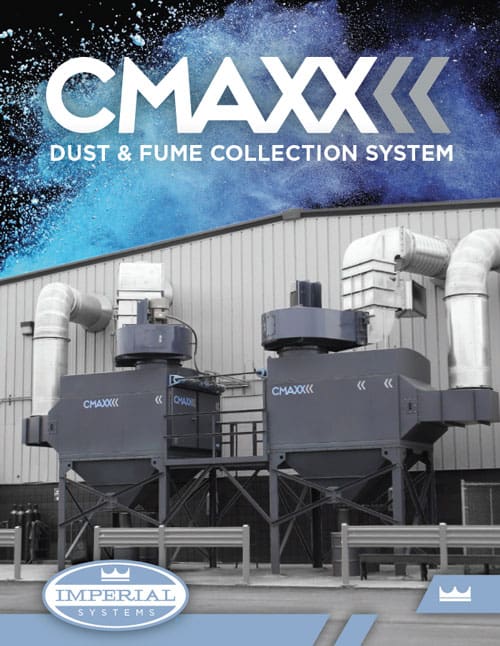

CMAXX Industrial Dust & Fume Collection System

The CMAXX Dust and Fume Collection System offers maximum cleaning performance with 10% more filter media than competitors’ models. The CMAXX features powerful pulse cleaning technology to increase filter life and efficiency. Heavy duty design makes the CMAXX the most durable industrial dust collector in the industry. It offers the patented weather-resistant CrownTech roof and no external bolt holes. In addition, the modular design of the CMAXX means it can be customized for each application.

BEST DUST COLLECTION with the SHORTEST LEAD TIMES

We’re working hard to maintain the shortest lead times in the industry. Here are the steps we’re taking to get the best industrial dust collectors on Earth out the door for our customers.

Increased Stocking & Aggressive Inventory Management

We have pinpointed areas of delay and are working with vendors to ensure our production and progress are not slowed by the excuses of others. We are initiating stocking programs to make sure the parts we need are on the shelf when we need them.

No Expediting Fees

We’re doing everything we can to uphold our best-in-industry lead times. This means no expediting fees; we’ll get you a dust collector when you need it. We believe that you deserve the best we can do – at no additional cost.

CMAXX Industrial Dust & Fume Collection System Advantages

The CMAXX offers better value and performance than any dust and fume collector on the market. At Imperial Systems, we are constantly innovating the CMAXX design for improvement. A CMAXX industrial dust collection system will always offer you features that you can’t find anywhere else. In addition, each CMAXX is manufactured in the USA in our Pennsylvania facility. Our ServiceMAXX team travels the country to provide you with dust collection system support.

- CrownTech domed roof for weather resistance

- Lift rails designed for easy and safe filter changes

- No external bolt holes to prevent rust or leaks

- Industrial powder coating for wear-resistant surface

- Vertical filter arrangement for improved filter function

- Angled inlet baffles to protect filters

- Available In-Line Deflagration Arrestor (IDA) function

- Lifetime manufacturer’s warranty

- Heavy duty construction, extra durable doors and latches

CMAXX™ is now certified as IDA (In-Line Deflagration Arrester)

