by Scott Stearns | Nov 26, 2018 | Uncategorized

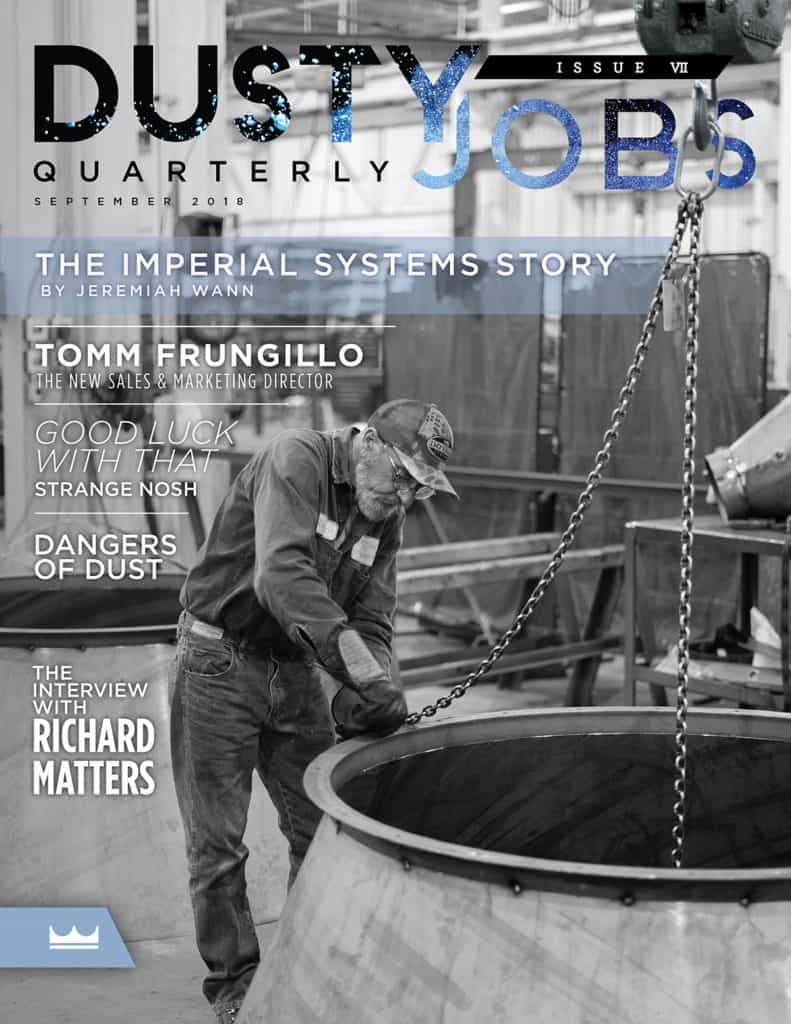

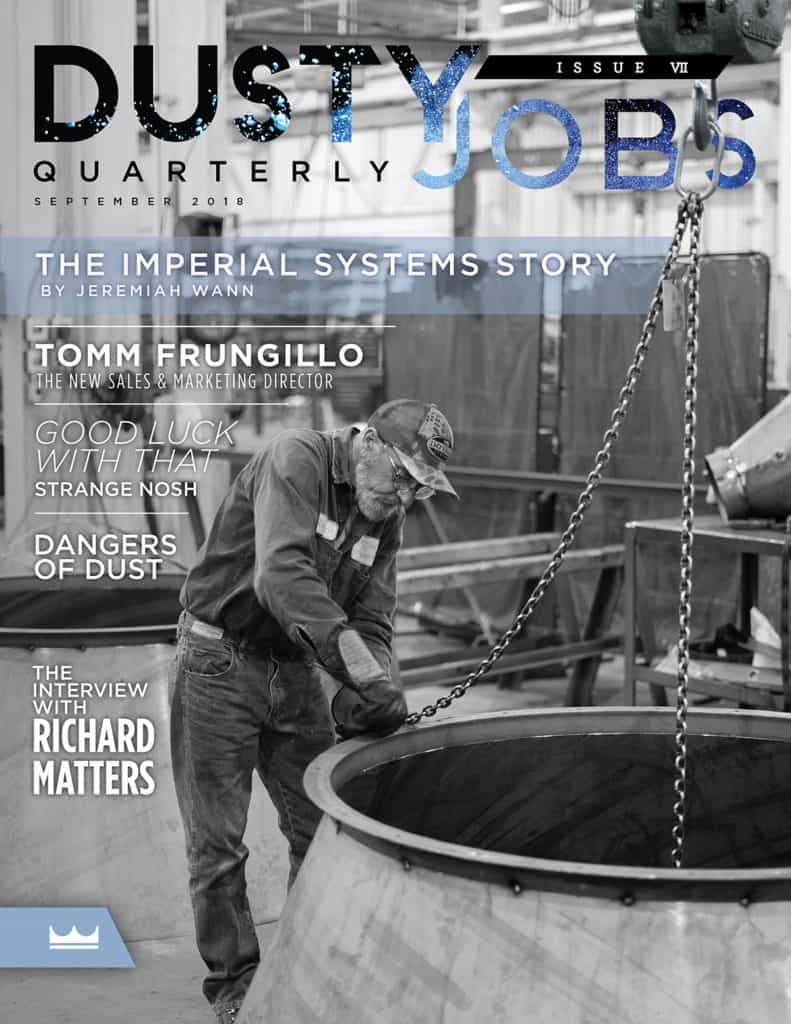

Dusty Jobs Issue 7 is the third quarter of the year. Check out the articles! Charlie is back with an article about food, and we interview one of our welders, Richard Matters. If you would like a printed hard copy of this issue of the quarterly newsletter, contact your Imperial System Sales Rep.

