Does everything with your dust collector look like it’s working properly? That doesn’t mean there aren’t problems you can’t see. Dust collector valves are often the culprits of hidden costs due to internal damage.

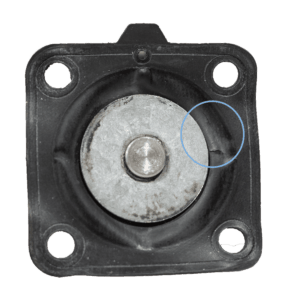

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

In this photo, the diaphragm from a valve clearly has a crack in the material. Although the system appears to be working perfectly, compressed air escapes through this crack. As a result, this dust collector valve is not getting sufficient air. While this might not be a major problem at first, it’s going to become one.

Because of this damaged valve, the filter that it’s cleaning is getting less compressed air than the other filters. So, each pulse is not fully cleaning it. That means that filter is going to blind off and need replacement sooner, costing you money. Multiple small valve leaks can have a major impact on shortening the life of your filters.

Springing for New Dust Collector Valves

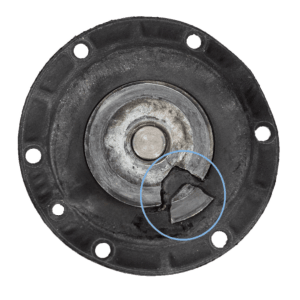

The following photo is from a ServiceMAXX visit for a problem completely unrelated to the diaphragm valves. However, when our technician did a routine inspection of the valves, he found a problem. The springs inside of them had completely fallen apart:

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

The broken pieces of spring were wreaking havoc inside the valve. They were damaging the valve itself and even starting to scrape and deform the metal parts. The company had no idea this issue was going on because the valves had not failed yet. Fortunately, a routine inspection discovered the broken springs and valve damage. So they replaced the valves before they could fail and wreck the filters. Further, it prevented downtime and thus, more problems.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

Valves are just one of many things that a ServiceMAXX technician can check. And a damaged valve like this one highlights the value of routine maintenance. Just like your doctor recommends routine bloodwork to catch problems before you see symptoms or a vehicle inspection can reveal wear and tear on engine parts, a yearly ServiceMAXX maintenance visit can find potential problems and fix them before they start to cost you money.

We’re Dying to Find Leaks!

Another ServiceMAXX option is a dye test. In this test, a harmless fluorescent powder runs through the dust collection system, which is then inspected with ultraviolet light. The powder glows brightly. If everything is working properly, the glow will be seen only on the outside of the filters, on the dirty air side of the collector. Any glow on the clean air side means that the dye and other dust is getting through a leak somewhere. This test identifies even very small holes in filters that can’t otherwise be seen.

ServiceMAXX technicians can also perform many other services. Please contact us to schedule a ServiceMAXX visit or a yearly maintenance program. A yearly scheduled maintenance program will give you priority scheduling during times when our technicians are very busy, and makes sure your system is always running at maximum efficiency.