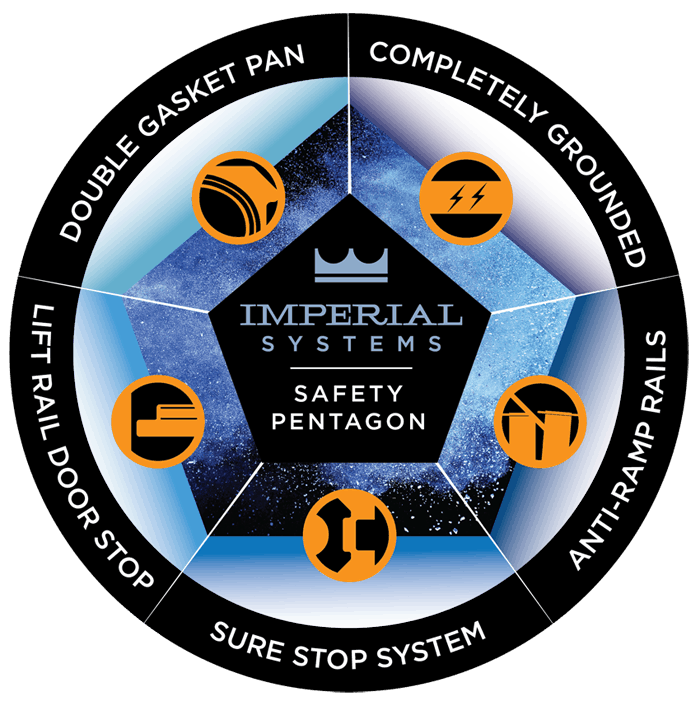

REDESIGNED, SAFER FILTER INSTALLATION SYSTEM

Our new and innovative lift rail system works with our DeltaMAXX Prime filters to make filter installation safer and easier than ever. Anti-ramping pans prevent filters from sliding over each other. Self-indexing lift rails work with the DeltaMAXX Prime’s unique filter pan to make sure filters always line up correctly. A double gasket ensures a tight seal with the tube sheet. A grounding tab built into the filter provides an added level of safety. Once the filters are installed, the lift rail door stop will only allow the door to close if the lift rails are raised and locked in position. The Sure-Stop system features a filter pan indexing channel that must line up with the door indexing bar for the door to close.

NEW LIFETIME WARRANTY

Because the CMAXX is the best-built dust and fume collector in the industry, we now offer a lifetime warranty. We’re confident that the CMAXX is made to outlast and out-perform any other industrial dust collector, so we are the only manufacturer to offer a lifetime warranty. We want our customers feel certain they are choosing the highest quality dust and fume collector available. With our new extended warranty, we’re promising to stand by our products for life. Compare the CMAXX to the competition and you’ll understand why we’re so confident it will last you a lifetime.

Maintaining your industrial dust collector is easier than ever with the power of the Keystone Controller at your finger tips!

All Keystone Controller panels will have the following capabilities:

- Startup and shutdown sequencing

- Explosion Vent

- Broken Bag Detector

- EIV Valve

- Smoke detector

- Fire suppression system input

- Drum sensors or level indicators in hopper

- Ability to control multiple Airlocks

- Outputs to a stack light or customer’s system to indicate a fault

- Run confirmation outputs for customer

Here’s what our customers say about the CMAXX dust and fume collector:

“Our first CMAXX worked so well, and we were really impressed with the quality. So there was no reason to go anywhere else for our second one.” (fiberglass application)

“It took about five minutes for the shop to start clearing out after we turned it on.” (welding application)

“Consistency is the first descriptor that comes to mind. Consistent and exceptional performance of the CMAXX dust collector, the DeltaMAXX filters, and the outstanding customer and technical support from Imperial Systems.” (sandblasting application)

“Imperial was very easy to work with. There was no lack of communication. I know if I need something in the future, I can call in and somebody from Imperial Systems will be here as soon as possible.” (paper application)

Still not convinced?

Let us show you with a live virtual demo

Virtual demos are live, one-on-one, and catered to the needs of your company. Contact us to connect. with the rep in your area and schedule a demo.

CrownTech Arched Roof

The CMAXX is the first industrial dust collector to have CrownTech, the fully welded arched roof. This patented roof design guarantees that the roof will not leak, hold water, or allow snow or ice to accumulate. Competing dust collectors have a flat roof, and as a result they frequently develop holes from rust. The CrownTech roof protects your cartridge filters from water damage. In addition, it allows us to offer an industry leading lifetime warranty by protecting your CMAXX from weather damage.