Click the cover to download and print the newsletter.

CLICK THE ARTICLE TO READ.

Read more

by Imperial Systems | May 16, 2018 | Uncategorized

Sometimes it’s necessary to cut or weld, or hot work in the vicinity of your dust collector. However, this can be extremely dangerous if your dust is explosive. A dust collector, after all, is an accumulation of dust. If that material is combustible, careless hot work could lead to a catastrophic explosion.

“Hot work” is defined by OSHA as “welding, brazing, cutting, soldering, thawing pipes, using heat guns, torch applied roofing and chipping operations, or the use of spark-producing power tools, such as drilling or grinding”. Most of us would think twice about welding or cutting in near a dust collector or any other combustible dust. But some tools, even ones that shouldn’t produce sparks, may have faulty wiring. This can lead to a fire or explosion.

Hot Work Procedures

No hot work should be done near the dust collector without the correct procedures (see NFPA 51B). This NFPA standard specifically defines the procedures for conducting this type of work anywhere that it might cause an explosion.

Hot work near or on a dust collector might include repairs or adding/removing a piece of equipment or ductwork. It may include any number of other projects. Before doing this kind of work around the dust collector, you must have a hot work procedure IN WRITING:

- Shall be in writing and available to anyone conducting hot work in the area

- It must require an inspection of the work area before the work starts

- Must have a permit signed to show that all phases of the work have been inspected and approved

The program should assess safety equipment in the area. On a dust collector that might include a spark arrestor, spark detector, fire suppression or sprinkler system, abort gate, explosion venting, or other types of fire and explosion safety devices.

Hot work may require completely blocking the ductwork to the dust collector, or if the work is on or close to the collector, may require removing the filters, emptying or removing the hoppers, and thoroughly cleaning the entire dirty air side of the dust collector. a strong g recommendation is that a fire suppression system is in place before hot work begins. This will suppress any fire that might start. Further, remove as much of the dust as possible if it is explosively combustible.

Permits Ensure Safety

NFPA 51B specifies that the company safety specialist will issue a permit for work to proceed once achieving an inspection and determination of safety for hot work. It’s the job of this designated safety specialist to inspect the area of hazards. The specialist ensures the removal of all combustible dust. They confirm the isolation of all sparks and heat and establish safety procedures in the event of a fire.

No one should be allowed to perform ANY type of hot work, including the use of spark-producing power tools, in the vicinity of the dust collector without a permit. However, it happens all the time and puts lives at risk if the dust is combustible. Take the time to assess this hazard in your own workplace. If the hazard exists, your safety professional should set up hot work procedures to make sure no one puts themselves or the facility at risk.

Read more

by Greg | Apr 11, 2018 | Hidden from Archive

Q: You’ve been here at Imperial Systems pretty much since the beginning, right?

A: I started when we were still over in Grove City. Me, Russ, and Steve are the three still left from that original crew. I’ve been here twelve years. I started off doing welding and then did fabrication, and did a little bit of everything. In the past year I’ve been doing a lot of field work and traveling.

Q: How has the company grown since you started?

A: It’s grown like crazy. When I was in Grove City and we were moving to the Jackson Center place, I’d work ten-hour days all week and then go with Russ to Jackson Center and work on the new place. And it didn’t take long before we started to outgrow that.

Q: What do you think about the new building?

A: It was totally necessary for us to be able to grow. We’re already just about full. Since we moved in back in January things are starting to get settled in and they’re running a lot smoother.

Q: How much more do you see us growing?

A: The way things are growing I could see us outgrowing this building someday. We keep getting more and more orders for equipment.

Q: What are your favorite things to do here, since you do some of everything?

A: I like running the plasma table, and I like doing fitting and welding. I run the forklift, and now I do a lot of field work so I’m off traveling around a lot. You get to see some interesting things out there.

Q: What would you tell people about working here?

A: We have a lot of fun working here. Maybe a little too much sometimes. It’s a really good bunch of guys.

Q: And you’re still happy working here after twelve years?

A: Absolutely. It hasn’t been perfectly smooth sailing for the entire twelve years and we’ve had our ups and downs, but it’s a great place to work.

Q: And when you’re not here, you’re at your farm.

A: That’s right. My dad’s the third generation and I’m the fourth generation on that farm. I’ve worked there since I was a kid. We didn’t have sitters… we just went to the farm. If I’m not at work, that’s where I am.

Q: And you’ve got a lot going on there right now with all the baby goats, right?

A: We had triplets the other day. We’re bottle feeding one of them. We had eleven babies out of the five goats I bought on my last trip.

Q: What are you going to do with all these goats?

A: They’re meat goats, Boer goats. They originated in Africa. They can get up to 200 pounds. There’s a big demand for goat meat in some places.

Q: How many goats do you plan on having?

A: My dad and I are still talking about that one. A lot, I know that. My oldest kid, my nine-year-old, is starting 4H this year. He’s got two goats. The younger ones will start here pretty soon.

Q: So you’ve got ducks, chickens, horses, cows, goats, pigs…

A: And my dog, Molly. She’s a chocolate lab. She’s my farm dog. She minds me and no one else, and I love it.

Q: And you’ve got your tractors.

A: I’m into the Mercer County Antique Power Association, antique farm equipment, antique tractor pulls. I have a tattoo of my first tractor. Took a picture of it and took it in to them.

Q: So you’re passing on the farming tradition to the fifth generation?

A: Of course I am!

Read more