BRF Baghouse Dust Collector

The Imperial Systems BRF baghouse dust collector excels in challenging applications. It features options not available in any other bag type dust collector on the market, including custom design and available ServiceMAXX support. With longer filter life and high energy efficiency, the BRF also offers the best value and quality in the industry.

The BRF baghouse dust collector is available in reverse air and medium pressure options. Both types feature online cleaning, keeping the whole baghouse in continuous operation. In addition, the high-efficiency cleaning mechanisms provide longer life for filter bags. Further, designed for easy filter bag changeouts, the BRF requires without tools.

APPLICATIONS

Th BRF baghouse performs above industry standards in many applications, including:

Grain Handling and Processing

Woodworking

Recycling

Seed and Feed Handling and Processing

Aggregate Materials

Silica Dust

BRF BAGHOUSE VS COMPETITION

Shopping for and comparing industrial baghouse dust collectors can be confusing. Why choose Imperial Systems over other baghouse manufacturers? Here’s what you need to know.

The BRF baghouse outperforms its competitors with superior design and manufacturing. It’s made from heavy gauge 10 & 3/16 steel with strong welded construction so it can withstand many years of constant use. Also, the BRF is the only round industrial baghouse on the market with a powder-coat finish, which improves wear resistance and durability.

Furthermore, the BRF uses a direct drive shaft and it requires minimal maintenance with no plant compressed air hookup needed. Due to our custom system design, we can include many features to make a BRF that handles your application’s unique challenges.

Finally, our ServiceMAXX team is ready to pay a visit for installation, troubleshooting, or routine maintenance. By comparison, no other company works as hard to keep your BRF up and running efficiently.

BRF BAGHOUSE DUST COLLECTOR FEATURES:

