It is important to understand duct velocity when considering a design for a dust collection system. This term refers to the speed at which air moves through ductwork. This velocity is crucial in determining the effectiveness of a dust collection system and ensuring that it operates efficiently. Let’s look at why duct velocity matters in dust collection and how it can impact the performance of a system.

Why Duct Velocity Matters

Duct velocity plays a critical role in dust collection. That’s because it affects the amount of dust that can convey through the system. The size of the ductwork, the type of collected dust, and the airflow rate determine the ideal velocity. If the velocity is too high, it can cause premature wearing of the ductwork, especially in applications with abrasive dusts. A velocity that is too high can also cause increased system static pressure. Further, If the velocity is too low, it can lead to dust settling in the ductwork. This can reduce the efficiency of the system.

In addition to affecting the collection efficiency of the system, duct velocity can also impact the energy consumption of the system. If the velocity is too high, it can increase the energy required to move the air through the ductwork. On the other hand, if the velocity is too low, it can result in insufficient airflow. This will cause the system to work harder to collect the dust.

Optimizing Velocity to Increase Efficiency

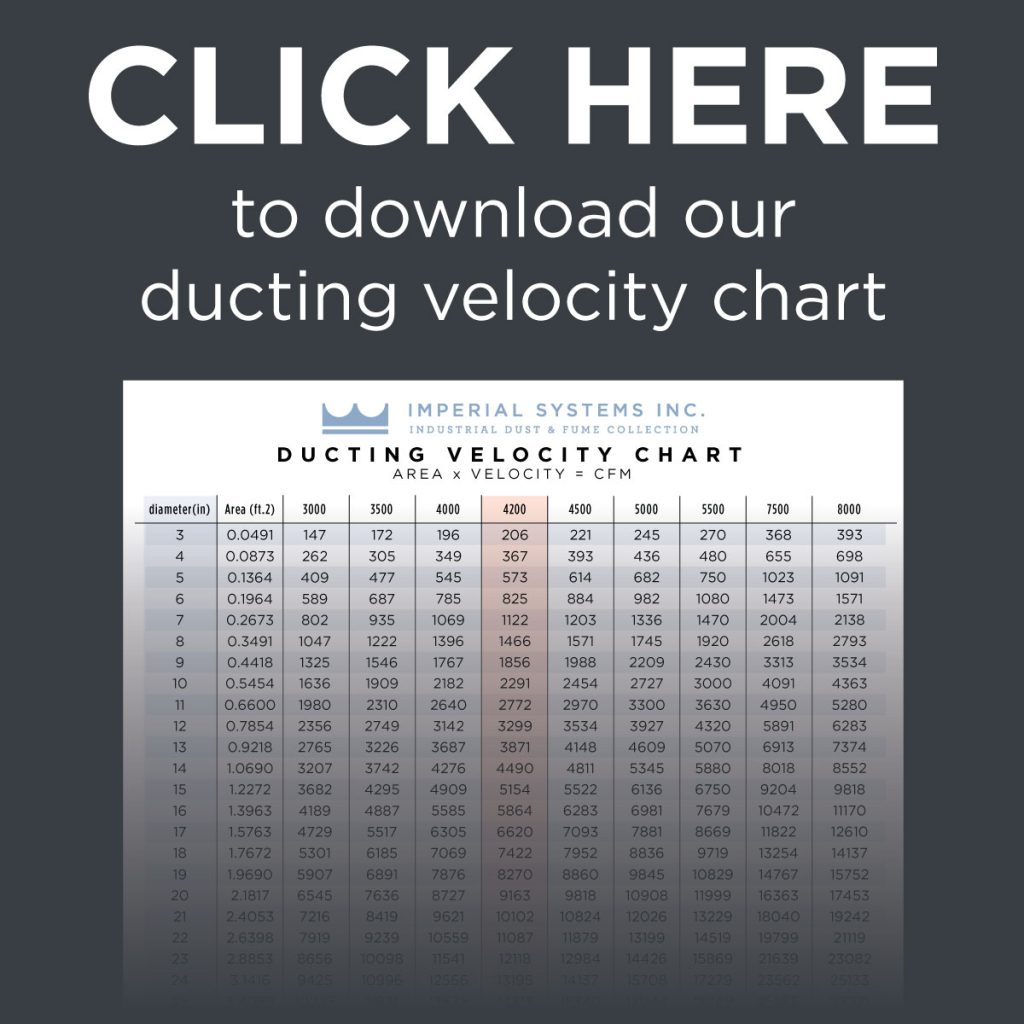

To optimize duct velocity, it is important to consider several factors. This includes the size of the ductwork, the type of collected dust, and the airflow rate. One way to ensure optimization is to use a duct sizing calculator, which can determine the appropriate velocity for a given system.

Using ductwork with smooth, straight runs and long-radius elbows can optimize duct velocity. This can reduce turbulence in the air stream and minimize the potential for dust settling in the ductwork. Additionally, using appropriate branch fittings, bends, and transitions in the ductwork can help to maintain a consistent airflow rate and minimize system static pressure. This reduces overall energy costs.

The best and easiest way to ensure duct velocity is optimized is to reach out to a team of trusted professionals to design your system. Our team of experts have the knowledge and experience necessary to design a new system, or evaluate your existing system and identify areas for improvement. They can help you select the right size ducts and fittings, and ensure that your system is properly balanced to achieve the desired velocity. By working with professionals in the field, you can be confident that your dust collection system will operate efficiently and effectively, helping to protect your workers’ health and safety while also reducing maintenance costs and downtime.