The CMAXX is a vertical pulse-jet dust collection system. So how does a dust collector work? What’s going on inside there, and why is it designed the way it is?

The concept is basic: dirty air goes in, dust or particulate gets removed, and clean air comes out. However, the details become important when you’re looking for the right central vacuum system for your machinery.

Considering a shop dust collector system for your business? If so, this information may be helpful for you.

Dust Collection System Design

The CMAXX is a reverse pulse-jet cartridge dust collector. The best way to explain what this means is to go on a tour of the path that air follows through the dust collection system.

Dirty Air

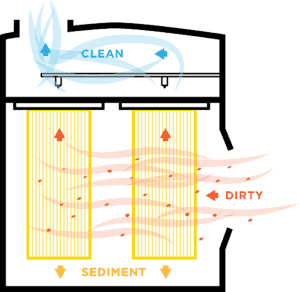

- Dirty air containing particles of dust enters the collector through the ductwork. Fans either push or pull the air through the ducts.

- The air hits a set of baffles, which are angled pieces of metal that slow it down. As a result, this keeps the dust from hitting the filters at full speed.

- Then the air enters what we call the dirty air plenum. This just means the side of the collector where the air is dirty. At the bottom of this space, collected dust drops out into a drum or hopper.

Dust Capture

- Next, the air passes through the dust collector’s cartridge filters. In the CMAXX, these hang vertically from the tube sheet, which is the metal sheet separating the dirty and clean air spaces.

- Pleating the filters gives them more surface area. DeltaMAXX filters are also coated with a nanofiber material. This makes the spaces that the air must go through smaller.

- The filters capture the dust. Some of it falls off. Some of it sticks to the filters. Gaskets at the top of each filter seal it to the tube sheet to keep dust from sneaking through.

Filter Cleaning

- A pulse of compressed air blows into the filters. Because the pulse of compressed air goes in the reverse direction of the regular airflow, we call it a reverse pulse-jet collector.

- The pulse of compressed air blows the accumulated dust off the filters. The dust drops out of the collector and the filters are ready to collect more dust.

- On the other side of the filters, filtered air enters the clean air plenum. From there, it can go back into the facility or vented outside.

How Does the Pulse-jet Dust Collection System Clean the Cartridge Filters?

A pulse-jet collector is a very effective type of industrial dust collection system. Diaphragm valves control the compressed air in a pulse-jet collector. Often a timer controls the diaphragm valves. To make the cleaning more efficient, the pulses can also be controlled by differential pressure sensors.

Differential pressure sensors read the air pressure on the dirty air and clean air sides of the filters. The dirtier the filters are, the more resistance they have to air going through them. When the difference in the two pressure readings gets too high, it signals the filter cleaning mechanism.

Using differential pressure sensors makes a pulse-jet dust collector more efficient because it reduces the use of compressed air. It also helps the cartridge filters last longer, because the pulses of compressed air cause wear and tear on them.

Pulse-jet dust collection systems are efficient because of this filter cleaning. With an industrial dust collection system, replacement filters can be a big expense. By making filters last longer, a pulse-jet collector is the most cost-efficient shop dust collection system. Read about offline cartridge filter cleaning.

How Does a Vertical Pulse-jet Dust Collection System Work Better?

Cartridge collectors have the filters in either a horizontal or vertical arrangement. In horizontal dust collection system design, the filters lay on their sides and are stacked on top of each other. The filters hang down from the tube sheet in a vertical filter dust collector.

In a horizontal pulse-jet dust collector, the pulse cleaning causes dust to be blown off the filters. However, because they’re on top of each other, the dust from the top filters falls on top of the others.

In a vertical pulse-jet collector, the dust that pulses off of the filters drops directly down into the hopper. The dust falls free and doesn’t land on the other filters.

Most CMAXX competitors on the market are horizontal dust collectors. Only a few companies make vertical pulse-jet cartridge collectors. Vertical systems are the most effective shop dust collection systems.

In conclusion…

If you’re looking for a central machinery dust collector for your facility, make sure it has a self-cleaning, pulse-jet system. To get a good idea of how the CMAXX works, check our product page. If you still have questions, please feel free to ask us!