-

- Sloped roof

- Powder coated finish

- Self-cleaning

- Heavy duty construction

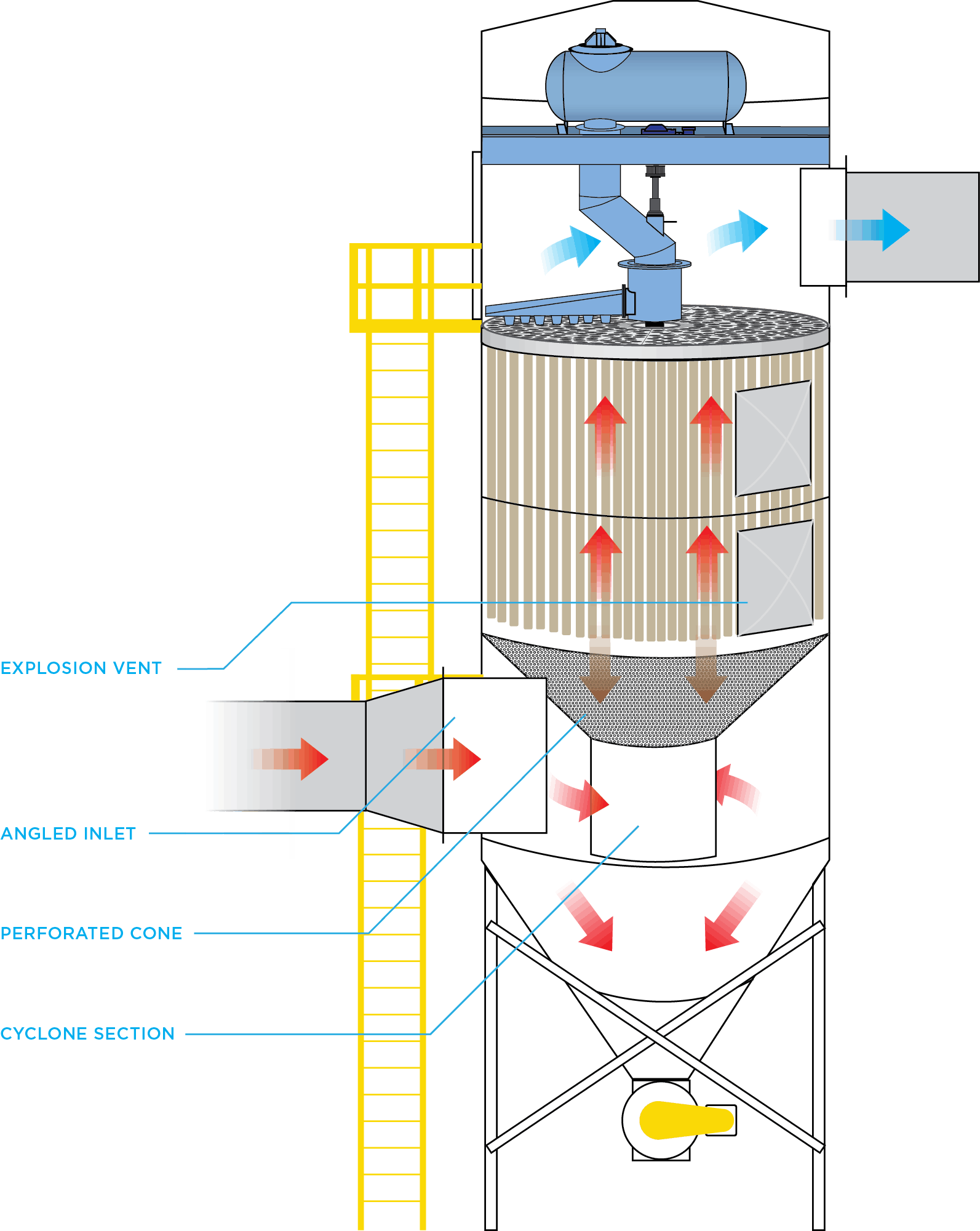

- NFPA approved explosion venting

- No plant compressed air hookup

- Direct drive shaft

- High entry option

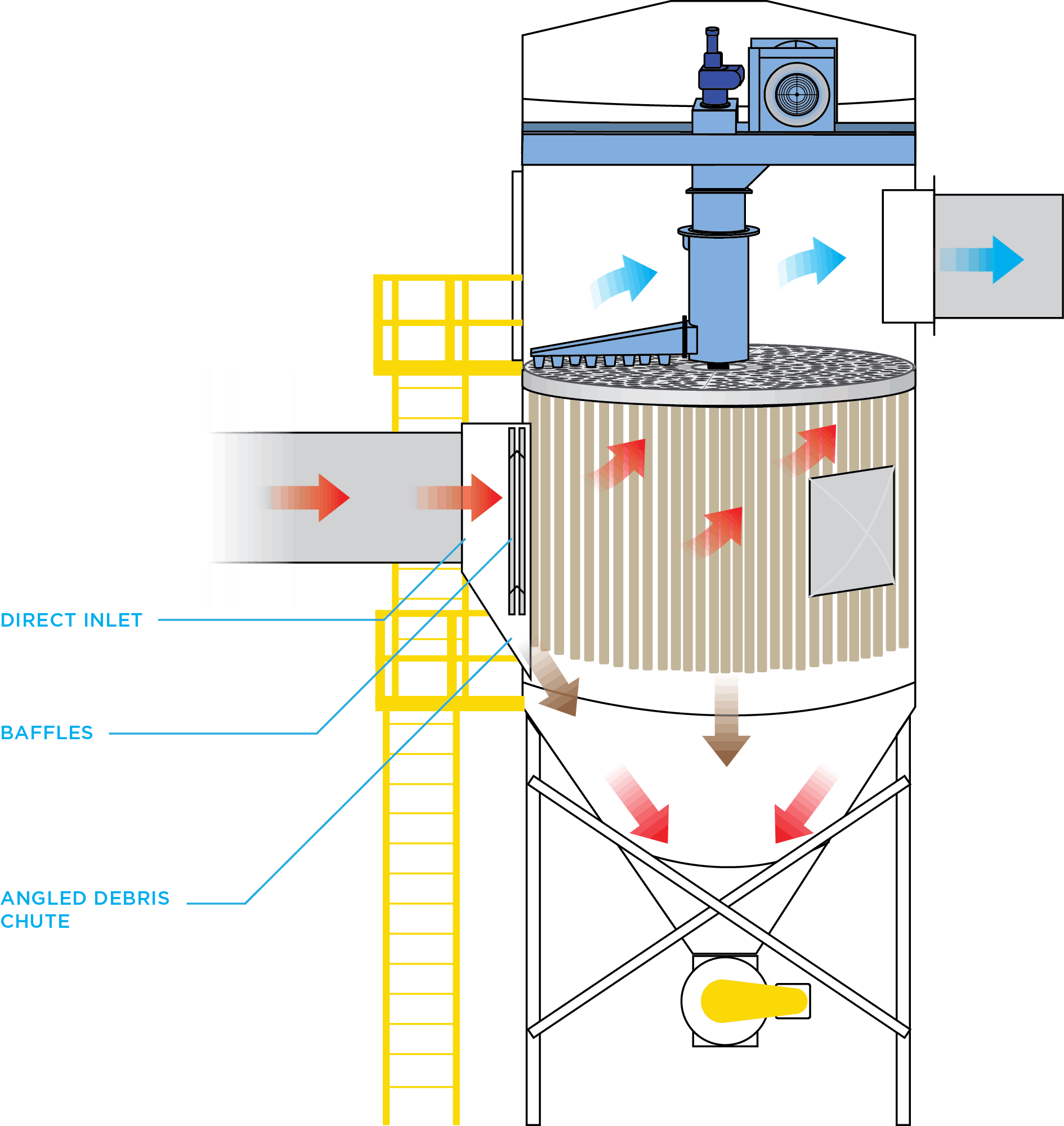

- Tangential inlet option

- Inlet baffles

- Perforated cone

- Tool-free filter bag changes

- Top access and hopper access doors

- Exact Pulse technology (available on the BRF MP)

- Auto-calibrate (available on the BRF MP)

CONFIGURED FOR YOUR NEEDS

Our variety of options make the BRF the perfect baghouse for handling challenging applications, including fibrous, abrasive, and sticky materials. Agricultural industries, feed and seed processing, and woodworking are traditional baghouse applications, as well as foundries, recycling operations, aggregate materials, and silica dust.