No External Bolt Holes

Unlike any other dust and fume collector, the CMAXX is designed with no external bolt holes. Because dust collectors are often outside, exposed to the elements, bolt holes can rust and let water in. With no external bolt holes, the CMAXX resists rust damage and leaking. This protects your filters and prevents rust from eating away at your dust collector. And since the CMAXX is also powder coated, it has an extra level of wear resistance.

Vertical Cartridge Collector

Most of our competitors use cartridge filters that sit horizontally inside the dust collector. These horizontal dust collection systems experience problems with filter life, gasket leaks, and complicated filter changes. The CMAXX uses vertical cartridges with longer filter life and better pulse cleaning. The anti-ramp lift rails make changing the filters easy. They also prevent filters from ramping, or sliding over each other, while being changed. A filter locking system ensures gasket compression for a solid seal against dust leaks.

Available IDA Certification for Industrial Dust Collectors

The CMAXX has been third-party tested and certified to act as an in-line deflagration arrester. When used with DeltaMAXX IDA filters, the CMAXX stops a flame front from passing through the dust collector. The IDA cartridge filters work just like normal DeltaMAXX filters, so they are cleaned by the standard CMAXX pulse cleaning system. The IDA adds a level of protection to your fire safety plan.

SAFETY PENTAGON

The CMAXX Dust & Fume Collector is outfitted with the most innovative features including a redundant safety design. The features include:

- Anti-Ramp Lift Rails – stops filters from overlapping each other

- Double Gasketed Filters – Double layer of protection to ensure a good seal

- Completely Grounded – Filters are grounded to the dust collector

- Lift Rail Door Stop – Stops the door from closing if the lift rails are not in the proper upright position

- Sure-Stop System – Ensures filters are installed properly or the door will not close, using pan indexing channel and door indexing bar

Anti-Ramp Lift Rails

Double Gasketed Filters

Double Gasketed Filters

Lift Rail Door Stop

Sure-Stop System

CMAXX™

Installation

CMAXX™

System Start-up

CMAXX™

Filter Replacement

MODULAR CONSTRUCTION

LIFT

RAILS

Vertical VS Horizontal

No Bolt Holes, No Problem!

THE CMAXX DUST AND FUME COLLECTION SYSTEM IS USED FOR:

• Weld fumes

• Plasma and laser cutting fumes

• Fiberglass

• Plastic

• Paper dust

• Metal recycling

• Battery manufacturing

• Grain and seed

• Silica and cement

• Woodworking

• Bakery and food processing

• Salt bath

• Thermal spray

• Metalworking

• Hammer mills

- Weld fumes

- Plasma and laser cutting fumes

- Fiberglass

- Plastic

- Paper dust

- Metal recycling

- Battery manufacturing

- Grain and seed

- Silica and cement

- Woodworking

- Bakery and food processing

- Salt bath

- Thermal spray

- Metalworking

- Hammer mills

WHAT ELSE MAKES THE CMAXX SPECIAL?

All our dust collectors are made in the USA, and you’ll always have the full support of our dust and fume collection experts here in our Pennsylvania facility. Each CMAXX is designed by our team of engineers.

Our professional ServiceMAXX teams can travel almost anywhere to make sure your CMAXX is working as it should be. No other dust collector company offers better, more personal support.

Consult with us to find out how a CMAXX system can help you meet combustible dust safety standards. We have extensive experience in designing systems to meet NFPA and OSHA standards for health and safety.

The CMAXX Dust & Fume Collector is designed for DeltaMAXX™ Prime Replacement Cartridge Filters. The DeltaMAXX™ Prime High Efficiency Replacement Cartridge Filter delivers the longest filter life, cleanest air and greatest cost savings.

With DeltaMAXX Prime nanofiber filters, the CMAXX handles a variety of dust and fumes. With an optional HEPA after-filter, it handles even strictly regulated materials like hexavalent chromium. A continuous pulse cleaning system keeps the filters operating efficiently.

