When selecting a fan wheel for a dust collection system, it’s crucial to understand the differences between radial blade fan wheels and backward inclined fan wheels. These two types of industrial fans serve distinct purposes and best suit specific applications. Below, we’ll explore their differences and when to choose one over the other.

Understanding the Fan Wheels

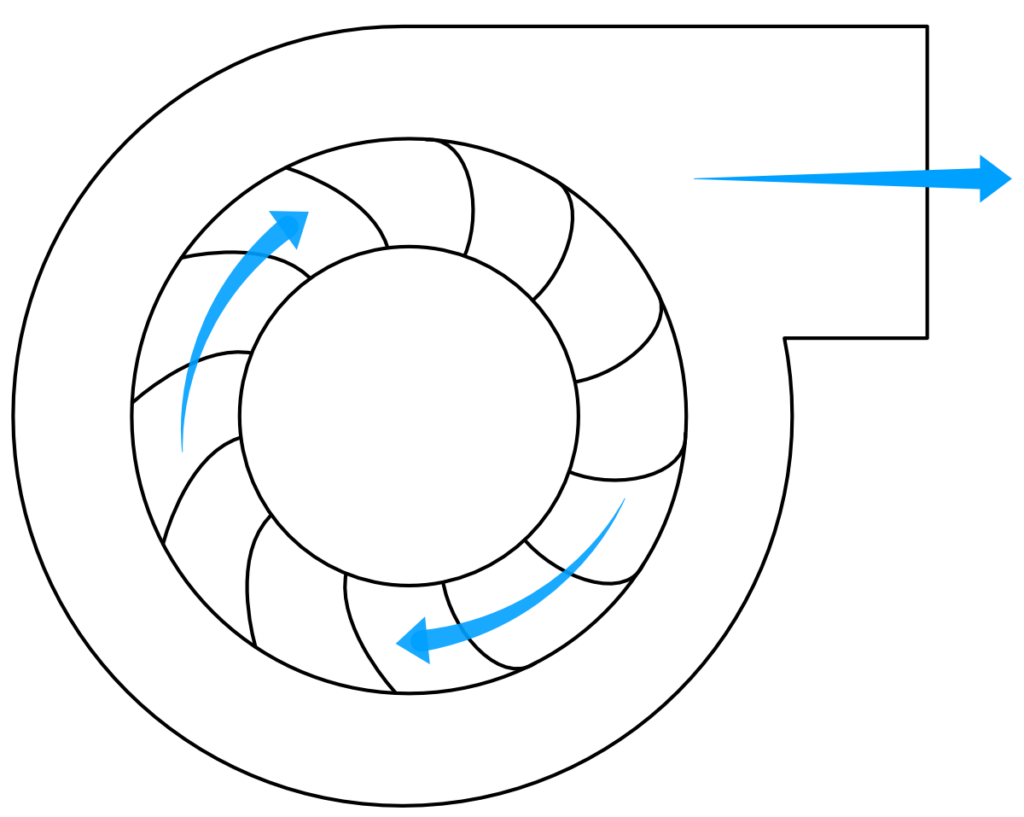

Backward Inclined Fan Wheel

A backward inclined fan wheel is a type of centrifugal fan in which the blades curve away from the direction of rotation. This design allows for efficient air movement. Its common use is for general ventilation, forced cooling at higher pressures, and also in dust collection systems where the fan operates on the clean air side of the dust collector. The curved blades enhance efficiency by reducing energy consumption and noise while maintaining strong airflow.