We design each BRF baghouse system for your needs. Because one size doesn’t fit all, we offer BRF sizes from 7 to 14 feet in diameter, with bags from 8 to 12 feet long. We also make filter bags available for high temperature or other special requirements. In addition, two inlet options offer improved performance for different applications:

REVERSE AIR OR MEDIUM PRESSURE BAGHOUSE?

BRF Reverse Air Baghouse Dust Collector

The Reverse Air BRF is an all-purpose baghouse that works well for most applications. The airflow to clean the bag filters is provided by a fan. This requires. no compressed air. All filter bags stay in use during cleaning.

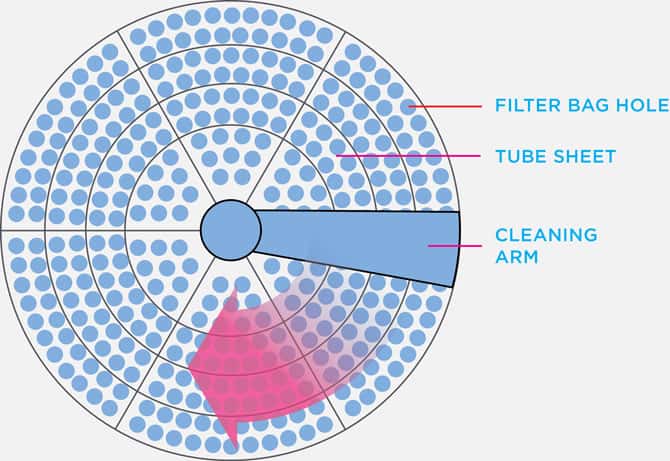

The Reverse Pressure BRF is an all-purpose baghouse suitable for most materials. In this baghouse, dust or particles collect on the outside of the bags as air flows through them. Meanwhile, a fan that rotates over the bags cleans them. Specifically, air blows into the bags and releases dust from the surface. (Learn more about how a filter baghouse works.)

