Stalemate Between Federal Agencies May Be Moving Toward Resolution

A combustible dust standard may mean more stringent control measures and a lot more new tests and reports. Additionally, major growth in the air quality control industry may result, especially for dust collection systems.

Since 2008, the National Fire Protection Association (NFPA) and the U.S. Chemical Safety Board (CSB) have been making recommendations to OSHA. They assert a need for a formal standard for combustible dust. This is to prevent worker injuries and deaths due to dust explosions. OSHA established a “National Emphasis Program” to provide more information and awareness about dust control and combustible dust hazards. They have yet to establish any formal, enforceable standards. The CSB continues to make recommendations for such a standard in their investigations of explosions and resulting fatalities (http://www.csb.gov/us-chemical-safety-board-determines-osha-response-to-seven-open-csb-recommendations-on-dust-fuel-gas-and-process-safety-management-to-be-unacceptable/) and has deemed OSHA’s response to their recommendations to be “unacceptable”. They consider an OSHA combustible dust standard to be the most important safety measure they have recommended.

Combustible Dust Standard 652 in Revision

According to John S. Forester, the managing editor at Powder & Bulk Solids, (http://www.powderbulksolids.com/) the NFPA is currently working on revisions of its standard 652, its proposed standard for combustible dust, intended to be comprehensive and to cover all industries to which it would apply.

This combustible dust standard (https://www.nfpa.org/Assets/files/AboutTheCodes/652/652_PreliminaryDraft.pdf) would require all facilities, new or existing, complete Dust Hazard Analysis testing and report their results. Also, some of the standards will apply retroactively to existing businesses. In response, OSHA seems to be responding to the call for increased regulation for the first time since 2010. However, there’s no sign of new enforceable regulations in the immediate future. Facilities that need to meet NFPA standards may find themselves dealing with the mandated Dust Hazard Analysis. This will mean increased investment in dust control systems.

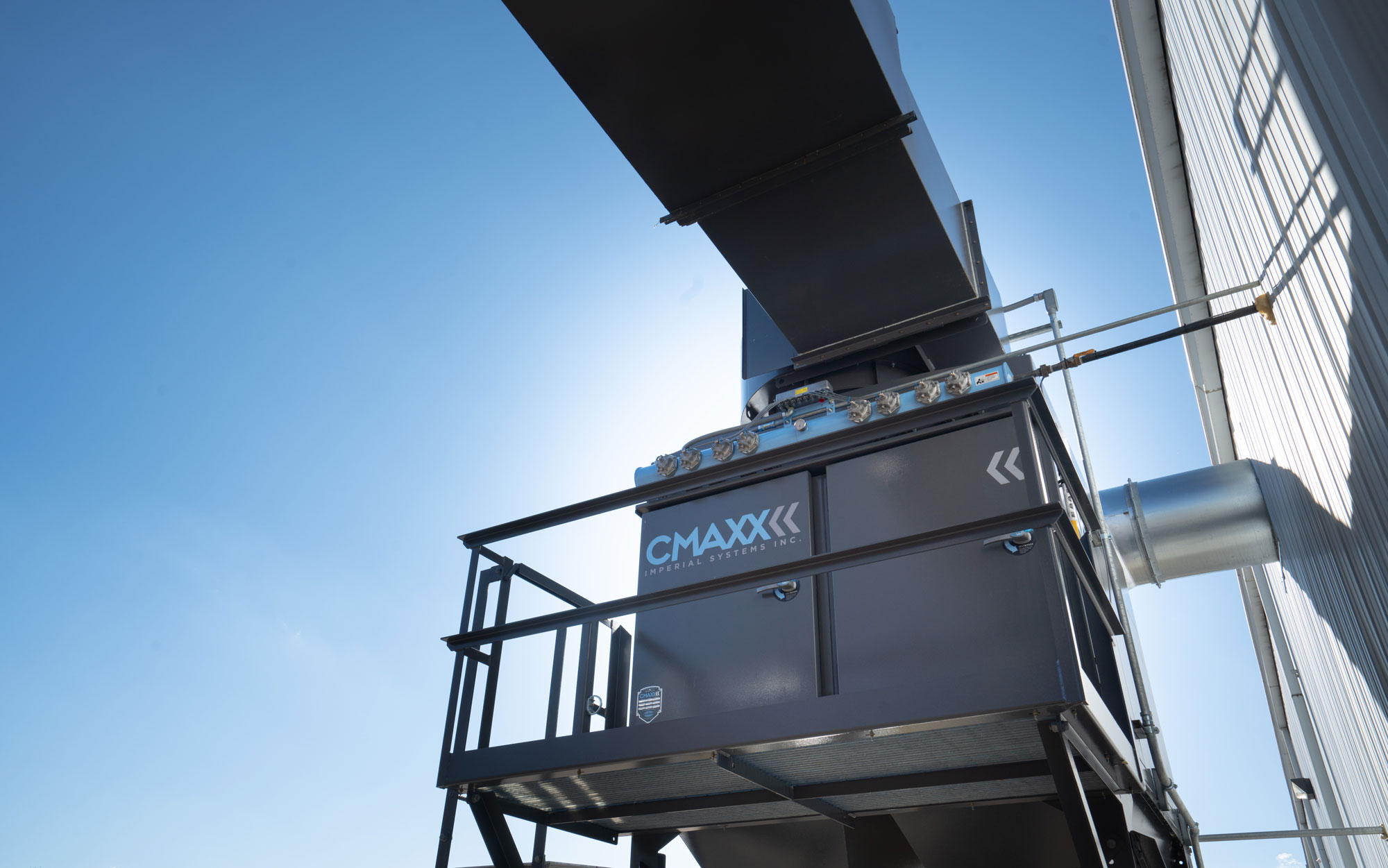

The article notes market changes due to increasing regulation and the adoption of NFPA standards globally. Specifically, the market for industrial dust collectors will likely increase significantly in the following years. Demands for explosion isolation equipment will predictably be even higher. This due to reports of industrial accidents and stricter regulations circulating in the industry. An example is Imperial Systems’ independently tested, NFPA-standard CMAXX with In-Line Deflagration Arrester filters.

Testing and Analysis

The NFPA 652 will require industry-wide testing of all dusts that might be combustible. This includes a full analysis of all facilities for areas and equipment that might create a risk of dust accumulation. Examples are conveyor belts, elevators, ductwork, and ovens. Dust testing may include standards on the amount of dust allowed to accumulate on any surface and testing to determine whether the dust is in contact with hot surfaces or static buildup that could trigger ignition of that particular dust. These assessments will be an ongoing headache for many companies. Installing a system of correctly functioning dust collection equipment (and maintaining it or having our ServiceMAXX professionals maintain it) can minimize that headache by keeping the dust problem minimal and keeping the facility up to standards.

While the expected boom in sales of industrial dust extraction and explosion suppression equipment is good news for our industry, it’s especially good news for Imperial Systems, since our CMAXX with IDA filters already meets NFPA standards and should continue to meet the new standards in the future. If you already have one of our systems and it is well-maintained and operating properly, you should be prepared to weather any new regulations for explosion-containing dust collection systems. Perhaps you’re using another type of dust collector. In that case, measures such as high-speed abort gates and our fire-retardant DeltaMAXX nanofiber filters can help you be in compliance with current and future standards.

Have questions about what you need to be prepared? Then give one of our knowledgeable team members a call today at 800-918-3013!