Hydraulic fracturing (“fracking”) is a process used to extract oil and gas by high-pressure fracturing of rock or shale. Exposure to respirable crystalline silica is a major hazard in this industry. Massive amounts of sand are used in the process, and silica exposure is a constant issue.

NIOSH has identified silica exposure as the single biggest health issue in hydraulic fracturing. Their research also demonstrated that silica levels on these sites are so high that standard respirators are not sufficient for protection. With a 2018 deadline for hydraulic fracturing sites to comply with new OSHA limits for silica exposure, new tactics for silica dust control are needed.

SILICA IN THE HYDRAULIC FRACTURING PROCESS

The hydraulic fracking industry uses huge amounts of sand (silica). Most grains are 2 mm or smaller in size. By some estimates, the average site requires somewhere between 1 and 7 million pounds of sand over its lifetime.

After high-pressure water and chemicals are pumped into the rocks to create fractures, the spaces must be filled with sand to keep them open and allow oil and gas to flow. So much sand is used in this industry that mining and production of “frac sand” has become a major industry of its own.

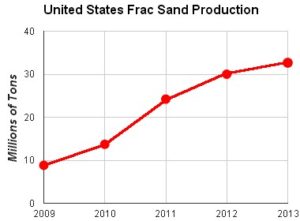

(Frac sand production: This chart illustrates the spectacular rise in the production of frac sand in the United States. Data from the United States Geological Survey Minerals Yearbook, Silica, 2011)

AREAS OF HIGH SILICA EXPOSURE

image: National Institute for Occupational Safety and Health/Centers for Disease Control and Prevention/OSHA/CDC

Massive amounts of silica move around a hydraulic fracturing site. NIOSH has identified several points in the silica moving process that create the largest amount of silica dust. These areas are:

- Open hatches on sand movers

- Through side ports on sand movers during refilling

- Depositing sand onto transfer belts

- Sand moving on transfer belts between movers, hoppers, and blenders

- Blender hoppers that mix sand

- Accumulated dust stirred up by vehicles driving around the site

NIOSH strongly recommends that engineering controls be put in place to control silica exposure at these points. They emphasize that the silica exposure at these points in the process is so heavy that respirators do not provide enough protection.

HYDRAULIC FRACTURING SILICA EXPOSURE; CONTROLLING DUST ON SITE

In some situations, newer equipment has been designed to minimize silica dust release. In other situations, older equipment can be modified or rebuilt to these designs.

For many companies, especially with the industry still recovering from the severe drop in oil prices several years ago, these expensive modifications aren’t reasonable.

Another option is to install dust collectors directly on the equipment. A collector specially designed for hydraulic fracturing equipment can be fitted on sand movers, transfer belts, and blenders. With these systems installed, the amount of silica dust released is much lower.

Controlling silica release at these points of capture can decrease silica exposure all over the site. With less silica dust escaping, the overall amount of fugitive silica dust around the site is more manageable. This helps with the amount of dust raised by vehicles or wind all over the site.

https://blogs.cdc.gov/niosh-science-blog/2012/05/23/silica-fracking/

http://geology.com/articles/frac-sand/

https://www.osha.gov/dts/hazardalerts/hydraulic_frac_hazard_alert.html