One major advantage to the BRF design is that unlike some other baghouses, the entire BRF can stay online while cleaning the filters. In contrast, some baghouses are divided into sections and each section has to be taken off-line for the bags to be cleaned. All the filters in the Reverse Pressure BRF are constantly in operation. Because the Reverse Pressure BRF uses a fan for cleaning, it does not require any compressed air.

Different types of filter bags are available for special applications such as high temperatures or abrasive dust. Wear and tear on the bags is reduced over time due to the low pressure used by the fan.

BRF Medium Pressure Baghouse Dust Collector

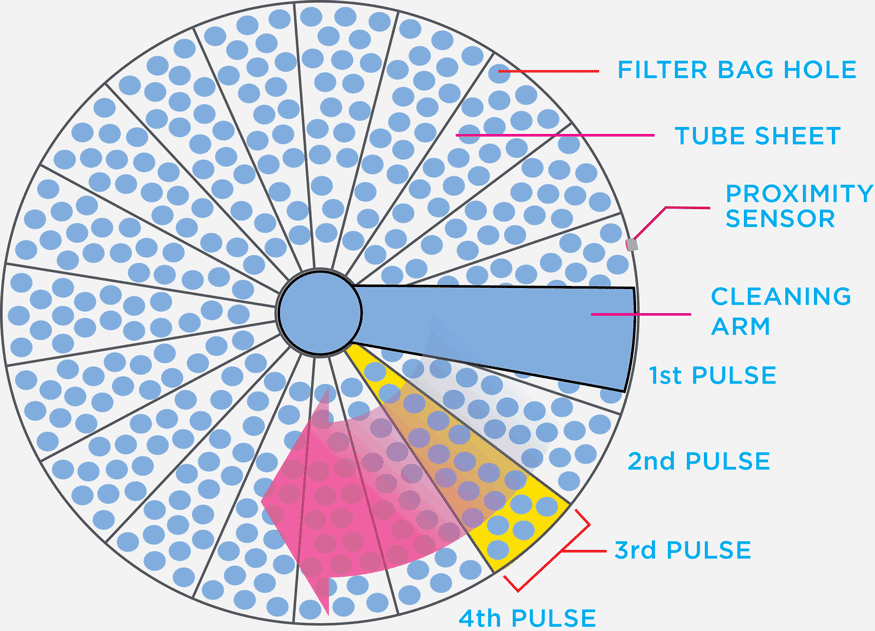

The Medium Pressure BRF is a high-efficiency baghouse that uses its own compressor to generate pulses of air that clean the filter bags. A proximity sensor keeps the rotating arm in alignment for precise filter bag cleaning.

The Medium Pressure BRF is suitable for all of the materials that the Reverse Pressure BRF can be used for. The Medium Pressure BRF is especially good for applications with a heavy load of powdery or sticky dust.

This is because the Medium Pressure BRF uses its own compressor to produce compressed air that pulses through the filter bags. A rotating arm design makes sure that every bag gets cleaned consistently. Because the bags are cleaned with a pulse of compressed air, more dust is broken loose from the bag surface. The 5hp motor used in this collector is much more efficient than the 30hp fan motor used by other types of baghouses.

Because the Medium Pressure BRF uses its own compressor, it requires no compressed air hook-up from an outside source. Different kinds of filter bags can be used for demanding applications like high heat, moisture, or abrasive dust.

Still not convinced?

Let us show you with a live virtual demo

Virtual demos are live, one-on-one, and catered to the needs of your company. Contact us to connect. with the rep in your area and schedule a demo.