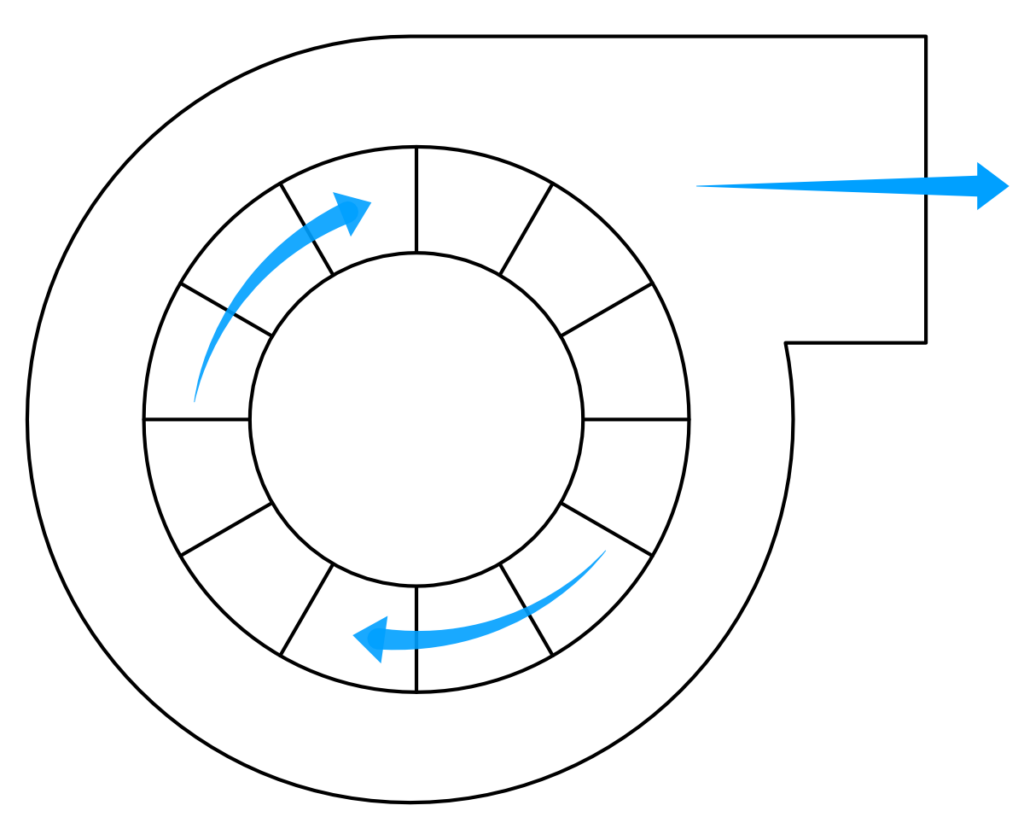

Radial Blade Fan Wheel

A radial blade fan wheel features flat blades instead of curved blades. These fans operate at high pressure and move air radially outward from the center of rotation. Due to their design, radial blade fans handle particulate-laden airstreams more effectively than backward inclined fans. This makes them ideal for dust collection applications where some dust bypasses the separation process.

Choosing the Right Fan for a Dust Collector

The choice between a radial blade fan wheel and a backward inclined fan wheel largely depends on the placement of the fan in the dust collection system:

Backward Inclined Fan Wheel: Best suited for applications where the fan is positioned after a dust collector that uses filters to remove dust from the air. Since these fans are designed for clean air environments, they work efficiently with minimal maintenance concerns.

Radial Blade Fan Wheel: Ideal for situations where the fan follows a cyclone separator, which may allow some dust to pass through. Radial blade fans are designed to handle dust-laden air efficiently without clogging or experiencing excessive wear.

Best Applications for Each Fan Type

Backward Inclined Fan Wheel Applications:

- General ventilation systems

- HVAC systems requiring higher pressure

- Dust collection systems where the fan is on the clean air side (after filter-based dust collectors)

- Industrial processes that require efficient airflow with minimal energy consumption

Radial Blade Fan Wheel Applications:

- Dust collection systems including a cyclone where dust-laden air must still be handled by the fan

- High-pressure industrial applications where particulates are present

- Material handling systems where the air carries solid particles

- Processes involving sticky or fibrous materials that might clog other fan types

Choosing the right fan wheel for a dust collection system is essential for maintaining efficiency and longevity. If the fan operates in a clean air environment, a backward inclined fan wheel is the best choice due to its efficiency and quieter operation. However, if the fan must handle dust-laden air, a radial blade fan wheel is the preferred option because of its ability to resist clogging and handle particulate matter effectively. By understanding these distinctions, you can select the optimal fan wheel for your specific dust collection needs, ensuring reliable performance and system longevity.