- 400 square feet of filter media for significantly more surface area

- Unique grounding for safety from static buildup

- Oval cartridge shape for more effective pulse cleaning

- Double gaskets prevent air leaks

- Low initial pressure drop for increased filter life

- Nanofiber material efficient down to 0.3 micron particle size

- Increased filter media improves air to cloth ratio

Frequently Asked Questions

What’s the difference between dust collection and fume collection?

Dust and fumes are both made up of small particles. The particles in fumes are often very small, while dust particles are usually larger. Both can be handled by a CMAXX™. Words like smoke and fumes are often used for the particles produced by welding or metal cutting. Many manufacturers claim that their dust collecting systems are also fume collectors. Only filtration efficiency will confirm that.

What size system do I need?

The size of the system depends on the size of your facility, the amount of air that needs to go through it, and how many points of capture you need. A system that’s not big enough for your needs may result in dust accumulating in the facility or inside the ductwork, or you may run into other problems. We can help you design a system that’s sized to fit your needs.

Will a CMAXX™ be compliant with local emissions standards?

Each CMAXX™ is designed to meet the customer’s individual needs. We can work with you to make sure that your system will meet even the strictest emissions standards.

Will a CMAXX™ be compliant with NFPA standards?

A CMAXX™ with appropriate fire and explosion protection is NFPA compliant. The types of fire and explosion protection required will be determined by how flammable or explosive your dust is. This can be done with a Dust Hazard Analysis (DHA). CMAXX™ dust collector systems are equipped with industry-leading safety features.

When are cartridge filters better than bag filters?

Cartridges are superior to bags for most applications. They are easier to change and more efficient. A major advantage that cartridge dust collectors have is that the filter pleats allow much more media to be fit into the same space. One application where bags might be more suitable is at high temperatures. Bags can be made out of material that withstands very high temperatures.

How are the filters in a CMAXX™ cleaned?

The CMAXX™ is a reverse pulse dust collector, meaning the filters are cleaned by pulses of compressed air. Pulses can be on a timer or can be set to start whenever sensors detect that the filters need cleaned. This is recommended, because it saves on compressed air costs since the system only pulses when needed. It also improves filter life by reducing how often they are cleaned.

Washing a cartridge filter or taking it out of the collector to blow off dust is not recommended. This will damage the filters and cause holes that allow dust to leak through. Improved airflow after this kind of cleaning may not be because the filters are actually cleaner but because air is now flowing through holes in the filter media.

Why does the CMAXX™ use vertical instead of horizontal filters?

We use vertical filters because our customers prefer them and because they work better. Horizontal filters provide a surface for dust to build up and settle on top of the filter, reducing airflow and filter life. Dust pulses more efficiently off a vertical filter. Also, in a horizontal dust collector system, dust that is pulsed off the upper filters will land on the ones below it, while in a vertical collector that dust will drop out. Learn more about vertical versus horizontal filters.

What’s the best location for placement of a dust collector?

For safety reasons as well as saving valuable indoor space, it’s recommended that you place your CMAXX™ outside. An outdoor dust collector allows any fire or explosion to be vented safely away from the building. The CrownTech™ roof design and lack of external bolt holes makes the CMAXX™ the best dust collector that will stand up to all weather conditions without leaking.

Is the CMAXX™ rated for combustible dust?

The CMAXX™, when equipped with fire retardant DeltaMAXX™ filters, has been third-party tested to stop a flame front and control a deflagration. This is a key part of dealing with combustible dust safely. Most industrial dust filtration systems are not third-party tested for combustible dust.

What does IDA stand for?

IDA stands for in-line deflagration arrestor. A CMAXX™ collector with DeltaMAXX™ IDA filters will isolate a deflagration, preventing flames or sparks from continuing through the system. This makes IDA filters an important tool in controlling a fire or explosion and minimizing damage outside the collector. Learn more about an IDA here.

Is my dust combustible?

