparing our new manufacturing facility! This move will benefit the company in many ways and offer lots of new opportunities for us to improve our product and services. We’re adding new offices, tons of manufacturing and storage space, and some exciting new processes.

Over the years, Imperial Systems Inc has outgrown its familiar Jackson Center home. While people agree they’ve got fond memories of the building and their time there, they also seem to agree that it’s time to move on to a bigger manufacturing facility.

“We’re going to have so much room to work,” one of our metalworkers says, talking about the new building. “Sometimes when we’re busy, it’s hard to fit all the projects in at once. Now everything will have lots of space for us to work on it.”

From an inventory and stocking standpoint, the guys in charge of these tasks are extremely excited about having so much new storage space for completed collectors, parts, filters, and all other inventory items that we need to stock and ship.

“We’re going to be able to keep a lot more filters in stock, and a lot more parts and equipment,” the sales manager explains. “We’ll have more items in stock for our customers, and we’ll be able to build and store completed collectors.”

President and CEO Jeremiah Wann is looking excitedly at the vast new space and all the room for expansion that it offers.

“This is the space we need for growth,” he says. “This is our future as we expand the company. We’re going to need every bit of this manufacturing space sometime soon. Demand for the CMAXX just keeps increasing, and we’re going to need to be able to keep up.”

For the guys who handle the difficult task of getting some of our larger items out of the shop or coordinating the loading and unloading of trucks, having several new shipping docks will make their jobs easier. And for the paint shop crew, the transition to a powder coating line is a huge change for the better.

“Powder coating is a much better process, better for the environment, and better for our workers’ health,” Jeremiah says. “Getting away from our old process and getting into powder coating is going to be a big improvement for everyone.”

It’s not just the fabrication and storage parts of the new facility that are an upgrade from the old one, though. New offices for engineering, accounting, and other essential functions will help them do their jobs better. New technology throughout the entire building will make everybody’s job smoother and move us toward our Two Second Lean improvement goals.

The new manufacturing facility will feature a training facility so all employees can receive regular training. It will also feature a fully equipped product testing lab for current and new products. A new dust testing lab, a feature that few dust collection manufacturers can offer, will let us pinpoint the specific features of each customer’s dust and recommend exactly the right system, fire protection and prevention, safety procedures, and filter type.

Another feature of the new manufacturing facility we’re all excited about? The huge new showroom! Visitors will be able to check out a working model of our CMAXX and other equipment in this spectacular new space, and we’ll be able to show off how great our products look along with how well they work.

“We’ve never had the space to really show off our products like this before,” Jeremiah says. “People are going to be really impressed with this new showroom space and we’re really excited to show off our products the way they should be.”

Read more

BECCA THE EDITOR

BECCA THE EDITOR