High-efficiency dust collectors are well recognized for keeping industrial manufacturing environments clean. However, dust infiltration from neighboring manufacturing operations or particulate contaminants in outdoor air must be safeguarded in these facilities’ offices, conference rooms, control rooms, server rooms, and other similar places. An effective approach to this problem is room pressurization combined with adequate air filtration. While high-efficiency HVAC filters are often regarded as the most popular solution, cartridge-type industrial dust collectors used in conjunction with an existing HVAC system can be a more effective alternative.

How Room Pressurization Works

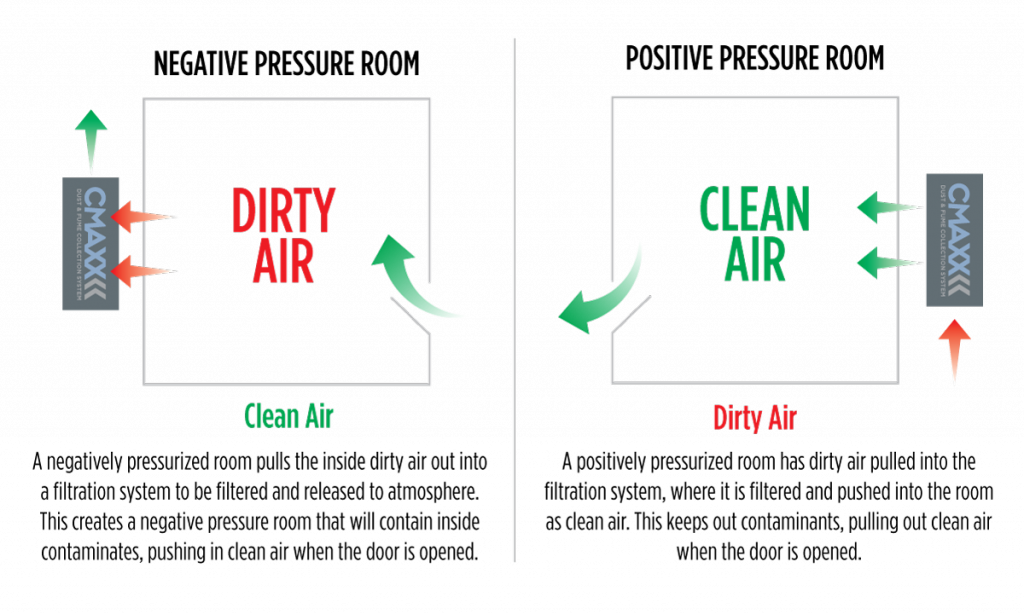

The application of positive or negative air pressure in a room to prevent dust entry is known as pressurization. Positive pressure (also known as “inflating the building”) keeps particle and gaseous pollutants out of a space by forming an air barrier between the interior and outside. When you go into a positively pressured environment from the outside, you’ll notice a “whoosh” of air fleeing owing to the greater pressure within the space. Positive pressure can keep hazardous outside air out of an office, server room, or other enclosed areas.

Negative pressure, on the other hand, may be employed in a pharmaceutical facility when strong substances are used to prevent dust from contaminating other portions of the plant — often in conjunction with containment systems. Negative pressure rooms are also commonly used in hospitals and medical settings to prevent the spread of contagious illnesses from one area to another. The air is blasted out of the treatment room, creating a negatively pressurized situation where, for example, when a door from the lobby is opened, the air rushes in instead of out. The air blasted out of the contaminated space passes through three filters, culminating in a HEPA (high-efficiency particular air) filter that filters to the same level as a N95 mask.

What are applications suitable for room pressurization with dust collectors?

Cement and lime manufacturing, metal and coal mining, pharmaceutical processing, grain processing, and power generation are the most common industries with dust collector pressurization needs. However, the procedure can be applied anywhere there is a lot of dust. Control rooms, server rooms, manufacturing clean rooms, compressor rooms, offices, quality control labs, substations, and motor control center (MCC) rooms are among the most typically pressurized areas.

To Pressurize or Not to Pressurize

Now that we’ve covered what room pressurization is, how do you decide if it’s a good choice for your facility? Consider the sort of dust, the conditions within and outside the area, and what (or whoever) you want to protect first. If workers in an office area are exposed to hazardous amounts of dust or fumes, you must clear the air to protect occupants from health risks and assure compliance with OSHA exposure rules. If your facility hosts expensive equipment, it would be worth it to invest in a pressurizing system to protect it. On the flipside, pressurization may not be worthwhile if it isn’t occupied by people and the equipment isn’t valuable.

How Dust Collection Can Help

Room Pressurization with dust collectors is intended for situations with high dust loads where HVAC filters would not last long enough. High-efficiency HVAC filters can quickly become overwhelmed in particularly dusty environments, needing to be replaced every few months or even weeks in some cases. If there are already HVAC systems in place, a dust collection system can be designed to take the existing system into account.

Cartridge dust collector filters, on the other hand, are made to manage heavy dust loads in industrial settings. Dust collector filters are automatically pulse-cleaned by blowing dirt off the filter surfaces and into a collection device with very brief bursts of compressed air. High-efficiency cartridge filters can last for years in a pressurization system before needing to be replaced. Imperial Systems’ DeltaMAXX Prime cartridges have 400 sq ft of filter media for longer filter life and better filtration.

If you work in a highly regulated business like pharmaceutical or food manufacturing, there may be limitations on the sorts of filters you can use and the level of filtration you can achieve. This would certainly be a factor when deciding if dust collection is the best choice for your room pressurization needs. On the other hand, a cost analysis will allow you to compare HVAC vs. dust collection filters. The dust collection professionals at Imperial Systems can assist you in determining the best solution for your facility and application.