Almost all organic dust, like cellulose, sugar, grain, or corn starch is combustible. Grain handling facilities deal with frequent dust explosions. Many metal dusts are combustible, including aluminum, zinc, and magnesium, and metal dust fires can be very difficult to extinguish. Many types of plastic and resin are also combustible as dust. Testing can determine how combustible your dust is. A Kst value is a measurement of how explosive a material is and is a common way of measuring combustibility. Learn more about combustible dust here.

How do I calculate the correct air-to-cloth ratio?

How do I calculate CFM (airflow)?

The easiest way to calculate CFM for an ambient system is to stop by our website and use our helpful airflow calculator. CFM (cubic feet per minute) is a measurement of duct area (in square feet) multiplied by the velocity of the air.

What is the correct airflow for my system?

Required CFM for an ambient system can depend on factors such as how often the air in a room needs to be changed or how heavy the dust is that needs to be moved. Your CMAXX™ industrial dust collector will be designed for your individual needs.

How long will my filters last?

This is the question everyone wants an answer to, but the answer will be different for everyone. The type of dust, the filter media, the number of hours each day that the dust collector system operates, moisture or oils in the dust, and other factors will all affect your filter life. Choosing a higher quality media such as DeltaMAXX™ nanofiber results in longer filter life because less dust becomes stuck in the material and more of it is pulsed off.

What is differential pressure and what does it tell you?

Differential pressure is the amount of resistance to airflow through the filters. It is the difference in pressure between the dirty and clean air plenums. A gauge measures pressure on both sides of the filter, and the reading tells you how much resistance there is across the filters.

Tracking differential pressure will allow you to tell when the filters have accumulated too much dust and need to be changed. If the differential pressure is too high, the air is not flowing properly through the filters. Pulse cleaning of the filters can be set to occur when the differential pressure reaches a designated level. This means that the filters are cleaned only when they need to be, which saves on compressed air, energy, and filter life.

When should I change my filters?

You should change your filters if the differential pressure readings are too high. This means that the filter media has too much dust embedded in it to function properly. If the differential pressure is significantly below normal, it could mean that the filters have developed holes or that there is a leak in the airflow.

Attempting to remove and clean dirty filters often causes holes in them. When they are put back, the differential pressure may be lower, but this doesn’t necessarily mean that the efficiency of the filters has been restored by cleaning. It often means they now have small holes in them that are letting air and dust through.

What type of filter do I need?

We recommend DeltaMAXX™ nanofiber for most applications. If fire is a concern, these filters are available with a fire retardant coating. Filters are available with hydrophobic (moisture-resistant), oleophobic (oil-resistant), or PTFE (nonstick) material to meet the needs of specific applications. DeltaMAXX™ filters are manufactured to fit almost all industrial dust collectors.

How do I know if I need a dust or fume collector?

If you have dust of fumes that contain materials with OSHA exposure limits, you are responsible for making sure those limits aren’t exceeded. Most fumes and dust from metalworking fall in this category. If your dust is combustible, it’s very important to remove it from the work area. When combustible dust is allowed to build up, even a small fire can turn into a disaster. If your dust is not combustible but still causes problems for maintenance and keeping the work area clean, an industrial dust collector will prevent hazardous working conditions.

When you are venting dust or fumes outside, you should be aware of EPA regulations. The materials you are putting into the air may exceed EPA limits, and if there is too much visible smoke, fume, or dust coming from your facility you can be cited. Check local regulations to find out.

Are there applications where a cartridge collector won’t work?

Cartridge dust collectors can be designed for most applications. In some situations, such as extremely high temperatures entering the dust collector, cartridges may not be the best choice. If the dust contains coarse or fibrous materials, the system may be designed to allow larger particles to drop out to keep them from hitting the filters. Filters can also be fitted with overbags to protect them. If the air entering the collector is very humid or contains a lot of oily material, special filter media may be necessary.

Fibrous material, like larger wood dust, can cause problems for a pleated filter cartridge dust collector, and a baghouse can sometimes be a better solution for these types of applications. Since we manufacture both the CMAXX™ cartridge collector and the BRF baghouse, we will always offer you the best fit for your needs.