Whether you call it additive manufacturing, rapid prototyping, or 3D printing, the principle is the same: a tangible object is built, one layer at a time. The need to capture 3D printer dust for health and safety grows as this machinery evolves.

A New Type of Manufacturing

Within that definition, you’ll find multiple kinds of 3D printing. The term 3D printing encompasses a broad range of layer-by-layer manufacturing. Although still mostly used for rapid prototyping, there is an increasing trend of using additive manufacturing for production parts.

As with any shift in industrial practices, it’s important to keep employee wellness and protection in mind as businesses adopt new technology, and this new technology becomes mainstream.

Three Types of 3D Printing – Three of Many

Fused deposition modeling (FDM) is the most common type that most people think of when they think 3D printing. FDM is the kind of 3D printing where you have a resin filament feeding into the 3D printer. Desktop FDM 3D printers have increased in popularity over the last few years. They are a low-barrier entry point to 3D printing. On an industrial scale, FDM creates parts with layer lines that might require additional finishing.

Another type of 3D printing is stereolithography. With this kind of additive manufacturing, a hardened liquid pool becomes a resin. This happens when a computer-controlled ultraviolet laser moves precisely across the surface. Because of its high precision, stereolithography is useful in producing accurate prototypes, even of irregular shapes.

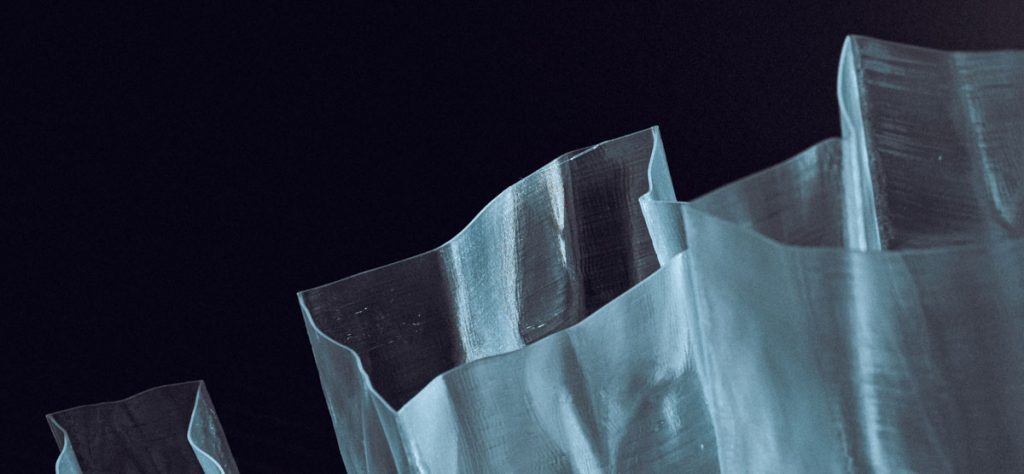

Selective laser sintering (SLS) also uses a computer-controlled laser. But instead of a pool of liquid, the material is a powder bed. Layer by layer by layer, the laser binds this finely powdered material together. This creates a solid object or structure on the build plate. Companies currently use SLS to make jigs and fixtures for other manufacturing applications. They also use it for short-run production in its own right.

Why Collect 3D Printer Dust?

There is one commonality between all these different ways of 3D printing (and other kinds, too!). It’s that all of them are dealing with chemicals, dust, or fumes. As with any manufacturing setting, companies must take steps to mitigate these hazards and provide workers with a safe environment. Whether the hazardous particulate is part of the process or created during finishing, it’s important to capture excess dust and fume.

#1 Employee Health

It’s not hard to understand the value of clean air to employee health. Using a proper extraction and dust collection system means employees have less exposure to VOCs and other potential hazards to long-term health. It also reduces exposure to irritants that are unpleasant for employees, such as chemical odors. Chemicals and particulate produced as a result of 3D printing could be potential eye, nose, and throat irritants. Employees can be more productive in an environment that is not causing itchy eyes or headaches. The powder used in stereolithography is similar in texture to the flour you might find in a bakery; proper dust-handling equipment is therefore essential.

#2 Cleaner Work Environment

Not only does adequate ventilation keep your employees safe and productive. It also means that the 3D printed parts are not negatively impacted by dust and particles. Some manufactured parts can be scratched or damaged by coming in contact with particles from other processes; for example, they may appear to rust if they come in contact with even a little steel dust.

#3 Combustible Dust Hazards

Many of the dust types created as a by-product of 3D printing are flammable or combustible in the presence of an ignition source. This is not ideal in an application that uses a laser. Combustible dust that is not properly taken care of accumulates on surfaces. Thus, it becomes fuel for secondary explosions during a deflagration event.

Your Industrial 3D Printer Dust Solution

A properly designed dust collection system is sure to keep your work areas clean and your employees safe and healthy. The CMAXX Dust & Fume Collector will filter hazardous particulate from the air and withstand a combustible dust explosion. Our team will determine the best system for your application. We’ll ensure that your facility is up to code and NFPA compliant. Learn more about your dust collection options by scheduling a virtual demo with our team.